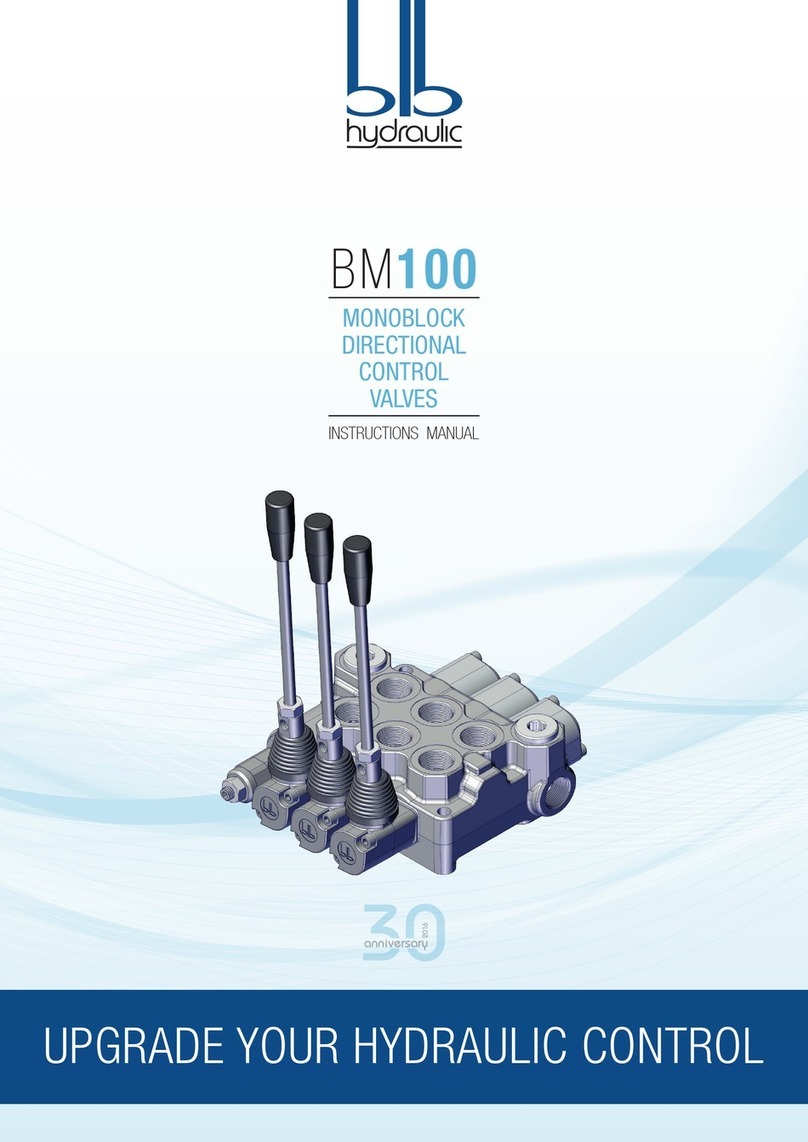

BLB hydraulic BM40 Series User manual

BM40

MONOBLOCK

DIRECTIONAL

CONTROL

VALVES

INSTRUCTIONS MANUAL

UPGRADE YOUR HYDRAULIC CONTROL

BM40 MONOBLOCK DIRECTIONAL CONTROL VALVES | INSTRUCTIONS MANUAL2

ITEM 86503000 - 91411009 BM40/1 ZB GU P/MO B1/T TAR5

BM40/1 installation dimensions

3

ITEM 86503001 – 91411019 BM40/1 ZB GU P/MO A1/T TAR5

BM40/1 installation dimensions

BM40 MONOBLOCK DIRECTIONAL CONTROL VALVES | INSTRUCTIONS MANUAL

BM40 MONOBLOCK DIRECTIONAL CONTROL VALVES | INSTRUCTIONS MANUAL4

ITEM 86503002 – 91411010 BM40/2 ZB GU P/MO B1/MO B1/T TAR5

BM40/2 installation dimensions

BM40 MONOBLOCK DIRECTIONAL CONTROL VALVES | INSTRUCTIONS MANUAL 5

ITEM 86503003 – 91411020 BM40/2 ZB GU P/MO A1/MO A1/T TAR5

BM40/2 installation dimensions

BM40 MONOBLOCK DIRECTIONAL CONTROL VALVES | INSTRUCTIONS MANUAL6

ITEM 86503004 – 91411021 BM40/3 ZB GU P/MO A1/MO A1/MO A1/T TAR5

BM40/3 installation dimensions

BM40 MONOBLOCK DIRECTIONAL CONTROL VALVES | INSTRUCTIONS MANUAL 7

ITEM 86503005 – 92111005 BM40/4 ZB GU P/MO A1/MO A1/MO A1/MO A1/T TAR5

BM40/4 installation dimensions

BM40 MONOBLOCK DIRECTIONAL CONTROL VALVES | INSTRUCTIONS MANUAL8

ITEM 86503006 – 92111006 BM40/5 ZB GU P/MO A1/MO A1/MO A1/MO A1/MO A1/T TAR5

BM40/5 installation dimensions

BM40 MONOBLOCK DIRECTIONAL CONTROL VALVES | INSTRUCTIONS MANUAL 9

ITEM 86503007 – 92111001 BM40/6 ZB GU P/MO A1/MO A1/MO A1/MO A1/MO A1/MO A1/T TAR5

BM40/6 installation dimensions

BM40 MONOBLOCK DIRECTIONAL CONTROL VALVES | INSTRUCTIONS MANUAL10

ITEM 86503008 – 91411011 BM40/7 ZB GU P/MO A1/MO A1/MO A1/MO A1/MO A1/MO A1/MO A1/T TAR5

BM40/7 installation dimensions

BM40 MONOBLOCK DIRECTIONAL CONTROL VALVES | INSTRUCTIONS MANUAL 11

PRESSURE DROP

TECHNICAL SPECIFICATIONS

Work Flow / Max Flow 35 l/min / 45 l/min

Relief valve setting 140 bar

Relief valve range 100 to 250 bar

Inlet/Outlet Ports 1/2" G Side / 3/8” G Top

Work Ports 3/8” G

MAIN FEATURES

Zinc plating protects against corrosion and rust

Precise ow metering to accurately control actuator speed

Power beyond capability for easy addition of valves downstream

Easy to convert from Open to Closed center

Customizable with a variety of spool and positioner options

BM40 MONOBLOCK DIRECTIONAL CONTROL VALVES | INSTRUCTIONS MANUAL12

PARTS LIST:

Drawing 1

BM40 SPARE PARTS

Nº PARTS PARTS Nº SUB PART SUB PART

1Relief Valve Kit 1.1 Adjusting Screw

1.2 Nut

2Check Valve

3Handle

4Handle Cap Kit 4Handle Cap

4.1 Screw

5Spool Kit 5.1 O-Ring Seal

5Spool

6Spool Control kit

6Spool Control Cap

6.1 Positioner Kit

6.2 Screw

INSTALLATION

The installation of the valve calls for tightening of screws, ttings and hoses. Proper force must be used for the tightening of each element, in order

to prevent functional problems: excessive tightening might cause deformation to the valve and compromise the correct operation of the same; weak

tightening may effect functionality and safety. Refer to the below table to determine correct torque for each element.

Never us provisional extension nor act with bumps on the wrenches.

1

1.2

1.1

3

2

4

4.1

5

5.1

6.1

6

6.2

BM40 MONOBLOCK DIRECTIONAL CONTROL VALVES | INSTRUCTIONS MANUAL 13

Before installing the product, check that it has not been

damaged during internal transport.

Step 1. Install the valve in shock and vibration free areas. While moving the valve do not cause accidental bumps or shocks. The valve must be

secured with M8 screws. Apply thread-lock accessories. Mounting position is irrelevant as long as the valve is resting on a rigid and

perfectly at surface; this is necessary so that the tightening of the screws does not cause harmful deformation.

Step 2. Use hoses and ttings suitable for indicated max ow and pressure. It is strictly prohibited the usage of conic ttings and the reversal of

connections between inlet (P, P2) and tank (T, T2) lines. Remove the protective plugs from the valve ports just before connecting the hoses

to prevent contamination of the circuit with dust or other materials. Do not use wrapped on threads to seal. Tighten ttings with the torque

indicated in the table.

Step 3. Before starting, ux oil from an auxiliary system. Start the system and then operate the actuators individually and not under load. Operate

slowly until the system is lled with oil. Set the relief valve and carry out a complete test of the system. Do not perform calibration of valves

without having rst applied a pressure gauge on the inlet section of the valve and on line where deemed necessary.

CHANGING THE VALVE SPOOL AND SEALS (See drawing 1):

Step 1. Remove the Handle (Part 3).

Step 2. Remove the Screws (Part 6.2) with a 5 mm hex key and remove the Spool Control Cap (Part 6).

Step 3. Using a 5 mm hex key remove the Spool Control Kit (Part 6.1).

Step 4. Remove the Screws (Part 4.1) with a 5 mm hex key and remove the Handle Cap (Part 4).

Step 5. Always start on the Spool Control Cap side when removing the O-rings Seals. Move the Spool (Part 5) only far enough to expose the O-ring

Seals (Part 5.1). Be careful not to push the Spool too far past the O-ring Seal groove as this will cut the O-ring Seal on the Handle Cap side.

Remove the O-ring Seal with a pick.

Step 6. Remove the Spool through the Spool Control Cap end of the valve. Remove the Handle Cap side O-ring Seal with a pick.

Step 7. Lightly oil the new Spool with clean hydraulic uid. Insert the Spool into the valve and push and pull it within the valve casting to make sure

there is very little resistance. If resistance is felt please try a new Spool to eliminate binding.

Step 8. Push the Spool back on the Handle Cap end, so the O-ring Seal can be installed in the groove.

Step 9. After the O-ring Seal is installed in the Handle Cap end, slowly push the Spool from the Spool Control Cap end to expose the O-ring Seal

groove. Be careful not to push the Spool too far past the O-ring Seal groove as this will cut the O-ring Seal on the Handle Cap side. Install

the O-ring Seal in the groove.

Step 10. Install the Handle Cap rst and tighten the Screws to 8,5 Nm.

Step 11. Install the Spool Control onto the spool and tighten to 16 Nm, then install the Spool Control Cap and tighten the Screws to 8,5 Nm.

Step 12. Add the Handle to the valve and move it back and forth to feel any eventual sticking of the Spool. If it feels sticking, loose the Caps and

realign, then try again, this will x the sticking issue.

If it is not sticking the installation is complete.

CHANGING THE SPOOL CONTROL FROM SPRING CENTERED TO DETENT (See drawing 1):

Step 1. Remove the Screws (Part 6.2) with a 5 mm hex key and remove the Spool Control Cap (Part 6).

Step 2. Using a 5 mm hex key remove the old Spool Control (Part 6.1).

Step 3. Install the new Spool Control onto the Spool and tighten to 16 Nm.

Step 4. Install the Spool Control Cap and tighten the Screws to 8,5 Nm.

SETTING THE RELIEF VALVE (See drawing 1):

An adjustable relief valve is standard on all monoblock directional valves. Standard factory setting is 140 bar.

The relief pressure is adjusted by releasing the Nut (Part 1.2), and turning the Adjusting Screw (Part 1.1) with a 4 mm hex key wrench. Turning the

Adjusting Screw clockwise will increase the pressure, and counter-clockwise will decrease the pressure (a pressure gauge must be installed in the

inlet line whenever the relief valve pressure is adjusted). Adjustable pressure range is 100 bar to 250 bar.

Do not backout the Adjusting Screw to the point it falls out.

COMPONENT THREAD Nm

Fixing Screws M8 23

Connectors,

Plugs

3/8” G; 3/4”-16 UNF 32

1/2” G; 7/8”-14 UNF 45

Relief Valve, RVP M20 x 1,5 45

14 BM40 MONOBLOCK DIRECTIONAL CONTROL VALVES | INSTRUCTIONS MANUAL

OPTIONAL

Carry Over - CO (Power Beyond Adapter)

Closed Center Plug - CCP

Relief Valve Plug - RVP

A

A

T2

A

A

T2

15BM40 MONOBLOCK DIRECTIONAL CONTROL VALVES | INSTRUCTIONS MANUAL

HOW TO INSTALL CARRY OVER - CO (POWER BEYOND ADAPTER)

Step 1. Screw the Power Beyond Adapter into the T2 port with 27 mm hex wrench and tighten to 45 Nm.

When the Power Beyond Adapter is installed a hose must be attached to the T port and run back to the tank.

Failure to do this will cause the valve not to function properly.

HOW TO INSTALL CLOSED CENTER PLUG - CCP

Step 1. Screw the Closed Center Plug into the T2 port with 10 mm hex key and tighten to 45 Nm.

When the Closed Center Plug is installed a hose must be attached to the T port and run back to the tank.

Failure to do this will cause the valve not to function properly.

HOW TO INSTALL RELIEF VALVE PLUG - RVP

Step 1. Remove the Relief Valve (Part 1) with a 22 mm wrench.

Step 2. Take out the Check Valve (Part 2) and install on the Relief Valve Plug.

Step 3. Screw the Relief Valve Plug into the Relief Valve port with 8 mm hex key and tighten to 45 Nm.

WARNING

All hydraulic valves must be properly installed into the hydraulic system to prevent personal injury and/or property damage. Further, the improper

servicing of a valve may result in personal injury and/or property damage. Please read and understand all catalogue and service information before

starting. As with all mechanical work, the proper tools, knowledge, and safety equipment are required. Always wear safety disposals.

Make sure all pressure has been relieved in the hydraulic lines before installing or servicing a hydraulic valve.

Escaping hydraulic uid under pressure can have sufcient force to penetrate skin, causing serious personal injury. Do not use your hand to check

for hydraulic leaks.

Before installing or servicing a hydraulic component make sure all weight has been removed from the cylinders or motors before disconnecting

hydraulic lines.

Disconnecting the hydraulic lines while the cylinder or motor is under load may result in the unexpected rapid movement of machine resulting in

serious personal injury.

Do not exceed the operating specications for pressure, ow or temperature. All hydraulic systems need to have a maximum pressure set; to do

this, it is necessary to have either a pressure relief valve in the system or a pump that has pressure compensation.

Overpressure may cause sudden and unexpected failure of a component in the hydraulic system resulting in serious personal injury.

Always use a gauge when adjusting a relief valve.

Quality management system certied according to ISO 9001:

2008 Certicate Nr 50 100 11533

BLB S.r.l. Via Natta, 1

36040 Brendola (VI) - Italy

T. +39 0444 401141

W. www.blbhydraulic.com

MNL/GB BM40 February 2018 - © BLB Srl - All rights reserved

This manual suits for next models

33

Table of contents

Other BLB hydraulic Control Unit manuals

Popular Control Unit manuals by other brands

salmson

salmson SC-L Installation and starting instructions

DEFA

DEFA SmartStart quick guide

Advantech

Advantech WISE-1510 user manual

Parker

Parker 60VM4071 Operation and maintenance manual

schmersal

schmersal SRB 301AN operating instructions

Bell and Gossett

Bell and Gossett Circuit Sentry Flo-Setter instruction manual

Albalá Ingenieros, S.A.

Albalá Ingenieros, S.A. DAB2008C01 manual

National Instruments

National Instruments NI 9516 Operating instructions and specifications

SOYO

SOYO BT24G03 user manual

LASER COMPONENTS

LASER COMPONENTS COUNT Series user manual

Viessmann

Viessmann Vitocal WPR 300 Service instructions

ST

ST STM32F051R8T6 user manual