Contents

1 General Instructions......................................................................... 4

1.1 About the manual............................................................................................................................................4

1.2 Intended use.....................................................................................................................................................4

1.3 Warranty.............................................................................................................................................................4

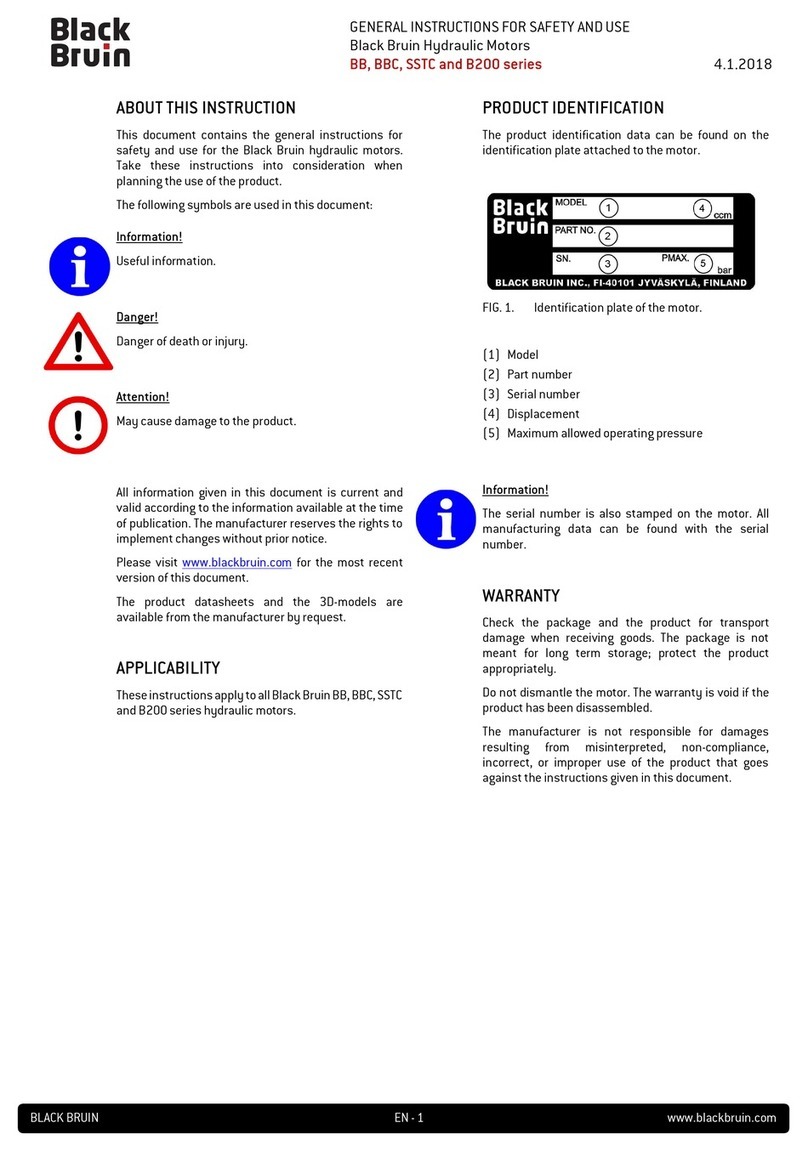

1.4 Product identication..................................................................................................................................... 4

1.5 Publication date............................................................................................................................................... 5

1.6 Declaration of incorporation......................................................................................................................... 5

2 Safety Instructions........................................................................... 6

2.1 Warning symbols..............................................................................................................................................6

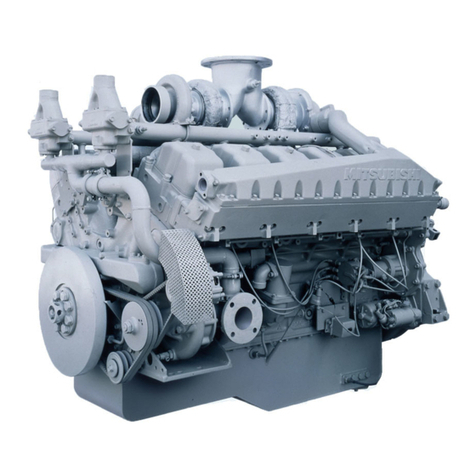

3 Motor Description.............................................................................. 7

3.1 Working principle.............................................................................................................................................. 7

3.2 Motor model code BB series.........................................................................................................................8

3.3 Motor model code BBC series...................................................................................................................... 9

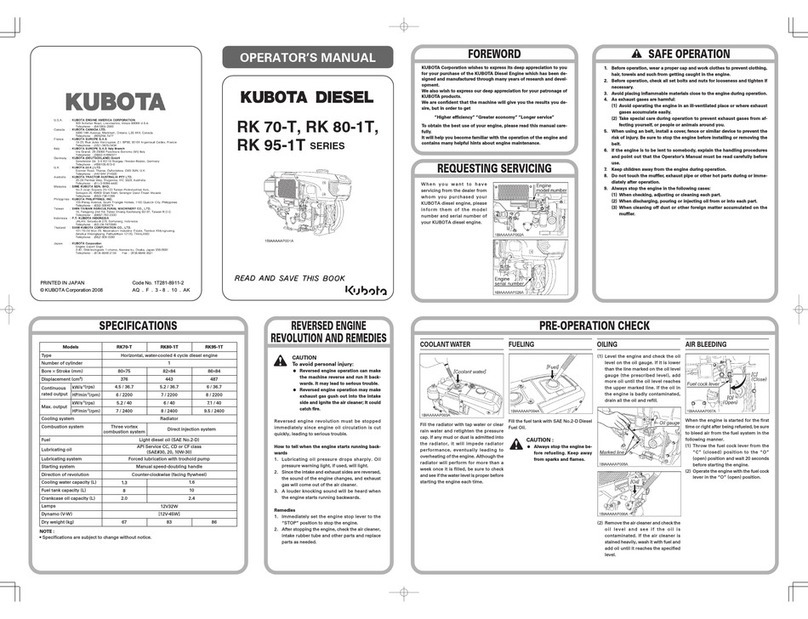

3.4 Technical data BB series..............................................................................................................................10

3.5 Technical data BBC series........................................................................................................................... 12

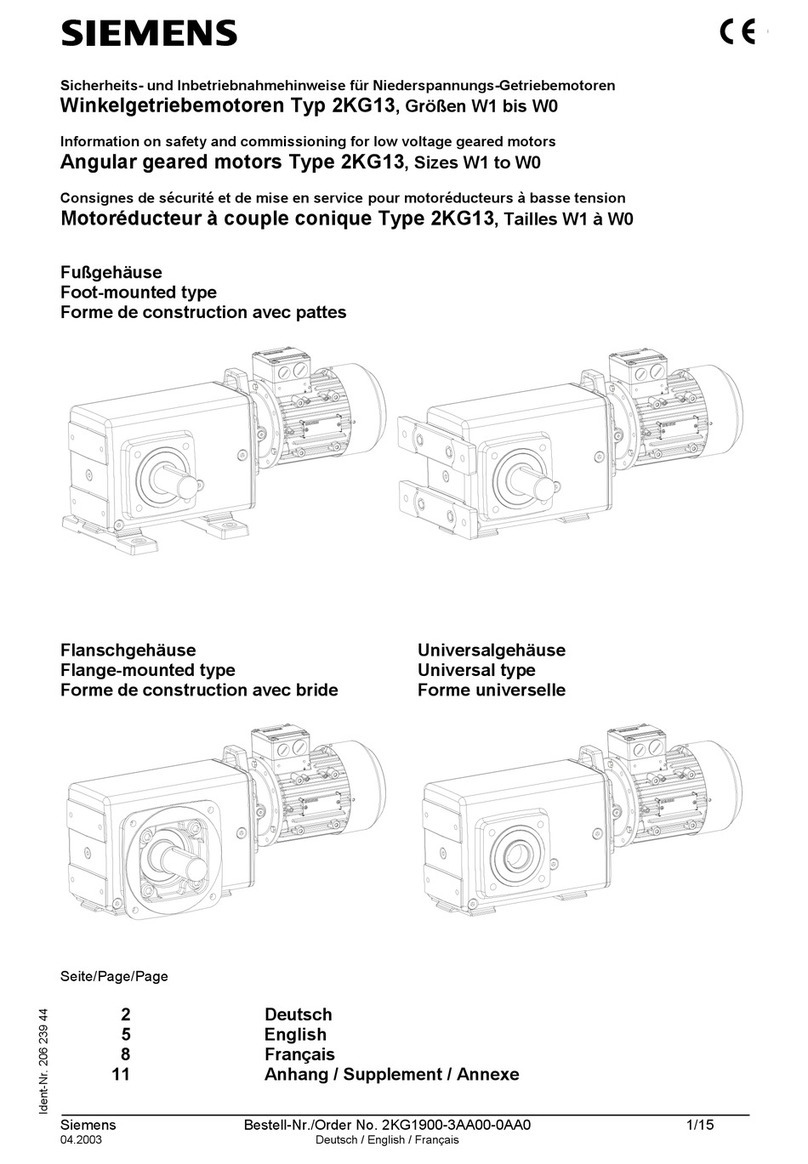

3.6 Motor interfaces............................................................................................................................................. 14

3.6.1 Main dimensions..........................................................................................................................14

3.6.2 Shaft interfaces........................................................................................................................... 16

3.6.3 Hub interfaces..............................................................................................................................21

3.7 Rotating direction..........................................................................................................................................25

3.8 Freewheeling..................................................................................................................................................26

3.8.1 Hydrostatic freewheeling......................................................................................................... 26

3.8.2 Mechanical freewheeling.......................................................................................................... 27

3.9 1-speed motors..............................................................................................................................................28

3.10 Multi-speed motors...................................................................................................................................... 29

3.11 Seal protector and grease nipples.............................................................................................................31

3.12 Brakes................................................................................................................................................................31

3.12.1 Static wet multi-disc brake for BBC and BB series motors..............................................31

3.12.2 Double brake for BBC series motors......................................................................................32

4 System Design................................................................................. 33

4.1 Motor hydraulic circuit................................................................................................................................. 33

4.1.1 Simple connection......................................................................................................................33

4.1.2 Counter pressure operation..................................................................................................... 33

4.1.3 Hydrostatic braking....................................................................................................................34

4.1.4 Short circuit operation...............................................................................................................34

4.2 Hydraulic connections................................................................................................................................. 35

4.3 External freewheeling valve........................................................................................................................37

4.4 Hydraulic uid................................................................................................................................................ 39

4.4.1 Motors in parallel or series circuit...........................................................................................39

4.4.2 Hydraulic uid type.....................................................................................................................41

4.4.3 Hydraulic uid properties.......................................................................................................... 41

4.4.4 Hydraulic uid cleanliness.........................................................................................................41

4.5 Operating pressures...................................................................................................................................... 41

4.5.1 Case pressure...............................................................................................................................41

4.5.2 Pilot pressure............................................................................................................................... 42

4.5.3 Working line pressure.................................................................................................................42

Contents

2 Product Manual