#$%*#&$ #%%#* !#%% $

(# #&#$%$%#&% $.

Failure to follow all instructions listed below, may result in electric shock, fire and/or serious

personal injury.

(:=6=0,

•00;D:@=B:=6,=0,.70,9,9/B07774? Cluttered benches and dark areas invite

accidents.

•:9:?:;0=,?0;:B0=?::7>490C;7:>4A0,?8:>;30=0>>@.3,>49?30;=0>09.0:1

17,88,-7074<@4/>2,>0>:=/@>?Power tools create sparks which may ignite the dust

or fumes.

•00;-D>?,9/0=>.347/=09,9/A4>4?:=>,B,DB3470:;0=,?492,;:B0=?::7

Distractions can cause you to lose control.

70.?=4.,7$,10?D

•:9:?,-@>0?30.:=/0A0=@>0?30.:=/?:.,==D?30?::700;.:=/,B,D1=:8

30,?:47>3,=;0/20>:=8:A492;,=?>#0;7,.0/,8,20/.:=/>4880/4,?07D

Damaged cords may create a fire.

•-,??0=D:;0=,?0/?::7B4?349?02=,7-,??0=40>:=,>0;,=,?0-,??0=D;,.68@>?-0

=0.3,=20/:97DB4?3?30>;0.4140/.3,=20=1:=?30-,??0=DA charger that may be

suitable for one type of battery may create a risk of fire when used with another battery.

•&>0-,??0=D:;0=,?0/?::7:97DB4?3>;0.414.,77D/0>429,?0/-,??0=D;,.6Use of any

other batteries may create a risk of fire.

!0=>:9,7$,10?D

•$?,D,70=?B,?.3B3,?D:@,=0/:492,9/@>0.:88:9>09>0B309:;0=,?492,

;

:B0=?::7:9:?@>0?::7B3470?4=0/:=@9/0=?3049[email protected]:1/=@2>,7.:3:7:=80/4.,?4:9 A moment of inattention while operating power tools may result in serious

personal injury.

•=0>>;=:;0=7D:9:?B0,=7::>0.7:?3492:=50B07=D:9?,497:923,4=00;D:@=

3,4=.7:?3492,9/27:A0>,B,D1=:88:A492;,=?> Loose clothes, jewelry, or long hair

can be caught in moving parts. Air vents cover moving parts and should be avoided.

•A:4/,..4/09?,7>?,=?4920>@=0>B4?.34>49?307:.60/:=:11;:>4?4:9-01:=0

49>0=?492-,??0=D;,.6 Carrying tools with your finger on the switch or inserting the

battery pack into a tool with the switch on invites accidents.

•#08:A0,/5@>?49260D>:=B=09.30>-01:=0?@=9492?30?::7:9 A wrench or a key that

is left attached to a rotating part of the tool may result in personal injury.

•:9:?:A0==0,.3 00;;=:;0=1::?492,9/-,7,9.0,?,77?480>Proper footing and

balance enable better control of the tool in unexpected situations.

•&>0>,10?D0<@4;809?7B,D>B0,=0D0;=:?0.?4:9 Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for appropriate conditions.

%::7&>0,9/,=0

•&>0.7,8;>:=:?30=;=,.?4.,7B,D?:>0.@=0,9/>@;;:=??30B:=6;40.0?:,>?,-70

;7,?1:=8 Holding the work by hand or against your body is unstable and may lead to loss

of control.

•:9:?1:=.0?::7&>0?30.:==0.??::71:=D:@=,;;74.,?4:9 The correct tool will do the

job better and safer at the rate for which it is designed.

•:9:?@>0?::741>B4?.3/:0>9:??@=94?:9:=:11 A tool that cannot be controlled with

the switch is dangerous and must be repaired.

•4>.:990.?-,??0=D;,.61=:8?::7:=;7,.0?30>B4?.349?307:.60/:=:11;:>4?4:9

-01:=08,6492,9D,/5@>?809?>.3,92492,..0>>:=40>:=>?:=492?30?::7 Such

preventive safety measures reduce the risk of starting the tool accidentally.

•$?:=04/70?::7>:@?:1=0,.3:1.347/=09,9/:?30=@9?=,490/;0=>:9>Tools are

dangerous in the hands of untrained users.

•(309-,??0=D;,.64>9:?49@>0600;4?,B,D1=:8:?30=80?,7:-50.?>7460;,;0=

.74;>.:49>60D>9,47>>.=0B>:=:?30=>8,7780?,7:-50.?>?3,?.,98,60,

.:990.?4:91=:8:90?0=849,7?:,9:?30=Shorting the battery terminals together may

cause sparks, burns, or a fire.

•,49?,49?::7>B4?3.,=000;.@??492?::7>>3,=;,9/.70,9Properly maintained

tools, with sharp cutting edge are less likely to bind and are easier to control.

•30.61:=84>,7429809?:=-49/492:18:A492;,=?>-=0,6,20:1;,=?>,9/,9D:?30=

.:9/4?4:9?3,?8,D,110.??30?::7Q>:;0=,?4:91/,8,20/3,A0?30?::7>0=A4.0/

-01:=0@>492 any accidents are caused by poorly maintained tools.

•&>0:97D,..0>>:=40>?3,?,=0=0.:8809/0/-D?308,9@1,.?@=0=1:=D:@=8:/07

Accessories that may be suitable for one tool may create a risk of injury when used on

another tool.

$0=A4.0

•%::7>0=A4.08@>?-0;0=1:=80/:97D-D<@,74140/=0;,4=;0=>:9907Service or

maintenance performed by unqualified personnel may result in a risk of injury.

•(309>0=A4.492,?::7@>0:97D4/09?4.,7=0;7,.0809?;,=?>:77:B49>?=@.?4:9>49

?30,49?09,9.0>0.?4:9:1?34>8,9@,7 Use of unauthorized parts or failure to follow

aintenance Instructions may create a risk of shock or injury.

•:7/?::7-D49>@7,?0/2=4;;492>@=1,.0>B309;0=1:=8492,9:;0=,?4:9B30=0?30

.@??492?::78,D.:9?,.?34//09B4=492 Contact with a "live" wire will also make exposed

metal parts of the tool "live" and shock the operator.

The label on yo r tool may incl de the following symbols.

Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber. (CCA)

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter out

microscopic particles.

•

Allowing dust to get into your mouth, eyes, or lay on the skin may

promote absorption of harmful chemicals.

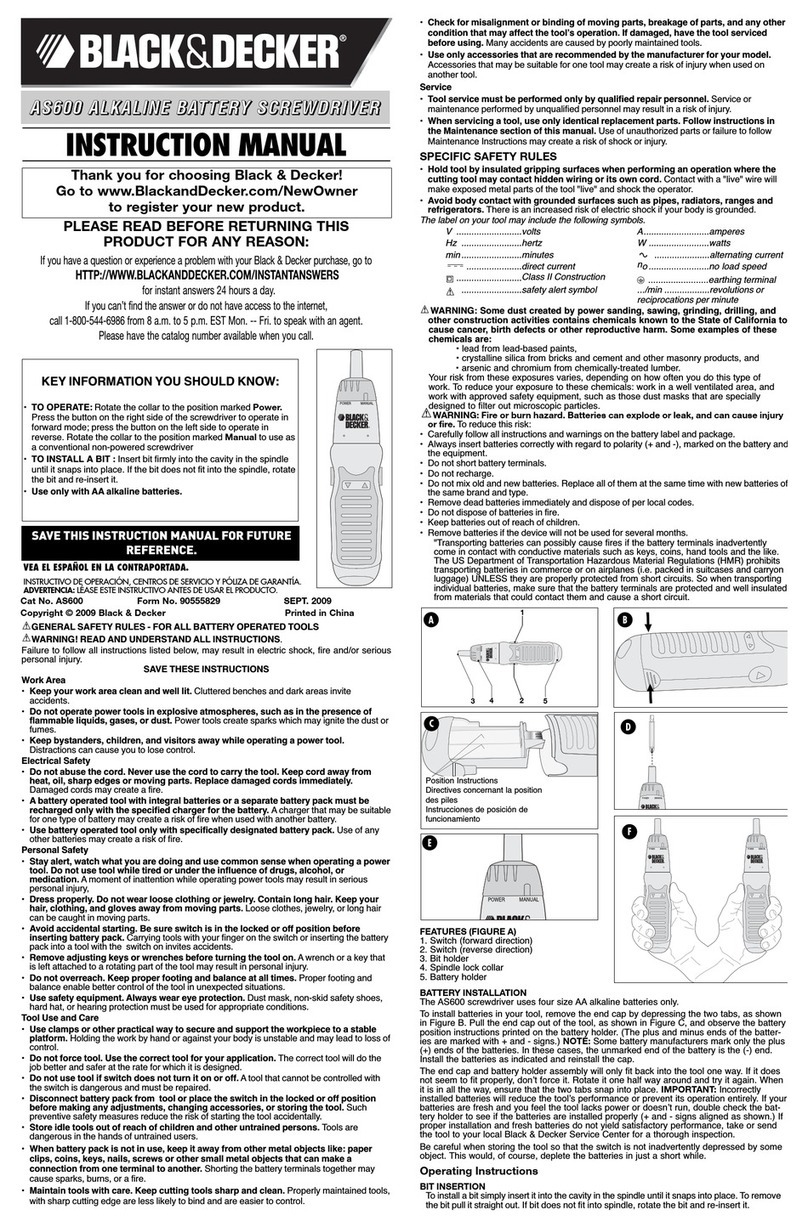

1. On/off switch with forward/reverse function

2. Torque adjustment collar

3. Bit holder

4. Handle adjustment button

5. Handle

6. Battery cover

Before attempting to charge your screwdriver, thoroughly read all of the safety instructions.

To charge your screwdriver, follow the steps below.

1. Plug the output cord of the charger (7) into the socket in the back half of the

screwdriver handle (8) as shown in Figure B.

2. Plug the charger into any standard electrical outlet.

%The tool was sent from the factory in an uncharged condition. Before attempting to

use it, it must be charged for 12 hours.

1. Charger will work best at normal room temperature.

2. The charger plug and the tool handle may become warm while charging. This is normal

and does not indicate a problem.

3. The tool can be left on charge as long as you desire. A minimum charge time of 12 hours

is required to recharge a completely discharged tool.

4. For most fix up jobs a charge of 3 to 4 hours will be adequate.

(#When disconnecting the screwdriver from the charger, be sure to unplug the

charger from the outlet first then disconnect the charger cord from the screwdriver.

To install a screwdriver bit (9) Fig. C simply insert it into the cavity in the bit holder (3) until it

snaps into place. To remove the bit pull it straight out. If bit does not fit, rotate the bit and re-

insert it. To insert a bit tip (11) first insert a bit tip holder (10) into the spindle and then insert

the bit tip into the holder. % Screwdriver bit types and quantity may vary.

For optimum versatility, the handle can be be set to different positions as shown in Fig. D. To

adjust the handle, press the handle adjustment button (4) and swivel the handle into the

desired position. Release the button and the handle will lock in that position.

To avoid being pinched, grasp the handle below the pinch point shown in Figure D.

!#%! (#

:=B,=/

• Slide the button (1) shown in Fig. E to the =423?, exposing the triangle pointing forward.

• Press the button and the tool will run; release the button and the tool will stop.

#0A0=>0

• Slide the button (1) shown in Fig. E to the 701?, exposing the triangle pointing backward.

• Press the button and the tool will run; release the button and the tool will stop.

!#%&

• The tool can be used as a conventional non-powered screwdriver whenever the

forward/reverse button is not depressed. With the button (1) in the 84//70 position, the tool

will not activate.

This tool is fitted with a collar to set the torque for tightening screws. Large screws and hard

workpiece materials require a higher torque setting than small screws and soft workpiece

materials. The collar has a wide range of settings to suit your application.

• Turn the collar (2) to the desired setting. If you do not yet know the appropriate setting,

proceed as follows:

• Set the collar to the lowest torque setting.

• Tighten the first screw.

• If the clutch ratchets before the desired result is achieved, increase the collar setting and

continue tightening the screw. Repeat until you reach the correct setting. Use this setting

for the remaining screws.

• Always use the correct type of screwdriver bit. Never use a screwdriver bit tip without a bit

tip holder

• If screws are difficult to tighten, try applying a small amount of washing liquid or soap as a

lubricant.

• Use the spindle lock to loosen very tight screws or to firmly tighten screws.

• Always hold the tool and screwdriver bit in a straight line with the screw.

A

B

C

D

Pinch Point

EF

V .........................volts A ......................... amperes

Hz .......................hertz W ........................watts

min ..................... min tes ...................... alternating c rrent

....................direct c rrent no ....................... no load speed

........................Class II Constr ction ........................ earthing terminal

.......................safety alert symbol .../min ..................revol tions or reciprocations

per min te

ENGLISH