Blindleistungsregler BR 604 User manual

Power Factor Controller

BR 604

Manual

Version 3.0 E

Power Factor Controller

BR 604

21 3 4

Program Enter

Version 3.0 E; 2021

!

CAUTIONS:

1. High voltage !

2. BR604 may only be used indoor !

3. Make sure that discharge time set in controller

matches capacitor discharge time !

CONTENTS

Section 1 General 4

Section 2 Installation of the controller 6

2.1 Current measurement

2.2 Fault messages

Section 3 Operating modes and programming 8

3.1 Automatic operation / display functions

3.2 Programming

3.3 Programming lock 12

Section 4 Manual operation / Fixed stages 13

Section 5 Service menu 14

Section 6 Expert mode 14

Section 7 Initial operation 15

Section 8 Control principle 16

Section 9 Troubleshooting 17

Section 10 Maintenance and warranty 18

Section 11 Technical data 19

Annex: Annex 1 Table of phase-shifting 18

Annex 2 Table of control series 20

Annex 3 Default settings 21

Operating diagram (Brief programming) 22

- 3 -

Section1 General

BR 604 is distinguished by user-friendly operation based on menu-

guided displays in plain text. Its new features permit an intuitive mode

of operation. Easy-to-understand symbols and texts in the local

language combine simplest operability with self-evident displays.

The display of diverse line parameters as well as storage of various

values of the compensation network permit simple fault analysis and

system monitoring.

BR 604 contains a number of additional features:

þ4 switching outputs (depending on the version)

þ23 pre-programmed control series with a self-optimized

intelligent control response

þComplete menu-guided operation and display

þGraphic display with 2 x 16 characters

þFour-quadrant operation

þDisplay of various line parameters (V, I, Q, P, S...)

þStorage of maximum line-parameter

þManual / automatic operation

þProgramming of fixed stages and the option of skipping

individual outputs

þNo-voltage turn-off

þFault messages

þSwitchboard-integrated housing 100x100x40 mm

- 4 -

The controller is supplied for a voltage of 230 VAC (L-N), 50/60 Hz and

a measuring current of 5A or 1A (programmable). A voltage converter

is required for different operating voltages. Operating voltage =

measuring voltage !

Caution!

Voltages which exceed the allowed voltage range

can damage the device !

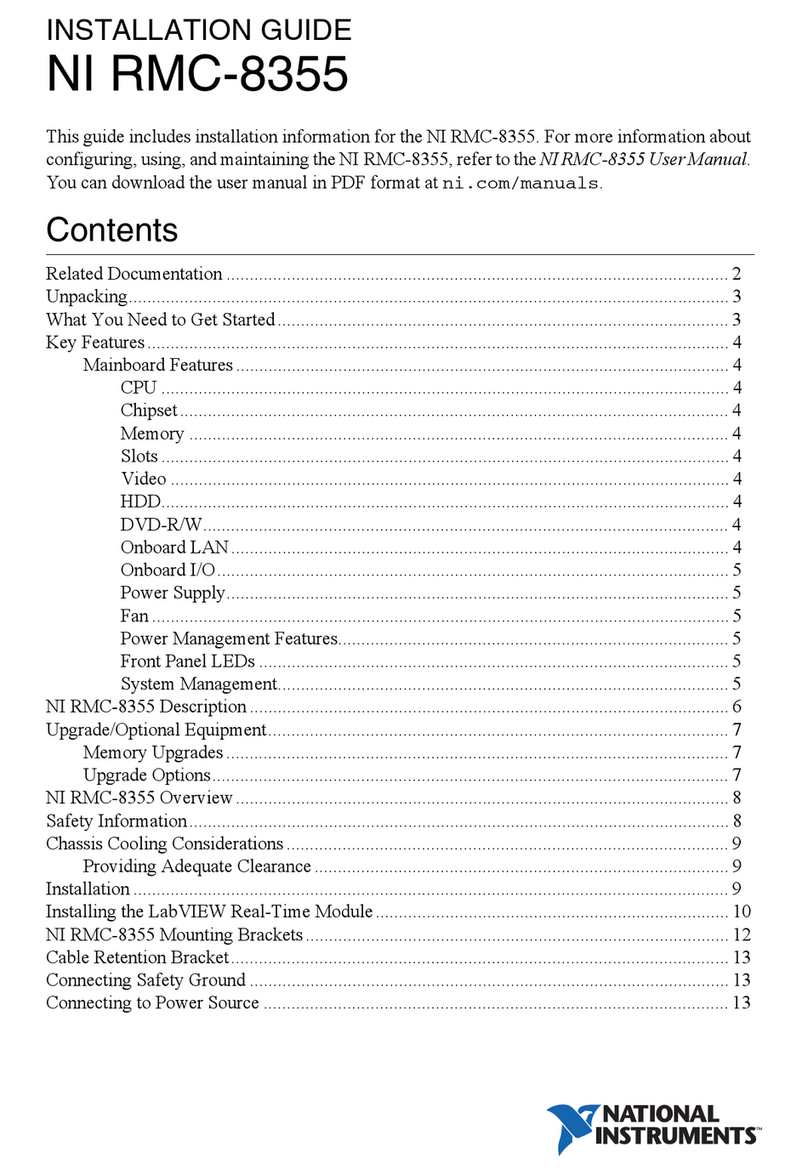

Fig. 1 BR 604 front view

Operating mode

- Automatic

- Programming

- Manual operation

- Service

- Expert mode

Increase

selected

parameter

Power Factor Controller

BR 604

21 3 4

Program Enter

Enter / ok

confirm and

store values

Reduce

selected

parameter

- 5 -

!

Section 2 Installation and connection of the controller

The BR 604 is designed to be incorporated into the front panel of a PFC-

cabinet. It requires a switchboard section of 92 x 92 mm to DIN 43 700.

The controller is inserted from the front and is attached by means

of the appended clamps.

Before the BR 604 is connected up, all leads and cables must be

checked to ensure that no current is flowing through them and the

current converter must be short-circuited. Care should be taken to

ensure that the measuring voltage and current are in the correct phase

position. The measuring-current circuit must be wired with copper

2

leads of 1.5mm . The connection should be set up as shown in Fig. 2.

The specified safety regulations must be observed.

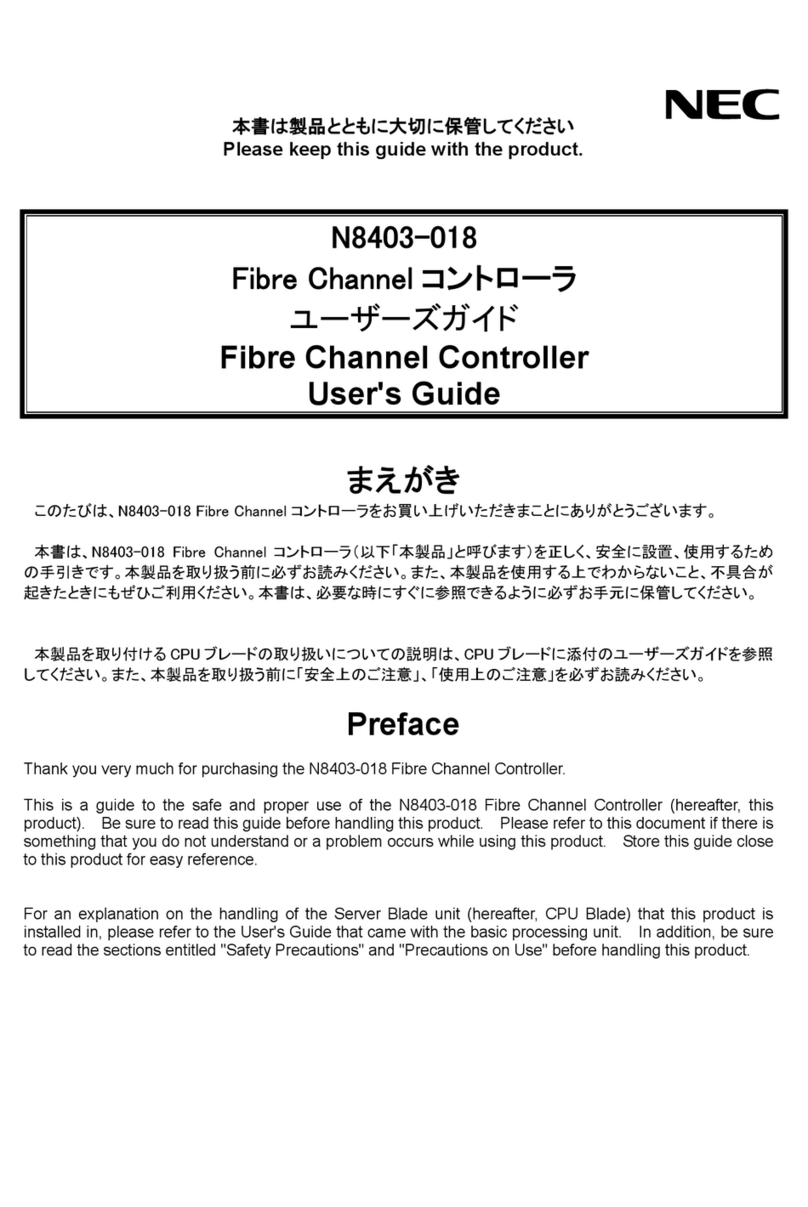

Fig. 2: BR 604 Connection plan

L1 (R)

L2 (S)

L3 (T)

N

meas.c u rrent

Im (5A/1 A )

1. capac i tor

branch

supply- a nd

meas. Voltage

Vb k l

1 2 3 4

Capacitor conta c t o rs 1-4

Po w er factor

controlle r B R 604

T 6,3 A

PE

K1

Vb Im

L N k l

- 6 -

2.1 Current measurement

When installing the current converter, care should be taken to ensure

that the load current flows through it. The outputs of the compensation

network must be installed behind the current converter (in the

direction of current flow). If the BR 604 is connected up via sum-

current converters, the overall conversion ratio is entered.

kK k K

lL l L

Feed 1 Feed 2

K L K L

Measurement via sum current converter

BR604

Current

measurement

k l

k l

- 7 -

Example:

C.converter 1: 1000/5A

C.converter 2: 1000/5A

Sum-current converter: 5A+5A/5A

C.converter ratio is: 2000/5A

2.2 Fault messages

The fault is shown on the display in plain text (alternating with the

standard display in automatic operation). The following fault messages

are displayed:

þUNDER-COMPENSATED

þOVER-COMPENSATED

þOVERCURRENT

þOVERVOLTAGE

þUNDERVOLTAGE

þ

Section 3 Operating modes and programming

When the operating voltage is switched on, the BR 604 briefly displays

its designation and software version, then changes to its normal

operating status (automatic operation). The active cos-phi value is

always displayed in the upper line and the currently connected

capacitors are shown as symbols in the lower line (operating display).

MEASURING CURRENT <

Automatic operation

Display of active power-line cos phi

Active capacitor

branches

Control direction

(here connected-in)

Supply display (for

4-quadrant operation)

The control direction is symbolized

by a closed arrow

The connecting-in arrow is always

located after the maximum possible

number of stages (end stop)

An open arrow indicates that the

required blocking time (discharge

time) is running before an impending

switching step

A double arrow symbolizes fast

switching of several branches

Connecting-in

Connecting-out

21 3 4 5 6 7 8 9

10

11

12

- 8 -

cos =0.98 IND

j

5s

3.1 Automatic operation - display functions

The BR 604 is set to automatic operation as standard. Capacitor stages

are then automatically connected in or out in order to reach the target

power factor. This happens when the required reactive power exceeds

the value of the smallest capacitor stage.

In automatic operation, various network parameters can be displayed

by repeatedly pressing the "ENTER” key:

Action Display

ENTER 1 LINE VOLTAGE in V

ENTER 2 APPARENT CURRENT in A

ENTER 3 REACTIVE POWER in kvar

ENTER 4 ACTIVE POWER in kW

ENTER 5 APPARENT POWER in kVA

ENTER 6 DIFF. kVAR TO TARGET COS

ENTER Software version

ENTER Return to: 1 LINE VOLTAGE

The power value specifies the total power (3-phase) assuming

symmetrical load. If no key is pressed for 60 seconds, the display

automatically returns to the operating status!

3.2 Programming

Pressing the "Operating mode” key once takes the user from automatic

operation to Programming mode. Parameter 1 ( I-CONVERTER) is

reached by pressing "ENTER”.

The upper display always shows the parameter and the lower one the

set value. The values are changed by pressing the é / ê keys.

Subsequent pressing of the "ENTER” key stores the value and takes the

user to the next parameter.

To quit programming mode in any step, press the "Operating mode”

key.

Repeated pressing of the "Operating Mode” key takes the user to the

various menus in sequence: Automatic operation - Programming -

Manual (manual operation)- Service - Expert mode and back.

- 9 -

0 LANGUAGE SELECTION: This selects the language of the

operating menu ( English, German, Spanish, Portuguese) )

1 I-CONVERTER PRIM: This selects the primary current of the

current converter. Adjustment is via the é / ê keys.

(5...7500A) Save and continue with ENTER

2 I-CONVERTER SEC: This sets the secondary current of the current

converter.(5A or 1A possible). Selection via é / ê. Save

and continue with ENTER

3 END STOPP: By setting the end stopp, the number of active

capacitor branches is matched to the respective

capacitor bank. This is done via the é / ê keys. The visible

symbols of the capacitors correspond to the connected

outputs. The setting is confirmed and saved with ENTER.

4 CONTROL SERIES: The ratio of the capacitor branch powers

determines the control series, the power of the first

capacitor always being assigned the value 1. The control

series required for the compensation network is again

selected via the é/ê keys. The selected series is entered

with the ENTER key, which also takes the user to the next

step.

5 CONTROL PRINCIPLE: Control preference may be selected here:

þSEQUENTIAL connection

þLOOP connection

þINTELLIGENT loop connection (default )

See Section 8 for an explanation of the various control

modes.

Selection with é / ê keys and confirmation with ENTER

leads to the next point:

6 POWER 1. STAGE: To determine the controller's response

sensitivity, the dimensions of the network's smallest

capacitor (stage 1) must be known. They are entered in two

steps in kvar. The integral kvar values (before the comma)

are initially selected via the é / ê keys and saved with

ENTER. The positions after the comma are then selected,

again via the é / ê keys. Saving with ENTER..

7 TARGET COS PHI: By setting the target cos phi, the power factor to

be attained via the PF correction is defined. It is also set via the é

/ ê keys. The range may be selected from 0.3 inductive to 0.3

capacitive. Confirming and saving the value with ENTER leads to

the next point.

8 CONNECTING TIME: This refers to the time between connecting

the capacitors to increase the momentary network capacitance. It

should be noted that in practical operation the real connection time

is affected by the discharge time (locking time).

Setting range: 1 ...255 sec.

Default setting: 40 sec.

Selection is performed via the é /ê keys. Continue with ENTER

9 DISCONNECTING TIME: This refers to the time between

disconnecting the capacitors to reduce the momentary network

capacitance.

Setting range: 1 ...255 sec.

Default setting: 40 sec.

Selection is performed via the é /ê keys. Continue with ENTER

10 DISCHARGE TIME: This is the time for which an individual output

is blocked between connecting and disconnecting. This blocking

time has priority over connecting and disconnecting times. It

depends on the capacitor discharge rating and thus is specified by

the compensation network. The discharge time of a conventional

network without additional fast-discharge resistors or chokes

should be set to no less than 40 seconds.

For setting of a second discharge time see 'Expert Mode' point 10

Setting range: 1 ...255 sec .

Default setting: 60 sec.

Selection is performed via the é /ê keys. Continue with ENTER

- 11 -

CONTRAST

The display contrast can be changed with this menu point.

The contrast depends to a certain degree on the

viewpoint of the observer, i.e. on the insertion height of the

equipment in the switching cabinet. The é /ê keys can be

used to set an optimal contrast. The contrast

changes after a slight delay.

BASIC SETTING: Selection YES / NO

When the selection is made with YES and confirmed with

ENTER, all parameters are reset to the basic setting made by

the PFC-system manufacturer.

(Optimal network values when the controller was supplied

with a complete PFC-system). If the controller is supplied

from the works, this point corresponds to the default setting.

CAUTION: All user settings are lost!

Programming is now completed. The controller has returned to point 1

of the programming menu.

3.3 Programming lock

The BR 604 is equipped with a programming lock to ensure protection

from unauthorized or inadvertent changes to the system parameters.

The lock can be activated in expert mode. If the lock is active, all

parameters can be checked but not changed.

- 12 -

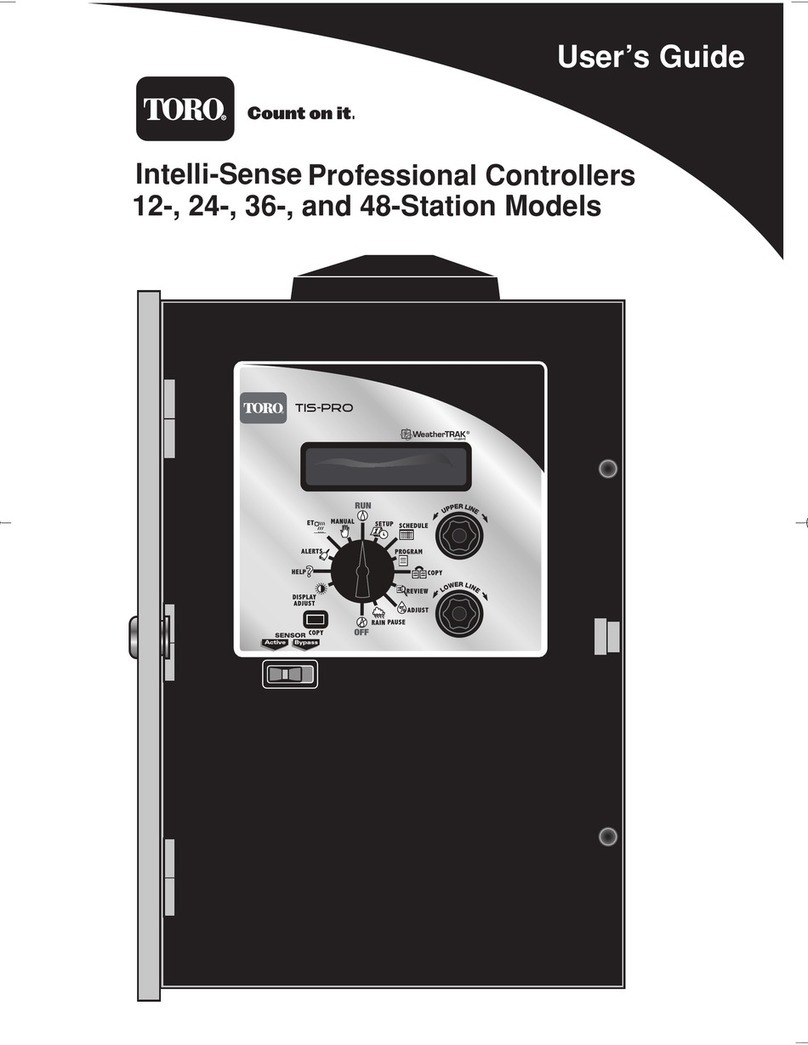

Section 4 Manual operation, Programming of fixed stages

I n m a n u a l o p e r a t i o n , c a p a c i t o r b r a n c h e s c a n b e

connected/disconnected in the set control series and switching

time - irrespective of prevailing power-line conditions. The starting

condition is STOPP (no stages connected). Connections are made by

pressing the é key. Pressing ê initially leads back to STOPP mode.

Repeated pressing of ê leads to the disconnection of stages. The

active operating status and active power factor are always shown on

the display (self-explanatory).

Pressing ENTER takes the user to the menu point "Programming of fixed

stages”. In the normal case, all stages are programmed for automatic

operation (default setting).

In special cases, controller outputs may be permanently defined in

succession (continued switching via ENTER) for the following statuses:

AUTO: Automatic (normal) operation. Output marked by a

capacitor symbol.

FIXED: The output is continuously connected, e.g. for fixed PFC.

The output is marked by an underlined capacitor symbol.

OFF: The output is continuously disconnected. The capacitor

symbol for this output is faded out. Underlining appears.

The active stage is marked by blinking. The required status is set via é

/ê. Save by pressing ENTER, and move to the next stage.

The programmed statuses for the outputs also remain visible on the

display in automatic operation.

After the required settings have been made, pressing the "Operating

Mode” key takes the user to the next menu ("Service”) or further to

"Automatic Operation”.

Currently selected stage blinks

Setting of fixed stages

Manual operation

- 13 -

1 2 3 4 5 6 7 8 9

10

11

12

STOPP C 0.98 CAP

1 2 3 4 5 6 7 8 9

10

11

12

C1: AUTO

Section 5 Service menu

The service menu is reached by the operating-mode key.

Action Display

ENTER 1 max. VOLTAGE in V

ENTER 2 max. REACTIVE POWER in kvar

ENTER 3 max. ACTIVE POWER in kW

ENTER 4 max. APPARENT POWER in kVA

Section 6 Expert mode

Expert mode is used to set values which remain unchanged for normal

operation. This level has an access code to protect it from improper

operation.

The stored maximum values of the network parameters can be

displayed here.

ENTER 5 max. Value RESET

ENTER Back to 1

1 PASSWORD 6343

2 BASIC SETTING NEW [NO]

(available: NO/YES)

Storage of active programming as a new basic setting (usually

performed by the PFC-system manufacturer). Caution: The

original values are overwritten in the process!

- 14 -

3

[L1] - L1 - N Adjustment of current phase

position

4 PHASE V [0°]

L1 - [L1 - N] Adjustment of voltage phase

position

Phase correction between voltage and current in the measuring

system. (see table 1 at page 18)

This setting allows to measure also in systems without neutral.

However, the measuring voltage may not exceed 300 V

(if necessary, a voltage converter must be used).

5 INTEGRATION TIME [1] s (1...255 sec.)

The integration time (the time required to form the mean values

of a measurement) can be changed for special applications.

6 TRIGGER VALUE [66] % (30...100 )

Threshold for switching on of next stage. It should not be changed

in the normal case!

7 SWITCHING POWER max [100] kvar

(multiples of the smallest stage)

This factor specifies the maximum power which may be switched in

one switching step. It can be used to control the intelligent control

system, which switches several stages as a function of the power-

factor requirement.

8 PROGRAM LOCK [NO] (NO / YES )

9 CONTROL [3] PHASE ( 3/1 )

PHASE I [0°]

Section 7 Initial operation

The controller must have been installed before being set up and

operated. All network-specific parameters are fully programmed as

described in Section 3.2 (Programming) by being entered in sequence

and stored. The controller is then set to automatic operation with the

operating mode key. It is now ready for operation.

- 15 -

Section 8 Control principle

The control response of the BR 604 can be selected in programming

mode. In principle, the controller has 3 different control modes:

1. Sequential connection

In sequential connection, the required capacitor stages are

successively connected and disconnected in stages (last in - first

out). The ranking of each step always corresponds to the power of

the smallest stage.

Advantage: Exact definition of the next capacitor to be

connected in each case

Disadvantage: Long settling time

In order to shorten the settling time, the BR 604 switches

several stages simultaneously for a large power-factor

requirement. This applies to all control types. The

maximum dimensions of the simultaneously switching

branches can be changed in expert mode.

2. Loop connection

In this variant, the controller operates in loop mode (first in - first

out) which minimizes the wear on the capacitor bank, i.e. where

stages are of equivalent dimensions, the stage which was

disconnected for the longest period of time is always connected

next.

Advantage: Balanced utilization of equivalent stages and thus an

increased operating life of the capacitor bank.

Disadvantage: This mode can only be used in control series with

groups of the same stage power.

3. Intelligent loop connection (default setting )

The intelligent control principle combines the advantages of the

network-sparing loop connection (first in - first out) with a much

faster settling time, even for large load skips, and reaches this

goal with the fewest possible switching operations of the capacitor

stages. The optimized time response is achieved by the

simultaneous switching of several or larger capacitor groups as a

function of the missing power factor in the power line. Both the

number of real switching frequencies of the capacitors as well as

the turn-on times of the branches are considered.

Advantage: Reaches the target cos phi in a fast-optimized

settling time with a low switching frequency of the capacitors.

- 16 -

At target cos phi=1 and inductive

load, switch-off or connection of

capacitor in the corrected line

Supply / Drawing mismatched

Wrong line cos phi is

Displayed

Display:"UNDER CURRENT”

Display: "OVERCURRENT”

Display: "UNDERCOMPENSATED”

Display: "OVERCOMPENSATED”

Stages are disconnected for an

inductive line or connected for a

capacitive line

The controller does not connect all

stages

In automatic operation, individual

stages are not connected or

disconnected

In strongly asymmetrically loaded

lines, differences may occur

between control response and

power-factor measurement, as the

power factor is measured in single

phase.

Check terminals of the measuring voltage

and current (l and k)!

Check phase position

Current in measuring range?

Line interruption?

Wrong current-converter factor?

Current transformer short-circuited?

Check current-converter ratio

Go through measuring current range

Check connection and phase position!

Compensation network sufficiently

dimensioned?

Check connection and phase position!

Capacitive grid, although all stages

disconnected

If a target cos phi is set which deviates

from 1 despite an inductive line load, the

display <- (disconnect stages) may light

up. The arrows indicate the control

direction and not the line conditions.

Check END STOPP!

Check whether individual stages are

programmed as fixed stages or OFF in the

"Manual operation / Fixed stages” menu!

Line measurements allow the most

favorable phase for measuring the power

factor to be determined. The current

converter is set accordingly for the

measuring current.

Section 9 Troubleshooting Check / Solution

- 17 -

- 18 -

Section 10 Maintenance and warranty

The BR 604 should need no maintenance if the operating conditions are

observed. However, it is recommended that a functional check of the

controller be performed in conjunction with the regular checking of the

capacitor bank. In the event of any interventions in the controller

during the warranty period, all warranty claims lapse.

Annex 1:

Phase correction between voltage and current in the measuring

system. ( compare with expert-mode: programming of phase shifting)

meas.current meas.voltage phase angle

L1 L1 - N --- 0°

L1 (k<->l) L3 - N --- 300°

L1 L2 - N --- 240°

L1 (k<->l) L1 - N --- 180°

L1 L3 - N --- 120°

L1 (k<->l) L2 - N --- 60°

Outputs

Switching power of relay

Number of outputs

Operation and display

No of control series

Control principle

Supply and

Measuring voltage

Measuring current

Power drawn

Sensitivity

Target cos phi

Connecting time

Disconnecting time

Discharge time

Fixed stages/ skipped stages

No-voltage trigger

Display of power-line

parameters

Storage of maximum values

Accuracy

Housing

Weight

Operating temperature

Protection type to DIN 40 050

Safety guidelines

Sensitivity to interference

4

250 VAC, 1000 W

Programmable

Graphic display 2 x 16 characters with

convenient operating level

23

Sequential connection, loop

connection,self-optimized switching

response, Four-quadrant operation

230 VAC, 50 / 60Hz ( L-N )

Phase - shift possible

X : 5 / 1A selectable

< 5 VA

40 mA / 10 mA

0.3 inductive to 0.3 capacitive

Selectable from 1 ...255 sec.

Selectable from 1 ...255 sec.

Selectable from 1 ...255 sec.

Programmable

Standard

Power factor, V, I, Q, P, S …

Voltage, reactive power, active power,

apparent power

Current / voltage: 1%

Power: 2%

Switchboard-integrated housing

DIN 43 700, 100 x 100 x 40 mm

0.5 kg

-10 to +60°C

Front: IP 54, Rear: IP 20

IEC 61010-1:2001

EN 50082-1

IEC 61000-4-2: 8kV

IEC 61000-4-4: 4kV

Section 11 Technical data

- 19 -

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Control series

1 : 1 : 1 : 1

1 : 2 : 2 : 2

1 : 2 : 2 : 3

1 : 2 : 2 : 4

1 : 2 : 2 : 5

1 : 2 : 2 : 6

1 : 2 : 3 : 3

1 : 2 : 3 : 4

1 : 2 : 3 : 5

1 : 2 : 3 : 6

1 : 2 : 3 : 7

1 : 2 : 4 : 4

1 : 2 : 4 : 5

1 : 2 : 4 : 6

1 : 2 : 4 : 7

1 : 2 : 4 : 8

1 : 1 : 2 : 2

1 : 1 : 2 : 3

1 : 1 : 2 : 4

1 : 1 : 2 : 5

1 : 1 : 1 : 2

1 : 1 : 1 : 3

1 : 1 : 1 : 4

Loop

connection

Possible

Possible

Possible

Possible

Possible

Possible

Possible

Possible

Possible

Possible

Possible

Possible

Possible

Possible

Possible

Possible

Possible

Possible

Possible

Possible

Possible

Possible

Possible

- 20 -

Annex 2: Table of control series

Table of contents

Popular Controllers manuals by other brands

Belimo

Belimo PRCA-S2-T Technical data sheet

Avigilon

Avigilon AC-HID-LSP-ACMEC-KIT4 installation guide

HighPoint

HighPoint RocketRAID 3G mini-SAS HBA Series installation guide

Technische Alternative

Technische Alternative UVR1611K-N-D Operation,programming and installation instructions

RKC INSTRUMENT

RKC INSTRUMENT PF900 Quick operation manual

Axis

Axis A1610 user manual