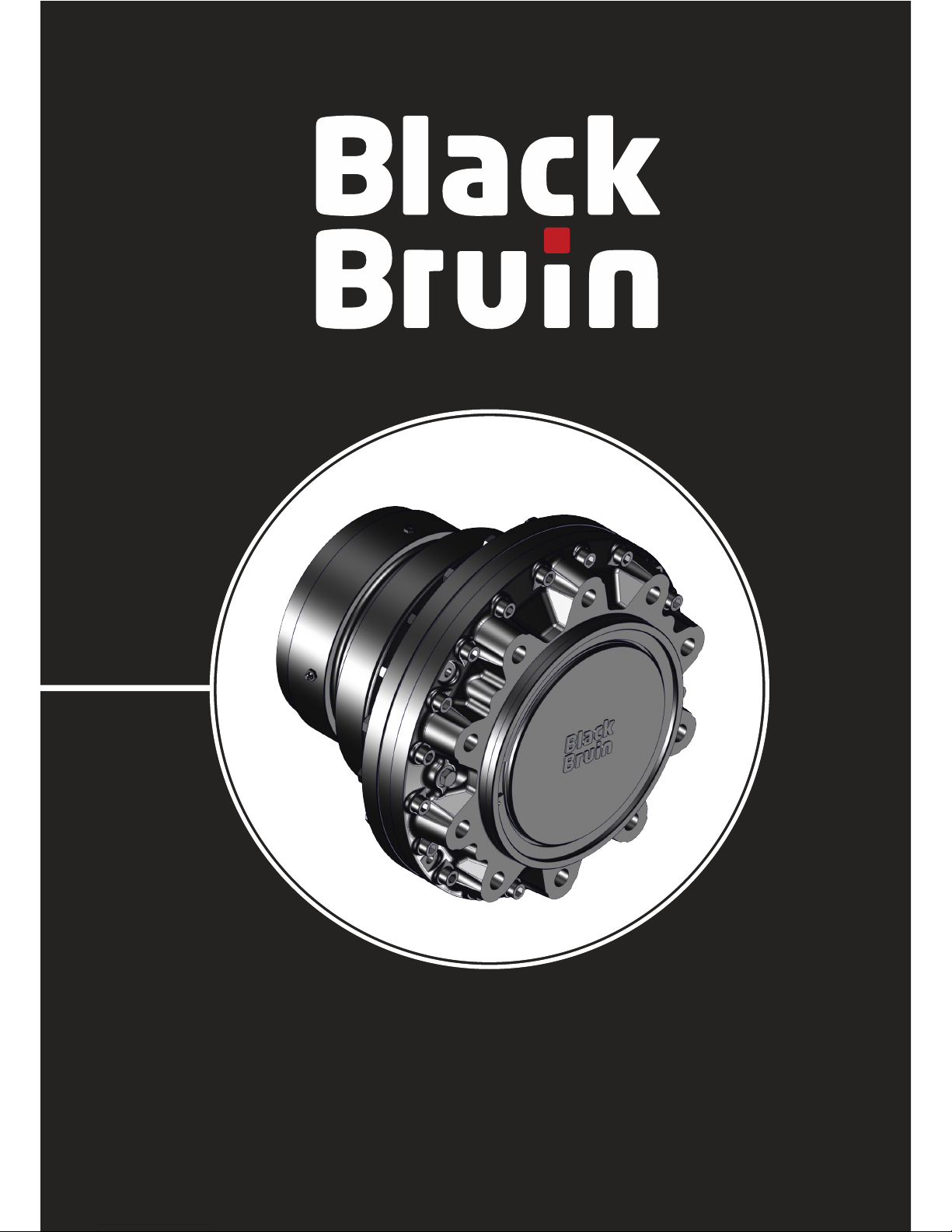

Black Bruin B240 User manual

Product Manual

B200 series

Contents

1 General Instructions......................................................................... 4

1.1 About the manual............................................................................................................................................4

1.2 Intended use.....................................................................................................................................................4

1.3 Warranty.............................................................................................................................................................4

1.4 Product identication..................................................................................................................................... 4

1.5 Revision comments.........................................................................................................................................4

1.6 Declaration of incorporation......................................................................................................................... 5

2 Safety Instructions........................................................................... 6

2.1 Warning symbols..............................................................................................................................................6

3 Motor Description.............................................................................. 7

3.1 Working principle.............................................................................................................................................. 7

3.2 Product identication code...........................................................................................................................8

3.2.1 Motor model code......................................................................................................................... 8

3.2.2 Processing ID................................................................................................................................. 9

3.3 Technical data.................................................................................................................................................10

3.4 Motor interfaces............................................................................................................................................. 12

3.4.1 Main dimensions..........................................................................................................................12

3.4.2 Shaft interface............................................................................................................................. 13

3.4.3 Hub interface................................................................................................................................14

3.4.4 Housing interface........................................................................................................................15

3.4.5 Drum brake interface.................................................................................................................. 17

3.5 Rotating direction.......................................................................................................................................... 18

3.6 Mechanical freewheeling............................................................................................................................. 19

3.7 1-speed : 1N00............................................................................................................................................... 20

3.8 2-speed valve : 2N0R / 2N0L......................................................................................................................21

3.9 Freewheeling valve : FW10 / FW20........................................................................................................... 22

3.10 Seal protector : NZ/GZ................................................................................................................................. 24

3.10.1 Fittings for one-time lubrication.............................................................................................24

3.10.2 Fittings for regular lubrication.................................................................................................24

4 System Design................................................................................. 26

4.1 Motor hydraulic circuit................................................................................................................................. 26

4.1.1 Simple connection......................................................................................................................26

4.1.2 Motors in parallel or series circuit...........................................................................................26

4.1.3 Counter pressure operation.....................................................................................................28

4.1.4 Hydrostatic braking....................................................................................................................28

4.1.5 Short circuit operation...............................................................................................................28

4.2 Hydraulic connections................................................................................................................................. 29

4.3 External freewheeling valve....................................................................................................................... 29

4.4 Hydraulic uid................................................................................................................................................. 31

4.4.1 Hydraulic uid type..................................................................................................................... 31

4.4.2 Hydraulic uid properties.......................................................................................................... 31

4.4.3 Hydraulic uid cleanliness.........................................................................................................31

4.5 Operating pressures...................................................................................................................................... 31

4.5.1 Case pressure...............................................................................................................................31

4.5.2 Pilot pressure............................................................................................................................... 32

4.5.3 Working line pressure.................................................................................................................32

Contents

2 Product Manual

5 Motor Sizing..................................................................................... 34

5.1 Load carrying capacity................................................................................................................................ 34

5.1.1 Wheel oset..................................................................................................................................34

5.1.2 Allowed wheel load.....................................................................................................................35

5.1.3 Service life.................................................................................................................................... 35

5.2 Performance...................................................................................................................................................36

5.2.1 Rotating speed and ow rate.................................................................................................. 36

5.2.2 Torque............................................................................................................................................ 37

5.2.3 Power.............................................................................................................................................38

6 Installation Instructions................................................................ 39

6.1 Mounting the motor......................................................................................................................................39

6.2 Flushing the hydraulic system...................................................................................................................39

6.3 Air bleeding procedure.................................................................................................................................39

6.4 Commissioning procedure..........................................................................................................................40

7 Operating Instructions................................................................... 41

7.1 Break-in period............................................................................................................................................... 41

7.2 Use..................................................................................................................................................................... 41

7.3 Operating temperature.................................................................................................................................41

7.4 Demounting the motor.................................................................................................................................41

8 Special Instructions........................................................................43

8.1 Storing the motor..........................................................................................................................................43

Contents

Product Manual 3

General Instructions

About the manual

This manual contains the technical instructions for the Black Bruin B200 series

hydraulic motors. Take these instructions into consideration when planning the use

of the product.

All information given in this manual is current and valid according to the information

available at the time of publication. The manufacturer reserves the rights to

implement changes without prior notice.

Please visit www.blackbruin.com for the most recent version of this manual. The

product datasheets and the 3D-models are available from the manufacturer by

request.

Intended use

Black Bruin B200 series hydraulic motors are designed to be used as hub motors to

produce traction on tractor-driven trailers and working equipment.

Warranty

Check the package and the product for transport damage when receiving goods. The

package is not meant for long term storage; protect the product appropriately.

Do not dismantle the product. The warranty is void if the product has been

disassembled.

The manufacturer is not responsible for damages resulting from misinterpreted, non-

compliance, incorrect, or improper use of the product that goes against the

instructions given in this document.

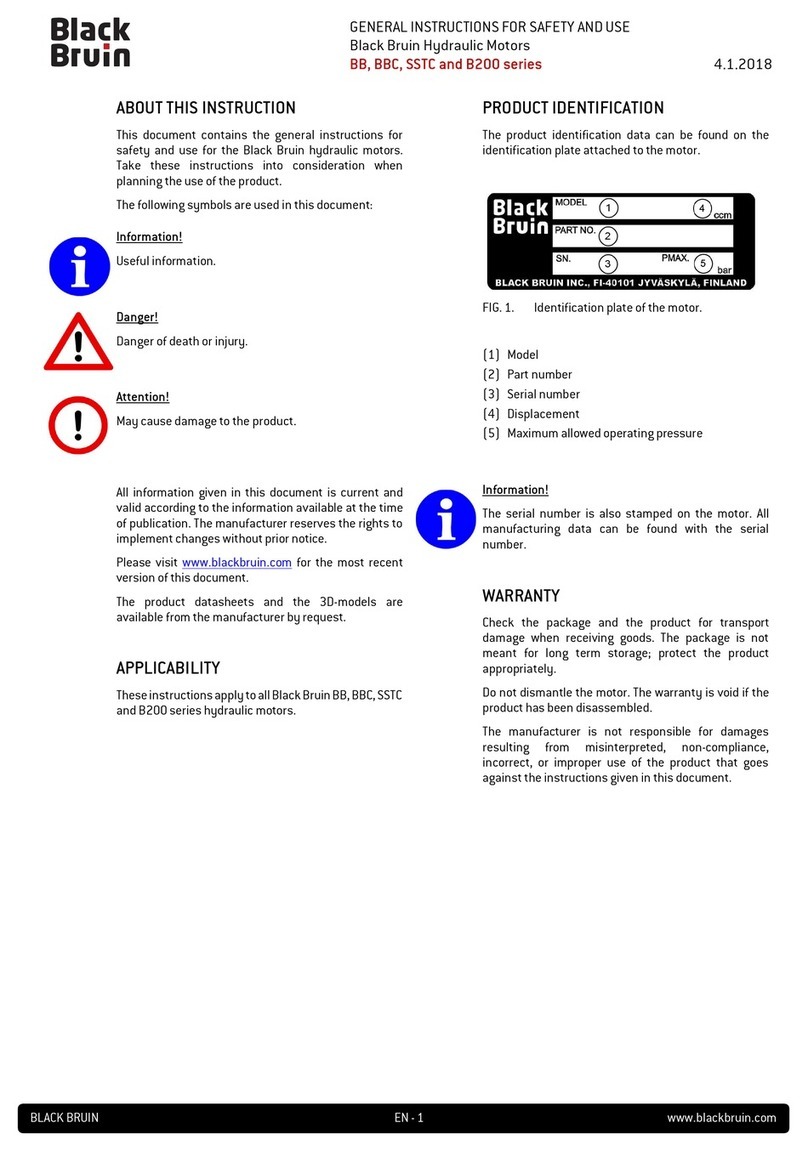

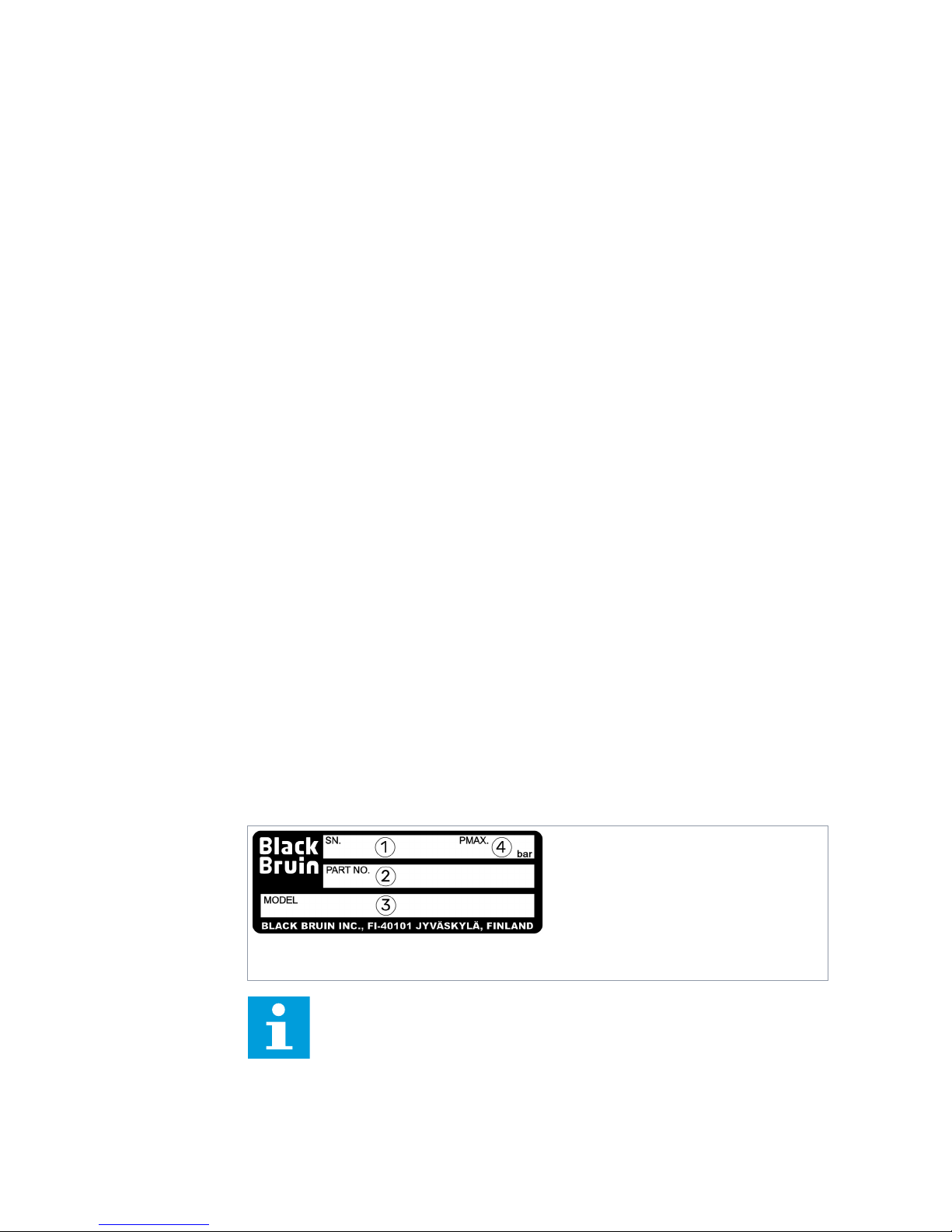

Product identication

The product identication data can be found on the identication plate attached to

the motor.

Figure 1. Identication plate of the motor.

1. Serial number

2. Part number

3. Model

4. Maximum allowed operating pressure

Note:

The serial number is also stamped on the motor. All manufacturing data

can be found with the serial number.

Revision comments

24.08.2018 - This manual is published.

1

1.1

1.2

1.3

1.4

1.5

General Instructions

4 Product Manual

Declaration of incorporation1.6

General Instructions

Product Manual 5

Safety Instructions

The following instructions apply to all procedures associated with the motor. Read

these instructions carefully and follow them closely.

• Use necessary personal protective equipment when working with the motor.

• Support the motor properly. Make sure the motor cannot fall over or turn around

by accident.

• Use only appropriate equipment and attachments for lifting and transferring the

motor.

• Do not use magnetic lifting devices.

• Always use the lifting equipment properly and check the load-bearing capacity.

• Prevent unintended use of the motor during installation and maintenance

procedures by preventing pressurization of the hydraulic lines.

• The operating temperature of the motor may be over 60 ºC (140 °F), which is hot

enough to cause severe burns. Beware of hot hydraulic uid when disconnecting

the hydraulic connections.

Warning symbols

The following symbols are used in this manual:

Note:

Useful information.

Danger:

Danger of death or injury.

Attention:

May cause damage to the product.

2

2.1

Safety Instructions

6 Product Manual

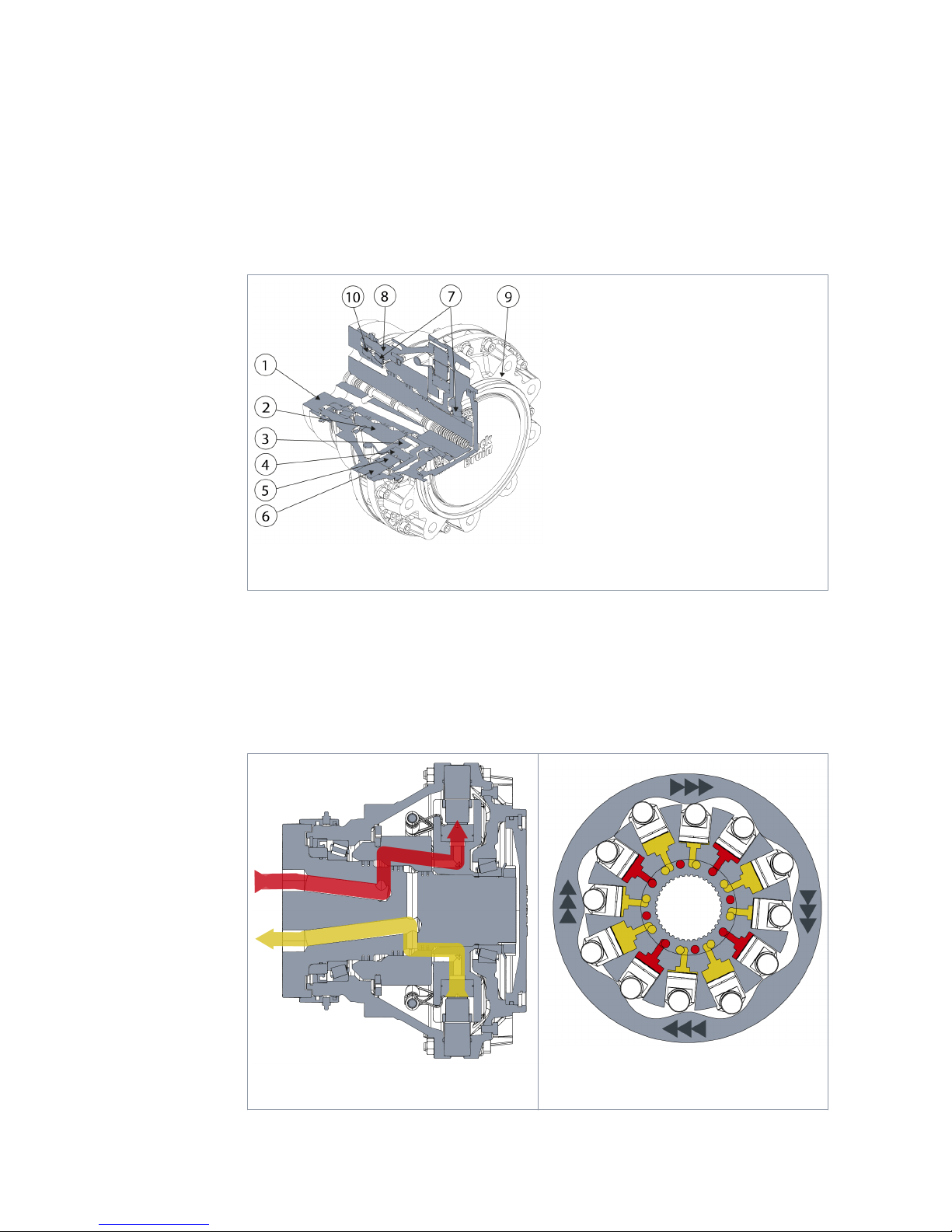

Motor Description

Working principle

B200 series motors are rotary-housing. This means the motor shaft and the cylinder

block remain in place while the motor is running.

Figure 2. The main components of the motor.

1. Shaft

2. Distribution valve

3. Cylinder block

4. Piston

5. Cam roll

6. Cam ring

7. Bearings

8. Housing

9. Hub

10. Shaft sealing

The rotation of the motor is achieved by feeding pressurized hydraulic uid through

the motor shaft to the distribution valve. The distribution valve directs the ow to the

pistons which are on a power stroke. Pressure pushes the pistons and cam rolls

outwards against the cam ring on the housing. The waveform of the cam ring

transforms the force into torque. When the pistons reach the end of the power stroke,

the distribution valve closes the ow to the pistons and switches the pistons to a

return stroke.The cam ring pushes the pistons back into the cylinder block preparing

them for the next outward power stroke.

Figure 3. Flow to the pistons.

Figure 4. Cylinder block, cam ring and pis-

tons.

3

3.1

Motor Description

Product Manual 7

Product identication code

Black Bruin product identication code consists of motor model code and processing

ID.

B260-0250-2NOL / GZ -1 1 0 0 0 0

Motor model code - Processing ID

Motor model code

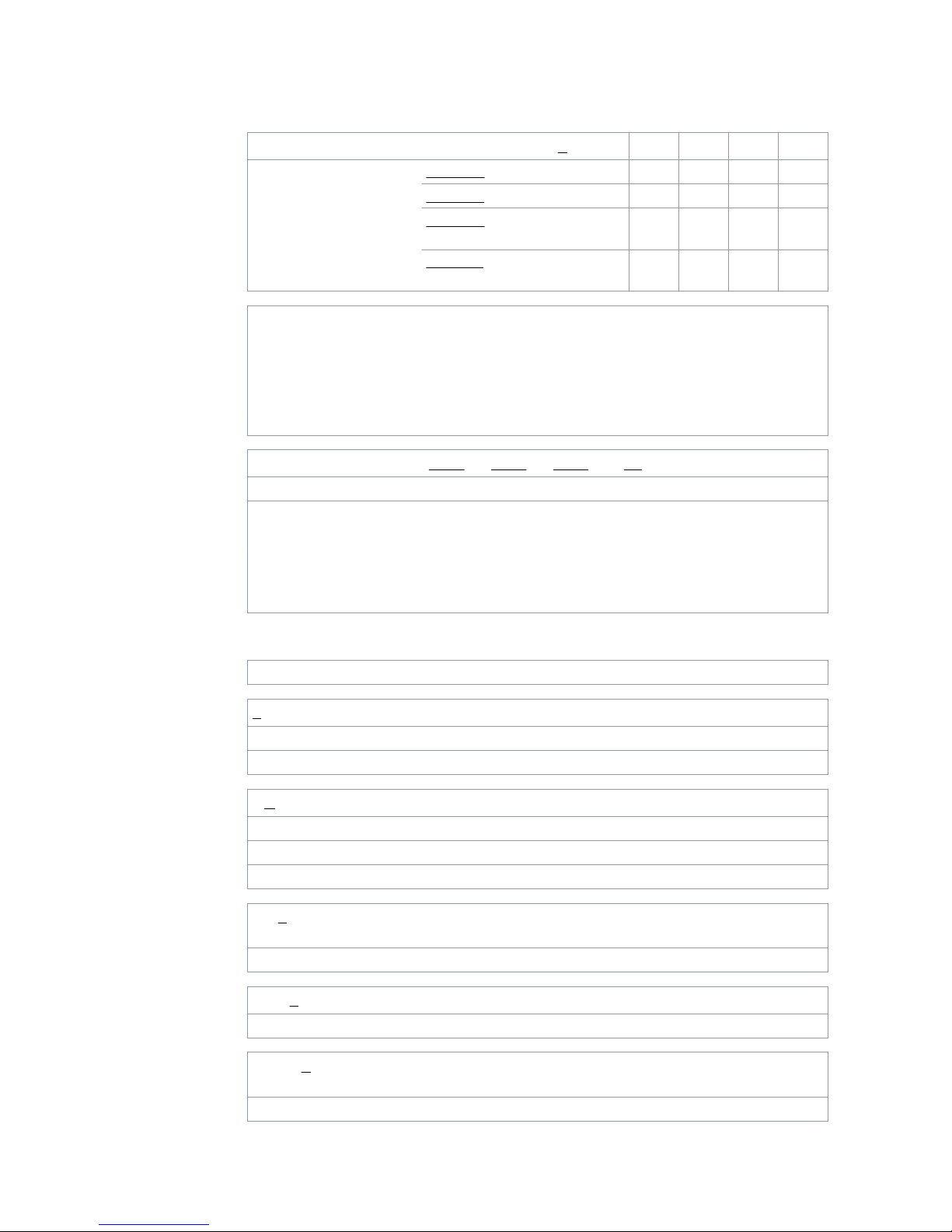

B200 SERIES MODEL CODE AAAA - BBBB - CCCC / D

Freewheeling hub motors

A: Frame AAAA-BBBB-CCCC/D B240 B250 B260 B270

B200 series frames

B240 ●

B250 ●

B260 ●

B270 ●

B: Displacement AAAA-BBBB-CCCC/D B240 B250 B260 B270

B240 displacements 0063 : 630 ccm/rev ●

0080 : 800 ccm/rev ●

B250 displacements

0100 : 1000 ccm/rev ●

0125 : 1250 ccm/rev ●

0160 : 1600 ccm/rev ●

B260 displacements

0200 : 2000 ccm/rev ●

0250 : 2500 ccm/rev ●

0315 : 3150 ccm/rev ●

B270 displacements

0400 : 4000 ccm/rev ●

0500 : 5000 ccm/rev ●

0630 : 6300 ccm/rev ●

C: Displacement control AAAA-BBBB-CCCC/D B240 B250 B260 B270

1-speed 1N00 : Fixed displacement ●●●●

2-speed valve 2N0R : Right side - CW preferred ●●●●

2N0L : Left side - CCW preferred ●●●●

Freewheeling valve

FW10 : Type 1 - Open freewheel-

ing position ●●●

FW20 : Type 2 - Closed free-

wheeling position ●●●

D: Accessory AAAA-BBBB-CCCC/D B240 B250 B260 B270

No drum brake

NZ : Fittings for one-time lubri-

cation ● ● ● ●

GZ : Fittings for regular lubrica-

tion ● ● ● ●

3.2

3.2.1

Motor Description

8 Product Manual

D: Accessory AAAA-BBBB-CCCC/D B240 B250 B260 B270

Drum brake*

MRJ40-0 : Brake size 320x75 ●

MRJ50-0 : Brake size 400x80 ●

MRJ60-R : Brake size 420x220 -

Right side ●

MRJ60-L : Brake size 420x220 -

Left side ●

* = Certied brakes, manufactured by Monroc.

More detailed information and mounting dimensions for each brake device can be found

on the product datasheet.

The drum brake increases the length of the motor assembly and aects the oset value of

the vehicle wheel rim.

Adding lubricant into the seal protector is prevented.

Code example B260 - 0250 - 2N0L / GZ

A - B - C / D

A = The frame of the motor is "B260"

B = The displacement of the motor is 2500 ccm/rev

C = Internal 2-speed valve for displacement control. The motor is CCW preferred in 2-

speed mode.

D = The seal protector of the motor is tted for regular lubrication

Processing ID

B200 SERIES PROCESSING ID R M S P D T

R M S P D T Lubrication Denition of factory lubrication

0 = Seal protector is not lled with lubricant. 1)

1 = Seal protector is lled with lubricant.

R M S P D T Painting Denition of the painted surfaces

0 = No painting - Motors are washed and protected from corrosion.

1 = Painting type 1 - Unpainted interfaces: SHAFT, HUB 2)

2 = Painting type 2 - Unpainted interfaces: SHAFT, HUB, HOUSING 2)

R M S P D T Protection Denition of the protection for storage/trans-

portation

0 = Default / Not dened 3)

R M S P D T Packaging Denition of the motor package

0 = Default / Not dened 4)

R M S P D T Documents Denition of the printouts to be attached to the

delivery

0 = Default / Not dened

3.2.2

Motor Description

Product Manual 9

R M S P D T Testing Denition of the testing and reporting

0 = Default / Not dened 5)

Code example 1 1 0 0 0 0

R M S P D T

R = The seal protector of the motor is lled with lubricant.

M = Prime coating. The shaft and hub interfaces of the motor are unpainted.

S = Pressure openings and threaded holes of the motor are protected according to

general practices of the manufacturer.

P = The motor is packaged according to general practices of the manufacturer.

D = The documentation delivered with the motor is according to general practices of

the manufacturer.

T = The motor is tested according to general practices of the manufacturer.

1) If necessary, the seal protector is not lled with lubricant at the factory.

2) Prime coating: HEMPATHANE HS 55610 or equivalent. Tint: glossy black.

3) Pressure openings and threaded holes are capped with plastic ttings. Hydraulic

uid is drained out.

4) Delivery on wooden pellet or in plywood box.

5) The manufacturer keeps test records of every manufactured motor.

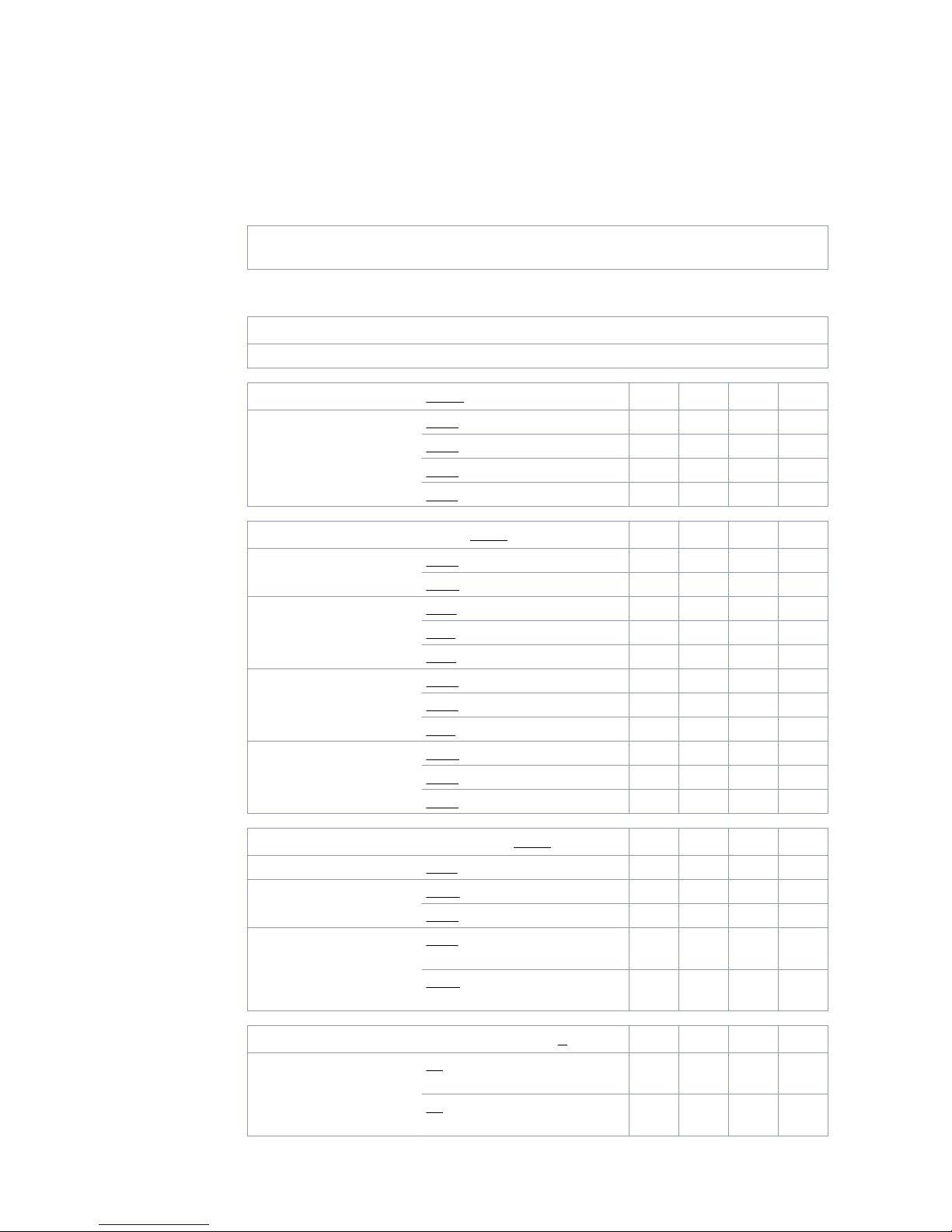

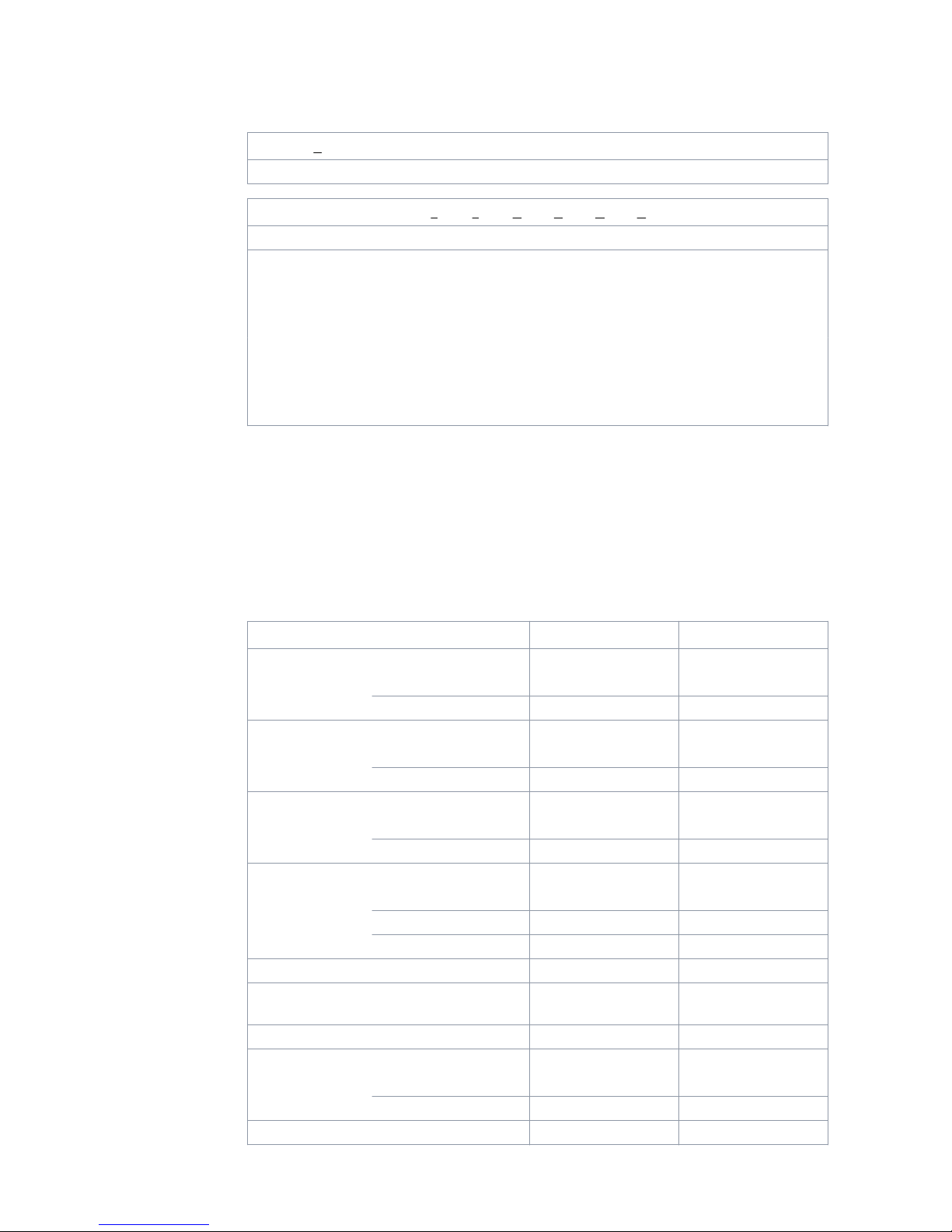

Technical data

TECHNICAL DATA B240 B250

Displacement [ccm]

at full displacement 630 800 1000 1250 1600

at half displacement 315 400 500 625 800

Maximum torque [Nm]

theoretical 3510 4460 5570 6960 8910

with 100 bar 1000 1270 1590 1990 2550

Max. operating power [kW]

at full displacement 35 50

at half displacement 21 30

Max. rotating speed [rpm]

at full displacement 240 185 200 160 125

at half displacement 360 275 300 240 185

at freewheeling 600 500

Min. rotating speed [rpm] 2 2

Max. engaging speed (out of freewheel-

ing) [rpm] 120 93 100 80 63

Brake torque [Nm] 1) 8600 13500

Max. working pressure [bar]

peak pressure 350 350

intermittent 2) 300 300

Max. case pressure [bar]

3.3

Motor Description

10 Product Manual

TECHNICAL DATA B240 B250

average 2 2

intermittent 2) 10 10

Pilot pressure for internal valve [bar]

valve released 0-2 0-2

valve engaged 15-30 3) 15-30 3)

Max. ow rate [l/min]

at full displacement 150 200

at half displacement 113 150

Max. load capacity [t] 4) 4,0 5,4

Weight [kg] no brake 59 92

with drum brake 96 156

TECHNICAL DATA B260 B270

Displacement [ccm]

at full displacement 2000 2500 3150 4000 5000 6300

at half displacement 1000 1250 1575 2000 2500 3150

Maximum torque [Nm]

theoretical 14300 17900 22600 28600 35800 45100

with 100 bar 3180 3980 5010 6370 7960 10000

Max. operating power [kW]

at full displacement 90 130

at half displacement 54 80

Max. rotating speed [rpm]

at full displacement 175 140 110 125 100 80

at half displacement 225 180 145 160 130 105

at freewheeling 400 350

Min. rotating speed [rpm] 2 2

Max. engaging speed (out of freewheel-

ing) [rpm] 88 70 55 63 35 40

Brake torque [Nm] 1) 20100 -

Max. working pressure [bar]

peak pressure 450 450

intermittent 2) 400 400

Max. case pressure [bar]

average 2 2

intermittent 2) 10 10

Pilot pressure for internal valve [bar]

valve released 0-2 0-2

valve engaged 15-30 3) 15-30 3)

Max. ow rate [l/min]

Motor Description

Product Manual 11

TECHNICAL DATA B260 B270

at full displacement 350 500

at half displacement 225 325

Max. load capacity [t] 4) 12,5 15,4

Weight [kg] no brake 150 285

with drum brake 262 -

1) The braking torque is for information only. Braking performance should be

ensured by testing and / or certication.

2) Intermittent operation: permissible values for maximum of 10% of every minute.

3) If pilot pressure over 30 bar is used, the pilot line should be throttled.

4) The load capacity must be estimated for every application.

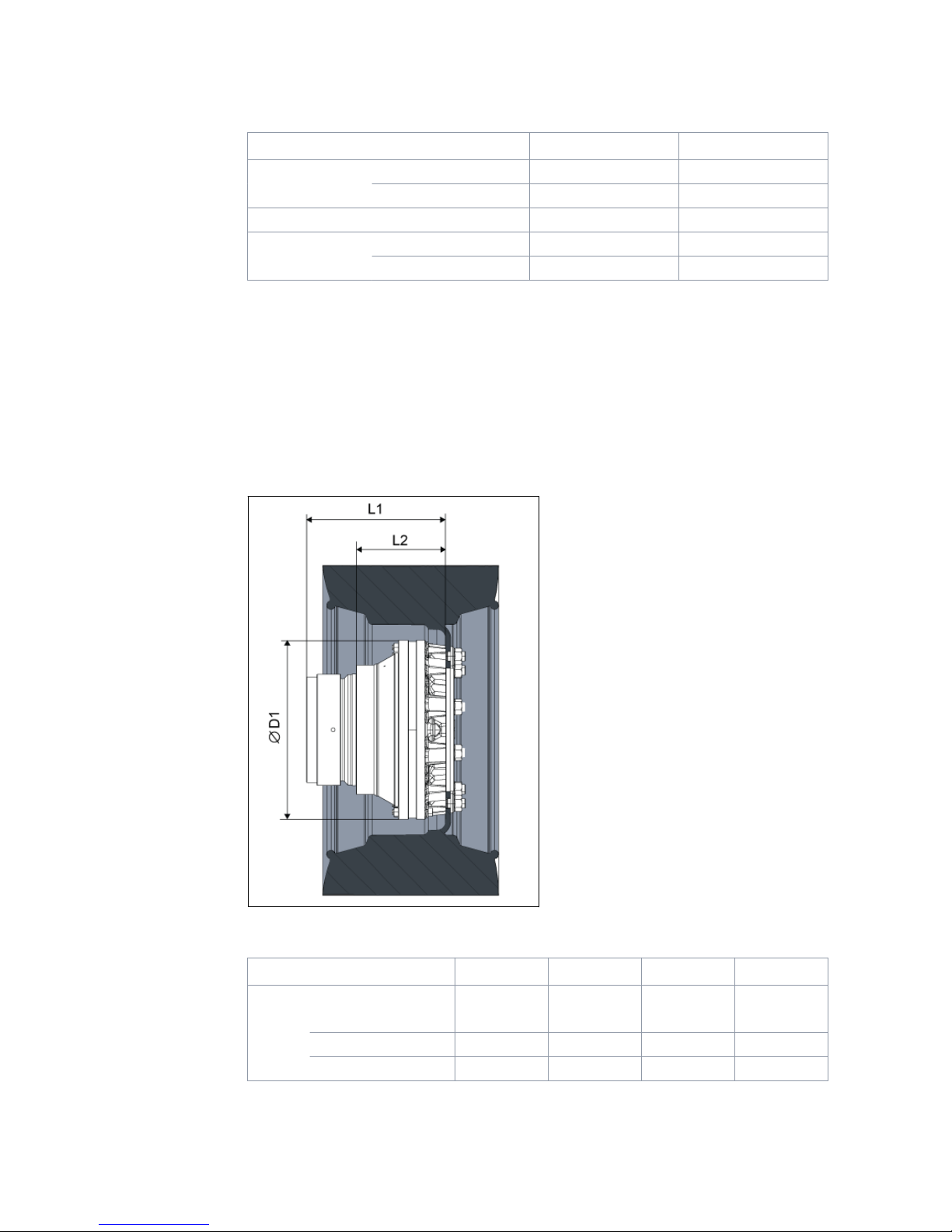

Motor interfaces

Main dimensions

Figure 5. Main dimensions of the motor.

MAIN DIMENSIONS B240 B250 B260 B270

Motor

L1 [mm] 262 279 317 377

L2 [mm] 163 177 204 262

D1 [mm] 278 342 408 512

3.4

3.4.1

Motor Description

12 Product Manual

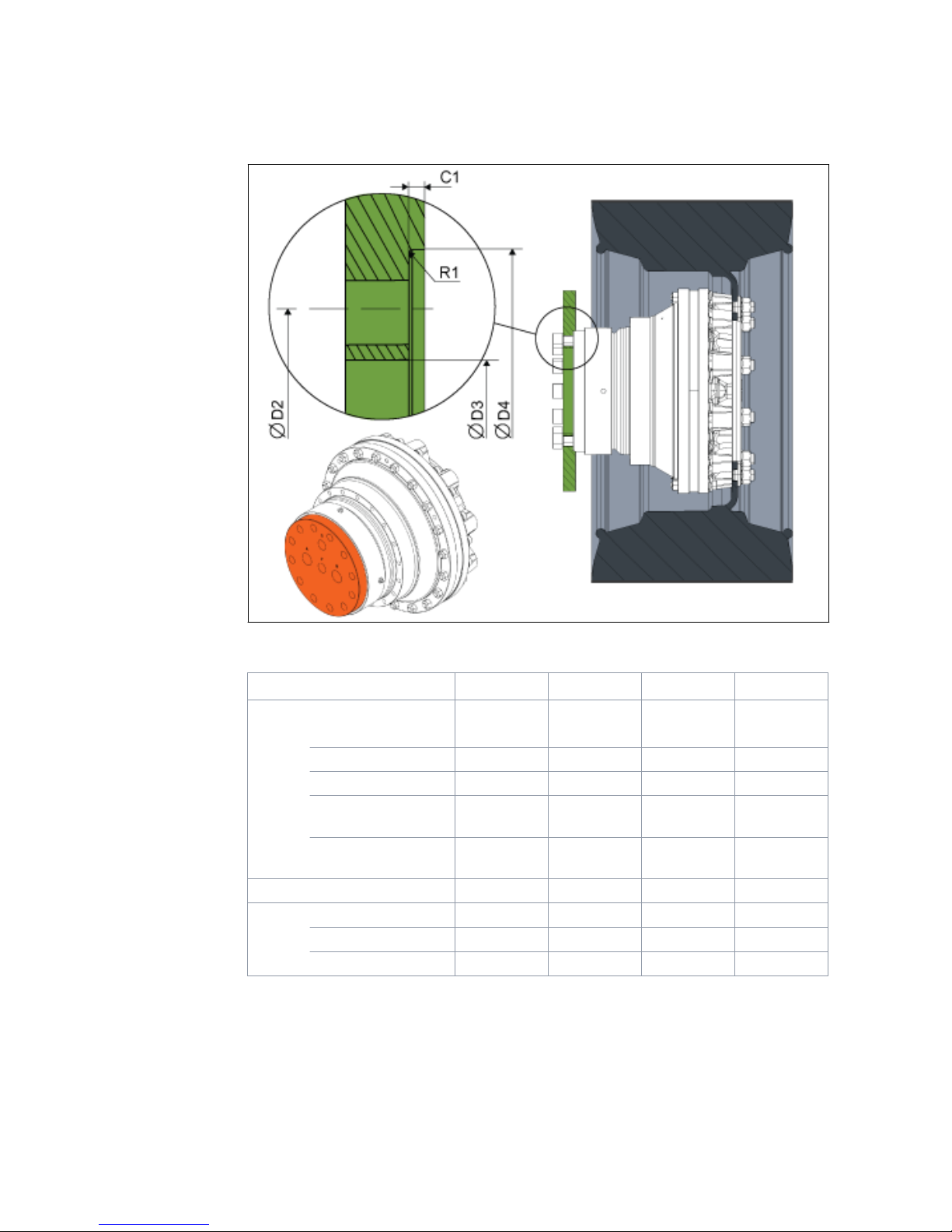

Shaft interface

Figure 6. Dimensions of the shaft interface.

INTERFACE DIMENSIONS B240 B250 B260 B270

Shaft interface

D2 [mm] 140 175 200 260

pattern 6x60° 8x45° 12x30° 16x22,5°

size M16x2,0 M16x2,0 M20x1,5 M20x1,5

strength class

1) 12,9 12,9 12,9 12,9

tightening tor-

que 2) [Nm] 330 330 650 650

D3 min. 3) [mm] 114 150 170 220

D4 min. 4) [mm] 165 200 240 300

R1 max. [mm] 1 1 1 1

C1 [mm] 4-10 4-10 4-10 4-10

1) Strength class as in ISO898-1. If using lower strength class, check interface load

capacity and tightening torque.

2) Declared values are for reference only. Always use application specic

tightening torques when given.

3) Free space for hydraulic connections.

4) Recommended feature to support and center the motor.

3.4.2

Motor Description

Product Manual 13

The motor is attached to the body of the vehicle or device from the shaft ange. The

hydraulic connections of the motor are located on the plane surface of the shaft

ange.

Hub interface

Figure 7. Dimensions of the hub interface.

INTERFACE DIMENSIONS B240 B250 B260 B270

Hub interface

D5 [mm] 205 275 335 425

pattern 6x60° 8x45° 10x36° 12x30°

size M18x1,5 M20x1,5 M22x1,5 M22x1,5

strength class

1) 10,9 10,9 10,9 10,9

tightening tor-

que 2) [Nm] 383 540 728 728

D6 min. [mm] 161 221 281 381

V1 min. [mm] 1x45° 1x45° 1x45° 1x45°

D7 min. [mm] 255 325 390 470

1) Strength class as in ISO898-1. If using lower strength class, check interface load

capacity and tightening torque.

3.4.3

Motor Description

14 Product Manual

2) Declared values are for reference only. Always use application specic

tightening torques when given.

The wheel rim or the rotatable device is attached to the motor hub.

Note:

The attachment screws are not included in the motor delivery. Ensure

correct dimensioning and availability of the hub screws.

There are multiple dierent type of fastening screws for hub interface.

Select the hub screws according to the wheel rim design.

Figure 8. Hub fastening screw variants.

Housing interface

Figure 9. Dimensions of the housing interface.

3.4.4

Motor Description

Product Manual 15

INTERFACE DIMENSIONS B240 B250 B260 B270

Housing interface

D8 [mm] 204 236 274 330

pattern 12x30° 12x30° 18x20° 18x20°

size M10x1,5 M12x1,75 M12x1,75 M16x2,0

strength class1) 10,9 10,9 10,9 10,9

tightening tor-

que 2) [Nm] 64 110 110 275

D9 min. [mm] 184 205 254 302

V2 min. [mm] 1x45° 1x45° 1x45° 1x45°

1) Strength class as in ISO898-1. If using lower strength class, check interface load

capacity and tightening torque.

2) Declared values are for reference only. Always use application specic

tightening torques when given.

The necessary accessories can be attached to the housing interface. The interface

can be used, for example, to attach a brake disc of a disc brake or a speed sensor

pulse ring.

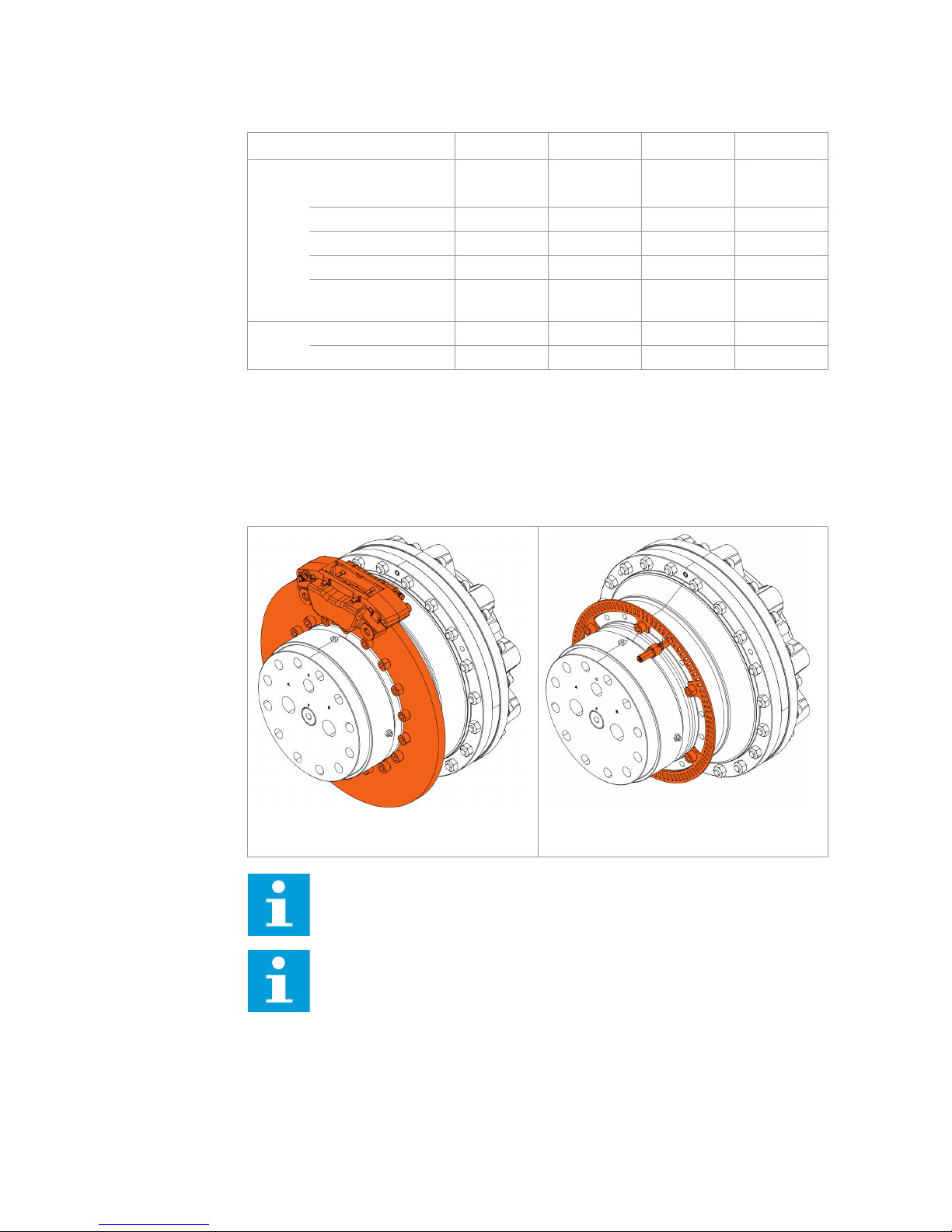

Figure 10. The motor with a disc brake. Figure 11. The motor with a pulse sensor.

Note:

If necessary, the grease nipples and plugs of the seal protector can be

removed temporarily when attaching accessories to the housing interface.

Note:

Surface roughness (Ra) of the counterparts must be 12,5μm or better.

More detailed interface dimensions and tolerances are indicated on the

product datasheet.

Motor Description

16 Product Manual

Drum brake interface

Figure 12. Interface dimensions of the motor with the drum brake (B240, B250).

Figure 13. Interface dimensions of the motor with the drum brake (B260).

INTERFACE DIMENSIONS B240 B250 B260

Drum brake interface

L3 [mm] 277 295 451

D10 [mm] 349 444 460

D11 [mm] 140 175 200

pattern 6x60° 8x45° 12x30°

size M16x2,0 M16x2,0 M20x1,5

strength class

1) 12,9 12,9 12,9

3.4.5

Motor Description

Product Manual 17

INTERFACE DIMENSIONS B240 B250 B260

tightening tor-

que 2) [Nm] 330 330 650

D12 [mm] max. 121 max. 156 min. 235,5

C2 [mm] 4,5 4,5 4,5

V3 min. [mm] 1x45° 1x45° 1x45°

R2 max. [mm] 1 1 1

D13 [mm] 114 150 170

1) Strength class as in ISO898-1. If using lower strength class, check interface load

capacity and tightening torque.

2) Declared values are for reference only. Always use application specic

tightening torques when given.

Rotating direction

Figure 14. Rotating direction of the motor.

The rotating direction of the motor is dened as the rotating direction of the housing

viewed from the hub to the shaft.

The rotating direction of the motor and the ow direction in the working lines is given

in the table below.

Table 1: Rotating direction and ow direction.

ROTATING DIRECTION ow direction

A → B B → A

1N00, FW10, FW20 CW CCW

2N0R CW CCW

2N0L CCW CW

Preferred operating direction

AAAA - BBBB - 2N0R / D

AAAA - BBBB - 2N0L / D

3.5

Motor Description

18 Product Manual

The preferred operating direction applies to motors with 2-speed valve (see 2-speed

valve : 2N0R / 2N0L on page 21).

The preferred operating direction is the rotating direction of the motor when the ow

direction is from port A to B.

•2N0R = CW motor (For the right side of a vehicle.)

•2N0L = CCW motor (For the left side of a vehicle.)

Mechanical freewheeling

The mechanical freewheeling is a standard feature in the B200 series motors.

Figure 15. A piston with the freewheeling spring.

The motor is equipped with mechanical freewheeling springs, which enable the motor

disengagement. When disengaged the motor may be used without active uid supply

from the hydraulic system.

USING THE FREEWHEELING

When the motor is depressurized and not rotating, the motor will disengage

automatically. The motor disengagement during motion is done with a freewheeling

valve.

The freewheeling valve may be in-built to the motor (see Freewheeling valve : FW10 /

FW20 on page 22) or a separate external valve (see External freewheeling valve on

page 29), which connects the working lines (A and B) and the case drain line (C)

together. The purpose of the valve is to remove pressure dierence over the motor

pistons. This allows the pistons to retract with aid of mechanical springs.

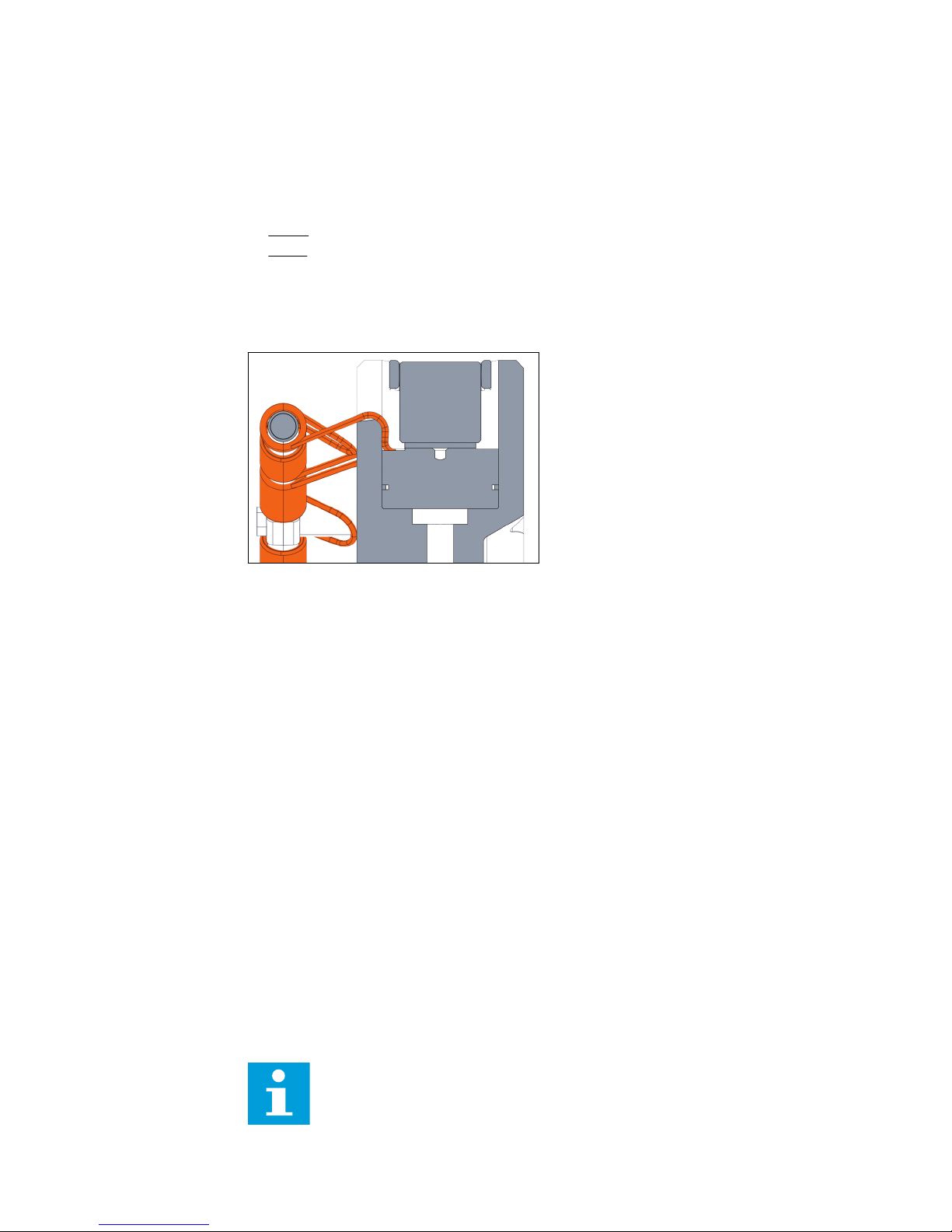

• DISENGAGING THE MOTOR

Open the freewheeling valve and depressurize the motor with the directional

control valve to disengage the motor.

• ENGAGING THE MOTOR

Close the freewheeling valve and pressurize the motor with the directional control

valve to engage the motor.

The directional control valve and the freewheeling valve are usually activated

simultaneously.

Note:

Another use of the freewheeling is a more extensive speed range for

vehicles having several hydraulic motors. Hydraulic system capacity may

3.6

Motor Description

Product Manual 19

be divided between fewer motors, when some of the motors are

disengaged.

Attention:

Any pressure in the working lines (A and B) during the freewheeling

pushes the pistons out of the freewheeling position. This causes clattering

noise when the pistons connect to the cam ring.

Constant clattering of the pistons may cause premature wear or failure of

the motor.

ROTATING SPEED

The rotating speed of the motor should be taken into account when implementing

freewheeling.

• FREEWHEELING SPEED

The freewheeling speed is the highest permissible rotating speed of the motor

during freewheeling.

• ENGAGING SPEED

The engaging speed is the highest permissible rotating speed when engaging the

motor.

The permissible freewheeling and engaging speeds can be found on the technical

data (see Technical data on page 10).

DISENGAGING DELAY

While the pistons are retracting, there is a momentary ow of hydraulic uid from the

working lines to the casing of the motor. This causes always a small delay when

disengaging the motor. Normal delay is about 1 - 2 seconds.

To minimize the disengaging delay the hydraulic uid should have as open channel as

possible:

• The external freewheeling valve should be positioned as close to the motor as

possible.

• All components and lines, which connect the working lines to the case drain line,

should be sized for highest feasible ow rate.

Attention:

Without freewheeling valve, the delay is considerably longer as the uid

must seep through the motor. Disengaging the motor during motion

without a freewheeling valve may cause premature wear or failure of the

motor.

1-speed : 1N00

AAAA - BBBB - 1N00 / D

Displacement control selection 1-speed means the motor has a xed displacement.

These motors are known as 1-speed motors and are always in full displacement

during operation.

3.7

Motor Description

20 Product Manual

This manual suits for next models

3

Table of contents

Other Black Bruin Engine manuals