Table of Contents

1 About this manual.........................................................................................................5

1.1 How to work with the manual............................................................................................5

1.2 Record of changes............................................................................................................5

2 Safety .............................................................................................................................6

2.1 Intended use.....................................................................................................................6

2.2 Liability..............................................................................................................................6

2.2.1 General liability.....................................................................................................6

2.2.2 Machine-specific liability.......................................................................................6

2.3 User qualification for installation.......................................................................................7

2.4 Certifications.....................................................................................................................7

2.5 Safety symbols on the machine........................................................................................8

2.6 Safety symbols in the manual...........................................................................................8

2.7 Disposal of the machine ...................................................................................................8

3 Operator manual ...........................................................................................................9

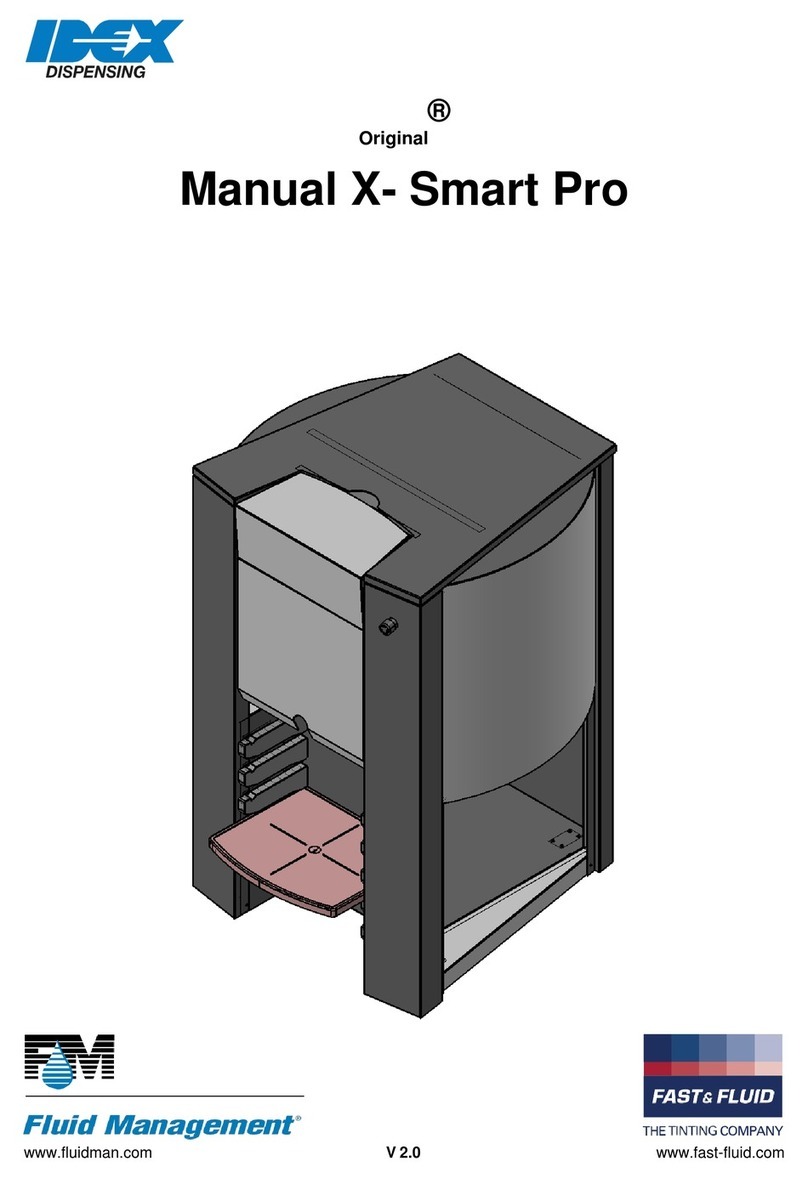

3.1 Description........................................................................................................................9

3.1.1 Overview of the machine......................................................................................9

3.1.2 Type plate: serial number....................................................................................10

3.1.3 Type plate: details...............................................................................................11

3.2 Operation.........................................................................................................................11

3.2.1 General dispensing procedure............................................................................11

3.2.2 Placing a can......................................................................................................12

3.2.3 Using the emergency stop switch.......................................................................12

3.3 Maintenance ...................................................................................................................13

3.3.1 Blendorama Maintenance Kit..............................................................................13

3.3.2 General cleaning: daily.......................................................................................13

3.3.3 Cleaning the brush unit: daily .............................................................................14

3.3.4 Cleaning the nozzles: daily.................................................................................15

3.3.5 Refilling a canister ..............................................................................................16

4 Installation....................................................................................................................17

4.1 Unpack the machine……………………………………………………………………………16

4.2 Move the machine to final location……………………………………………………………17

4.2.1 Assembly………………………………………………………………………….…….18

4.3 Turning on the achine......................................................................................................20

4.4 First Use..........................................................................................................................20

4.5 Flushing the air out of the pump .....................................................................................20