2

P R E PA RING TO WORK

SETTING TE M P ERATURE PRESSURE AND TIME

I N U S E

Connect the press to a suitable mains elec tricity supplyand ensure th at

the work area is clear of obstructions.

When the press is sw itched on, the main display will read - In Pwhile

the unit initialises and per forms some internal checks. The - In Pdis-

play will, after some seconds have elapsed, change to the number - 4 0 0

while the units internal checks continued. The unit will then display

the current actual platen temperature in degrees centigrade / Celsius

on the main display, and the target or most recently set temperature

on the green auxiliary display for example - 1 6 5 You can now use the

blue set button to access on e of two input mo des. These modes are - SP

which is concern ed with the temperature related functionof the press

and the second mode of operation is - S T which is concerned with time

setting. Time and temperature can be adjusted using the up and down

arrow keys which are coloured orange and are located next to th e blue

set button on the control console. The blue button can bepressed re -

peatedly to cycle between the two modes above and the operational

mode which displays the current platen temperature as measured in

degrees centigrade / Celsius for example – 1 4 0 . The - In Pvalue must be

setup to 2 0 .

Successful operation is a combination of time, pressure and tempera-

ture. Consult the data sheet for your transfer material and experiment

to get the result you’re looking for.

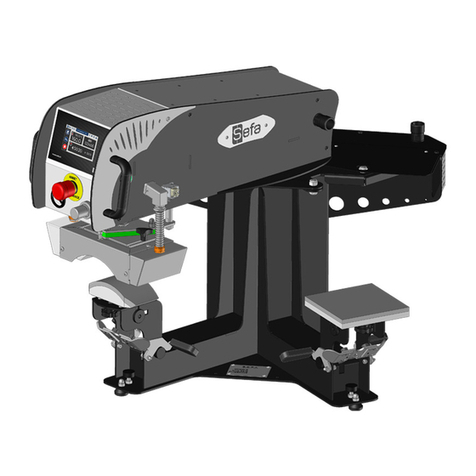

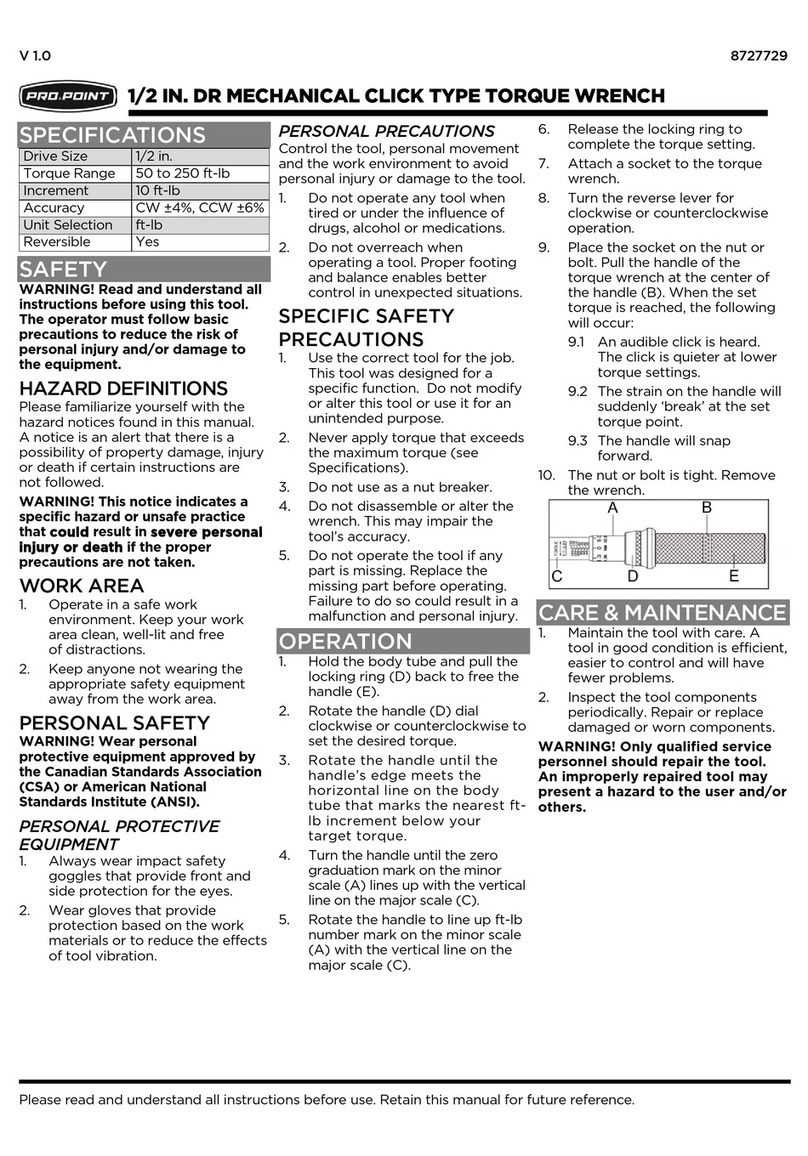

1.Lift the press handle and place the item you want to print upon the

rubber mat with the transfer medium, colour side down and correctly

positioned upon the item. Pressure is a matter of some experimentation

using the press bolt identified in the illustration below. Timing is again

a mater of experimentation using the unit’s timer. An audiblealarm

rings when the set time is elapsed and the cycle starts automatically

when the handle is lowered.

2 . Af ter the required time is elapsed, left the handle and remove th e

printed item.