1.0 INTRODUCTION

THIS MANUAL SHOULD BE READ IN CONJUNCTION WITH THE ALPHA INSTALLATION AND SERVICING MANUAL

FOR THE E-E-Tec 20S, 30S & 35S BOILERS WHICH IS APPENDED TO THIS MANUAL IN APPENDIX “A” AND SHOULD

BE ADHERED TO IN ALL RESPECTS WHERE APPLICABLE,

For reference the boilers within each TWIN PLUS WATER HEATERS package are identical and the following

references should be used.

TPWH60 Equates to 2No E-Tec 30S Boilers

TPWH80 Equates to 2No E--Tec 40S Boilers

The boiler must only be used in conjunction with flue components supplied by ALPHA unless written consent to

use an alternative is obtained prior to installation from Blades LCS

The boiler and cylinder must be checked and serviced annually in accordance with section 6.0 in the Alpha

Boiler Manual and section 7.0 and relevant items shown in the commissioning and service check list on pages

21 & 22 of this manual. Failure to comply with this note may invalidate the warranty. A service record logbook

must be kept on site at all times detailing date of service, any action undertaken.

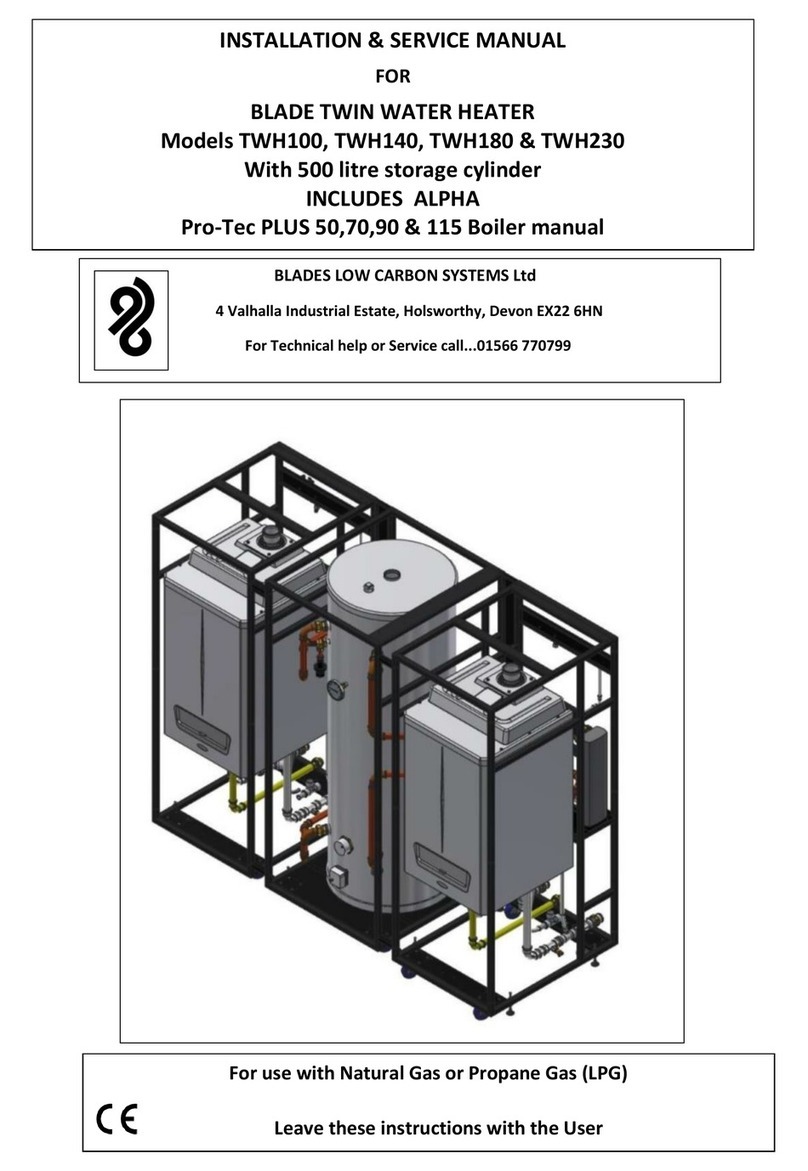

The Blade Twin Water Heater has been specifically developed as a compact energy efficient boiler cylinder

module for use where high domestic hot water volumes are required together with fast recovery and a high

degree of fault tolerance is required.

The Water Heater can also be configured to supply space heating if required see schematic layout on page 17.

Each boiler module can work independently to supply the cylinder with hot water so if a boiler failure occurs

then the hot water system will still function.

The Blade Water Heater has been specifically developed as a compact energy efficient boiler cylinder module

for use where high domestic hot water volumes are required.

The frame also contains the appropriate number of Passive Flue Gas Heat Recovery Devices (PFGHRD) which

usesthe normally wasted latent heat within the flue exhaust gases. These are connected tothe boiler via the boiler

flue spigot. The recovered energy from the Passive Flue Gas Heat Recovery Devices is used to pre-heat the

cold feed to the DHW cylinder this increases the overall system efficiency of this unit to 97%. It should be

noted on this boiler the PFGHRD can be used in conjunction with standard ALPHA concentric flue

components.

Each Twin Water Heater contains two standard high efficiency condensing fan assisted system boilers. See

ALPHA manual Appendix A for boiler performance data, together with a 500 litre hot water cylinder

The burner is ignited electronically and the heat output is controlled by a modulating fan and gas valve.

Together with a 500 litre stainless steel domestic hot water storage vessel with all necessary inter- connecting

pipework, hot water circulating pumps, plate heat exchangers, internal controls and wiring terminating at

convenient interface points for extension into the building services.

The equipment is mounted within a rigid powder coated mild steel mobile frames suitable for free-standing within

the plant room. Each boiler has a built-in controls system allowing boilers to operate as part of a modular

system or individually dependent on application.

The boiler is fitted complete with a DHW time control, switch live for external CH control and a remote boiler

fault indication signal connection.

The units are factory tested prior to dispatch, allowing ease of installation with reduced on-site works

requirement

The benefit of the Water Heater is that by the incorporation of a high recovery plate heat exchangers with a

cylinder destratification pump the recovery time can be dramatically reduced . This allows high volumes of DHW

to be delivered from a 500 litre storage cylinders, reducing cylinder heat losses and increasing the overall energy

efficiency of the system.

To increase fault tolerance the cylinder is fitted with a manually operated 3kW immersion heater.