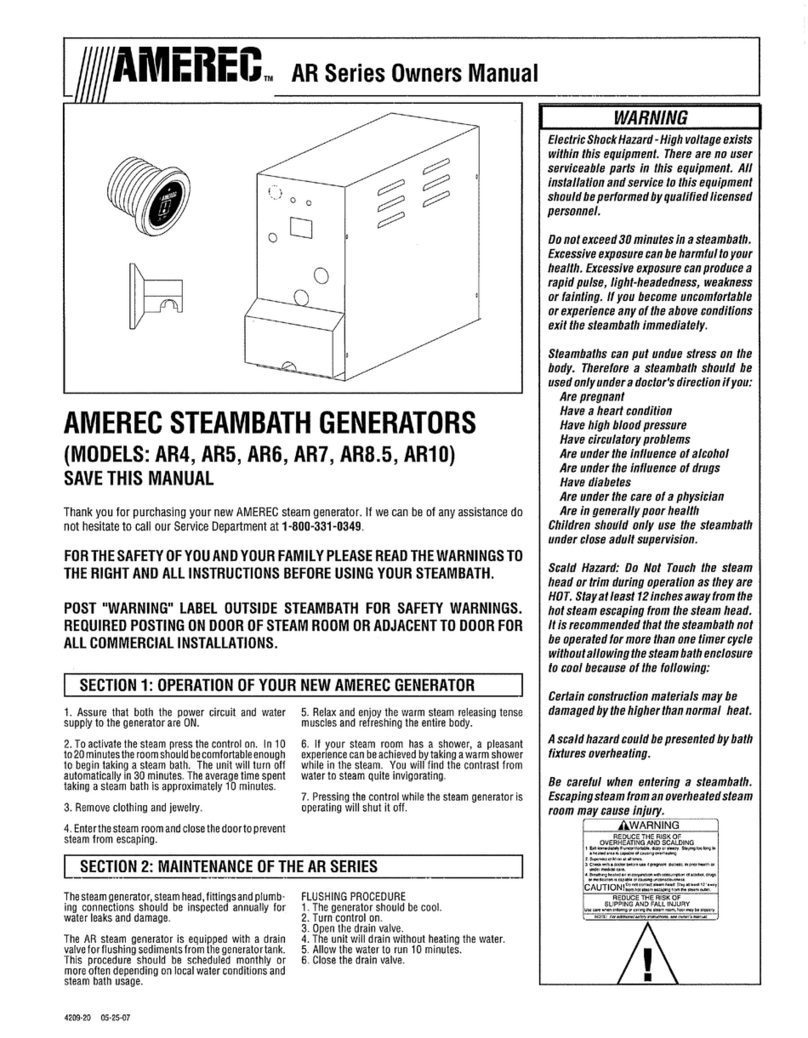

BLEMO ER24 Series Owner's manual

BLEMO

®

ER24

Variable Speed Drives

for Asynchronous and Synchronous Motors

Programming Manual

05/2018

2

The information provided in this documentation contains general descriptions and/or technical characteristics

of the performance of the products contained herein. This documentation is not intended as a substitute for

and is not to be used for determining suitabilityor reliabilityof these products for specific user applications. It

is the dutyof any such user or integrator to perform the appropriate and complete risk analysis, evaluation and

testing of the products with respect to the relevant specific application or use thereof. Neither BLEMO nor

any of its affiliates or subsidiaries shall be responsible or liable for misuse of the information contained

herein. If you have any suggestions for improvements or amendments or have found errors in this

publication, please notifyus.

No part of this docum ent maybe reproduced in anyform or byanymeans, electronic or mechanical, including

photocopying, without express written permission of BLEMO.

All pertinent state, regional, and local safety regulations must be observed when installing and using this

product. For reasons of safety and to help ensure compliance with documented system data, only the

manufacturer should perform repairs to components.

When devices are used for applications with technical safetyrequirements, the relevant instructions must be

followed.

Failure to use BLEMO software or approved software with our hardware products mayresult in injury, harm,

or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2017 BLEMO. All rights reserved.

3

Table of Contents

Table of Contents

Safety Information .............................................................................................................7

About the Book................................................................................................................11

General Overview

........................................................................................................................15

Chapter 1 Overview...........................................................................................................................17

Factory configuration .........................................................................................................18

Application functions .........................................................................................................19

Basic functions ..................................................................................................................23

Graphic display terminal option.........................................................................................24

Powering up the drive for the first time .............................................................................27

Remote display terminal option.........................................................................................30

Structure of the parameter tables......................................................................................31

Finding a parameter in this document...............................................................................32

Description of the HMI.......................................................................................................33

Structure of the menus......................................................................................................35

Chapter 2 Setup.................................................................................................................................37

Steps for setting-up the drive ............................................................................................38

Initial steps.........................................................................................................................39

Programming

...............................................................................................................................41

Chapter 3 Reference Mode (rEF).....................................................................................................43

Introduction........................................................................................................................44

Organization tree ...............................................................................................................45

Menu..................................................................................................................................46

Chapter 4 Monitoring Mode (MOn)..................................................................................................47

Introduction........................................................................................................................48

Organization tree ...............................................................................................................49

Menu..................................................................................................................................50

[MONIT. MOTOR]

.......................................................................................................50

[I/O MAP]

...................................................................................................................51

[MONIT. SAFETY]

......................................................................................................54

[MONIT. FUN. BLOCKS]

.............................................................................................55

[COMMUNICATION MAP]

...........................................................................................56

[MONIT. PI]

................................................................................................................62

[MONIT. POWER TIME]

..............................................................................................62

[ALARMS]

..................................................................................................................63

[OTHER STATE]

........................................................................................................64

[DIAGNOSTICS]

.........................................................................................................64

[PASSWORD]

............................................................................................................75

Chapter 5 Configuration Mode (ConF)............................................................................................77

Introduction........................................................................................................................78

Organization tree ...............................................................................................................79

My Menu ............................................................................................................................80

4

Table of Contents

Factory Settings ................................................................................................................81

Macro Configuration ..........................................................................................................82

Full.....................................................................................................................................85

[SIMPLY START]

........................................................................................................85

[SETTINGS]

...............................................................................................................89

[MOTOR CONTROL]

................................................................................................105

[INPUTS / OUTPUTS CFG]

.......................................................................................125

[COMMAND]

............................................................................................................154

[FUNCTION BLOCKS]

..............................................................................................158

[APPLICATION FUNCT.] (FUn-)

................................................................................162

REFERENCE SWITCHING

..................................................................................167

REFERENCE OPERATIONS

...............................................................................168

RAMP

.............................................................................................................170

STOP CONFIGURATION

....................................................................................173

AUTO DC INJECTION

........................................................................................176

JOG

................................................................................................................178

PRESET SPEEDS

.............................................................................................180

+/- SPEED

........................................................................................................184

+/- SPEED AROUND A REFERENCE

....................................................................186

REFERENCE MEMORIZING

...............................................................................188

FLUXING BY LOGIC INPUT

................................................................................189

BRAKE LOGIC CONTROL

..................................................................................191

EXTERN AL WEIGHT MEASUREMENT

.................................................................199

HIGH SPEED HOISTING

....................................................................................201

PID REGULATOR

..............................................................................................206

PID PRESET REFERENCES

...............................................................................214

TORQUE LIMITATION

........................................................................................215

2ND CURRENT LIMITATION

...............................................................................218

DYN CURRENT LIMIT

........................................................................................219

LINE CONTACTOR COMMAND

...........................................................................220

OUTPUT CONTACTOR COMMAND

.....................................................................222

POSITIONING BY SENSORS

..............................................................................224

PARAMETER SET SWITCHING

...........................................................................229

MULTIMOTORS / MULTICONFIGURATIONS

.........................................................232

AUTO TUNING BY LOGIC INPUT

.........................................................................236

TRAVERSE CONTROL

......................................................................................237

[COMMUNICATION]

.................................................................................................275

Access Level ...................................................................................................................278

Chapter 6 Interface (ItF)..................................................................................................................279

Access Level (LAC).........................................................................................................280

Language (LnG) ..............................................................................................................282

Monitoring Configuration (MCF)......................................................................................283

Display configuration (dCF) ............................................................................................287

Chapter 7 Open / Save as (trA) ......................................................................................................295

Chapter 8 Password (COd) ............................................................................................................299

Chapter 9 Multipoint Screen..........................................................................................................301

Maintenance and Diagnostics

...............................................................................................303

Chapter 10 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

305

Chapter 11 Diagnostics and Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

307

Error code

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

308

Clearing the detected fault

. . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

308

Fault detection codes which require a power reset after the detected fault is cleared

309

Fault

detection codes that can be cleared with the automatic restart function after the

cause has disappeared ...................................................................................................311

5

Table of Contents

Fault detection codes that are cleared as soon as their cause disappears ...................314

Option card changed or removed....................................................................................314

Control block changed.....................................................................................................314

Fault detection codes displayed on the remote display terminal....................................315

Annex

...........................................................................................................................................317

Chapter 12 Index of Functions.........................................................................................................319

Chapter 13 Index of Parameter Codes............................................................................................321

Chapter 14 Glossary .........................................................................................................................341

6

Table of Contents

7

Safety Information

§

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device before trying

to install, operate, or maintain it. The following special messages mayappear throughout this documentation

or on the equipment to warn of potential hazards or to call attention to information that clarifies or simplifies a

procedure.

The addition of this symbol to a Danger or Warning safety label indicates that an electrical hazard

exists, which will result in personal injuryif the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal injuryhazards. Obey all

safety messages that follow this symbol to avoid possible injuryor death.

DANGER

DANGER indicates a hazardous situation, which, if not avoided, will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation, which, if not avoided, could result in death, serious injury, or

equipment damage.

CAUTION

CAUTION indicates a potentiallyhazardous situation, which, if not avoided, could result in minor or

moderate injury, or equipment damage.

NOTICE

NOTICE is used to address practices not related to physical injury.

Safety Information

8

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained onlyby qualified personnel. No

responsibilityis assumed byBLEMO for any consequences arising out of the use of this material.

A qualified person is one who has skills and knowledge related to the construction and operation of electrical

equipment and its installation, and has received safety training to recognize and avoid the hazards involved.

Qualification Of Personnel

Only appropriatelytrained persons who are familiar with and understand the contents of this manual and all

other pertinent product documentation are authorized to work on and with this product. In addition, these

persons must have received safety training to recognize and avoid hazards involved. These persons must

have sufficient technical training, knowledge and experience and be able to foresee and detect potential

hazards that may be caused byusing the product, by changing the settings and bythe mechanical, electrical

and electronic equipment of the entire system in which the product is used. All persons working on and with

the product must be fullyfamiliar with all applicable standards, directives, and accident prevention regulations

when performing such work.

Intended Use

This product is a drive for three-phase synchronous and asynchronous motors and intended for industrial use

according to this manual.The product mayonly be used in compliance with all applicable safetyregulations

and directives, the specified requirements and the technical data.Prior to using the product, you must perform

a risk assessment in view of the planned application. Based on the results, the appropriate safety measures

must be implemented.Since the product is used as a component in an entire system, you must ensure the

safety of persons bymeans of the design of this entire system (for example, machine design). Any use other

than the use explicitly permitted is prohibited and can result in hazards. Electrical equipment should be

installed, operated, serviced, and maintained onlyby qualified personnel.

Product related information

Read and understand these instructions before performing any procedure with this drive.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

•

Only appropriatelytrained persons who are familiar with and understand the contents of this manual and

all other pertinent product documentation and who have received safety training to recognize and avoid

hazards involved are authorized to work on and with this drive system. Installation, adjustment, repair and

maintenance must be performed by qualifiedpersonnel.

•

The system integrator is responsible for compliance with all local and national electrical code

requirements as well as all other applicable regulations with respect to grounding of all equipment.

•

Many components of the product, including the printed circuit boards, operate with mains voltage. Do not

touch. Use only electricallyinsulated tools.

•

Do not touch unshielded components or terminals with voltage present.

•

Motors can generate voltage when the shaft is rotated. Prior to performing anytype of work on the drive

system, block the motor shaft to preventrotation.

•

AC voltage can couple voltage to unused conductors in the motor cable. Insulate both ends of unused

conductors of the motor cable.

•

Do not short across the DC bus terminals or the DC bus capacitors or the braking resistor terminals.

•

Before performing work on the drivesystem:

- Disconnect all power, including external control power that maybe present.

- Place a "Do Not Turn On" label on all powerswitches.

- Lock all power switches in the openposition.

- Wait 15 minutes to allow the DC bus capacitors to discharge. The DC bus LED is not an indicator of the

absence of DC bus voltage that can exceed 800 Vdc.

Measure the voltage on the DC bus between the DC bus terminals (PA/+ and PC/-) using a properly

rated voltmeter to verify that the voltage is <42 Vdc.

- If the DC bus capacitors do not discharge properly, contact your local BLEMO representative. Do not

repair or operate the product.

•

Install and close all covers before applying voltage.

Failure to follow these instructions will result in death or serious injury.

Safety Information

9

Drive systems mayperform unexpected movements because of incorrect wiring, incorrect settings, incorrect

data or other errors.

Damaged products or accessories maycause electric shock or unanticipated equipment operation.

Contact your local BLEMO sales office if you detect any damage.

1 .

For USA: Additional inf ormation, ref er to NEMA ICS 1.1 (latest edition), “Saf ety Guidelines f or the Application, Installation, and

Maintenance of Solid State Control” and to NEMA ICS 7.1 (latest edition), “Saf ety Standards f or Construction and Guide f or Selection,

Installation and Operation of Adjustable-Speed Driv e Sy stems”.

WARNING

UNEXPECTED EQUIPMENT OPERATION

Carefullyinstall the wiring in accordance with the EMC requirements.

Do not operate the product with unknown or unsuitable settings or data.

Perform a comprehensive commissioning test.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

ELECTRIC SHOCK OR UNANTICIPATED EQUIPMENT OPERATION

Do not use damaged products or accesssories.

Failure to follow these instructions will result in death or serious injury.

WARNING

LOSS OF CONTROL

• The designer of any control scheme must consider the potential failure m odes of control paths and, for

critical control functions, provide a means to achieve a safe state during and after a path failure. Examples

of critical control functions are emergencystop, overtravel stop, power outage and restart.

• Separate or redundant control paths must be provided for critical control functions.

• System control paths mayinclude communicationlinks. Consideration must be given to the implications

of unanticipated transmission delays or failures of the link.

• Observe all accident prevention regulations and local safetyguidelines.1

• Each implementation of the product must be individuallyand thoroughlytested for proper operation before

being placed into service.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

NOTICE

DESTRUCTION DUE TO INCORRECT MAINS VOLTAGE

Before switching on and configuring the product, verify that it is approved for the mains voltage.

Failure to follow these instructions can result in equipment damage.

Safety Information

10

WARNING

HOT SURFACES

Ensure that any contact with hot surfaces is avoided.

Do not allow flammable or heat-sensitive parts in the immediate vicinityof hot surfaces.

Verify that the product has sufficientlycooled down before handling it.

Verify that the heat dissipation is sufficient byperforming a test run under maximum load conditions

Failure to follow these instructions can result in death, serious injury, or equipment damage.

WARNING

EXPLOSION HAZARD

Only use this device outside of hazardous areas (explosive atmospheres).

Failure to follow these instructions can result in death, serious injury, or equipment damage.

11

About the Book

About the Book

At a Glance

Document scope

The purpose of this document is to:

•

help you to set-up the drive,

•

show you how to program the drive,

•

show you the different menus, modes andparameters,

•

help you in maintenance anddiagnostics.

Validity note

NOTE: The products listed in the document are not all available at the time of publication of this document

online. The data, illustrations and product specifications listed in the guide will be completed and updated as

the product availabilities evolve. Updates to the guide will be available for download once products are

released on the market.

This documentation is valid for the ER24 drive.

The characteristics that are presented in this manual should be the same as those characteristics that appear

online. In line with our policyof constant improvement,we mayrevise content over time to improve clarityand

accuracy. If you see a difference between the manual and online information, use the online information as

your reference.

About the Book

12

Use your tablet or your PC to quickly access detailed and comprehensive information on all our products on www.blemo.com .

The internet site provides the information you need for products and solutions

Terminology

The technical terms, terminology, and the corresponding descriptions in this manual normallyuse the terms

or definitions in the relevant standards.

In the area of drive systems this includes, but is not limited to, terms such as error, error message, failure,

fault, fault reset, protection, safe state, safety function, warning, warning message, and so on.

Am ong others, these standards include:

•

IEC 61800 series: Adjustablespeed electrical power drive systems

•

IEC 61508 Ed.2 series: Functional safetyof electrical/electronic/programmable electronic safety-related

•

EN 954-1 Safety of machinery- Safety related parts of control systems

•

EN ISO 13849-1 & 2 Safety of machinery- Safety related parts of control systems.

•

IEC 61158 series: Industrial communication networks - Fieldbus specifications

•

IEC 61784 series: Industrialcommunication networks - Profiles

•

IEC 60204-1: Safety of machinery- Electrical equipment of machines - Part 1: General requirements

In addition, the term zone of operation is used in conjunction with the description of specific hazards, and is

defined as it is for a hazard zone or danger zone in the EC Machinery Directive (2006/42/EC) and in ISO

12100-1.

Also see the glossaryat the end of this manual.

15

General Overview

What's in this Part?

This part contains the following chapters:

Chapter Chapter Name Page

1

Overview 17

2

Setup 37

I

16

Overview

17

Overview

What's in this Chapter?

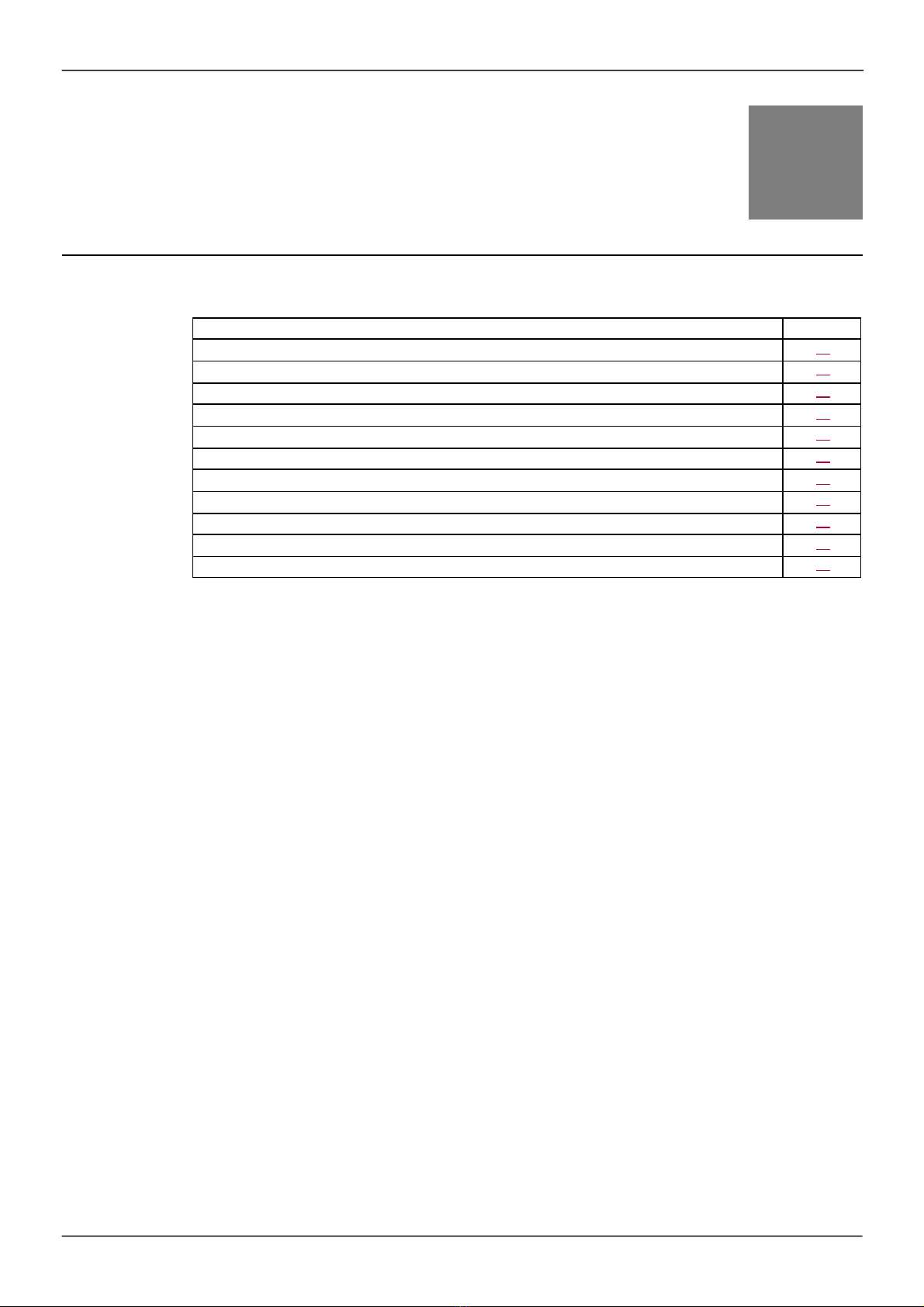

This chapter contains the following topics:

Topic Page

Factory configuration 18

Application functions 19

Basic functions 23

Graphic display terminal option 24

Graphic display terminal option 24

Pow ering up the drive for the first time 27

Remote display terminal option 30

Structure of the parameter tables 31

Finding a parameter in this document 32

Description of the HMI 33

Structure of the menus 35

1

Overview

18

Factory configuration

Factory settings

The ER24 is factory-set for common operating conditions:

•

Display: drive ready [Ready]

(rdY)

when motor is ready to run and the output frequency when motor is

running.

•

The LI3 to LI6 logic inputs, AI2 and AI3 analog inputs, LO1 logic output,AO1 analog output, and R2 relay

are unassigned.

•

Stop mode if error is detected:freewheel.

Code Description Factory settings values Page

bFr

[Standard mot. freq] [50Hz IEC] 86

tCC

[2/3 w ire control] [2 w ire ] (2C): 2-wire control 85

Ctt

[Motor control type]

[Standard]

(Std):

standard motor law

105

ACC

[Accele ration]

3.0 seconds 87

dEC

[Dece le ration]

3.0 seconds 87

LSP

[Low s peed]

0 Hz 87

HSP

[High spe e d]

50 Hz 87

ItH

[M ot. therm. current]

Nominal motor current (value depending on drive rating) 87

SdC1

[Auto DC inj. leve l 1]

0.7 x nominal drive current, for 0.5 seconds 93

SFr

[Sw itching freq.]

4 kHz 94

Frd

[Forw ard]

[LI1]

(

LI

1

):

Logic

input

LI1

126

rrS

[Reve rse assign.]

[LI2]

(

LI

2

):

Logic

input

LI2

126

Fr1

[Ref.1 channel] [AI1]

(AI1):

Analog input AI1

154

r1

[R1 As s ignment] [No drive flt]

(FLt):

The contact opens when a fault is detected or

w hen the drive has been sw itched off

138

brA

[Dec ram p adapt.] [Ye s ]

(YES): Function active (automatic adaptation of deceleration

ramp)

172

Atr

[Automatic restart] [No]

(nO): Function inactive 252

Stt

[Type of s top] [Ram p stop]

(rMP): On ramp

173

CFG

[M acr o configuration] [Start/Stop]

(StS)

82

Note: If you want to keep the drive presettings to a minimum, select the macro configuration

[Macro configuration]

(CFG) =

[Start/stop]

(StS)

followed by

[Restore c

onfig.

]

(

FCS

) =

[Config. CFG]

(

InI

). For m ore inform ation, see page 82.

Check whether the values above are com patible with the application.

Overview

19

Application functions

The tables on the following pages s how the com binations of functions and applications, in order to guide your

selection.

The applications in thes e tables relate to the following m achines, in particular:

•

Hoisting

: cranes, overhead cranes , gantries (vertical hois ting, trans lation, slewing), lifting platforms

•

Handling

: palletizers/depalletizers, conveyors , roller tables

•

Packing

: carton packers , labeling m achines

•

Textiles

: weaving loom s , carding fram es, was hing m achines, s pinners, drawing frames

•

Wood

: autom atic lathes , s aws,m illing

•

Process

Each m achine has its own s pecial features, and the com binations listed here are neither m andatory nor

exhaustive.

Som e functions are des igned specificallyfor a particular application. In this cas e, the application is identified

by a tab in the m argin on the relevant program ming pages.

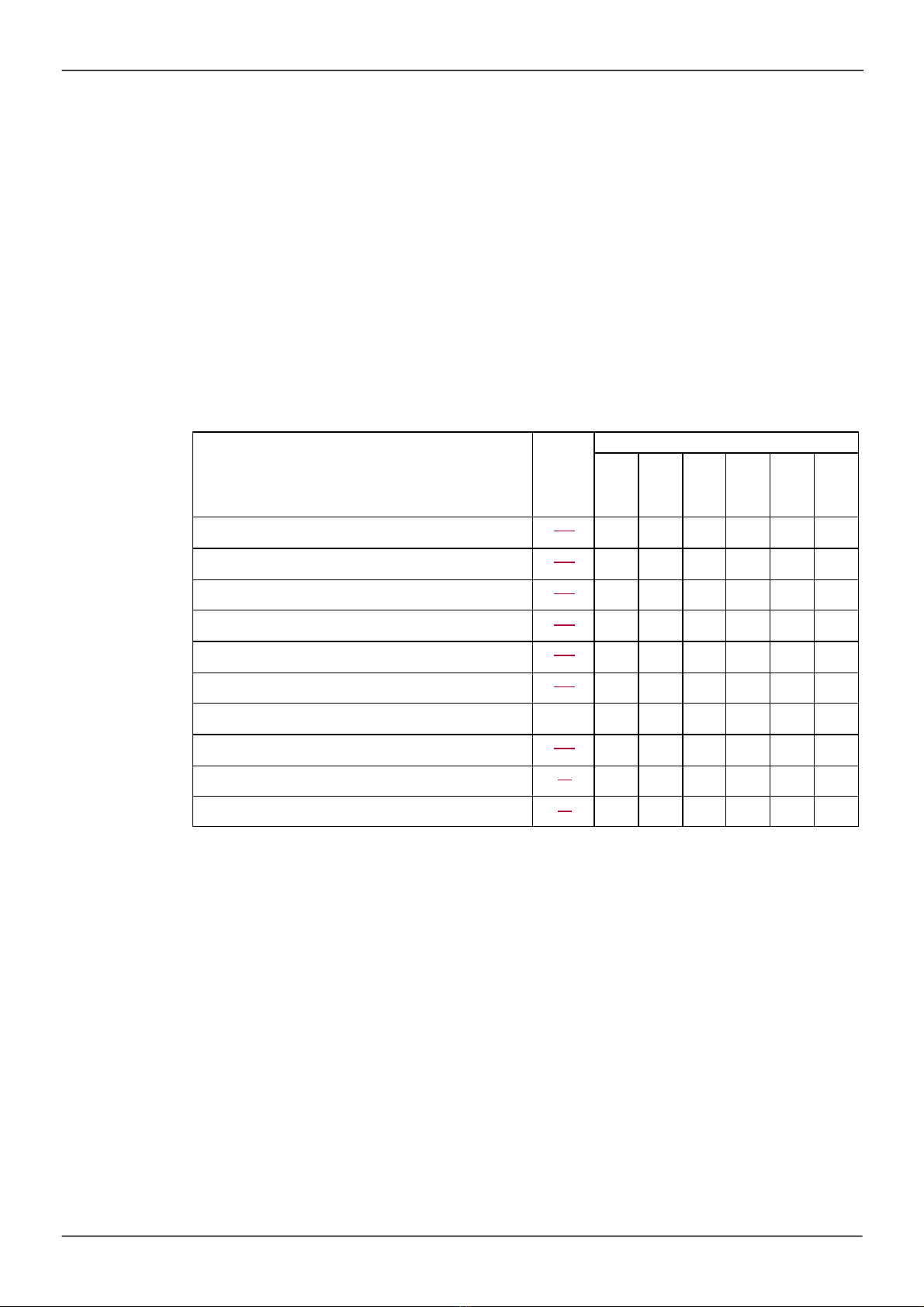

Motor control functions

Functions Page Applications

Hoist ing

Handlin g

Packin g

Textile s

Wood

Proce s s

V/f ratio 105

Sensorless flux vector control 105

2-point vector control 105

Open-loop synchronous motor 105

Output frequency up to 599 Hz 105

Motor overvoltage limiting 120

DC bus connection (see Installation manual)

-

Motor fluxing using a logic input 189

Sw itching frequency of up to 16 kHz 94

Auto-tuning 87

Overview

20

Functions on speed references

Functions Page Applications

Hoist ing

Handlin g

Packin g

Textile s

Wood

Proce s s

Differential bipolar reference 129

Reference delinearization (magnifying glass effect) 131

Frequency control input 154

Reference sw itching 167

Reference summing 168

Reference subtraction 168

Reference multiplication 168

Adjustable profile ramp 170

Jog operation 178

Preset speeds 180

+ speed / - speed using single action pushbuttons

(1 step)

184

+ speed / - speed using double action pushbuttons

(2 steps)

184

+/- speed around a reference 187

Save reference 188

Overview

21

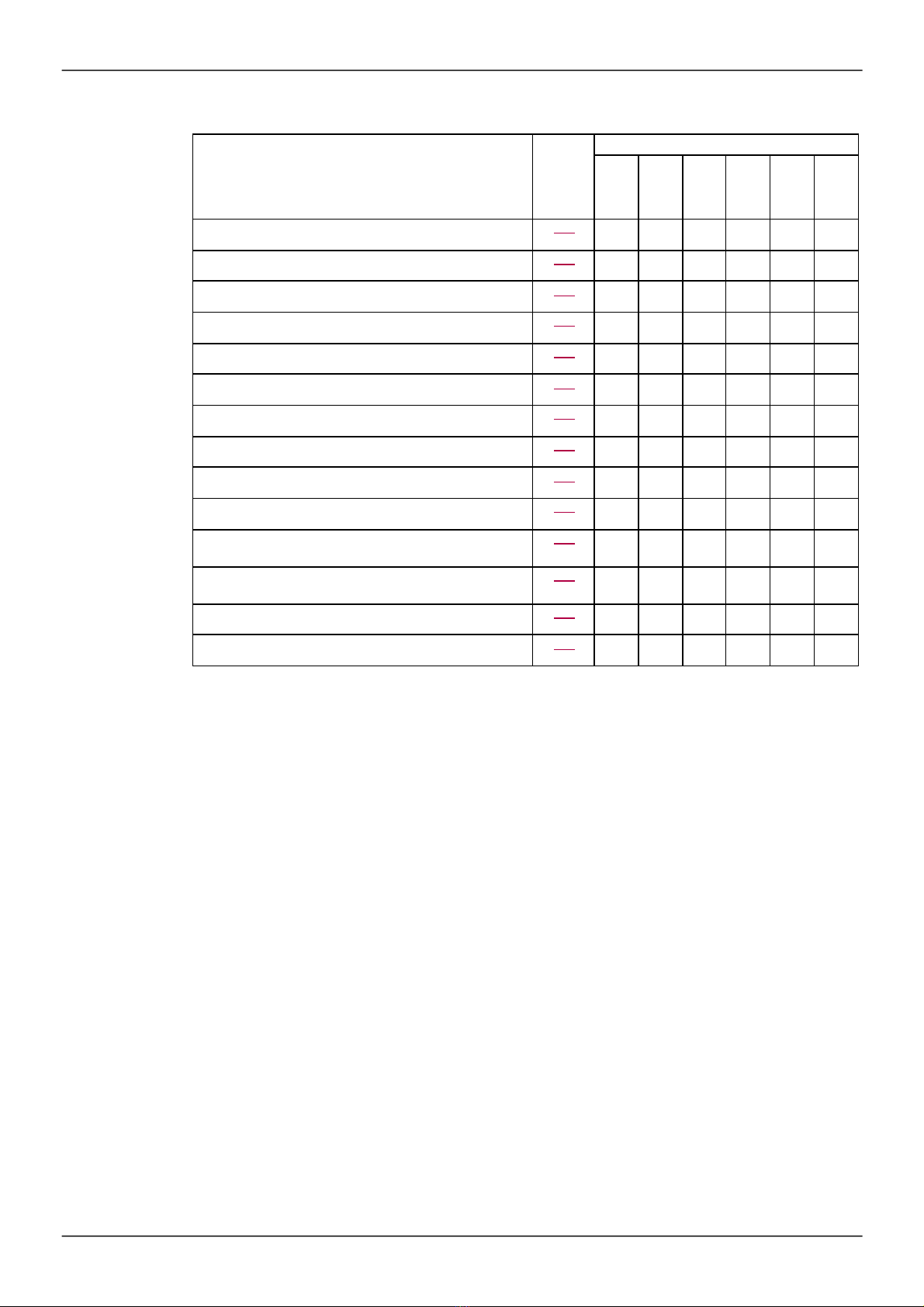

Application-Specific functions

Functions Page Applications

Hoist ing

Handlin g

Packin g

Textile s

Wood

Proce s s

Fast stop 173

Brake control 191

Load measurement 199

High-speed hoisting 201

Rope slack 204

PID regulator 206

Motor/generator torque limit 215

Load sharing 122

Line contactor control 220

Output contactor control 223

Positioning by limit sw itches or sensors 224

Stop at distance calculated after deceleration limit sw itch 226

Parameter sw itching 229

Motor or configuration switching 232

Traverse control 237

Stop configuration 173

Overview

22

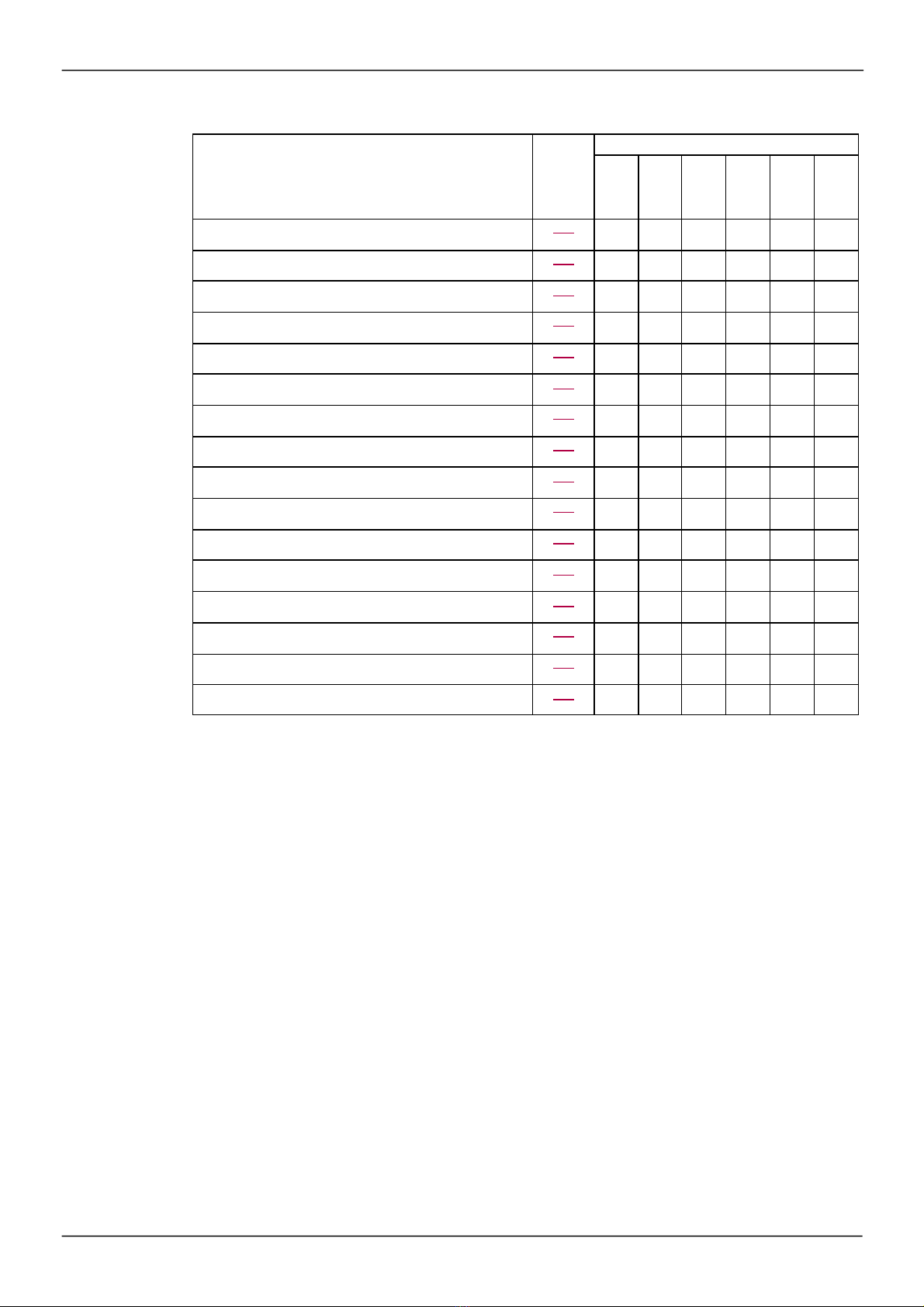

Safety functions/Fault management

Functions Page Applications

Hoist ing

Handlin g

Packin g

Textile s

Wood

Proce s s

Safe Torque Off (STO) (Safety function, see dedicated

document)

-

Deferred stop on thermal alarm 258

Alarm handling 145

Fault management 250

IGBT tests 260

Catch a spinning load 253

Motor protection w ith PTC probes 250

Undervoltage management 259

4-20 mA loss 260

Uncontrolled output cut (output phase loss) 256

Automatic restart 252

Use of the "Pulse input" input to measure the speed of

rotation of the motor

265

Load variation detection 267

Underload detection 270

Overload detection 272

Safety Integrated functions (see related documents page 12)

This manual suits for next models

12

Table of contents

Other BLEMO Inverter manuals