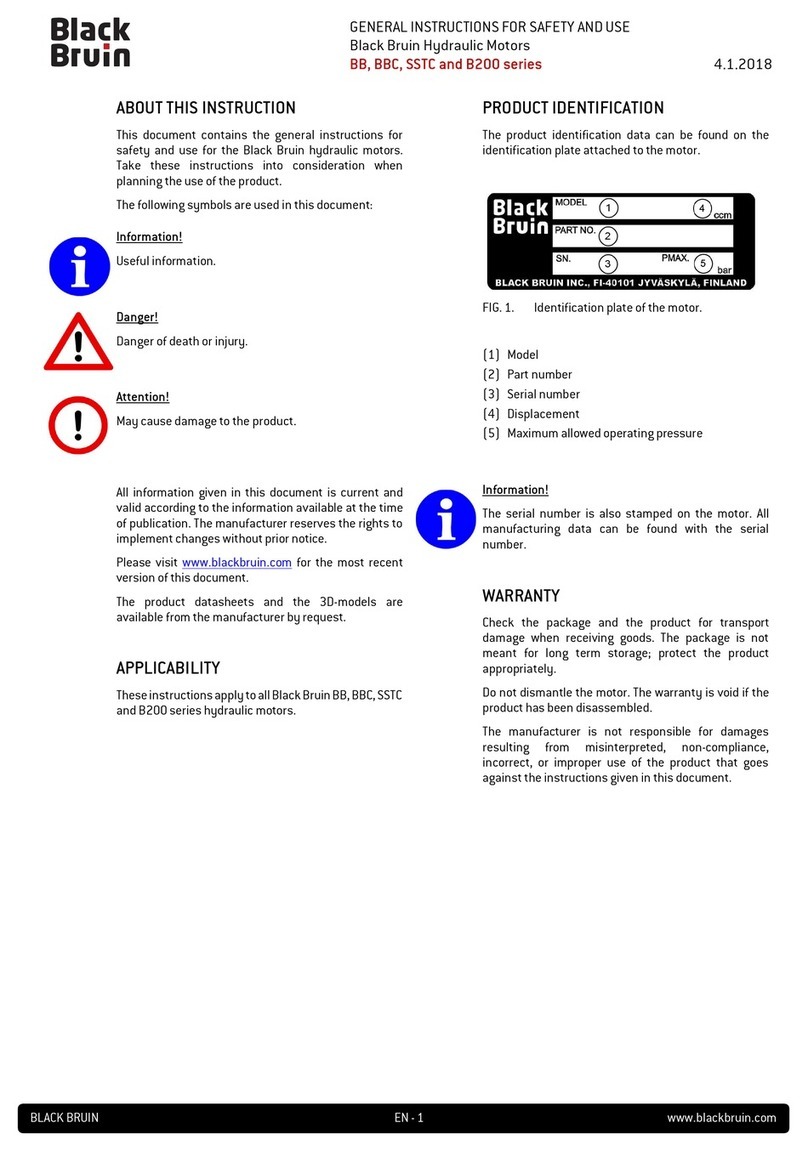

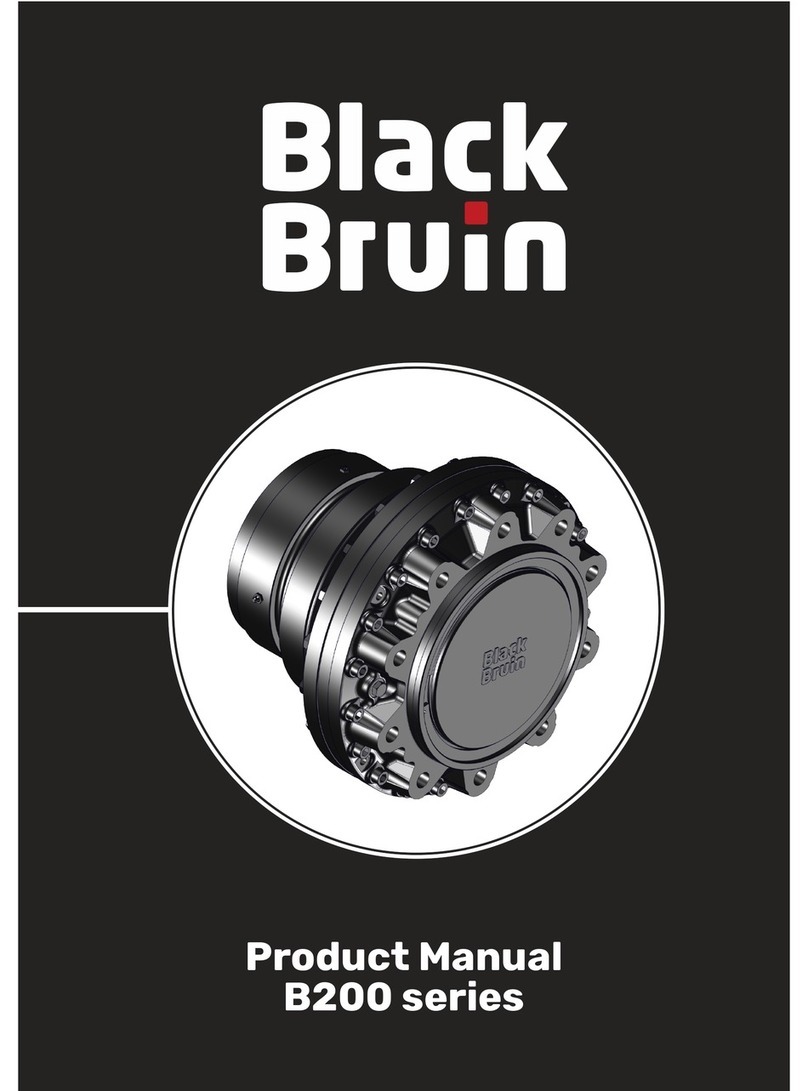

GENERAL INSTRUCTIONS FOR SAFETY AND USE

Black Bruin Hydraulic Motors

BB, BBC, SSTC and B200 series 4.1.2018

BLACK BRUIN EN - 3 www.blackbruin.com

COMMISSIONING PROCEDURE

Ensure that the following things are in order before

starting a new or replaced motor:

µThe hydraulic circuit of the motor is flushed.

µMotor is installed appropriately.

µAir bleeding procedure is carried out.

µThe reservoir of the hydraulic system is full.

During the initial stages use, also take the following

things into consideration:

µDo not run the motor immediately with full power.

Increase the load and speed of rotation gradually.

µObserve the motor and the hydraulic system for

external leaks or abnormal noises during the

commissioning procedure.

µStart the motor break-in.

Information!

During all installation and service procedures, plug any

open ports and hoses.

When filling the reservoir, add hydraulic fluid through a

filter.

Attention!

Do not start the motor, if the air bleeding procedure has

not been carried out.

Stressing an unused motor with full power may cause

premature wear or failure of the motor.

AIR BLEEDING PROCEDURE

Air bleeding procedure is carried out to fill the housing

of the motor completely with hydraulic fluid. Air is

removed from the housing with air bleeding screws as

follows:

µLocate the air bleeding screws of the housing and

turn the motor to a position in which the screw is at

its topmost position.

µMake sure the drain line of the motor is connected.

µFeed hydraulic fluid into the motor with low

pressure throughout the procedure.

µUnscrew the air bleeding screw by half a turn and

let air escape from the housing.

µClose the screw when only hydraulic fluid is

pouring through it.

µTighten the screw to a torque of 39 ± 3 Nm.

The location of the air bleed screws is given in the

product datasheet.

Information!

If feed pressure is not available, fill the housing

manually by pouring hydraulic fluid in the motor

through the topmost opening of the housing.

FLUSHING THE HYDRAULIC SYSTEM

Prior to connecting the motor as part of the hydraulic

system, the hydraulic circuit of the motor must always

be flushed by circulating hydraulic fluid through a filter

installed in place of the motor.

The flushing is carried out by circulating hydraulic fluid

through the entire system with a minimum pressure for

at least an hour.

µAfter flushing, renew all filters.

Information!

Flushing the hydraulic system should also be

performed after every system modification or repair.

BREAK-IN PERIOD

The motor achieves its final properties during the first

hours of use. Therefore all new and reconditioned

motors should go through an initial break-in period.

Things to be considered during break-in period:

µThe break-in period should last for at least first

eight hours (8 h) of use.

µThe power output should remain under 50 % of the

maximum power capacity of the motor.

µThe power output is limited by limiting the working

pressure, the speed of rotation or both.

µThe working pressure should be limited so, that

pressure peaks which last over two seconds (2 s)

remain under 75 % of the permissible values.

Information!

During the break-in period, the moving parts of the

motor wear against each other so, that the wear of the

parts sets to a stable state for the entire service life of

the motor.

USE

Things to be considered during use of motors:

µCheck the screw connections tightening torque

and hydraulic connections regularly.

µDo not use pressure cleaning directly between the

shaft flange and housing of the motor (the shaft

seal area).

µAvoid situations in which the motors are

completely submerged in water or mud.