Blue Diamond Mini Skid Steer 2 Series User manual

Operation and Maintenance Manual

Mini Skid Steer

Series 2 Brush Cutter

888-376-7027 | BlueDiamondAttachments.com

Register your

WARRANTY

within 30 days

of purchase

Blue Diamond® Attachments2

Thank you for your decision to purchase a Blue Dia-

mond® Mini Skid Steer Series 2 Brush Cutter To ensure

maximum performance of your equipment, it is manda-

tory that you thoroughly study the Operator’s manual

and follow the recommendations. Proper operation and

maintenance are essential to maximize equipment life

and prevent personal injury.

Operate and maintain this equipment in a safe man-

ner and in accordance with all applicable local, state,

and federal codes, regulations and /or laws. Follow all

on-product labeling and instructions.

Make sure that all personnel have read this Operator’s

Manual and thoroughly understand safe and correct

operating, installation and maintenance procedures.

Blue Diamond is continually working to improve its

products. Blue Diamond reserves the right to make any

improvements or changes as deemed practical and pos-

sible without incurring any responsibility or obligation

to make any changes or additions to equipment sold

previously.

Although great care has been taken to ensure the

accuracy of this publication, Blue Diamond makes no

warranty or guarantee of any kind, written or expressed,

implied or otherwise with regard to the information

contained within this manual. Blue Diamond assumes

no responsibility for any errors that may appear in this

manual and shall not be liable under any circumstances

for incidental, consequential or punitive damages in con-

nection with, or arising from the use of this manual.

Keep this manual available for frequent reference. All

new operators or owners must review the manual before

using the equipment and annually thereafter. Contact

your Blue Diamond Attachments Dealer for assistance,

information, or additional copies of the manual. Contact

www.bluediamondattachments.com or call 888-376-

7027 for a complete list of dealers in your area.

Serial Number Location:

Please record attachment information in the space pro-

vided for future reference.

Model Number:_____________________________

Serial Number: _____________________________

Dealer Name: ______________________________

Dealer Number:_____________________________

Date of Purchase:___________________________

The serial number plate is located on the deck brace.

Always use your serial number when requesting infor-

mation or when ordering parts.

NOTE: The directions left, right, front and rear, as

mentioned throughout this manual, are as viewed from

the operator’s position.

Introduction: Owner Information

Revision Date: 11.27.2023

3Blue Diamond® Attachments

Table of Contents

1. Introduction......................................................................................4

1.1 Attachment Identification.........................................................4

1.2 Attachment Model Numbers..................................................4

2. Safety ...........................................................................................5-8

2.1 General Safety Information.................................................... 5

2.2 Operators.................................................................................. 6

2.3 Safety Guidelines.....................................................................7

3. Operation .................................................................................. 9-15

3.1 Attachment Inspection Guidelines ....................................... 9

3.2 Entering & Exiting the Prime Mover....................................11

3.3 Attachment Installation..........................................................11

3.4 Operating the Attachment ................................................... 13

4. Maintenance ...........................................................................16-20

4.1 Service Schedule ....................................................................16

4.2 Drive Assembly ...................................................................... 17

4.3 Blade Assembly...................................................................... 18

4.4 Cleaning the Attachment .....................................................18

4.5 Troubleshooting .....................................................................19

5. Parts.........................................................................................20-26

5.1 Parts Breakdown ....................................................................20

5.2 Mount Options.......................................................................22

5.3 Hose Set ................................................................................. 23

5.4 Drive Assembly ..................................................................... 24

5.5 Blade Carrier..........................................................................25

5.6 Decal Identification & Location..........................................26

6. Specifications ........................................................................27-28

6.1 Attachment Specifications ................................................... 27

6.2 Torque Specifications ..........................................................28

7. Warranty ........................................................................................29

Blue Diamond® Attachments4

1. Introduction

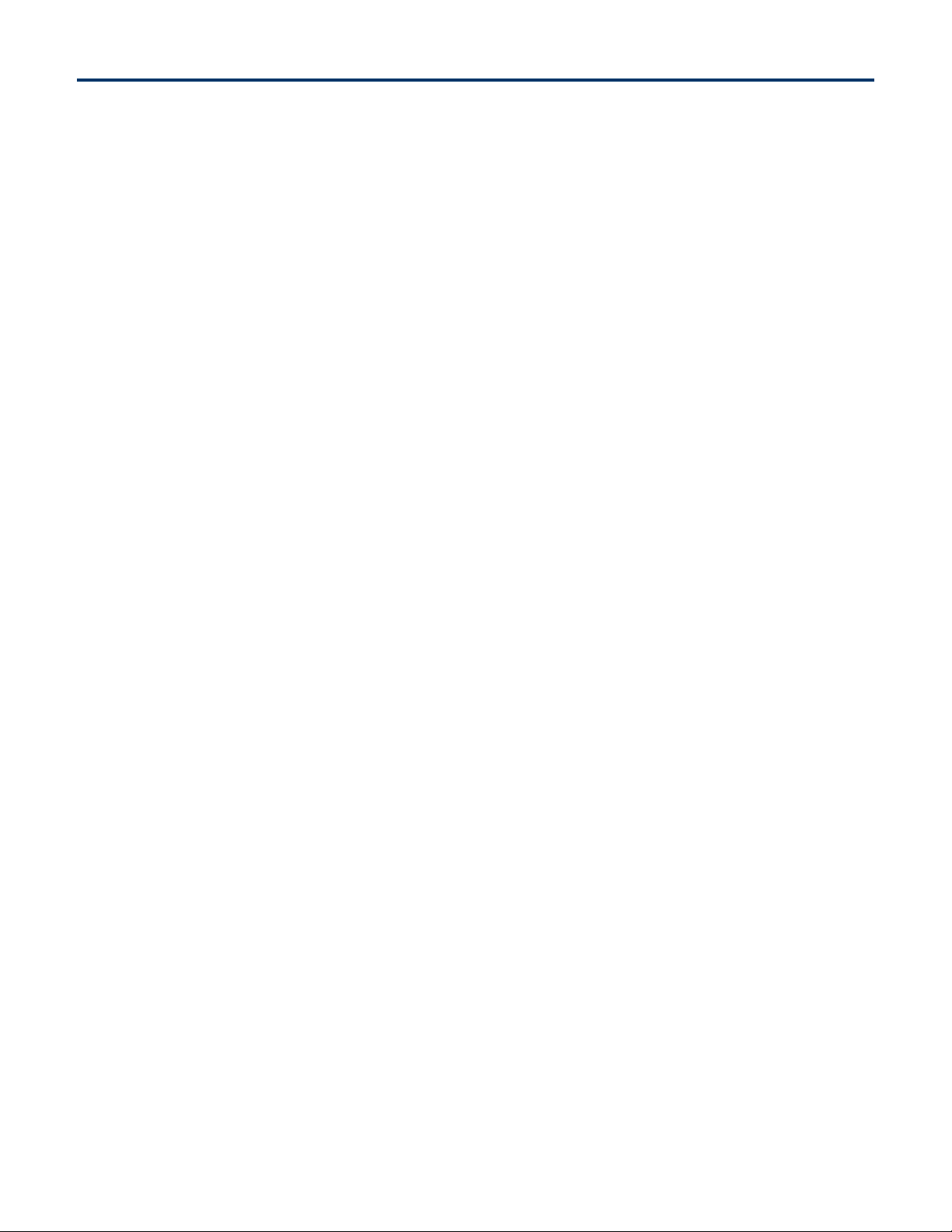

1.1 Attachment Identification

H M

C

M S 2 B C M M N

W F F

36” closed 9 – 20

GPM

Mini Universal 303716-25

Bobcat MT compatible 303716-26

Avant compatible 303716-35

42”

open 12 – 20

GPM

Mini Universal 303728-25

Bobcat MT compatible 303728-26

Avant compatible 303728-35

closed 12 – 20

GPM

Mini Universal 303722-25

Bobcat MT compatible 303722-26

Avant compatible 303722-35

50” closed 10 – 20

GPM

Mini Universal 303731-25

Bobcat MT compatible 303731-26

Avant compatible 303731-35

M

P

S P

C C

(closed front only)

H S

1.2 Attachment Model Numbers

5Blue Diamond® Attachments

2.1 General Safety Information Operating Safety

• Read and follow instructions in this manual

and the machine’s Operators Manual before

operating.

• The manual must always remain with the

machine. In case of loss or damage, request

a new copy from your dealer or from Blue

Diamond.

• Strictly follow all rules prescribed by the safety

pictograms/decals applied to the machine.

Ensure that all safety pictograms/decals are

legible. If pictograms/decals are worn, they

must be replaced with new ones obtained

from Blue Diamond and placed in the position

indicated by this manual.

• Before using the machine, make sure that

all safety devices are installed and in good

working conditions. In case of damage or

shields, replace them immediately.

• It is absolutely forbidden to remove or alter

safety devices and/or safety precautions

• Pay maximum attention to avoid any accidental

contact with rotating parts of the machine.

• If the use of the machine is required at night

or in conditions of reduced visibility, use

the lighting system of the prime mover and

possibly an auxiliary lighting system.

2. Safety

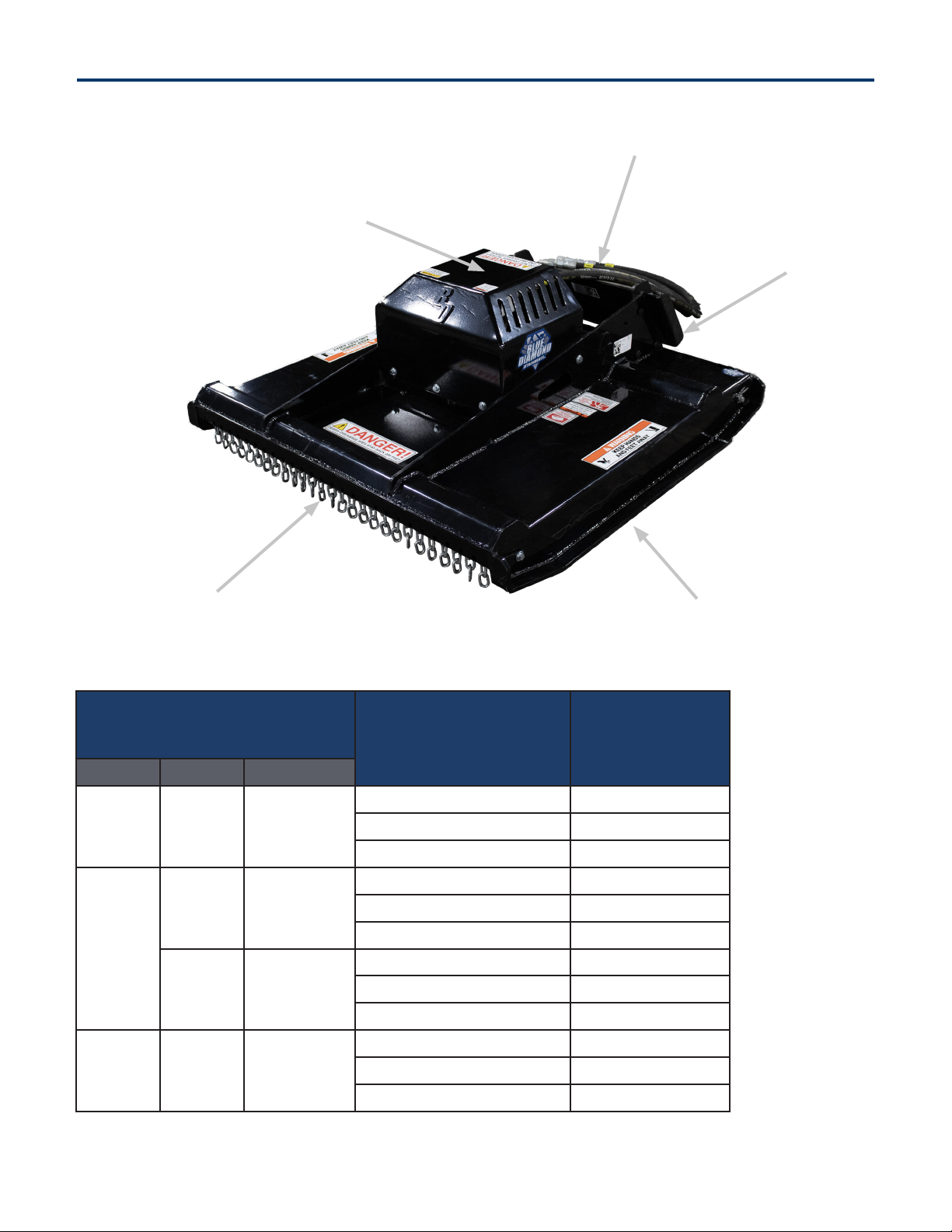

CAUTION

The signal word CAUTION on the machine and

in the manuals indicates a potentially hazardous

situation which, if not avoided, may result in minor

or moderate injury. It may also be used to alert

against unsafe practices.

WARNING

The signal word WARNING on the machine and

in the manuals indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

DANGER

The signal word DANGER on the machine and

in the manuals indicates a hazardous situation

which, if not avoided, will result in death or serious

injury.

SAFETY ALERT SYMBOL

This SAFETY ALERT SYMBOL identifies important

safety messages on the equipment and in the

owner’s manual. When you see this symbol, be

alert to the possibility of personal injury and

carefully read the message that follows.

IMPORTANT

The signal word IMPORTANT identifies

procedures which must be followed to avoid

damage to the machine.

Blue Diamond® Attachments6

2.2 Operators

Qualified Operators

The operator is a person suited to the work and

who is physically and psychologically able to

withstand the demands connected with operating

the equipment for its intended use. The operator

must not allow anyone to approach the machine

while it is working and must not allow external

personnel to operate the machine or attachment.

He is to follow the given instructions in this

manual and the machine operator’s manual in

order to obtain maximum performance, minimum

consumption, and maximum safety for himself and

for others.

The operator is responsible for scrupulously

observing all the instructions given in this manual.

Operator Training

• Check the rules and regulations at your

location. The rules may include an employer’s

work safety requirements. Regulations may

apply to local driving requirements or use

of a Slow Moving Vehicle (SMV) emblem.

Regulations may identify a hazard such as a

utility line.

• The new operator must start in an area without

bystanders and use all the controls until he or

she can operate the machine safely under all

conditions of the work area.

Operator Safety

• Before starting, and during operation of the

attachment, make sure there are no people

or animals in the operation area; the machine

can project material from the back with risks of

serious injury or death.

• During operation, adjustment, maintenance,

repairing, or transportation of the machine, the

operator must always use appropriate Personal

Protective Equipment (PPE) including but not

limited to safety glasses, working gloves, dust-

mask, safety helmet, and hearing protection.

• Do not operate the attachment or machine

while wearing loose fitting clothing that can be

entangled or caught in parts of the machine.

• Do not operate the implement when tired, not

in good condition, or under the influence of

alcohol or drugs.

2. Safety

AVOID SERIOUS INJURY OR DEATH

Operators must receive instructions before

operating the machine. Untrained operators can

cause serious injury or death.

For an operator to be qualified, he or she must

not use drugs or alcoholic drinks which impair

alertness or coordination while working. An

operator who is taking prescription drugs must

get medical advice to determine if he or she can

safely operate a machine and the equipment.

For an operator to be qualified, he or she must

have read and understood the instructions of this

manual, he or she must make adequate preparation

for the proper use of the machine, and he or she

must hold a driving license.

In case of doubt regarding the use of the machine

and/or the interpretation of this manual, the operator

must contact either their dealer or Blue Diamond.

DANGER

7Blue Diamond® Attachments

2.3 Safety Guidelines

Operating Safety

• Read and follow instructions in this manual

and the machine’s Operator’s Manual before

operating.

• Under no circumstances should young children

be allowed to work with this equipment.

• This equipment is dangerous to persons

unfamiliar with its operation.

• Check for overhead and / or underground lines

before operating equipment (if applicable).

• In addition to the design and configuration

of equipment, hazard control and accident

prevention are dependent upon the

awareness, concern, prudence and proper

training of personnel involved in the operation,

transport, maintenance and storage of

equipment.

• Check that the attachment is securely fastened

to the machine.

• Make sure all the machine controls are in the

NEUTRAL before starting the machine.

• Operate the equipment only from the

operator’s position.

• Operate the equipment according to the

Operator’s Manual.

• When learning to operate the equipment, do it

at a slow rate in an area clear of bystanders.

• DO NOT permit personnel to be in the work

area when operating the equipment.

• The equipment must be used ONLY on

approved machines.

• DO NOT modify the equipment in any way.

Unauthorized modification may impair the

function and / or safety and could aect the life

of the equipment.

• DO NOT make any adjustments or repairs on

the equipment while the machine is running.

• Keep shields and guards in place. Replace if

damaged.

• DO NOT operate equipment in poor visibility

conditions such as fog, darkness, or any

conditions that limit clear visibility less than

300 feet (100 m) in front of and to the sides of

the equipment.

• When conditions make it necessary to slow

ground speed, shift to a lower gear rather

than reducing engine speed. The engine will

maintain rated speed and keep cutter running

at optimum cutting speed.

• DO NOT operate in a work area that has

not been inspected for foreign debris and

obstacles.

• Remove any foreign objects and clearly mark

any objects that cannot be removed.

• Wear face shield, hard hat, gloves, hearing

protection, and other protective clothing when

required.

2. Safety

Blue Diamond® Attachments8

Machine Requirements and Capabilities

• The machine’s operator’s cab should be

equipped with a thermoplastic polycarbonate

or similar material front window, and similar

protection on the sides of the operator’s cab

before operating the equipment.

• Keep bystanders clear of moving parts and the

work area. Keep children away.

• Do Not exceed 3000 continuous PSI (206 bar)

operating pressure.

• Use caution on slopes and near banks and

ditches to prevent overturn.

Fire Prevention Safety

• Flammable debris (leaves, grass, etc.) must

be removed regularly. If flammable debris

is allowed to accumulate, it can cause a fire

hazard. Clean often to avoid this accumulation.

• The equipment’s hydraulic motor compartment

must be inspected every day and cleaned

if necessary to prevent fire hazards and

overheating.

• All fuels, most lubricants, and some coolant

mixtures are flammable. Flammable fluids that

are leaking or spilled onto hot surfaces or onto

electrical components can cause a fire.

Transporting Safety

• Comply with state and local laws governing

highway safety and movement of machinery on

public roads.

• Check local laws for all highway lighting and

marking requirements.

• Always yield to oncoming trac and move to

the side of the road so any following trac may

pass.

• Never allow riders on either machine or

equipment.

• If transporting the equipment on a truck or

trailer, make sure the equipment is properly

secured to the transport vehicle.

Hydraulic System

• Check hydraulic tubes, hoses and fittings for

damage and leakage. Never use open flame

or bare skin to check for leaks. Hydraulic tubes

and hoses must be properly routed and have

adequate support and secure clamps. Tighten

or replace any parts that show leakage.

• Always clean fluid spills. Do not use gasoline or

diesel fuel for cleaning parts. Use commercial

nonflammable solvents.

Personal Protective Equipment

2. Safety

Proper Work clothes: To help ensure your

safety as a designated operator wear

proper work clothes including tight fitting

clothes, protective gloves and shoes.

Safety Helmet: To help ensure your

safety as a designated operator wear

a safety helmet.

Protective Shoes: To help ensure your

safety as a designated operator wear

protective shoes.

Hand Protection: To help ensure your

safety as a designated operator wear

protective gloves.

Eye/Ear Protection: To help ensure your

safety as a designated operator wear a

safety helmet and eye/ear protection.

9Blue Diamond® Attachments

3.1 Attachment Inspection

Guidelines

Pre-Operation Inspection

Before operating the Mini Series 2 Brush Cutter

for the first time and each time thereafter, use

the following list as a guideline during equipment

inspection.

• Fully clean the attachment. See section 4.4

“Cleaning the Attachment” on page 18.

• Lubricate the attachment per the schedule

outline in the Maintenance Section. See

section 4.1 “Service Schedule” on page 16.

• Check the brush cutter mounting plate for

damage. Check for loose or missing parts.

Repair as needed before operation.

• Check that blades are in good condition.

Sharpen or replace them, if necessary.

• Check that all shields and guards are in place.

• Check for loose bolts and tighten them if

necessary.

• Check all welds on the attachment for wear

and damage each time the attachment is

removed from this machine.

• Check for damaged or missing safety decals.

Replace if necessary.

• Inspect the machine’s mounting frame. (See

the machine’s Operator’s Manual for inspecting

the mounting frame). Replace any parts

that are damaged, bent or missing. Keep all

fasteners tight. Look for cracked welds.

• Check condition of all hydraulic components

for leaks. Repair as required.

NOTE: Do not operate with hydraulic leaks.

• Verify that the brush cutter is properly

connected to the machine.

3. Operation

WARNING

AVOID SERIOUS INJURY OR DEATH

• Disengage machine’s auxiliary hydraulics,

engage the machine’s parking brake, stop the

engine and make sure all rotating components

are completely stopped before connecting,

disconnecting, adjusting, or cleaning

equipment.

• Always keep shields and all guards in place

when using the equipment.

• Disengage machine’s auxiliary hydraulics for

road travel.

• Keep hands, feet, and clothing away from

rotating parts.

WARNING

Leaking fluids under pressure can enter the skin

and cause serious injury or death. Immediate

medical attention is required.

Wear goggles. Use cardboard to check for leaks.

Blue Diamond® Attachments10

3.1 Attachment Inspection

Guidelines Cont’d

Daily Inspection

NOTE: Inspect the attachment by performing a

walk around daily before and after use. Use the

following inspection checklist as a guideline.

Check the following items every 10 hours of

operation:

• Verify that the brush cutter is properly

connected to the machine.

• Check that all shields and guards are in place.

• Check hydraulic lines, connections, and

fittings for hydraulic oil leaks. Repair or replace

damaged parts if necessary.

• Check the brush cutter mounting hardware for

wear or damage. Inspect the pins and mount

(on the attachment) for wear or damage. Repair

or replace damaged parts if necessary.

Weekly Inspection

Check the following items every 40 hours of

operation:

• Check blade bolts for correct torque 1440 ft/lb

(1952 N•m).

• Check all bolts for tightness (see Section 6.2

“Torque Specifications” on page 28).

• Inspect the deck for cracks, bends, or damage.

Monthly Inspection

• Inspect the blades for cracks, bends, or

excessive wear.

• Check the skid plates for wear.

• Check that all bolts are tight.

• Check blades and mounting plate for cracks or

damage. Replace if necessary.

• Check blade mounting hardware for correct

torque 1440 ft/lb (1952 N•m). Check mounting

plate hardware.

• Check deck, shields, and guards. Repair if

damaged or replace if necessary.

• Check for damaged or missing decals. Replace

if necessary.

• Check for damaged or leaking hydraulic hoses

or fittings. Replace if necessary.

• Clean all debris, leaves, grass, and flammable

material from deck area and under covers.

• Lubricate as required.

3. Operation

WARNING

AVOID SERIOUS INJURY OR DEATH

• Always park on a flat level surface.

• Lower and place attachment flat on the ground.

• Place all controls in NEUTRAL.

• Engage the park brake.

• Stop the engine and remove the key.

• Wait for all moving parts to stop.

SEE MACHINE’S OPERATOR’S MANUAL FOR

ADDITIONAL INFORMATION.

11Blue Diamond® Attachments

3.2 Entering & Exiting the

Prime Mover

Entering the Operator’s Position

When in the operator’s position, start the engine

and release the parking brake.

See the mini skid steer operator’s manual to

correctly operate the machine.

Leaving the Operator’s Position

Park the machine/attachment on a flat level

surface.

Place all controls in neutral, engage the park

brake, stop the engine and wait for all moving

parts to stop. Leave the operator’s position.

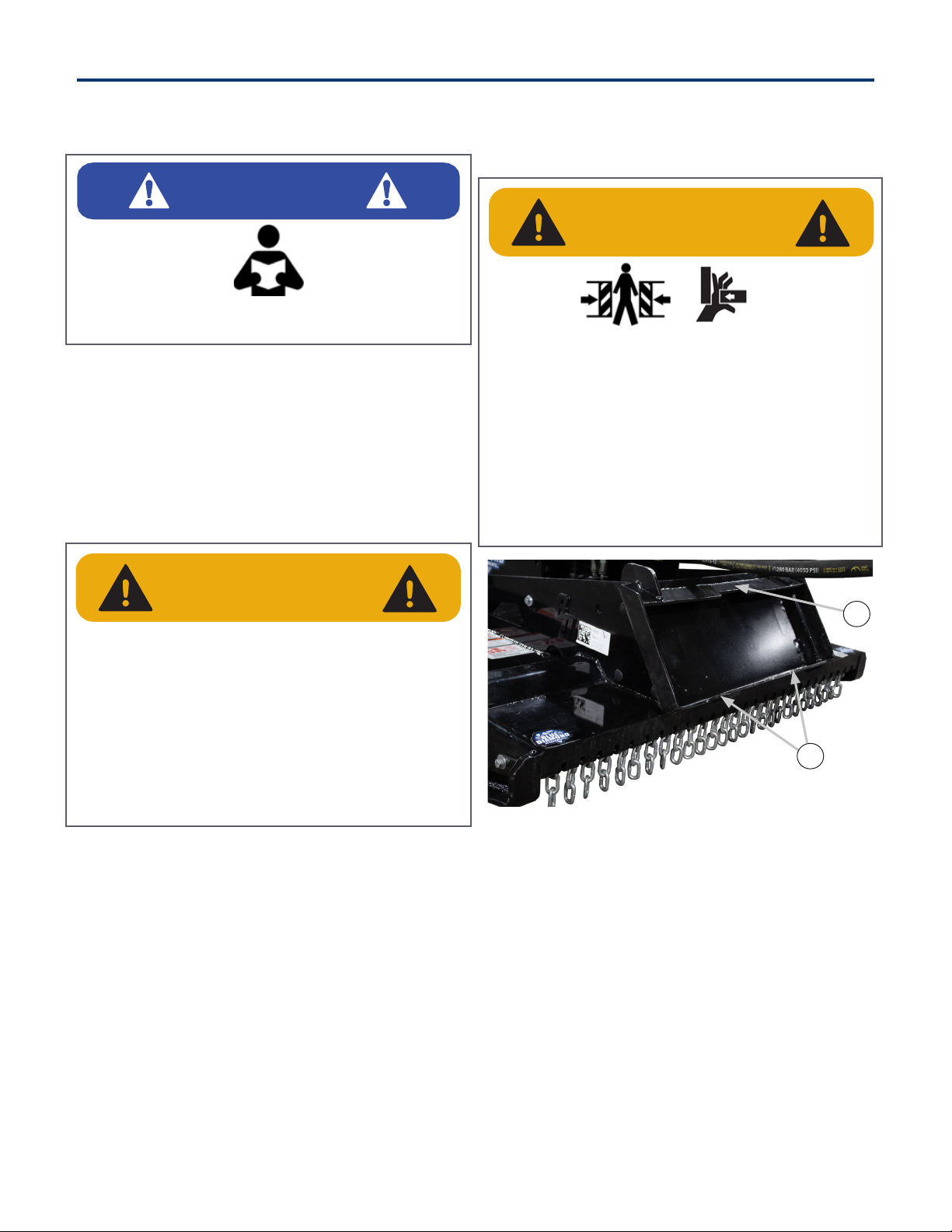

3.3 Attachment Installation

Connecting Attachment To The Machine

Figure 1

Inspect the brush cutter’s mounting flange (Item 1),

wedge mounts (Item 2) [Figure 1], mount hardware,

and all welds for wear or damage each time the

brush cutter is removed from the machine.

Before connecting to the attachment, inspect the

machine’s mounting plate. (See the machine’s

Operator’s Manual for inspecting the mounting

frame).

3. Operation

IMPORTANT

See the machine’s Operator’s Manual for detailed

information on operating the loader.

WARNING

CRUSH HAZARD

• Before moving the machine, look in all

directions and make sure no bystanders,

especially small children are in the work area.

• Do not allow anyone between the machine

and attachment when approaching the

attachment for connecting.

• Keep fingers and hands out of pinch points

when connecting and disconnecting the

attachment.

WARNING

AVOID SERIOUS INJURY OR DEATH

• Always park on a flat level surface.

• Lower and place attachment flat on the ground.

• Place all controls in NEUTRAL.

• Engage the park brake.

• Stop the engine and remove the key.

• Wait for all moving parts to stop.

SEE MACHINE’S OPERATOR’S MANUAL FOR

ADDITIONAL INFORMATION.

2

1

Blue Diamond® Attachments12

3.3 Attachment Installation

Cont’d

Connecting Attachment to the Machine

Cont’d

Enter the operator’s position. See “Entering the

Operator’s Position” on page 11.

Drive the machine slowly forward, until the top

edge of the machine’s mounting plate is under the

top flange of the attachment mounting frame.

Slowly tilt the machine’s mounting plate back until

the attachment mounting frame fully contacts the

front of the machine’s mounting plate.

Leave the operator’s position. See “Leaving the

Operator’s Position” on page 11.

Engage attachment locking levers / wedges (See

the machine’s Operator’s Manual for detailed

information).

Connecting Hydraulic Hoses

Remove dirt or debris from the male and female

couplers. Visually inspect the couplers for

corroding, cracking, damage, or excessive wear.

Replace as needed.

Connect the attachment hydraulic hoses to the

machine. Pull on each hose to verify the full

connection is made.

Disconnecting Hydraulic Hoses

Relieve auxiliary hydraulic pressure. (See

the machine’s Operator’s Manual for correct

procedure.)

Disconnect attachment hydraulic hoses from the

machine.

Disconnecting Attachment From the

Machine

Relieve auxiliary hydraulic pressure. (See

the machine’s Operator’s Manual for correct

procedure.)

Park the machine and attachment on a flat level

surface. Lower the attachment flat on the ground.

Leave the operator’s position. See “Leaving the

Operator’s Position” on page 11.

Disconnect attachment hydraulic hoses from the

machine.

Disengage locking pins / wedges. (See the

machine’s Operator’s Manual for correct

procedure.)

Enter the operator’s position. See “Entering the

Operator’s Position” on page 11.

Slowly tilt the machine’s mounting plate forward

until the attachment mounting frame is free from

the machine’s mounting plate.

Drive the machine slowly backward, away from the

attachment.

3. Operation

WARNING

AVOID SERIOUS INJURY OR DEATH

The locking pins / wedges must extend through

the holes in the attachment mounting frame.

Failure to secure locking pins / wedges can allow

attachment to come o.

SEE MACHINE’S OPERATOR’S MANUAL FOR

ADDITIONAL INFORMATION.

IMPORTANT

Throughly clean the quick couplers before

making connections. Dirt can quickly damage the

hydraulic system.

WARNING

AVOID SERIOUS INJURY OR DEATH

Hydraulic fluid, tubes, fittings, and quick couplers

can get hot during operation. Be careful when

connecting and disconnecting hydraulic hoses.

13Blue Diamond® Attachments

WARNING

THROWN OBJECTS OR ROTATING BLADES CAN

CAUSE SERIOUS INJURY OR DEATH

• Clear work area of all debris, such as rope,

wire, cable or other materials that can wrap

around blade carrier and blades, causing

entanglement and attachment damage.

• DO NOT operate brush cutter in vicinity of

bystanders, animals, or damageable property.

Objects can be thrown more than several

hundred feet.

• Keep all shields installed. Repair or replace if

damaged or missing.

• Check blade carrier, blades and mounting

hardware. Replace if damaged. Never weld or

modify.

3.4 Operating the Attachment

Machine Requirements

NOTE: Exceeding maximum hydraulic flow will

over-speed the drive motor and result in motor

failure.

Operation

Travel Position

Lift the attachment 4 – 6 inches o the ground

when traveling between one side and another.

C S H

F

W

(N )

36” Cutter 9 – 20 GPM 500 lbs

42” Cutter 12 – 20 GPM 600 lbs

50” Cutter 10 – 20 GPM 800 lbs

3. Operation

DANGER

ROTATING BLADES WILL CAUSE SERIOUS

INJURY OR DEATH

• Never put hands, feet or objects into or under

brush cutter when engine is running.

• Keep bystanders away.

• No riders.

• Stop engine before leaving the machine to

service.

Blue Diamond® Attachments14

3.4 Operating the Attachment

Cont’d

Travel Position Cont’d

NOTE: The ground conditions and the type of

brush being cut will determine the best cutting

procedure and ground speed. The Mini Skid Steer

Series 2 Brush Cutter is designed to cut short or

tall grass, brush, and small trees up to 3 in (76 mm)

in diameter.

Clearing Work Area

Initial Setup

Starting the Cutter

Install the Mini Skid Steer Brush Cutter onto the

machine.

Move to the operator’s position, start the engine

and release the parking brake.

Raise the mini skid steer brush cutter

approximately 6 inches (152 mm) o the ground.

With the mini skid steer engine RPM just above

idle, engage the auxiliary hydraulic flow (see the

mini skid steer operator’s manual) to the cutter

head.

Slowly raise the mini skid steer engine RPM to the

correct and desired cutter speed.

3. Operation

WARNING

Never allow riders on the brush cutter.

IMPORTANT

DO NOT operate brush cutter when excessive

vibration is present. Serious damage can result.

Check blade carrier, blades, and mounting

hardware. Replace if damaged.

DANGER

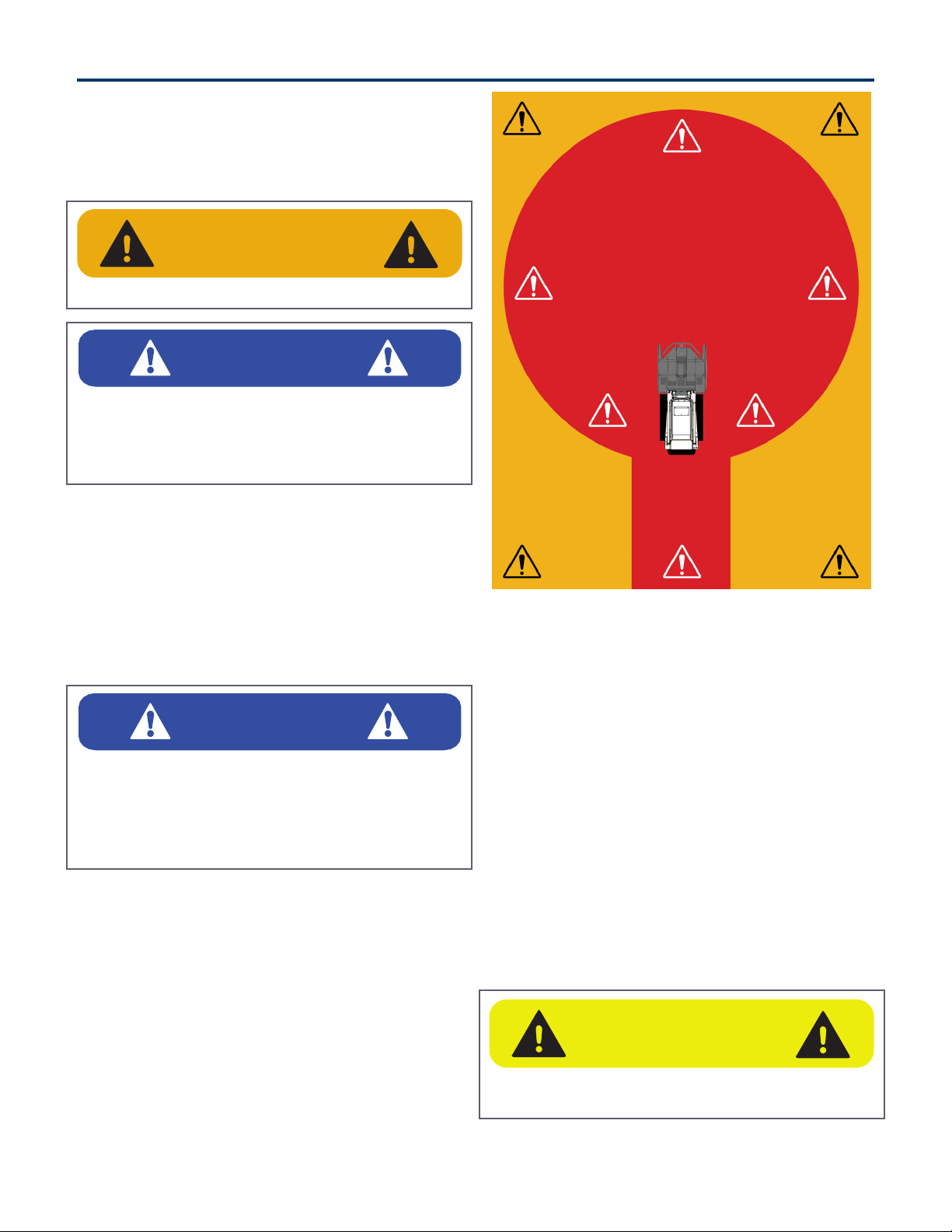

STAY BACK 300 FEET

IMPORTANT

• DO NOT operate in a work area that has not

been cleared of foreign debris and obstacles.

• Rocks, metal, construction debris, and other

objects can damage the blade carrier and blades.

• Clearly mark any objects that cannot be removed.

CAUTION

DO NOT exceed 3000 continuous PSI operating

pressure. Serious damage can result.

15Blue Diamond® Attachments

3.4 Operating the Attachment

Cont’d

Initial Setup Cont’d

Stopping the Cutter

Position the mini skid steer brush cutter

approximately 6 inches (152 mm) o the ground.

Disengage the auxiliary hydraulic flow (see the

mini skid steer operator’s manual) to the cutter

head.

Cutting Procedures

Brush Cutting

Because hydraulic flow may be aected while

raising the cutter, it is best to work from top down.

Lift the cutter to the height needed to begin

cutting.

NOTE: Always keep the angle of the blades on a

plane or angle so blades are never visible from the

operator’s position.

Engage auxiliary hydraulics to begin blade rotation.

Slowly lower mini skid steer arms, bringing the

brush cutter straight down as possible.

Always keep the brush cutter tilted away from the

operator’s position by correcting the angle as you

drop.

Grass Cutting

Set the brush cutter on the ground and then raise

it up a few inches from the ground.

Engage auxiliary hydraulics to begin blade

rotation. Be careful to compensate for rising or

falling ground as you may need to raise or lower

brush cutter to compensate.

Tree Cutting

Keep the bottom of the brush cutter pointed away

from the cab, raise the brush cutter to the top of

tree / brush you intend to cut.

Engage auxiliary hydraulics to begin blade rotation.

Slowly lower mini skid steer arms, bringing the

brush cutter straight down as possible.

NOTE: Avoid positioning the center of the blade

carrier directly over the material being cut.

Position larger material toward the end of the

blades when lowering the brush cutter directly

down on trees or brush.

3. Operation

IMPORTANT

To minimize larger cut material discharging to the

rear, always keep the machine between material

being cut (work area) and buildings, occupied

areas, or roadways.

WARNING

Never allow blades to be visible from the

operator’s position, this means you are in the

direct line of discharge.

Blue Diamond® Attachments16

4. Maintenance

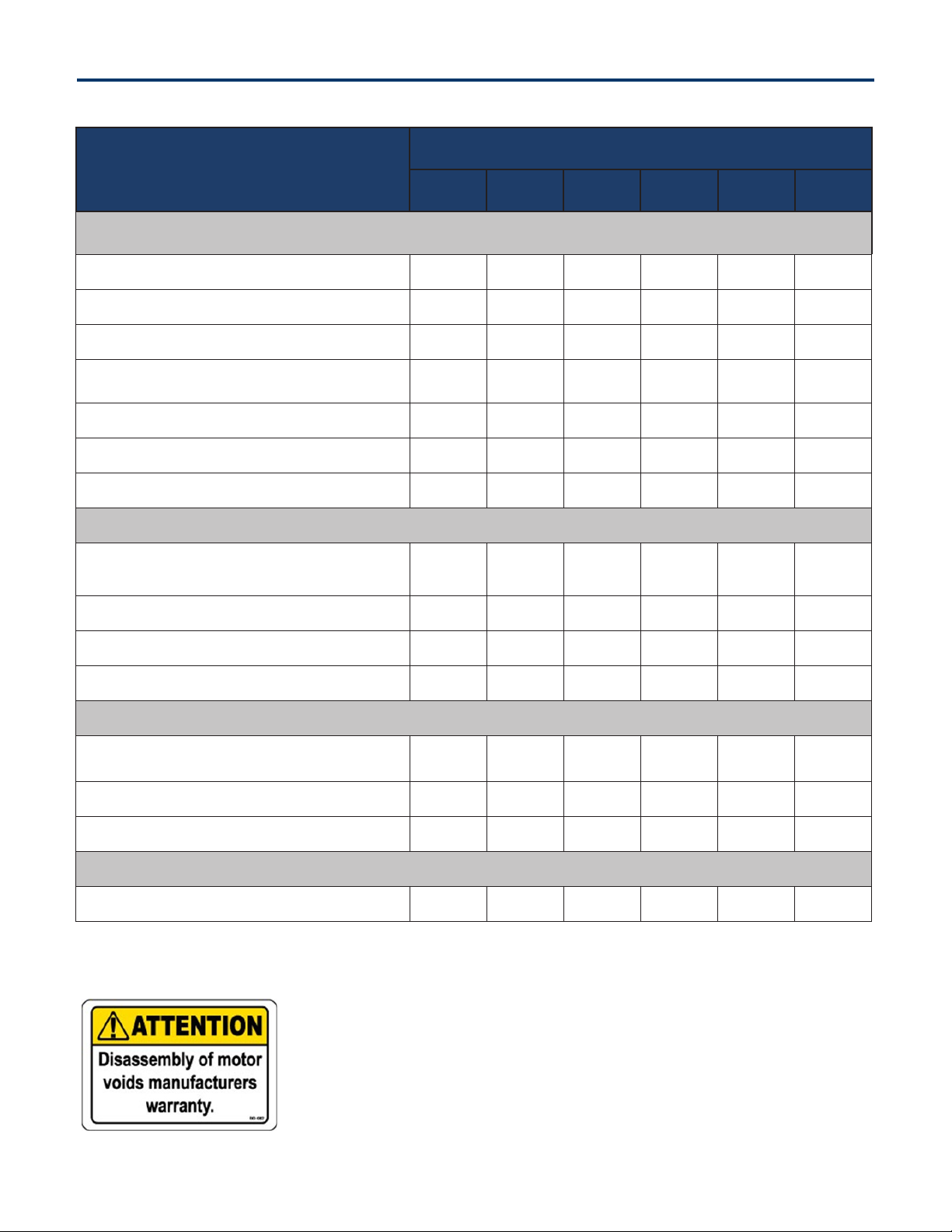

4.1 Service Schedule

DESCRIPTION

SERVICE PROCEDURES

Check Clean Lube Change Adjust Drain

Daily Maintenance (or every 8 hours)

Hydraulic Fittings •

Hydraulic Hoses •

Hydraulic Motor • •

Blades (wear, damage, and loosening) •

Blade Carrier •

All Hardware •

Deck • •

Weekly Maintenance (or every 40 hours)

Blade Bolt Torque - 500 ft/lb (678.0 N•m) •

All Hardware •

Deck (cracks, bends, or damage) •

Mount (cracks, bends, or damage) •

Monthly Maintenance

Blades (cracks, bends, or excessive wear) •

Skid plates •

All Hardware •

1000 Hour Maintenance

Drive Assembly •

17Blue Diamond® Attachments

4.2 Drive Assembly

Lubrication

Replace the oil in the direct drive assembly every

1000 hours.

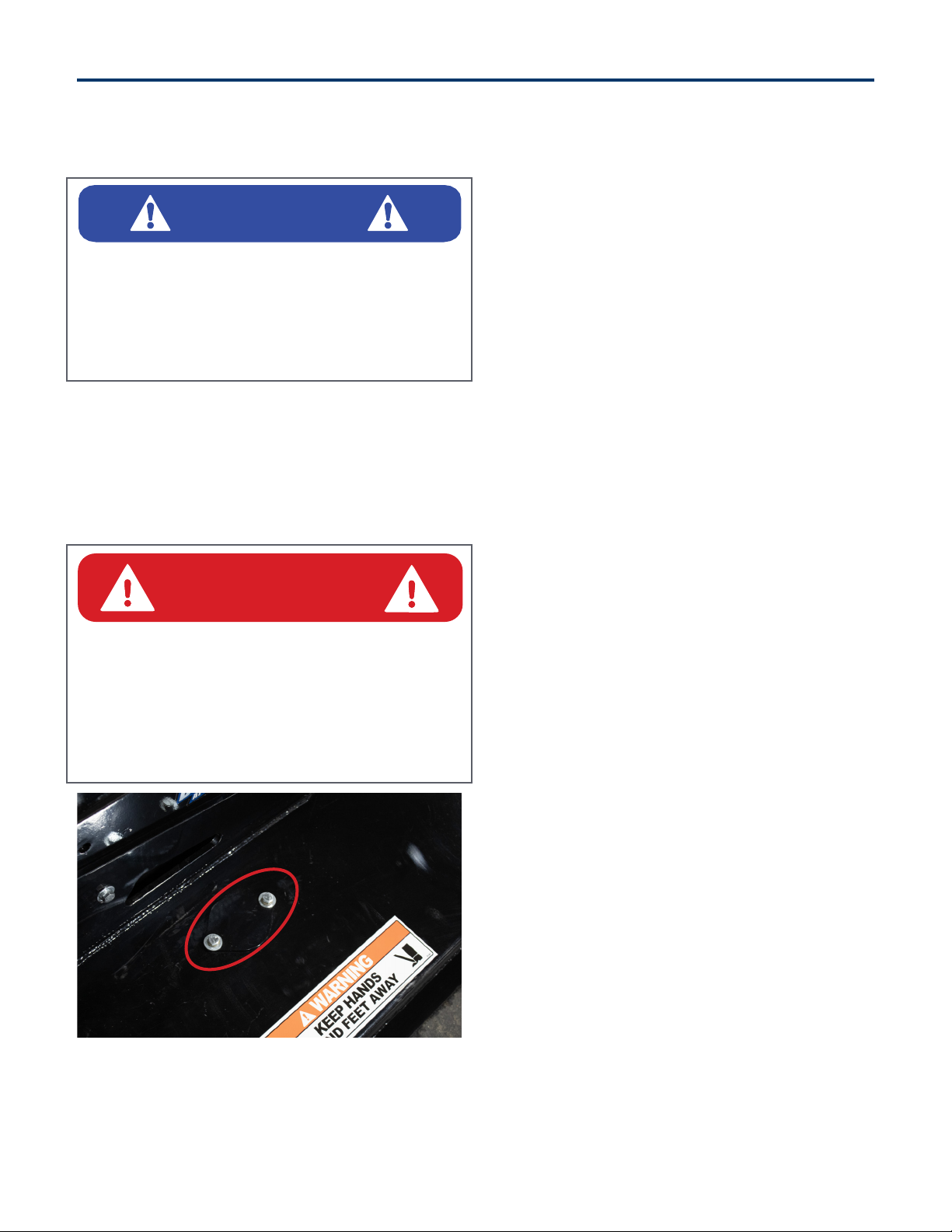

4.3 Blade Assembly

Blade Tightening / Replacement

Figure 2

Remove the two bolts (Item 1) [Figure 2] and cover

to access the blade nut.

Tightening Blade Bolts

Tighten bolts and nuts to 1440 ft/lb (1952 N•m) of

torque.

Turn blade carrier by hand to align the next blade

nut with the access hole.

Repeat procedure until all blade nuts and bolts

have been tightened.

Reinstall cover.

Blade Removal

Remove the nut and bolt from the blade. Remove

blade.

Turn blade carrier by hand to align the next blade

nut with the access hole.

Repeat procedure until all blade nuts and bolts

have been removed.

NOTE: Blue Diamond recommends replacing the

bolt and nut every time the blades are changed.

Blade Installation

Align blade with the hole in the blade carrier. Push

the bolt up through the blade into the blade carrier.

NOTE: Verify that blade bolt is fully seated.

Thread nut on blade bolt. Tighten nut to 1440 ft/lb

(1952 N•m) of torque.

Turn blade carrier to align remaining blade

mounting holes.

Repeat procedure until all blades have been

installed.

Reinstall cover.

4. Maintenance

IMPORTANT

Fluid such as hydraulic fluid, coolants, grease, etc.

must be disposed of in an environmentally safe

manner. Some regulations require that certain

spills and leaks on the ground must be cleaned

in a specific manner. See local, state, and federal

regulations for the correct disposal.

DANGER

AVOID SERIOUS INJURY OR DEATH

Before servicing the Brush Cutter:

• Lower and place the brush cutter on flat, level

surface.

• Engage parking brake, stop engine, and exit

the machine.

• Disconnect attachment hydraulic hoses.

Blue Diamond® Attachments18

4.4 Cleaning the Attachment

Park the machine and attachment on a flat level

surface. Lower the attachment flat on the ground.

Leave the operator’s position. See “Leaving the

Operator’s Position” on page 11.

Disconnect attachment hydraulic hoses from the

machine.

Enter the operator’s position. See “Entering the

Operator’s Position” on page 11.

Slowly raise the machine’s arms, while tilting the

brush cutter forward (down) until the front of the

brush cutter contacts the ground.

Stop the engine, engage the parking brake, and

leave the operator’s position. See “Leaving the

Operator’s Position” on page 11.

Use water or air pressure to clean debris from

under the brush cutter deck.

Be careful when removing any obstructions that

are wrapped around either the blades or the blade

carrier.

4. Maintenance

DANGER

AVOID SERIOUS INJURY OR DEATH

Before servicing the Brush Cutter:

• Raise the arms and tilt brush cutter fully forward

(down) until the front of the brush cutter

contacts the ground.

• Engage parking brake, stop engine, and exit

the machine.

• Disconnect attachment hydraulic hoses.

19Blue Diamond® Attachments

4. Maintenance

PROBLEM CAUSE SOLUTION

Cutter bogs down.

Dull blades. Remove and sharpen blades.

Ground speed too fast. Slow down ground speed.

Cutter speed too slow.

Raise engine RPMs or investigate other low oil

flow problems. Contact machine dealer or your

Blue Diamond Attachments® Product Support

Department.

Vibration felt when

running cutter.

Missing, loose, damaged, or

unbalanced cutter blades.

Replace blades with new or resharpened and

equally balanced blades.

Blade carrier damaged. Replace blade carrier.

Drive housing loose on

deck.

Tighten & torque drive mounting bolts. Replace

bolts if they are damaged.

Cutting height too low for

cutting in sandy or rocky

soils.

Raise cutter height.

Blades get dull too

quickly.

Blades have contacted solid

objects (rocks, steel pipes,

etc.)

Clear cutting area of solid objects before hitting

them, or raise the cutter height to clear exposed

rock surfaces.

Blades breaking. Excessive shock loads. Avoid hitting solid objects (rock, steel pipes, large

tree stumps, etc.)

Hydraulic oil level

goes down during

operation.

Leak at cutter motor or

other plumbing.

Investigate & repair. Contact your Blue Diamond

Attachments® Product Support Department.

Leak in machine hydraulic

system. Investigate & repair. Contact your machine dealer.

Blades do not spin

when auxiliary

hydraulics are

activated.

Hydraulic motor failed. Possible excessive hydraulic system pressure.

Contact your machine dealer.

Drive seized. Remove motor to isolate problems. Spin blade

carrier by hand to check drive.

4.5 Troubleshooting

Blue Diamond® Attachments20

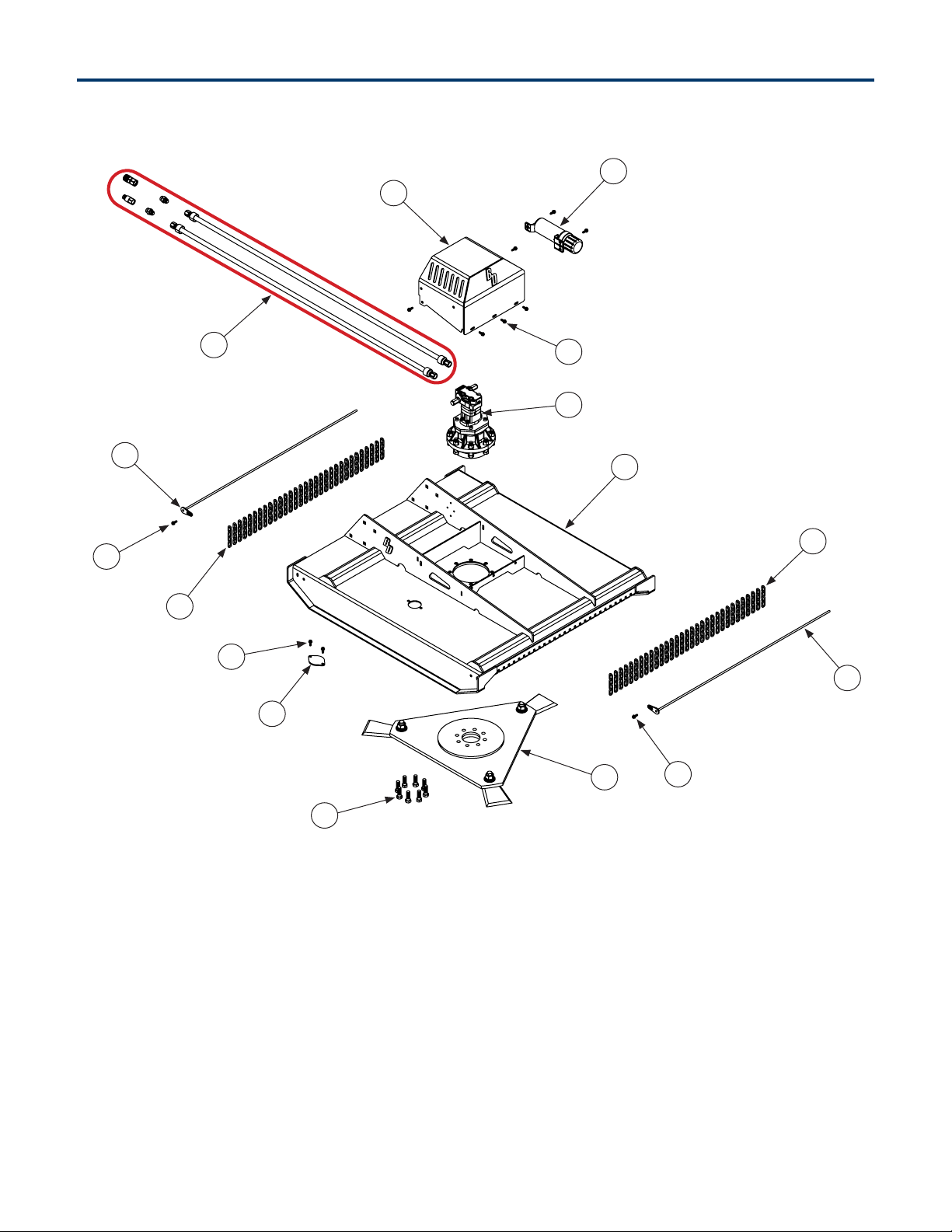

5. Parts

5.1 Parts Breakdown

3

2

8

4

6

9

8

10

8

7

11

58

9

10

1

Table of contents

Other Blue Diamond Brush Cutter manuals