Black & Webster air-hydraulics AP1900D Assembly instructions

1

BLACK & WEBSTER

AIR PRESS

MODEL AP1900D

INSTALLATION, OPERATING &

MAINTENANCE INSTRUCTIONS

545 Hupp Avenue ▪ Jackson, Michigan 49204

Ph: 517-787-9444 ▪ Fx: 517-787-7585

www.airhydraulics.com ▪ info@airhydraulics.com

Serial No.__________________

Document ID: UM-BWAP-1900-D-20170926

Revision: Original

2

TABLE OF CONTENTS

Installation and Setup ………………………………………………………………………………………………………… 3

Maintenance ………………………………………………………………….…………………………………………………… 3

Disassembly ….………………………………………………………………….………………………………………………… 4

Troubleshooting Guide …………………………………………………………………………………………………….… 4 & 5

Pneumatic Circuit …………………………………………………………………………………………………………….…. 6

Part List ………………………………………………………………………………………………………………….………….. 7

Parts Drawing …………………………………………………………………………………………………………….………. 8

MACHINE GUARDING

Machine guarding is the responsibility of the user. Provisions must be made to protect the operator

and other employees from injury as a result of contact with work in progress, moving parts, mechanical

motions of the press, etc. Air-Hydraulics cannot provide “standard” guards for its products due to the

variety of tooling used by its owners. However, Air-Hydraulics will be happy to install guards and similar

safety devices for operator protection. These safety devices must be produced at the request of and

with the design approval of the purchaser.

WARRANTY

We warrant to the original user that all products of our manufacture will be free from defects in

material and workmanship and will possess the characteristics represented in writing by us. Claim for

breach of the above warranty must be made within a period of one (1) year from the date of delivery to

the user. Upon satisfactory proof of claim, we will make any necessary repairs or corrections, or, at our

option, replace defective parts at the factory, transportation charges prepaid. Charges for correcting

defects will not be allowed, nor can we accept goods returned for credit unless we are notified in writing

and the return or correction is authorized by us in writing. The FOREGOING IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESSED OR IMPLIIED, INCLUDING ANY WARRANTIES THAT EXTEND BEYOND THE

DESCRIPTION OF THE PRODUCT. This paragraph sets forth the extent of our liability for breach of any

warranty in connection with the sale or use of our products. It is understood we will not be liable for

consequential damage such as loss of profit, delays, or expense whether based on tort or contract.

3

INSTALLTION

1. Place press on rigid bench or table at a convenient height for operator. Bolt securely to the

bench.

2. Connect 100 P.S.I. filtered shop air supply (40 micron min) to 3/8 N.P.T. inlet port of air prep

assembly.

SET UP AND OPERATION

1. Loosen locknut and adjust pressure regulator until pressure gauge reads desired pressure

(100 P.S.I.). CAUTION: Do not operate at pressure greater than 125 P.S.I.

2. Adjust speed control valve to slow position by turning valve stem clockwise (or in).

3. Check to make sure safety sleeve assembly is in the correct position on the press before

operating

4. Keeping hands clear of shaft, actuate press by depressing palm buttons.

5. Release palm buttons. Shaft should return to fully retracted position (2 pos. circuit) or stop

movement (3 pos. circuit)

6. Remove safety sleeve from press.

7. Loosen locking nut and adjust stop nut to obtain desired stroke. Distance between bottom

of the stop nut and top surface of stop cap or frame is the stroke of the shaft. CAUTION: Do

not back off locking nut beyond top of threaded shaft. Doing so may damage packings.

8. Replace safety sleeve and re-actuate press.

9. If necessary, re-adjust stop nut, speed control and pressure regulator to obtain desired

setting. CAUTION: Never operate press unless safety sleeve is in place and hands are clear

of shaft.

10. Install tooling into hole provided in shaft, securing with set screw.

11. Install dies, nests or anvils onto base using tapped holes provided.

12. Make any final stroke, speed and pressure adjustments to obtain desired workpiece

configuration with tooling in place.

MAINTENANCE

LUBRICATION

Air presses are lubricated at the factory and should require no additional lubrication. However, if a

press is disassembled for service or replacement of parts, all internal surfaces should be coated with a

light bearing grease such as Lubriko M6 (Master Chemical Co.) or equivalent.

CUSHION ADJUSTMENT

Model AP 1900D employs an external cushion spring for the return stroke. The cushion is preset at the

factory and should require no further attention. However, if the machine should begin to “hammer”

during the return stroke, cushion adjustment may be necessary, as follows:

1. Remove safety sleeve from press

2. Loosen cushion adjustment locking nut.

4

3. Rotate cushion adjustment locking nut upward to increase spring compression, slightly.

4. Re-tighten locking nut.

5. Replace safety sleeve.

6. Adjust return speed control to maximum fast position.

7. Actuate press & check for “hammering” during the return stroke

8. If necessary, repeat cushion adjustment until ram returns gently to its rest position.

9. Re-adjust return speed control to obtain desired return stroke speed.

GIB ADJUSTMENT

Model AP 1900D has a square shaft retained by two adjustable gibs. If any side play or rotation is

noticed in the shaft of these models, a gib adjustment may be necessary. Adjustments as follows:

1. Along the centerline of the shaft at the front and right side of the press, two (2) set screws will

be found for each of the two (2) gibs.

2. Adjust set screws inward on one (1) gib at a time until all side play is removed from shaft. Do

not overtighten gibs or press may jam or operate erratically. Gibs should be just tight enough to

remove all side play and rotation from shaft.

PRESS DISASSEMBLY

Should press disassembly become necessary in order to service or replace parts, use extreme caution.

Remove air supply. Cylinder should be in retracted position. Ram & shaft may fall, be sure to block up

ram in the platen area. Remove hex screws holding cylinder cap in place. Now remove any fastener you

need to replace parts. Re-assembly should be approached with the same cautious manner. Torque

cylinder mounting fasteners to 23 ft. lbs. each.

Air-Hydraulics, Inc. maintains complete facilities at all times for the repair of air presses. If qualified

maintenance personnel are not available at a customer’s plant, the press may be returned to the Air-

Hydraulics, Inc. for service.

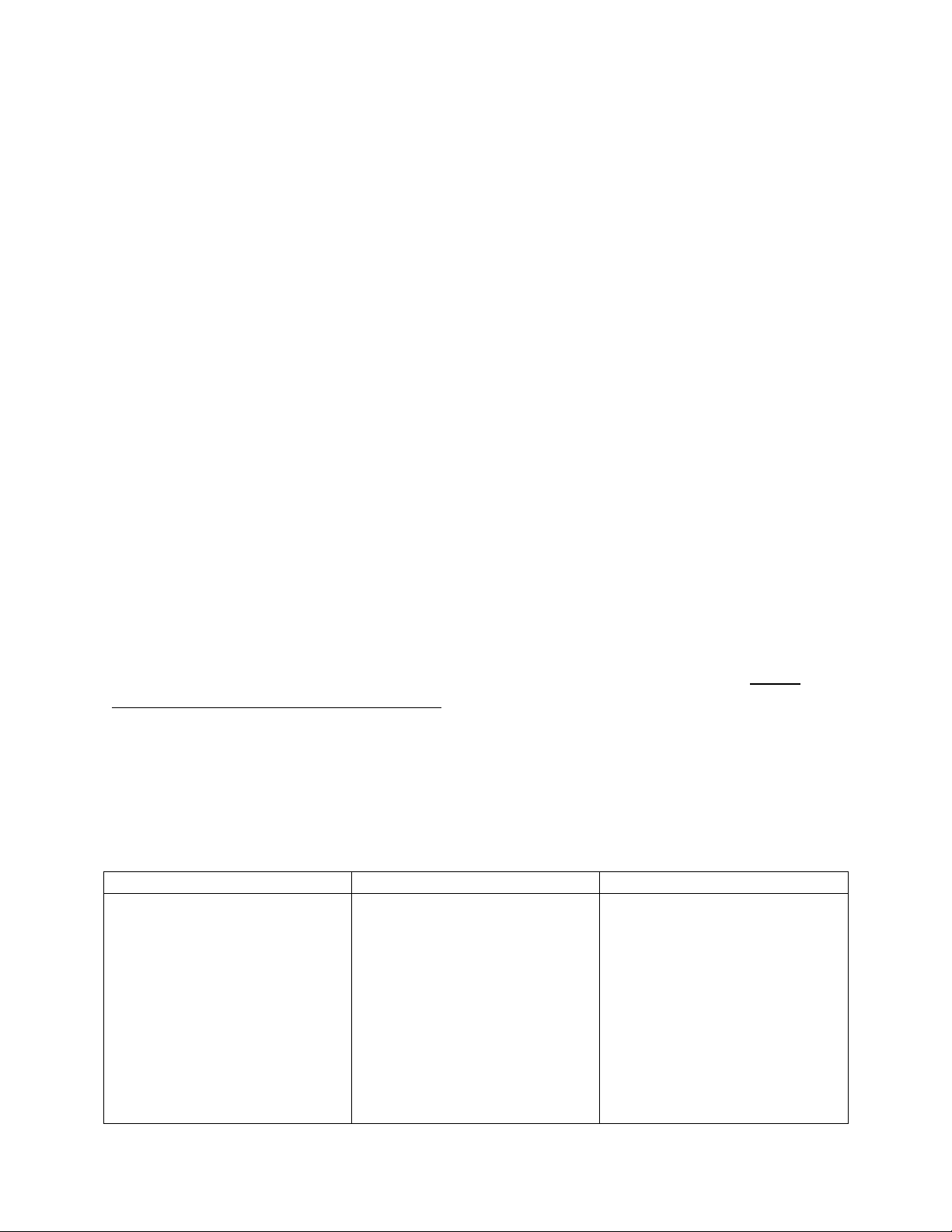

TROUBLESHOOTING GUIDE

PROBLEM

CAUSE

REMEDY

A. Shaft fails to extend

after hand valve

actuated or fails to

return to rest position

1. Insufficient air pressure

2. Speed control valve

closed or clogged

3. Power valve not shifted

1. Clean supply, adjust or

clean regulator

2. Open speed control

valve or clean blockage

3. Check for adequate pilot

air from hand valve & for

jammed spools

5

4. Hand valve clogged

5. Shaft bent

6. Gibs too tight

4. Clean hand valve

5. Replace shaft

6. Adjust gibs (see

maintenance)

B. Ram moves erratically

1. Gibs too tight

2. Insufficient lubrication

3. Air Leaking past packings

4. One or more valves

clogged or leaking

1. Adjust gibs (see

maintenance)

2. Re-lubricate press

3. Replace packing

4. Clean or repair valves

C. Excess rotation of shaft

1. Gibs loose or worn

1. Re-adjust gibs

(see maintenance)

D. Reduced force at a given

pressure

1. Air leaking past packings

2. Gibs too tight

1. Replace packings

2. Re-adjust gibs

(see maintenance)

E. Shaft “hammering” on

return stroke

1. Cushion spring loose or

broken

1. Replace spring if broken,

re-adjust cushion (see

maintenance)

6

PNEUMATIC DIAGRAM

SINGLE ACTING CYLINDER WITH

DUAL PALMS & ANTI-TIE DOWN

AP 1900

Length of Stroke 0-2” adjustable

Throat Depth 5.00”

Opening of Ram to Base 6.00”

Tool Hole in Ram .81 dia. X 1.50 deep

Force at 100 P.S.I. Up to 1900 lbs.

Ram Style Square with gib

Net Weight (less controls) 132 lbs.

Controls (optional) Flow Control Valve

Pressure Regulator

Pressure Gauge

High flow power valve

Exhaust Air Muffler

3 position valve (JOG)

7

PARTS LIST

AP1900 AIR PRESS

ITEM

PART #

DESCRIPTION

QTY

1

203035

Base

1

2

203075

Frame

1

3

203037

Cylinder

1

4

203038

Cylinder cap

1

5

203040

Cylinder base

1

6

203041

Ram

1

7

203076

Front cover

1

8

203077

Bronze gib

2

9

203044

Washer

1

10

203046

Cup retaining washer

2

11

203048

Spacer posts

3

12

203049

Retainer washer

1

13

203053

Stop nut

1

14

20305402

Spring cushion nut

1

15

203056

Shaft

1

16 (RK)

203045

Piston packing

2

17 (RK)

203050

Cylinder base packing

1

18 (RK)

203051

O-ring

2

19 (RK)

203052

Cylinder gasket

2

20

203055

Cushion spring

1

21

203108

Safety sleeve

1

22

203047

Spring return

1

23

203066

*

Repair kit

1

*Not shown on drawing (RK) Items in repair kit #203066

8

AP1900 PARTS DRAWING

Table of contents

Other Black & Webster Power Tools manuals

Popular Power Tools manuals by other brands

Bosch

Bosch GBH 2-20 D Professional Original instructions

Sealey

Sealey SB973 instructions

Max

Max CN565S Operating and maintenance manual

Makita

Makita GRH08 instruction manual

Parkside

Parkside PASSK 20-Li A1 Translation of the original instructions

SCHUNK

SCHUNK KSC2 40 Installation and operating instructions

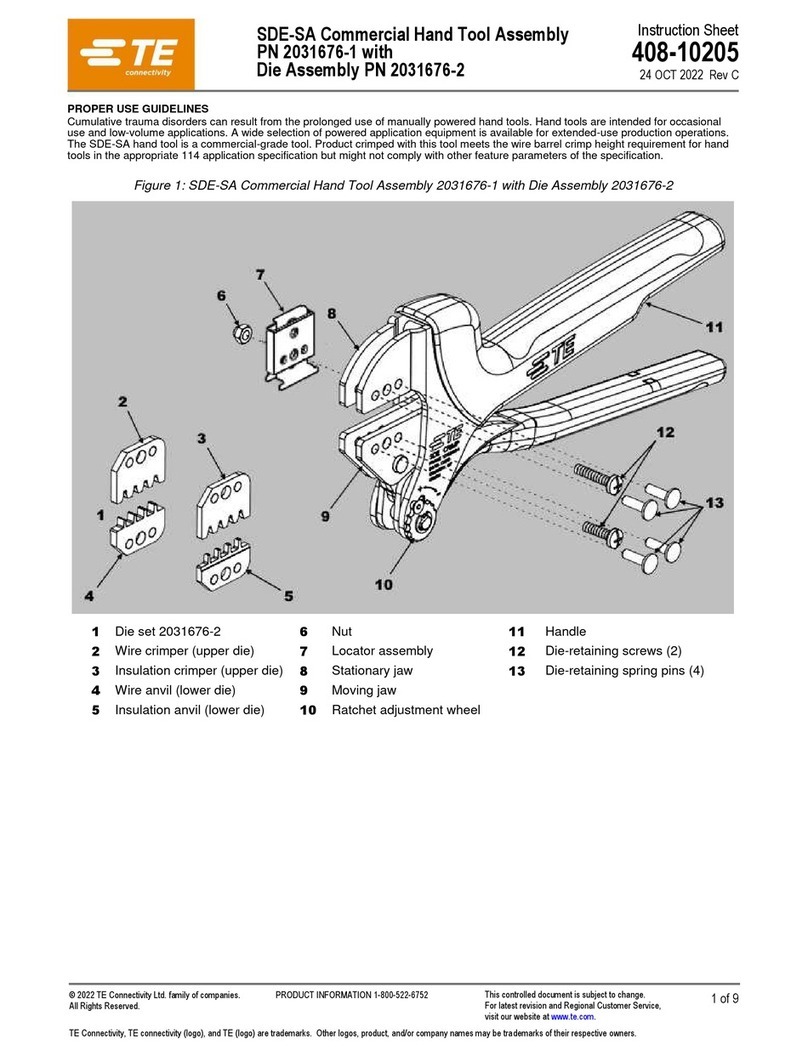

TE Connectivity

TE Connectivity 2031676-1 Assembly instructions

Ozito

Ozito ROU-5000 instruction manual

Worx

Worx WX473 Original instructions

Northern Industrial Tools

Northern Industrial Tools 12Volt Chainsaw Sharpener 141259 owner's manual

BASETech

BASETech ZD-70D operating instructions

Ryobi

Ryobi EPN6082C Original instructions