ENGLISH • 7

SAVE THESE INSTRUCTIONS

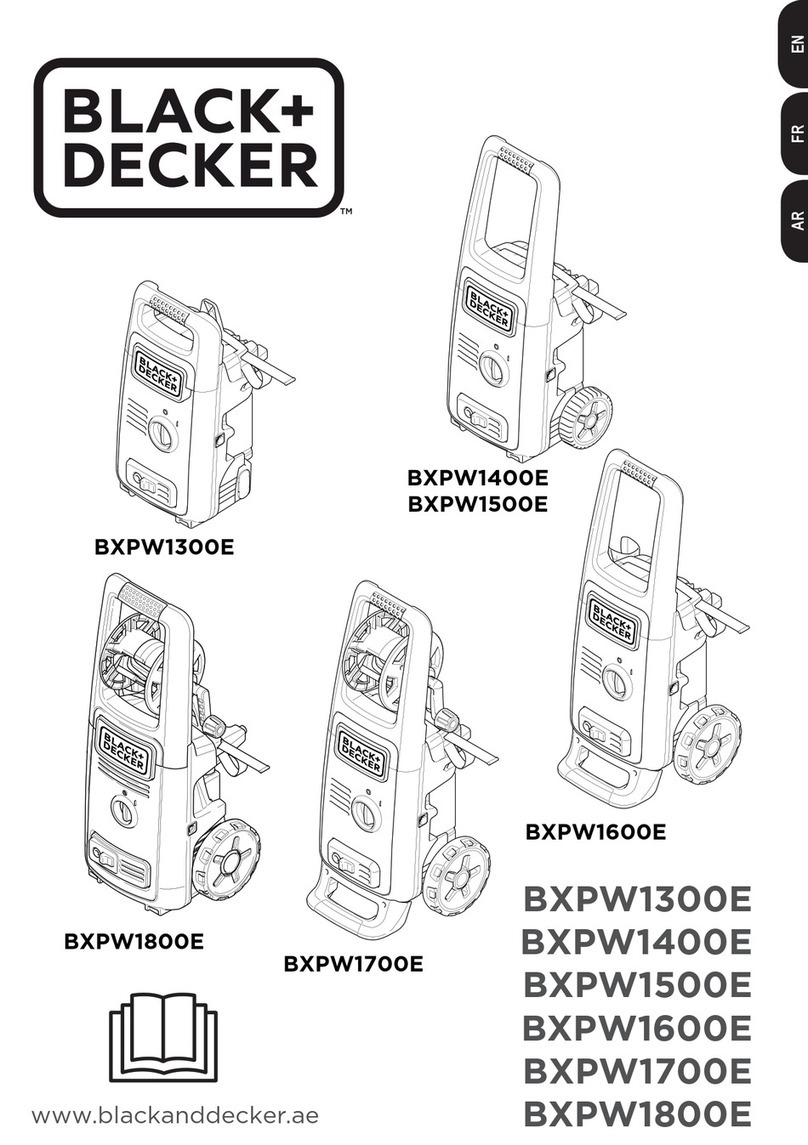

The appliance you have purchased is a technologically

advanced product designed by one of the leading

manufacturers of high pressure pumps. To obtain the best

performance from your unit, read this booklet carefully and

follow the instructions each time you use it. We congratulate

you on your choice and wish you successful operation.

GENERAL SAFETY RULES

SAFETY INSTRUCTIONS

General power tool safety warnings.

Warning! Read all safety warnings and

all instructions. Failure to follow the warnings and

instructions listed below may result in electric shock,

fire and/or serious injury.

Save all warnings and instructions for future reference.

The term in all of the warnings listed below refers to your

mains operated (corded) power tool or battery operated

(cordless) power tool.

1. Safety “Must Nots”

a. Explosion or poisoning hazard. Do not use the

appliance with inammable or toxic liquids, or any

products which are not compatible with the correct

operation of the appliance.

b. Injury hazard.Do not direct the water jet towards

people or animals.

c. Electric shock hazard. Do not direct the water jet

towards the unit itself, electrical parts or towards other

electrical equipment

d. Short circuit hazard. Do not use the appliance

outdoors in case of rain.

e. Injury hazard. This machine is not intended for use

by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience

and knowledge. Children should be supervised to

ensure that they do not play with the appliance.

f. Electric shock hazard. Do not touch the plug and/or

socket with wet hands.

g. Electric shock and short circuit hazard. Do not use

the appliance if the electrical cable is damaged.

h. Explosion hazard. Do not use the appliance if the

high pressure hose is damaged.

i. Accident hazard. Do not jam the trigger in the

operating position.

j. Accident hazard. Check that the data plates are

axed to the appliance, if not, inform your dealer.

Units without plates must not be used as they are

unidentiable and potentially dangerous.

k. Explosion hazard. Do not tamper with or alter the

calibration of the safety valve.

l. Hazardous alteration of operating performance.

Do not alter the original diameter of the spray

head nozzle.

m. Accident hazard. Do not leave the appliance

unattended.

n. Short circuit hazard. Do not move the appliance

by pulling on the electrical cable.

o. Make sure that cars do not drive over the high pressure

hose.

2. Safety “Musts”

a. Short circuit hazard. All electrical conductors must

be protected against the water jet.

b. Electric shock hazard. The appliance must only be

connected to an adequate power supply in compliance

with all applicable regulations.

fUse of a safety residual current circuit-breaker

(R.C.C.B.) will provide additional protection

for the operator (30mA).

c. Injury hazard. The high pressure may cause

materials to bounce of surfaces at speed; therefore

protective clothing and safety goggles, safety boots,

safety gloves, safety helmets with visors, hearing

protection must be worn.

d. Accidental start-up hazard. Before doing work on

the appliance, remove the plug.

e. Injury hazard. Before pressing the trigger, grip the

gun firmly to counteract the recoil.

f. Contamination hazard. Comply with the requirements

of the local water supply company. According to DIN

1988, the appliance may only be connected to the

mains drinking water supply if a backow preventer

valve with drain facility is installed in the supply hose.

Water that has flowed through backflow preventers

is considered to be non-potable.

g. Accident hazard. Maintenance and/or repair of

electrical components must be carried out by qualified

and Authorized BLACK+DECKER staff for the warranty

to take effect. If the supply cord is damaged, it must

be replaced by the manufacturer, an Authorized

BLACK+DECKER service centre or an equally qualified

person in order to avoid a hazard. If the supply cord

is replaced by an equally qualified person, but not

Authorized by BLACK+DECKER, the warranty will

lose effect.

h. Injury hazard. Discharge residual pressure before

disconnecting the unit hose.

i. Accident hazard. Before using the appliance, check

every time that the screws are fully tightened and that

there are no broken or worn parts.

j. Explosion and electric shock hazard. Only use

detergents which will not corrode the coating

materials of the high pressure hose/electrical cable.