TE Connectivity 2031676-1 User manual

Other TE Connectivity Power Tools manuals

TE Connectivity

TE Connectivity 2217074-1 User manual

TE Connectivity

TE Connectivity 59239-4 User manual

TE Connectivity

TE Connectivity 47386-4 User manual

TE Connectivity

TE Connectivity Hand tool for AMP DUOPLUG 2.5 User manual

TE Connectivity

TE Connectivity 2396645-1 User manual

TE Connectivity

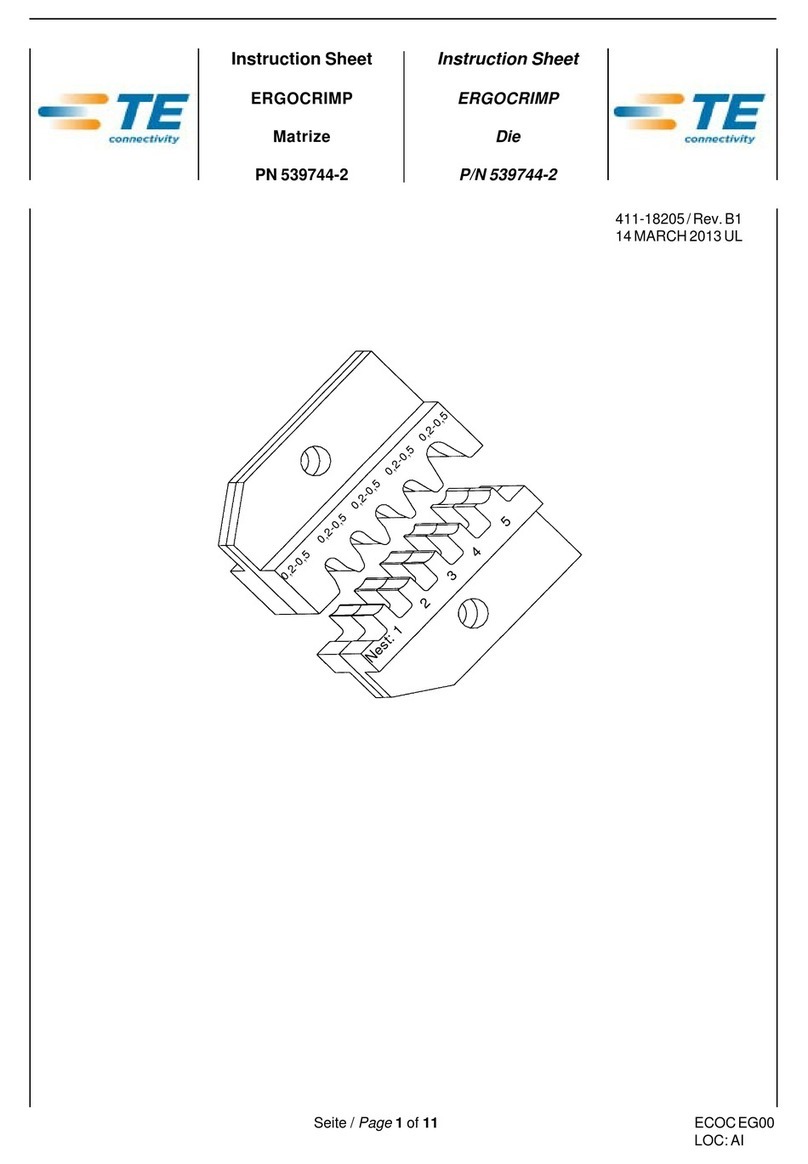

TE Connectivity 539744-2 User manual

TE Connectivity

TE Connectivity 2393336-1 User manual

TE Connectivity

TE Connectivity ERGOCRIMP User manual

TE Connectivity

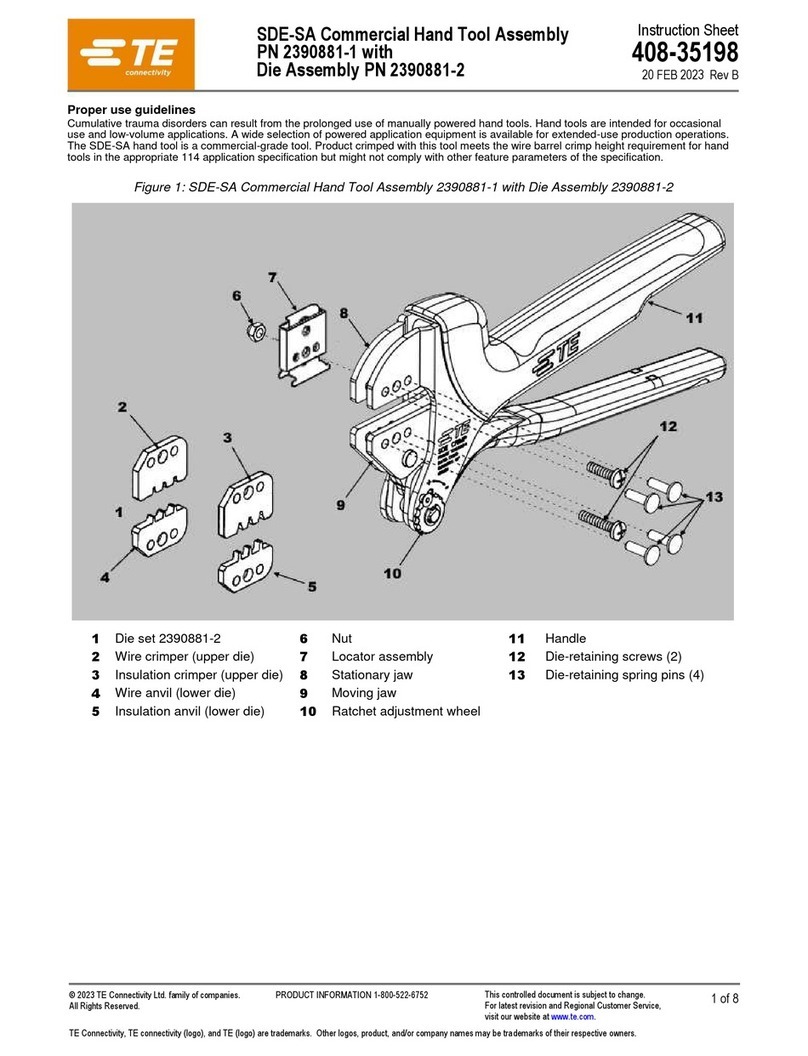

TE Connectivity 2390881-1 User manual

TE Connectivity

TE Connectivity 1976330-1 User manual

TE Connectivity

TE Connectivity SOLARLOK PN 1-1579004-1 User manual

TE Connectivity

TE Connectivity 2363592-1 User manual

TE Connectivity

TE Connectivity 539 666-2 User manual

TE Connectivity

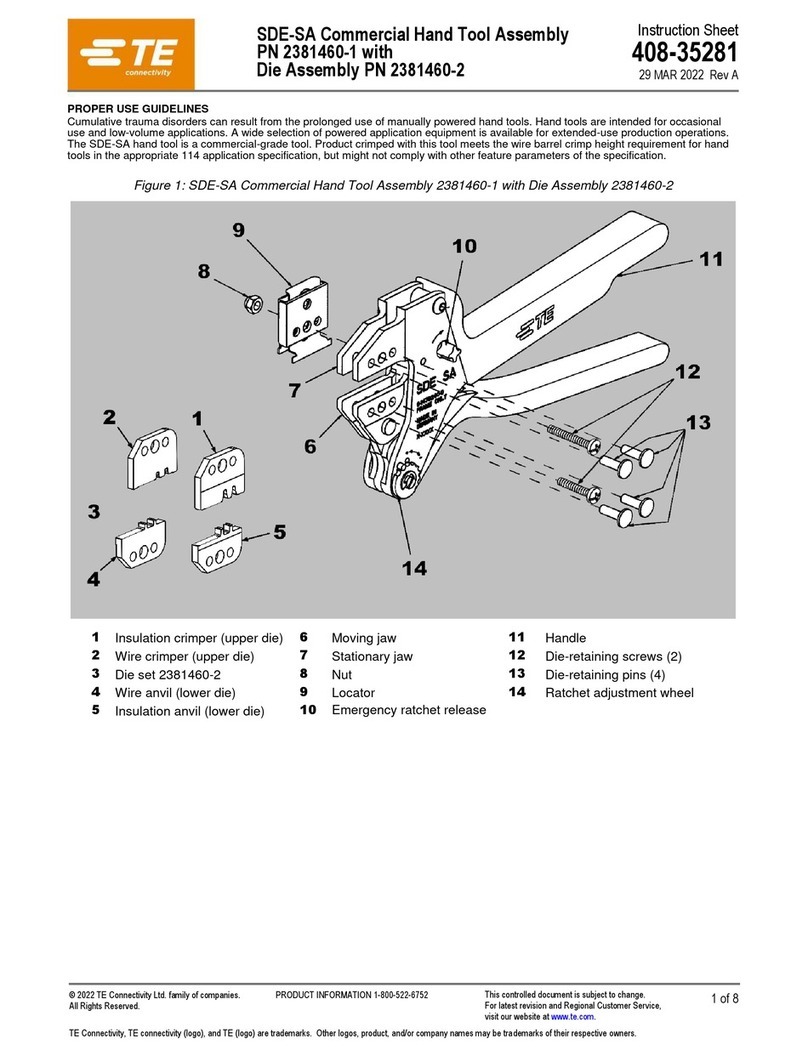

TE Connectivity 2381460-1 User manual

TE Connectivity

TE Connectivity 1976330-1 User manual

TE Connectivity

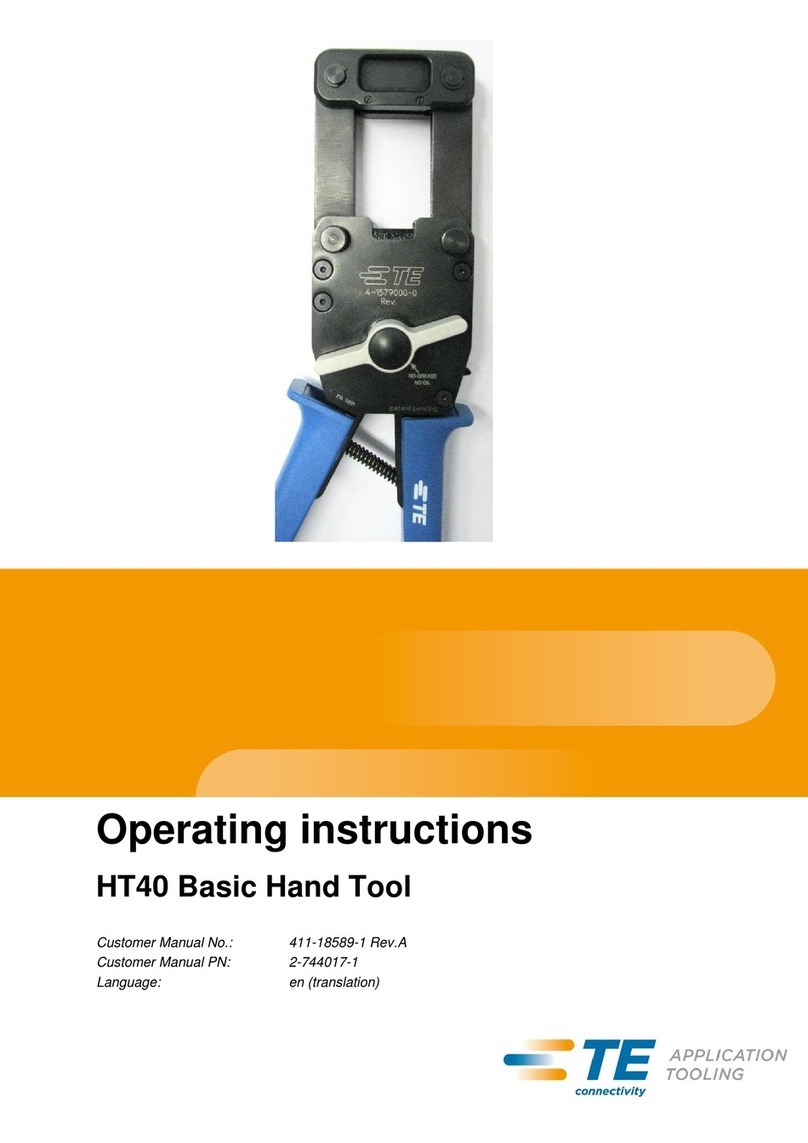

TE Connectivity HT40 User manual

TE Connectivity

TE Connectivity 2389783-1 User manual

TE Connectivity

TE Connectivity 1901343 Series Reference guide

TE Connectivity

TE Connectivity MATE-AX 2335290-1 User manual

TE Connectivity

TE Connectivity 2390879-1 User manual