3

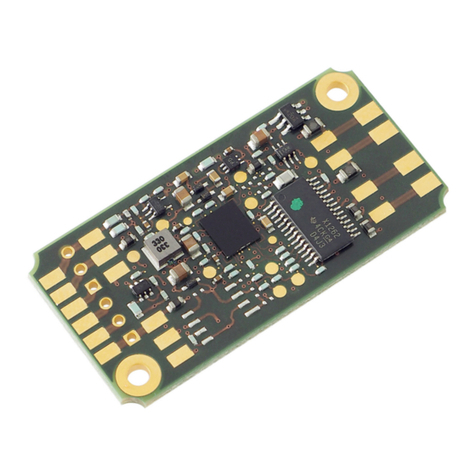

PME-MP55

A0563-7.2 en HBM

Contents Page

Contents

Safety instructions 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Introduction 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Scope of supply and accessories 9. . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 General 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Selecting amplifier settings with DIP switches 10. . . . . . . . . . . . . . . . . .

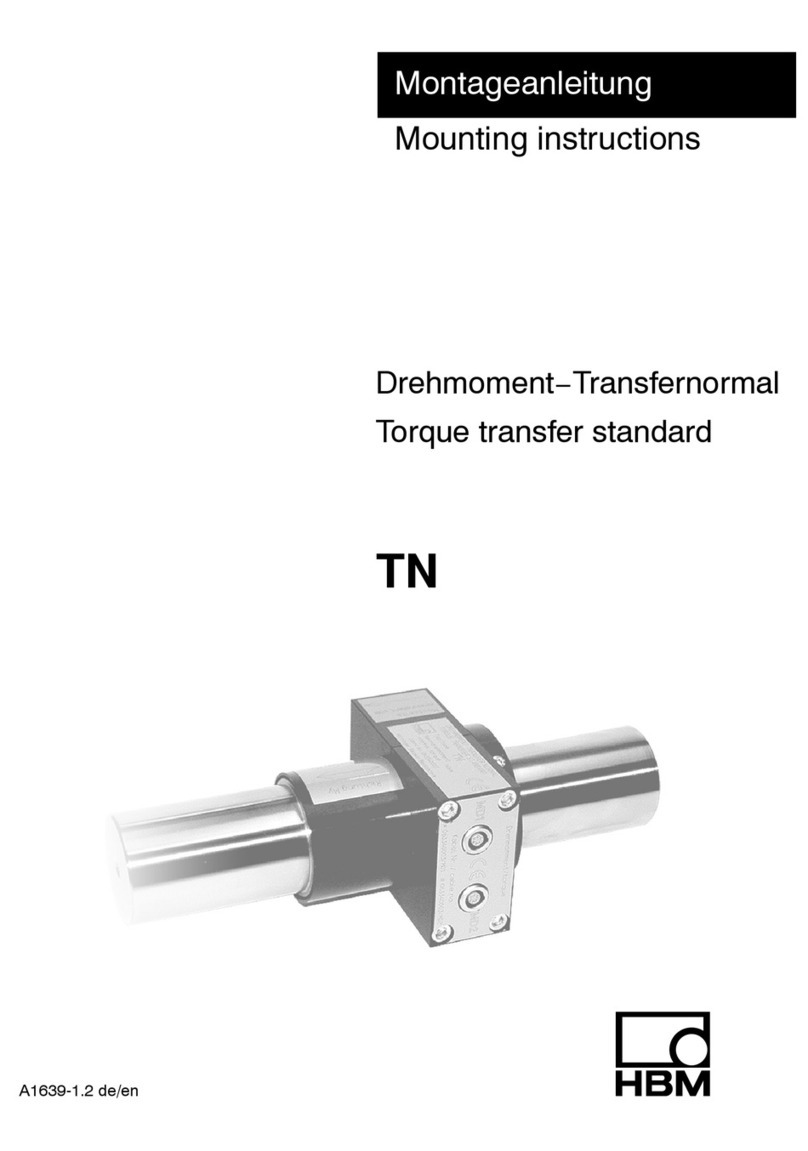

3 Mounting/dismountingMP55 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Connecting several modules 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Connection 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Overview of MP55 functions 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Supply voltage and control inputs/outputs 17. . . . . . . . . . . . . . . . . . .

4.2.1 External supply voltage for control outputs 18. . . . . . . . . . . . .

4.3 Transducers 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 Connecting transducers in a four‐wire configuration 19. . . . .

4.3.2 Connecting transducers when cables are more than

50m long 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

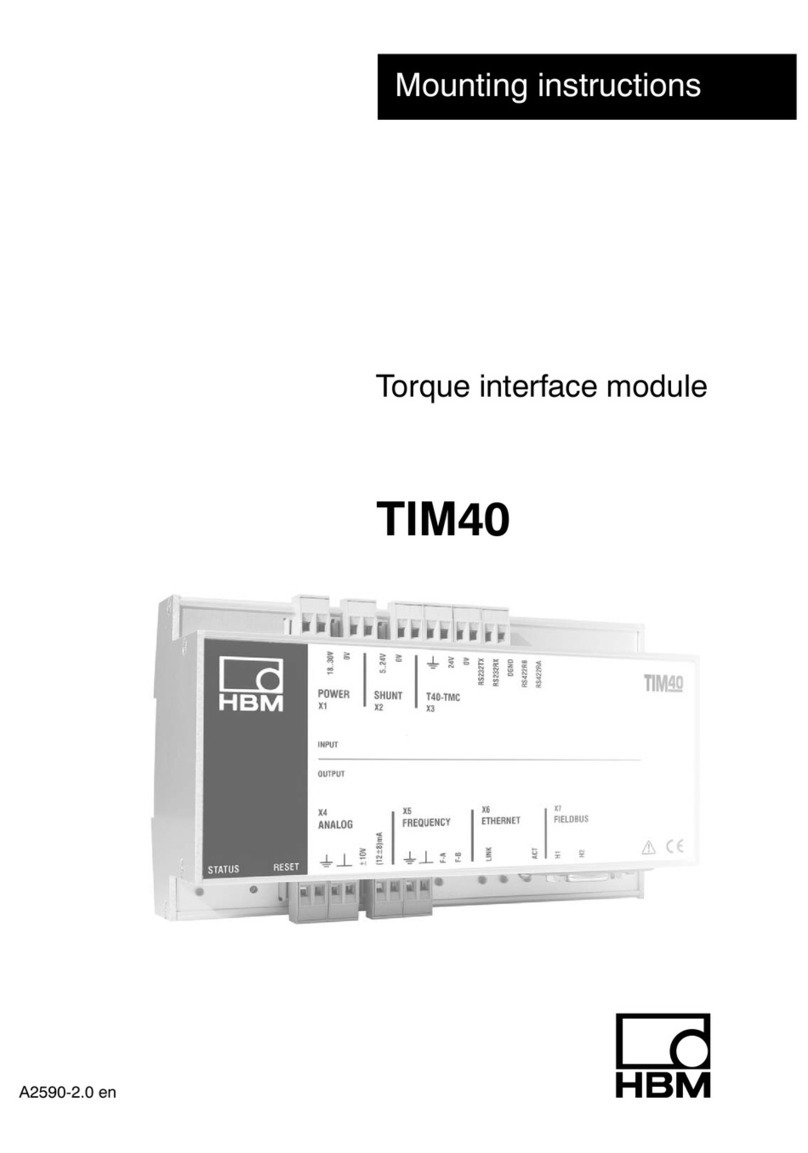

4.4 CAN interface 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Synchronization 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Setting and operating (MP55) 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Operating philosophy 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Starting up 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Overview of all groups and parameters 28. . . . . . . . . . . . . . . . . . . . .

5.3.1 Setting all parameters 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Clarification of important parameters 33. . . . . . . . . . . . . . . . . . . . . . . . . .

7 CAN interface description 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 General 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Cyclic transmission of measured values 41. . . . . . . . . . . . . . . . . . . .

7.3 Parameterization 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 Object dictionary: Communication profile range in accordance

with CANopen (CiA‐DS301) 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 Object dictionary: manufacturer‐specific objects 47. . . . . . . . . . . . . .

7.6 Manufacturer‐specific objects in FLOAT data format 56. . . . . . . . . .

7.7 Examples 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Error messages/operating state (LED) 60. . . . . . . . . . . . . . . . . . . . . . . . .

9 Index 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .