Bkon Craft Brewer User manual

SERVICE MANUAL

of 861

SAFETY

DANGER

WARNING

WARNING

CAUTION

DANGER

Indicates potentially life-threatening danger or grave injury from electrocution.

WARNING

Indicates risk of injury.

CAUTION

Indicates risk of minor injury.

WARNING

Indicates risk of injury from Heat / Hot Surface.

DANGER Electrical System

-Energized electrical circuits present a potentially life threatening hazard.

-Ensure all electrical power circuits connected to the unit and supply outlets

or connections are completely de-energized before performing any service.

-When testing electrical components, always follow the OSHA standard for

the control of hazardous Energy (Lockout/Tagout), Title 29 Code of Federal

Regulations (CFR) Part 1910.147.

Explanation of safety symbols

For your safety

This documentation has been created exclusively for trained and authorized service providers of Franke Foodservice

Systems, Inc.

WARNING Risk of burning or scalding

-Hot water and steam are released repeatedly during the cleaning cycle.

-Keep hands away from the outlet (purge valve) while in operation.

-The glass cylinder may be HOT to the touch.

-Do not disconnect “Hot Water” line before purging lines of hot water or

allowing sufficient time for water in lines to cool.

IMPORTANT SAFETY INSTRUCTIONS - READ, UNDERSTAND AND SAVE

This operation manual contains important instructions and safety information about the BKON™ Craft Brewer.

Observe the following dangers, warnings, cautions and notices when operating the BKON™ Craft Brewer.

of 862

Safety

WARNING

CAUTION

NOTICE

NOTICE

NOTICE General Reminders.

-Do not discard any loose parts as they may be required for proper

operation.

-Make sure line voltage matches voltage specifications in this manual.

Risk of injury and / or damage to the equipment!

Making improper changes in the form of modifications or unauthorized repairs

can lead to injury or damage to the equipment.

-Programming and settings may only be preformed by authorized service

technicians.

-Retrofits and repairs may only be preformed by authorized service

technicians.

-Do not make any modifications to the equipment that are not authorized by

documentation provided by Franke Foodservice Systems, Inc.

Damage can occur from improper transport.

Improperly transporting the equipment can cause faults or damage.

-Always transport in an upright position.

-Transport the equipment so that it is protected from the elements, such as

rain and moisture.

Damage can occur from using inappropriate tools.

-Using inappropriate tools can damage components of the equipment.

Possible health hazard from heavy lifting.

-Lifting heavy objects unaccompanied can cause injury.

-Do not lift or move the equipment without appropriate help or tools.

of 863

Table of Contents

Safety 1

Table of Contents 3

Service Prerequisites 4

Removal / Installation of Parts - Tower 7

Removal / Installation of Parts - WVSC 25

Programming 47

Testing and Adjustments 49

Troubleshooting 53

Water / Air Diagram 57

Electrical Diagram 59

Sequence of Operations 75

of 864

SERVICE PREREQUISITES

If the BKON unit is powered ON upon the service technician’s arrival, the water

system will be filled with hot water under pressure. Utilize the Cool Down function

within the service menu before making any repairs or disconnecting any water

lines.

WARNING

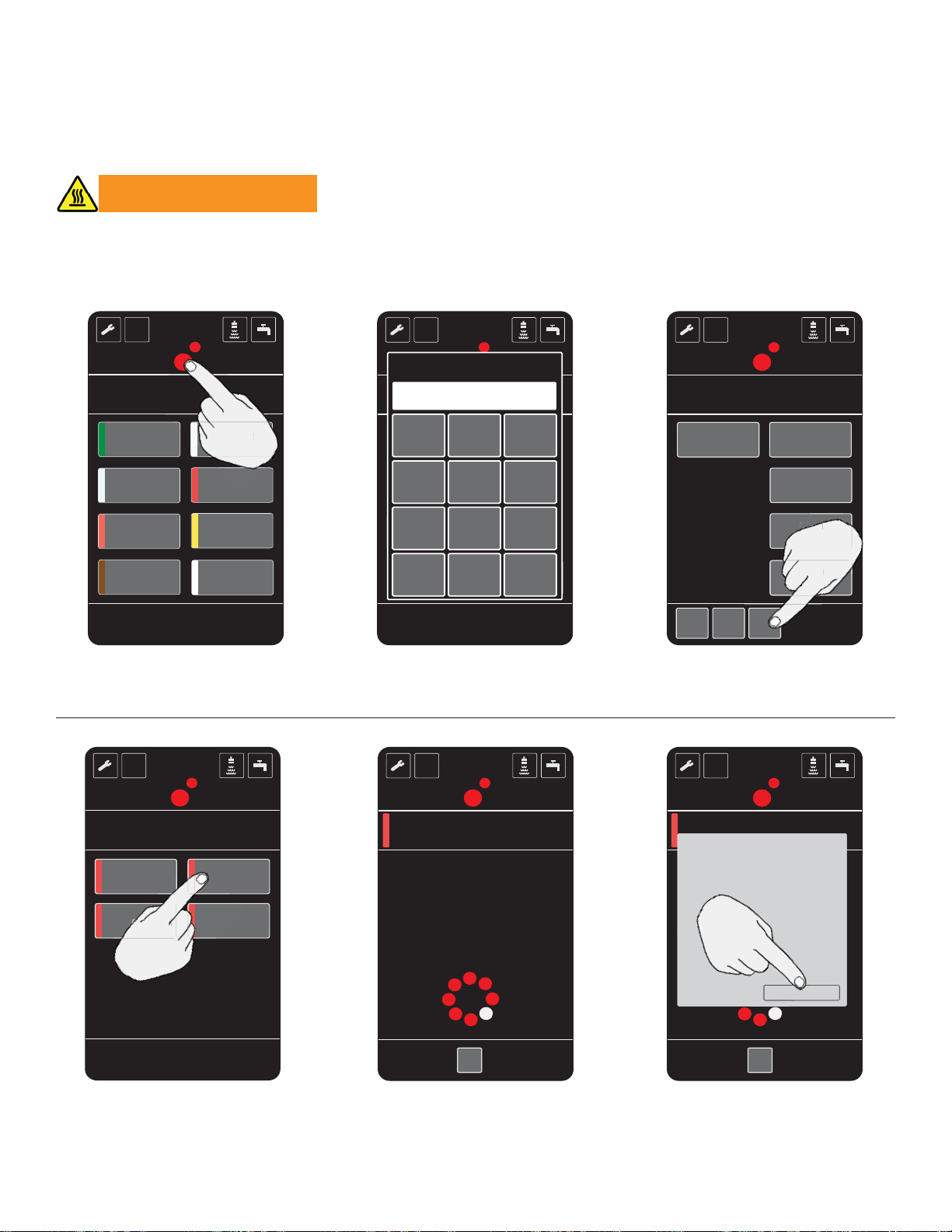

Cool Down Instructions

i

Green Tea White Tea

Black Tea

Spirits

Chai / Rooibos

Oolong Tea

Herbal / Fruit

Coffee

17:30

i17:30

Service Menu

Vacuum Calibrati

Cool Down

Nitrogren Flush

Calibration

i

Cool Down

Brewing Process...

17:30

X

i

Cool Down

Brewing Process...

17:30

X

COOL DOWN completed

Cool Down completed. Turn of mac

CONTINUE

i

Green Tea White Tea

Black Tea

Spirits

Chai / Rooibos

Oolong Tea

Herbal / Fruit

Coffee

17:30

Enter PIN

123

456

789

Cancel 0Enter

i

Update MB

Firmware

Administration

17:30

Export

Log

Clear

Log

Reset

Counters

View

Log

<III

Whi

te

Tea

ck

Tea

Vac

uum

C

Co

C

C

C

C

C

C

C

og

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

re

ren

ren

en

ren

en

e

ren

r

re

e

en

n

n

en

n

r

r

n

n

n

r

r

r

e

e

n

n

ren

r

r

e

e

n

r

r

r

e

e

n

r

r

r

r

e

r

r

r

Fl

ush

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

own

CON

T

TI

T

T

T

T

T

T

T

T

T

Cle

Cle

Cle

le

Cle

e

Cle

Cle

Cle

Cle

e

Cle

e

le

Cle

e

e

e

le

e

Cle

l

Cle

Cle

e

Cle

e

Cle

Cle

l

l

e

e

Cle

e

C

C

Cl

l

l

C

C

l

C

C

C

C

C

C

C

C

C

C

C

a

a

a

a

ar

ar

ar

a

a

a

a

a

a

a

a

a

a

a

a

a

Log

Res

e

e

e

et

Cou

ou

ou

o

ou

o

ou

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

nte

rs

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

rs

s

s

r

rs

II

Press and hold the BKON dots

for 5 seconds

Select Cool Down Cool Down is in process Cool Down is complete, select

Continue and power off the

WVSC

Enter PIN number 4576 and

press Enter Select page 21.

4. 5. 6.

2. 3.

4576

Purge Water System

of 865

Service Prerequisites

Protect Air and Water Line and Connections

Remove the water, air and drain

lines if the repair requires their

removal.

Place a piece of tape over the

water, air and drain tubing to

prevent foreign debris from

entering the system.

Before reconnecting the water,

air and drain tubing ensure any

foreign debris is expelled.

1. 2. 3.

of 866

of 867

REMOVAL / INSTALLATION OF PARTS - TOWER

Top Cover (Tower)

Procedure Qty Remarks

(1)

(2)

(3)

Disassembly Order

Electrical connection

Screw (Phillips)

End cover

Top cover

4

2

1

Assembly is in the reverse order of disassembly

Unplug at wall from WVSC

(1)

(3)

(2)

of 868

Removal / Installation of Parts - Tower

Locking Lever

Procedure Qty Remarks

(1)

(2)

(3)

(4)

Disassembly Order

Screw

Axel Clamp

Axis

Locking lever

4

2

1

1

Assembly is in the reverse order of disassembly

(1)

(2)

(3) (4)

Requisite Service Removal / Installation: Top Cover (Tower) - Page 7

of 869

Plunger Assembly

Procedure Qty Remarks

(1)

(2)

(3)

Disassembly Order

Screw (Phillips)

Valve Cylinder

Plunger

4

1

1

Assembly is in the reverse order of disassembly

Remove the silicone water and air lines and microswitch connections

Requisite Service Removal / Installation: Top Cover (Tower) - Page 7

Locking Lever - Page 8

(1)

(2)

(3)

Removal / Installation of Parts - Tower

of 8610

Requisite Service Removal / Installation: Top Cover (Tower) - Page 7

Locking Lever - Page 8

Plunger Assembly - Page 9

Micro Switch Plunger Assembly

Procedure Qty Remarks

(1)

(2)

(3)

(4)

(5)

Disassembly Order

Screw

Washer

Spring

Micro Switch

Safety Slide

1

1

1

1

1

Assembly is in the reverse order of disassembly

Caution: spring is easy to loose

Disconnect wiring

(1)

(2)

(3) (4)

(5)

Removal / Installation of Parts - Tower

of 8611

Logo LEDs

Procedure Qty Remarks

(1)

(2)

Removal Order

Screws

LED Board 2

1

Assembly is in the reverse order of disassembly

Disconnect wiring connection

Requisite Service Removal / Installation: Top Cover (Tower) - Page 7

(1)

(2)

Removal / Installation of Parts - Tower

of 8612

Tower Solenoid Valves

Procedure Qty Remarks

(1) Removal Order

Solenoid Valves Assembly is in the reverse order of disassembly

Disconnect silicone tubing and voltage connectors

Requisite Service Removal / Installation: Top Cover (Tower) - Page 7

Removal / Installation of Parts - Tower

of 8613

Tower Left Side Panel

Procedure Qty Remarks

(1) Removal Order

Side Panel 1 Assembly is in the reverse order of disassembly

Requisite Service Removal / Installation: Top Cover (Tower) - Page 7

(1)

Removal / Installation of Parts - Tower

of 8614

Temperature Sensors - Thot and Tmix

Procedure Qty Remarks

(1)

(2)

Removal Order

NTC Tmix sensor

NTC Thot sensor 1

1

Assembly is in the reverse order of disassembly

Ensure water supply is turned off.

Requisite Service Removal / Installation: Top Cover (Tower) - Page 7

Tower Left Side Panel - Page 13

(1)

(2)

Removal / Installation of Parts - Tower

of 8615

Tower LED Left Side Lights

Procedure Qty Remarks

(1)

(2)

Removal Order

LED strip (Upper)

LED strip (Lower) 1

1

Assembly is in the reverse order of disassembly

Disconnect wire connections

Requisite Service Removal / Installation: Top Cover (Tower) - Page 7

Tower Left Side Panel - Page 13

(1)

(2)

Removal / Installation of Parts - Tower

of 8616

Tower Right Side Panel

Procedure Qty Remarks

(1) Removal Order

Right Side Panel 1 Assembly is in the reverse order of disassembly

Disconnect (6) wire connections before lifting side panel

Thot sensor wires are green

Tmix sensor wires are grey

(1)

Requisite Service Removal / Installation: Top Cover (Tower) - Page 7

Removal / Installation of Parts - Tower

of 8617

User Interface Display

Procedure Qty Remarks

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

Removal Order

Screw

Cover

Screws

PCB Board

Stand off

Touch screen

User Interface mounting screws

User Interface gasket

1

1

4

1

4

1

2

1

Assembly is in the reverse order of disassembly

Disconnect wire connections before removing boards

(1)

(2)

(3)

(4)

(5)

(6)

(7)

Removal / Installation of Parts - Tower

(8)

of 8618

Tower LED Right Side Lights

Procedure Qty Remarks

(1)

(2)

Removal Order

LED strip (Upper)

LED strip (Lower) 1

1

Assembly is in the reverse order of disassembly

Disconnect wire connections

Requisite Service Removal / Installation: Top Cover (Tower) - Page 7

Tower Right Side Panel - Page 16

(1)

(2)

Removal / Installation of Parts - Tower

of 8619

Drain Pan

Procedure Qty Remarks

(1)

(2)

(3)

(4)

Removal Order

Drain Pan Cover

Screws

Drain Pan

Seal

1

4

1

1

Assembly is in the reverse order of disassembly

Not shown

(1)

(2)

(3)

(4)

Removal / Installation of Parts - Tower

Table of contents

Popular Brewing System manuals by other brands

Royal Catering

Royal Catering RCBM-40N user manual

Blichmann Engineering

Blichmann Engineering Fermenator G4 Assembly operation maintenance

Fetco

Fetco TBS-122D Users guide and operator instructions

Ruby Street Brewing

Ruby Street Brewing Alpha Ruby owner's manual

Curtis

Curtis Gemini Satellite user guide

Grindmaster

Grindmaster VS-1.5 Specification sheet