Blue Diamond 104605 User manual

Operation and Maintenance Manual

Swing Arm

Stump Grinder

888-376-7027 | BlueDiamondAttachments.com

Register your

WARRANTY

within 30 days

of purchase

104605, 104610, & 104615

Blue Diamond® Attachments2

Thank you for your decision to purchase a Blue Dia-

mond® Swing Arm Stump Grinder. To ensure maximum

performance of your equipment, it is mandatory that you

thoroughly study the Operator’s manual and follow the

recommendations. Proper operation and maintenance

are essential to maximize equipment life and prevent

personal injury.

Operate and maintain this equipment in a safe man-

ner and in accordance with all applicable local, state,

and federal codes, regulations and /or laws. Follow all

on-product labeling and instructions.

Make sure that all personnel have read this Operator’s

Manual and thoroughly understand safe and correct

operating, installation and maintenance procedures.

Blue Diamond is continually working to improve its

products. Blue Diamond reserves the right to make any

improvements or changes as deemed practical and pos-

sible without incurring any responsibility or obligation

to make any changes or additions to equipment sold

previously.

Although great care has been taken to ensure the

accuracy of this publication, Blue Diamond makes no

warranty or guarantee of any kind, written or expressed,

implied or otherwise with regard to the information

contained within this manual. Blue Diamond assumes

no responsibility for any errors that may appear in this

manual and shall not be liable under any circumstances

for incidental, consequential or punitive damages in con-

nection with, or arising from the use of this manual.

Keep this manual available for frequent reference. All

new operators or owners must review the manual before

using the equipment and annually thereafter. Contact

your Blue Diamond Attachments Dealer for assistance,

information, or additional copies of the manual. Contact

www.bluediamondattachments.com or call 888-376-

7027 for a complete list of dealers in your area.

Serial Number Location:

Please record attachment information in the space pro-

vided for future reference.

Model Number:_____________________________

Serial Number: _____________________________

Dealer Name: ______________________________

Dealer Number:_____________________________

Date of Purchase:___________________________

The serial number plate is located on the mount frame

on the upper right hand side.

Always use your serial number when requesting infor-

mation or when ordering parts.

NOTE: The directions left, right, front and rear, as

mentioned throughout this manual, are as viewed from

the operator’s position.

Introduction: Owner Information

Revision Date: 06.14.2023

3Blue Diamond® Attachments

Table of Contents

1. Introduction......................................................................................4

1.1 About the Stump Grinder .........................................................4

2. Safety ...........................................................................................5-6

2.1 General Safety Information.................................................... 5

2.2 Operators.................................................................................. 6

3. Operation .................................................................................. 7-10

3.1 Entering and Exiting the Prime Mover..................................7

3.2 Attachment Installation...........................................................7

3.3 Pre-Operation Guidelines ..................................................... 8

3.4 How to Grind Stumps............................................................10

4. Maintenance ..................................................................................11

4.1 General Maintenance..............................................................11

5. Parts..........................................................................................12-22

5.1 Deck Assembly Front.............................................................12

5.2 Deck Assembly Back ............................................................15

5.3 Bolt Kit for Deck Assembly .................................................. 17

5.4 Manifold ...................................................................................19

5.5 Manifold Deck Assembly ....................................................20

5.6 Cutting Wheel.........................................................................21

5.7 Manual Tube...........................................................................22

6. Specifications .............................................................................. 23

6.1 Attachment Specifications ................................................... 23

6.2 SAE Torque Specifications.................................................. 24

6.3 Metric Torque Specifications..............................................25

7. Warranty ........................................................................................ 27

Blue Diamond® Attachments4

1.1 About the Grinder

The stump grinder attachment is intended for use in

stump grinding. Use of this attachment for any other

use is considered to be contrary to the intended use

of the attachment.

The Blue Diamond® Stump Grinder attachment is a

necessity for tree companies, landscapers, agricultural

producers, and rental companies looking to increase

their productivity and eciency when stump grinding.

The grinder is designed by people with years of

experience with attachments for machinery. You can

be sure that quality of our products is our first priority.

The grinder has been designed to deliver the

productivity of a dedicated machine with four to five

times less cost. This grinder is engineered for skid

steers with high flow hydraulics (29 – 45 GPM). A

hydraulic grinder motor for maximum productivity,

heavy weight for increased stability, and super high

eciency cutting performance are just a few features

that combine to bring you the world’s finest stump

grinder.

1. Introduction

5Blue Diamond® Attachments

2.1 General Safety Information Operating Safety

• Read and follow instructions in this manual and

the machine’s Operators Manual before operating.

• The manual must always remain with the machine.

In case of loss or damage, request a new copy

from your dealer or from Blue Diamond.

• Strictly follow all rules prescribed by the safety

pictograms/decals applied to the machine.

Ensure that all safety pictograms/decals are

legible. If pictograms/decals are worn, they

must be replaced with new ones obtained

from Blue Diamond and placed in the position

indicated by this manual.

• Before using the machine, make sure that

all safety devices are installed and in good

working conditions. In case of damage or

shields, replace them immediately.

• It is absolutely forbidden to remove or alter

safety devices and/or safety decals.

• Pay maximum attention to avoid any accidental

contact with rotating parts of the machine.

• If the use of the machine is required at night

or in conditions of reduced visibility, use

the lighting system of the prime mover and

possibly an auxiliary lighting system.

• Any modifications to the equipment may void

warranty and relieve Blue Diamond® of liability

of any resulting injury or damage.

2. Safety

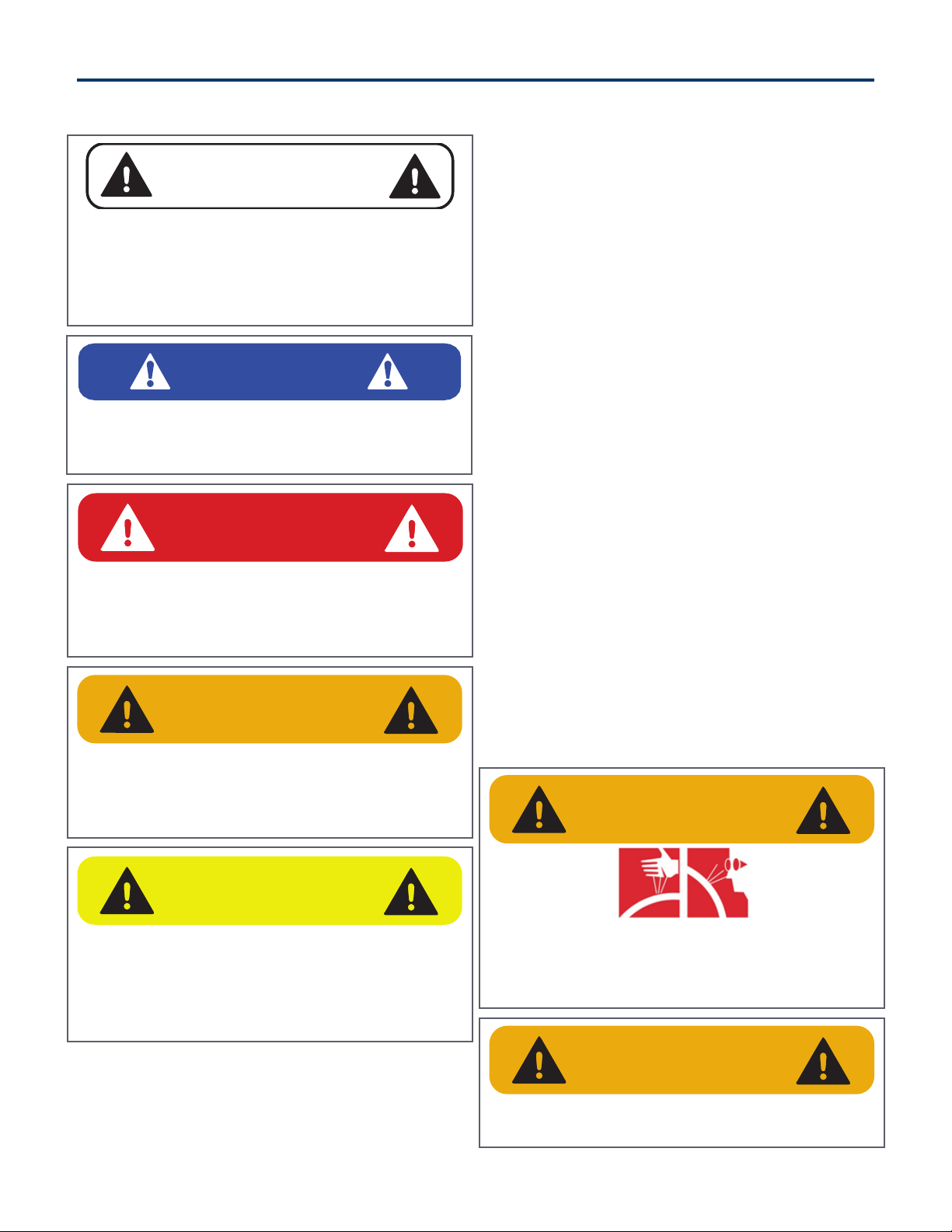

CAUTION

The signal word CAUTION on the machine and

in the manuals indicates a potentially hazardous

situation which, if not avoided, may result in minor

or moderate injury. It may also be used to alert

against unsafe practices.

WARNING

The signal word WARNING on the machine and

in the manuals indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

DANGER

The signal word DANGER on the machine and

in the manuals indicates a hazardous situation

which, if not avoided, will result in death or serious

injury.

SAFETY ALERT SYMBOL

This SAFETY ALERT SYMBOL identifies important

safety messages on the equipment and in the

owner’s manual. When you see this symbol, be

alert to the possibility of personal injury and

carefully read the message that follows.

IMPORTANT

The signal word IMPORTANT identifies

procedures which must be followed to avoid

damage to the machine.

WARNING

Leaking fluids under pressure can enter the skin

and cause serious injury or death. Immediate

medical attention is required.

Wear goggles. Use cardboard to check for leaks.

WARNING

Do not operate the grinder if any of the safety

guards are not in place.

Blue Diamond® Attachments6

2.2 Operators

Qualified Operators

The operator is a person suited to the work and

who is physically and psychologically able to

withstand the demands connected with operating

the equipment for its intended use. The operator

must not allow anyone to approach the machine

while it is working and must not allow external

personnel to operate the machine or attachment.

He is to follow the given instructions in this

manual and the machine operator’s manual in

order to obtain maximum performance, minimum

consumption, and maximum safety for himself and

for others.

The operator is responsible for scrupulously

observing all the instructions given in this manual.

Operator Training

• Check the rules and regulations at your

location. The rules may include an employer’s

work safety requirements. Regulations may

apply to local driving requirements or use

of a Slow Moving Vehicle (SMV) emblem.

Regulations may identify a hazard such as a

utility line.

• The new operator must start in an area without

bystanders and use all the controls until he or

she can operate the machine safely under all

conditions of the work area.

Operator Safety

• Before starting, and during operation of the

attachment, make sure there are no people

or animals in the operation area; the machine

can project material from the back with risks of

serious injury or death.

• During operation, adjustment, maintenance,

repairing, or transportation of the machine, the

operator must always use appropriate Personal

Protective Equipment (PPE) including but not

limited to safety glasses, working gloves, dust-

mask, safety helmet, and hearing protection.

• Do not operate the attachment or machine

while wearing loose fitting clothing that can be

entangled or caught in parts of the machine.

• Do not operate the implement when tired, not

in good condition, or under the influence of

alcohol or drugs.

2. Safety

AVOID SERIOUS INJURY OR DEATH

Operators must receive instructions before

operating the machine. Untrained operators can

cause serious injury or death.

For an operator to be qualified, he or she must

not use drugs or alcoholic drinks which impair

alertness or coordination while working. An

operator who is taking prescription drugs must

get medical advice to determine if he or she can

safely operate a machine and the equipment.

For an operator to be qualified, he or she must

have read and understood the instructions of

this manual, he or she must make adequate

preparation for the proper use of the machine,

and he or she must hold a driving license.

In case of doubt regarding the use of the machine

and/or the interpretation of this manual, the

operator must contact either their dealer or Blue

Diamond.

DANGER

Proper Workclothes: To help ensure your

safety as a designated operator wear

proper workclothes including tight fitting

clothes, protective gloves and shoes.

Safety Helmet and Eye/Ear Protection: To

help ensure your safety as a designated

operator wear a safety helmet and eye/

ear protection.

7Blue Diamond® Attachments

3.1 Entering and Exiting the

Prime Mover

Entering The Operator’s Position

Use the attachment safety treads, handles and

steps (on the machine) to enter the operator’s

position.

When in the operator’s position, lower safety seat

bar, start the engine and release the parking brake.

Leaving The Operator’s Position

Park the machine/attachment on a flat level

surface.

Place all controls in neutral, engage the park

brake, stop the engine and wait for all moving

parts to stop. Leave the operator’s position.

3.2 Attachment Installation

Connecting Attachment to the Prime

Mover

NOTE: Before attempting to attach the grinder to

the prime mover, verify that all hydraulic couplers

are compatible.

1. Place the grinder attachment on a level

surface.

2. Position and align the prime mover to the rear

of the attachment, within proximity of the front

of prime mover.

3. Insert and connect the prime mover into the

attachment.

4. Connect the hydraulic lines from the

attachment to the prime mover.

5. Close latches (or other locking mechanism) to

secure the attachment to the prime mover.

6. Using the prime mover with the Multifunction

controller and harness, raise the attachment

and move the attachment to ensure hydraulic

lines are clear of air and operate properly.

7. Lower the attachment to ground level.

3. Operation

WARNING

AVOID SERIOUS INJURY OR DEATH

• Always park on a flat level surface.

• Lower lift arms and place attachment flat on

the ground.

• Place all controls in NEUTRAL.

• Engage the park brake.

• Stop the engine and remove the key.

• Wait for all moving parts to stop.

SEE MACHINE’S OPERATOR’S MANUAL FOR

ADDITIONAL INFORMATION.

IMPORTANT

See the machine’s Operator’s Manual for detailed

information on operating the loader. CAUTION

Hydraulics should operate in an even and smooth

manner. Hydraulic movement that is not even and

smooth may indicate that air is in the hydraulic lines.

WARNING

Improper attachment to the prime mover may

cause personal injury.

CAUTION

All hydraulic connections must be clean and free

of debris before making any connections.

Blue Diamond® Attachments8

8. Route hoses away from pinch areas – install

cable ties if necessary to assure extended

hose life.

9. Inspect that the attachment is mounted

properly and securely. If the attachment

does not meet this requirement, follow the

instructions to remove the grinder and re-

attach using the instructions above.

Disconnecting Attachment from the

Prime Mover

1. Using the prime mover, lower the attachment

to the ground.

2. Relieve the pressure in the hydraulic system by

following these instructions:

a. Turn the ignition to o

b. Turn the ignition back to the on position

without starting the machine.

c. Move the auxiliary hydraulic function

level back and forth to relieve the pressure

in the hydraulic lines (this will greatly assist

you when hooking the unit back up so that

the hydraulic couplers connect easily).

3. Disconnect the hydraulic connection between

the attachment and the prime mover. To

prevent contamination, remove any dirt and

debris from the couplers.

4. Disengage the prime mover latches (or other

locking mechanism) from the attachment.

5. Remove the prime mover from the attachment.

NOTE: Hydraulic connections must be

disconnected before disengaging latches to

prevent damage to the prime mover or the

attachment.

3.3 Pre-Operation Guidelines

Equipment Inspection

NOTE: Replace any damaged hardware, hoses,

and fittings before using the equipment.

It is recommended to inspect the equipment for

damage and wear before use. Use the following

list as a guideline during equipment inspection.

It is recommended to inspect the equipment for

damage and wear before use. Use the following

list as a guideline during equipment inspection.

3. Operation

CAUTION

All hydraulic connections must be clean and free of

debris before disconnection.

WARNING

Improper disconnection may result in personal injury

or damage to the attachment and prime mover.

ITEMS

P

Check all hardware connections to the

prime mover for damage or fatigue such

as cracks or other structural flaws.

PCheck that all latches or locks are closed.

PCheck that all hydraulic fittings are tight

and free of leaks.

PCheck that all hydraulic lines are free of

leaks, holes, and/or cracks.

P

Check that the tires on the prime mover

are in good condition and have proper

load ratings.

WARNING

Leaking fluids under pressure can enter the skin

and cause serious injury or death. Immediate

medical attention is required.

Keep body parts away from the leaking hydraulic

lines and couplers that are under pressure.

Wear goggles. Never use hands to check for

hydraulic leaks. Use cardboard to check for leaks.

9Blue Diamond® Attachments

3.3 Pre-Operation Guidelines

Cont’d

Usage Guidelines

Before each use of the stump grinder, do the

following:

• Perform the equipment inspection by

performing a walk around.

• Perform daily inspection as indicated on the

Inspection Checklist on page 8.

• Verify that the proper attachment is being used

for the task.

• As with any power attachment, safety is

critical. An enclosed cab prime mover with

the operation wearing safety protection is

required.

• Never operate the grinder with persons within

100 feet of range.

• Disengage grinder and shut o the engine

before leaving the cabin of the prime mover.

• Use caution on slopes and uneven terrain.

• Never carry passengers.

• Never leave the machine running unattended.

• Never leave the stump grinder o the ground

when out of the operator’s seat.

• Never allow children or untrained personnel to

operate the grinder.

Inspection Checklist

3. Operation

CAUTION

Always be aware of what is overhead when

operating the grinder.

DANGER

Keep all body parts away from the grinder when

in use. The pivoting blade is dangerous and

hazardous and could potentially cause serious

bodily injury or death.

ITEMS

PAre all safety notices and warning

stickers in proper locations and visible?

PAre there any visible hydraulic leaks?

PAre any cracks visible in structure of the

grinder?

PIs the cutting wheel bent?

PAre bolts holding teeth secure and tight?

P

Has the prime mover been properly

inspected for hydraulic leaks and proper

tire inflation?

PHas the prime mover been properly

maintained?

Blue Diamond® Attachments10

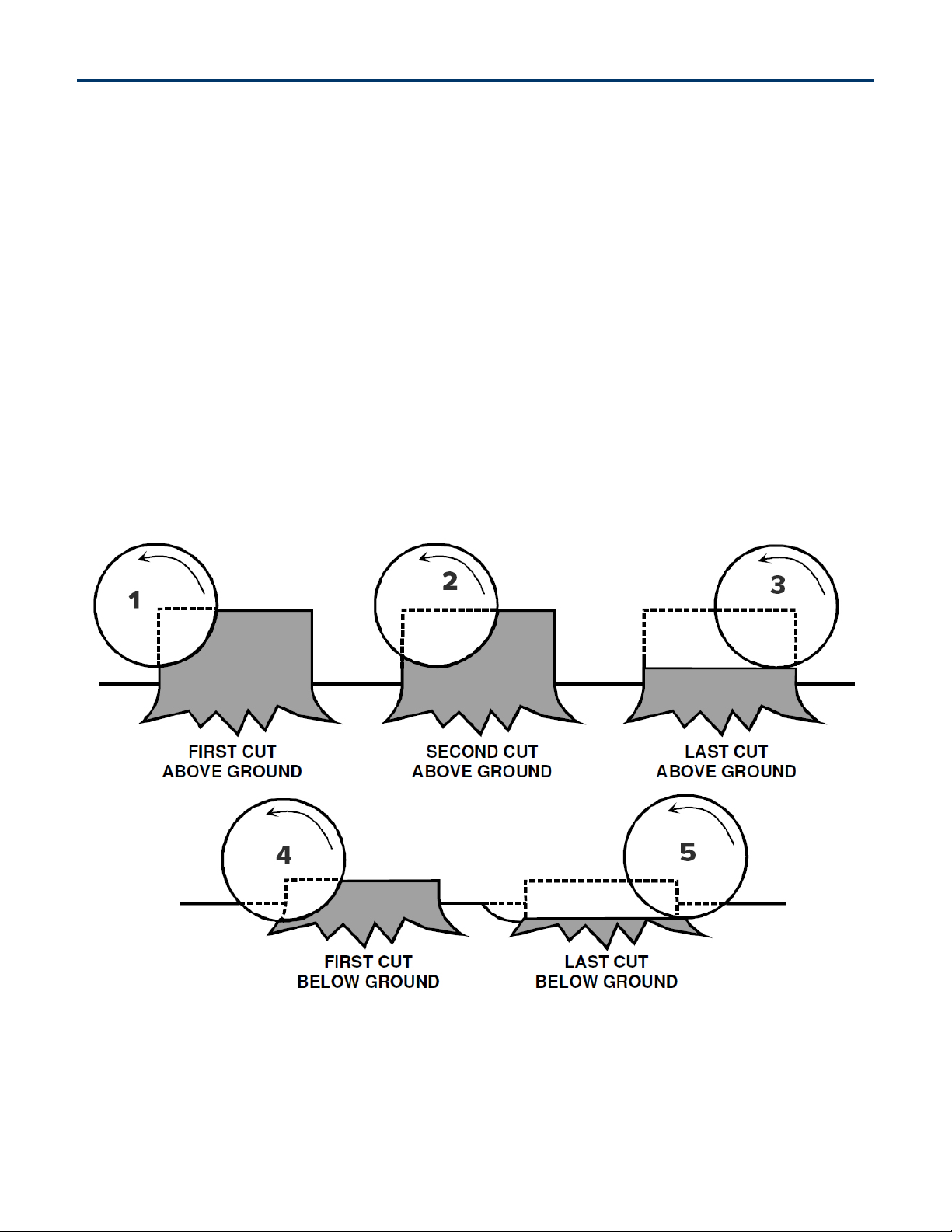

3.4 How to Grind Stumps

Align the cutter wheel with the left side of the

stump (viewed from the machine control area) and

position the machine so that it will cut about 4-6

inches o the top of the stump and 8-12 inches

from the left side of the stump [Figure 1].

The rate of cut will depend on the type of tree,

condition of the wood, and the condition of the

cutters. Too light a feed will produce sawdust.

The ideal feeding rate produces heavy wood

chips, some of which may be about 1/16” thick by

approximately 6-8 inches long, as well as chunks

of wood. After completing the first cut through

the stump, move the machine to the right (again

as viewed from the control area) so the wheel can

cut another 8-12 inches. Proceed with another cut.

Additional passes, when the tree stump is very

large, are made in the same manner as described

above. Repeat the procedure until the stump is cut

to ground level.

Before cutting below the ground level, make

certain that all rock or stone is removed from the

immediate area of the cutting wheel. When you

are cutting below the ground level, the feed rate

should be reduced and the operator should be

alert to the possibility of cutting hidden rock. Extra

care used in this part of the operation can avoid

costly damage to the cutting wheel and teeth.

The wheel is designed so that it can “saw” or cut

its way into solid wood by dropping straight down

on it. This operation works well for cutting o

large roots.

3. Operation

Figure 1

11Blue Diamond® Attachments

4.1 General Maintenance

NOTE: Disconnect the hydraulic connection

between the attachment and the prime mover

before performing any type of maintenance on the

grinder.

Cutting Wheel

Be certain to check carbide cutting teeth for wear.

Replace teeth as necessary.

Hoses

Check hoses occasionally for abrasion damage.

This may save you from downtime. If in doubt,

replace with genuine Blue Diamond® parts.

Pivot Pins

Pivot pins may be lubed with moly-type grease,

same as what is used on your machine. Please

check the cotter pins that retain all pivot/anchor

pins after each use. If missing, replace! Severe

damage could be caused by losing a pin.

Storage

Lubrication of pivot pins is recommended if unit

is stored outside. Be certain hydraulic quick

couplers are cleaned and joined together to keep

dirt out. A light coating of oil film or diesel fluid

is recommended to prevent corrosion. Touch-up

paint should be used on all scratches to prevent

further rust.

Grease Points

There are 7 grease points on the grinder. Each

grease point should have new grease applied daily

when being used. Approximately every 8 hrs. See

Figures 2, 3, and 4 for grease point locations.

Figure 2

Figure 3

Figure 4

4. Maintenance

Blue Diamond® Attachments12

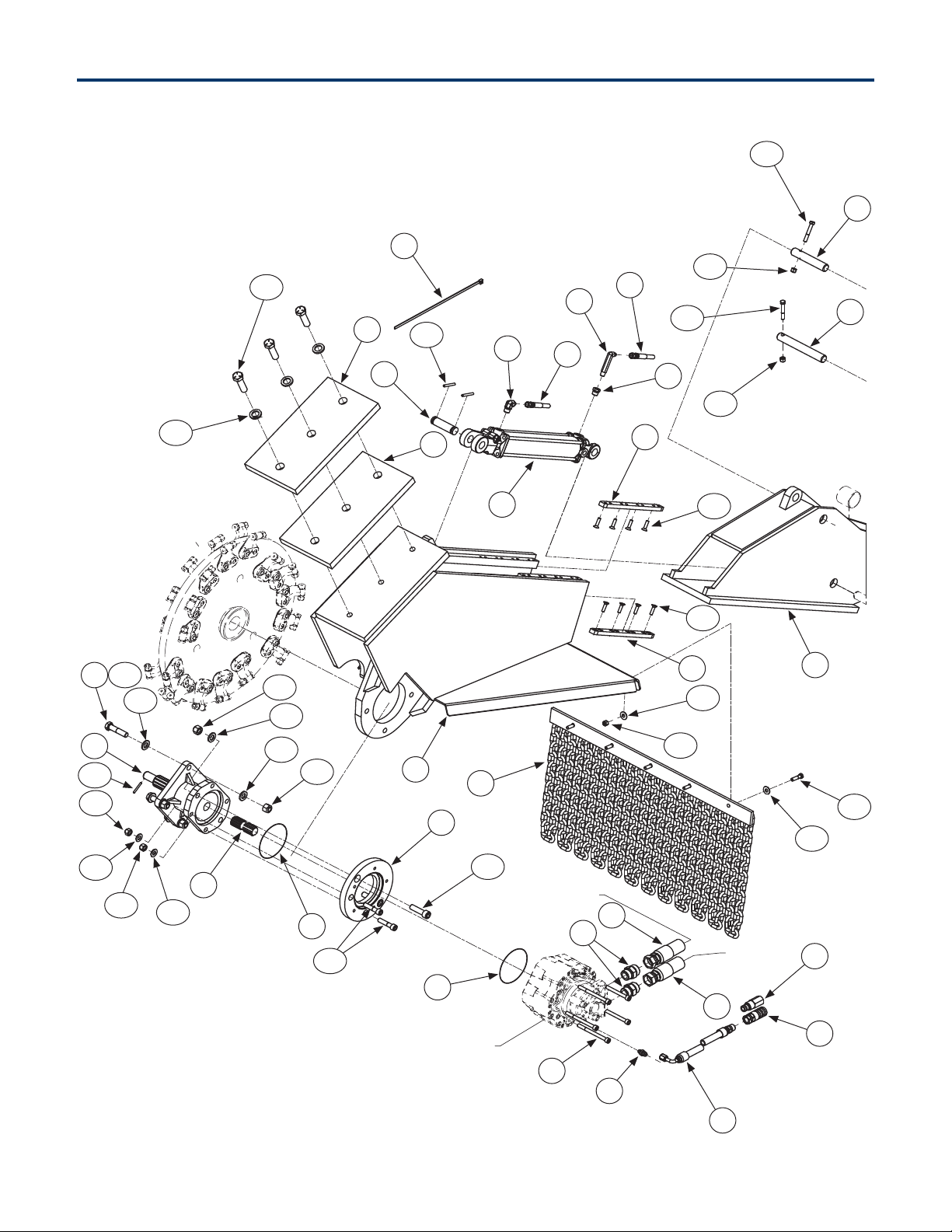

5. Parts

5.1 Deck Assembly Front

3.16

36

3.16

3.7

3.7

35

22

15

16

6

3.18

9

24

13

34

45

45

3.10

3.2

3.18

644

3.4

3.7

3.4

3.14

46

47

48

3.11

3.12

11

2

17

29

18

19

30

31

20

11

3.1733

3.1

10

3.13

3.3

3.8

3.8 3.3

40

Piston Motor Assembly

Pressure

Return

3.9

32

3.6

3.1

3.1

3.6

13Blue Diamond® Attachments

5. Parts

ITEM PART NUMBER DESCRIPTION QTY TORQUE

(ft-lb)

Piston

Motor

204093 Motor, 60cc, 16-20 GPM, High Press Seal

1

204077 Motor, 75cc, 21-24 GPM, High Press Seal

204075 Motor, 90cc, 25-28 GPM, High Press Seal

204204 Motor, 130cc, 29-33 GPM, High Press Seal

204097 Motor, 150cc, 34-39 GPM, High Press Seal

204095 Motor, 170cc, 40-45 GPM, High Press Seal

NS 204085 Motor Shaft Seal 1

2 203415 M10-1.5 X 120mm Socket Cap Screw, Gr 12.0 5 62

3 204484 Bolt Kit 1

3.1 299844 5/8 X 1.312 Thru-Hardened SAE FW, Yellow Zinc 10

3.2 299727 3/4 SAE Gr 8 Flat Washer, Yellow 3

3.3 299732 1/2 SAE Flat Washer Gr 8, Yellow Zinc 2

3.4 299725 3/8 Thru-Hardened Flat Washer, Yellow Zinc 22

3.6 109177 5/8"-11 Grade C Steel Top Lock 6 64

3.7 299625 3/8" NC Nylock Nut, Gr 8 15

3.8 204302 1/2-13 Top Lock Nut Gr C, Zinc 2 106

3.9 204482 Roll Pin, 1/4' X 2" 2

3.10 299489 3/4-10 X 2-3/4 Gr 8 Hex Cap Screw, Yellow Zinc 3 376

3.11 299453 5/8"-11 X 2-1/4" Socket Cap Screw, Plain 2 *238

3.12 299325 1/2-13 X 2-1/4 ASTM A574 Socket Cap, Black Oxide 2 *124

3.13 204061 M5 X 4mm Spring Pin, Plain 1

3.14 299487 3/8"-16 X 1-1/2" Gr 8 Hex Cap, Yellow Zinc 9 44

3.16 299329 3/8"-16 X 2-1/2" Gr 8 Hex Cap, Yellow Zinc 2 44

3.17 299459 5/8"-11 X 2-3/4" Gr 8 Hex Cap, Yellow Zinc 4 *212

3.18 299311 5/16”-18 X 1-1/4” Flat Socket Cap Screw, Black 16 29

5 204475 Cylinder - Tie Rod 2.50 X 12.0 1

6 204485 Block Slide, UHMW, Floating 4

8 (NS) 204455 Harness, 6-Function, Attachment Side 1

9 (NS) 204452 Controller, Multi-Function, Handheld 1

10 204220 Bearing Housing - DMG/DSG 1

5.1 Deck Assembly Cont’d

*Critical Torque Values MUST be followed.

Blue Diamond® Attachments14

ITEM PART NUMBER DESCRIPTION QTY TORQUE

(ft-lb)

11 204207 O-Ring, Stump Grinder 2

13 295030-M04JIC-M06NPT 1/4" MJIC X 3/8" MP–90EG, Fitting 2

15 295030-M04JIC-M04NPTXL 1/4" MJIC X 1/4" MP–90DEG, Fitting X-Long 1

16 204488 3/8" MP X 1/4" FP, Bushing 1

17 204416 6 MJIC X 4 BSPP Adapter 1

18 224064 3/8" Male Quick Coupler, Flat Face, No Spill 1

19 224063 3/8" Female Quick Coupler, Flat Face, No Spill 1

20 295010-M16ORFS-M16ORB –16 MOR X –16 MOFS 2

22 204489 Hose 1/4" X 21" (1/4" FJIC X 1/4" FJIC) 2

24 204491 Hose 1/4" X 36" (1/4" FJIC X 1/4" FJIC) 1

29 204496 Hose 3/8" X 143" (3/8" FJIC – 90 DEG X 1/2" MP) 1

30 204497 Motor to Manifold Pressure Hose 1 X 67” 4000 PSI (-16 FFS X -16FFS) Kevlar 2

31 204498 Motor to Manifold Return Hose 1” X 67 3000 PSI (1”FJIC X - 16FFS) Kevlar 2

32 204081 14" Zip Tie, Wide 4

33 204063 Loctite 243, 0.5mL (Blue) 1

34 204465 Clevis Pin, 1" X 3-1/2" 1

35 204500 Pin, Lift, Base End 1

36 204501 Pin, Lift, Rod End 1

40 204067 Stub Shaft, A3 Spline, For High Press HC05 Motor 1

44 204445 Beam 1

45 204446 Counter Weight Plate 2

46 204447 Bracket-Chain 1

47 204448 Slider 1

48 204069 Adapter - Motor 1

5. Parts

5.1 Deck Assembly Front Cont’d

15Blue Diamond® Attachments

5. Parts

5.2 Deck Assembly Back

41 3.14

3.4

3.15

3.7

43.1

38

43

26

14

21

4.1

43.2

42

7

27

14

21

39

3.15

44.1

42.1

3.7

37

49

1

3.5

44.1

3.4

43.2

4.1 4.2

3.4 3.7

4.1

3.4

3.7

28

12

4

25

12 22

13

4

23

12

31

30

Return

Pressure

Return

Pressure Manifold

Blue Diamond® Attachments16

ITEM PART NUMBER DESCRIPTION QTY TORQUE

ft-lb

1 204483 Snap Ring, 1” External 2

3 204484 Bolt Kit 1

3.4 299725 3/8 Thru-Hardened Flat Washer, Yellow Zinc 22

3.5 299486 3/8-16 X 5 Gr 5 Hex Cap, Zinc 2 31

3.7 299625 3/8" NC Nylock Nut, Gr 8 15

3.14 299487 3/8" -16 X 1-1/2" Gr 8 Hex Cap, Yellow Zinc 9 44

3.15 299488 3/8"-16 X 3-3/4" Gr 8 Hex Cap, Yellow Zinc 2 44

4 204476 Cylinder - Tie Rod 2.50 X 6.00 2

4.1 204481 3/16 R-Clip 4

4.2 204465 Clevis Pin, 1' X 3-1/2" 2

7 204486 Cylinder - Welded 3/50 X 8.00 1

12 295010-M04JIC-M06NPT 1/4" MJIC X 3/8" MP, Fitting 3

13 295030-M04JIC-M06NPT 1/4" MJIC X 3/8" MP-90deg, Fitting 2

14 295030-M04JIC-F04JIC 1/4" MJIC X 1/4" FJIC-90deg, Fitting 2

21 295010-M04JIC-M08NPT 1/4" MJIC X 1/2" MP, Fitting 2

22 204490 Hose 1/4" X 21" (1/4"FJIC X 1/4" FJIC) 2

23 204490 Hose 1/4" X 28" (1/4"FJIC X 1/4" FJIC) 1

25 204492 Hose 1/4" X 26" (1/4"FJIC X 1/4" FJIC-90deg) 1

26 204493 Hose 1/4" X 21" (1/4"FJIC X 1/4" FJIC-45deg) 1

27 204494 Hose 1/4" X 25" (1/4"FJIC X 1/4" FJIC-45deg) 1

28 204495 Hose 1/4" X 30" (1/4"FJIC X 1/4" FJIC) 1

30 204497 Motor to Manifold Pressure Hose 1 X 67” 4000 PSI (–16 FFS X –16FFS) Kevlar 2

31 204498 Motor to Manifold Return Hose 1” X 67 3000 PSI (1”FJIC X - 16FFS) Kevlar 2

37 204502 Pin, Telescopic Base 1

38 204503 Pin, Center Rotation 1

39 204504 Pin, Center Tilt 1

41 204602 Safety Glass 1

42 204480 Swivel 1

42.1 203072 Grease Zerk 1/4" Straight 2

43 204700 Skid Attach Brkt 1

43.1 204478 Bushing-Garlock 2.25 X 2 X 2 2

43.2 203072 Grease Zerk 1/4" Straight 2

44.1 204478 Bushing-Garlock 2.25 X 2 X 2 2

49 204449 Washer, Machined 2

5. Parts

5.2 Deck Assembly Back Cont’d

17Blue Diamond® Attachments

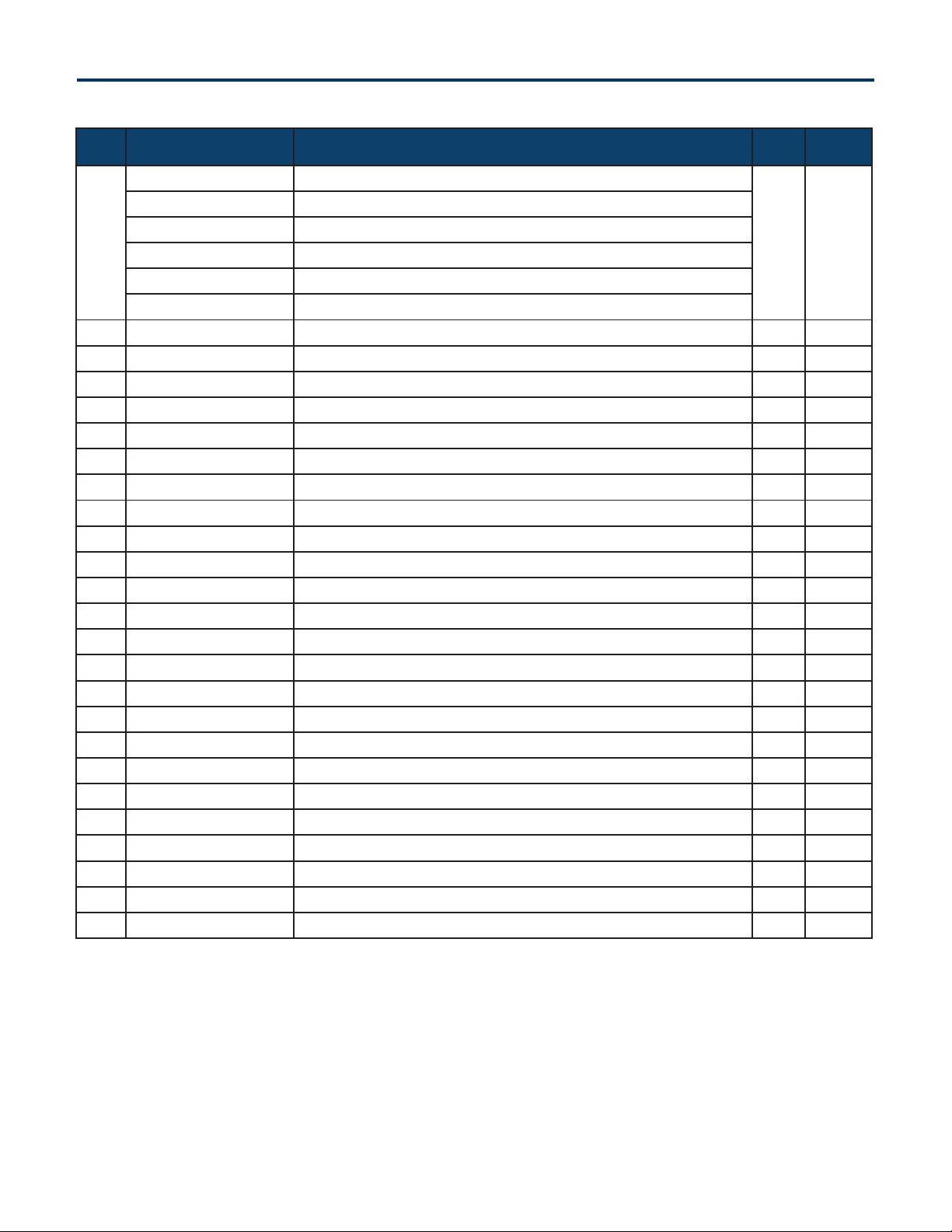

5. Parts

5.3 Bolt Kit for Deck Assembly

1019

2

13 6

1

8

3

11

12

1720

4

7

4

14

9

18

7

16

21 7

15

16

4

5

21

7

4

21

4

7

21

7

15

14 4

Blue Diamond® Attachments18

ITEM PART NUMBER DESCRIPTION QTY TORQUE

ft-lb

TORQUE

Nm

— 204484 Bolt Kit 1

1 299844 5/8 X 1.312 Thru-Hardened SAE Flat Washer, Yellow Zinc 10

2 299727 3/4 SAE Gr 8 Flat Washer, Yellow 3

3 299732 1/2 X 1.062 Gr 8 SAE Flat Washer, Yellow Zinc 2

4 299725 3/8 Thru-Hardened Flat Washer, Yellow Zinc 22

5 299486 3/8-16 X 5 Gr 5 Hex Cap, Zinc 2 31 42

6 109177 5/8"-11 Grade C Steel Top Lock 6

7 299625 3/8" NC Nylock Nut, Gr 8 15

8 204302 1/2-13 Top Lock Nut Gr C, Zinc 2

9 204482 Roll Pin, 1/4' X 2 2

10 299489 3/4-10 X 2-3/4 Gr 8 Hex Cap Screw, Yellow Zinc 3 376 510

11 299453 5/8-11 X 2-1/4 ASTM A574 Socket Cap, Black Oxide 2 238 323

12 299325 1/2-13 X 2-1/4 ASTM A574 Socket Cap, Black Oxide 2 124 168

13 299453 M5 X 40mm Spring Pin, Plain 1

14 299325 38"-16 X 1-1/2" Gr 8 Hex Cap, Yellow Zinc 9 44 60

15 204061 38"-16 X 3-3/4" Gr 8 Hex Cap, Yellow Zinc 2 44 60

16 299487 38"-16 X 2-3/4" Gr 8 Hex Cap, Yellow Zinc 2 44 60

17 299488 5/8-11 X 2-3/4 Gr 8 Hex Cap, Yellow Zinc 4 212 287

18 299329 5/16"-18 X 1-1/4" Flat Socket Cap Screw, Black 16 29 39

19 204082 Loctite Red 262 1

20 204063 Loctite Blue 243 1

21 204478 Bushing Garlock 2.25 X 2 X 2 4

5. Parts

19Blue Diamond® Attachments

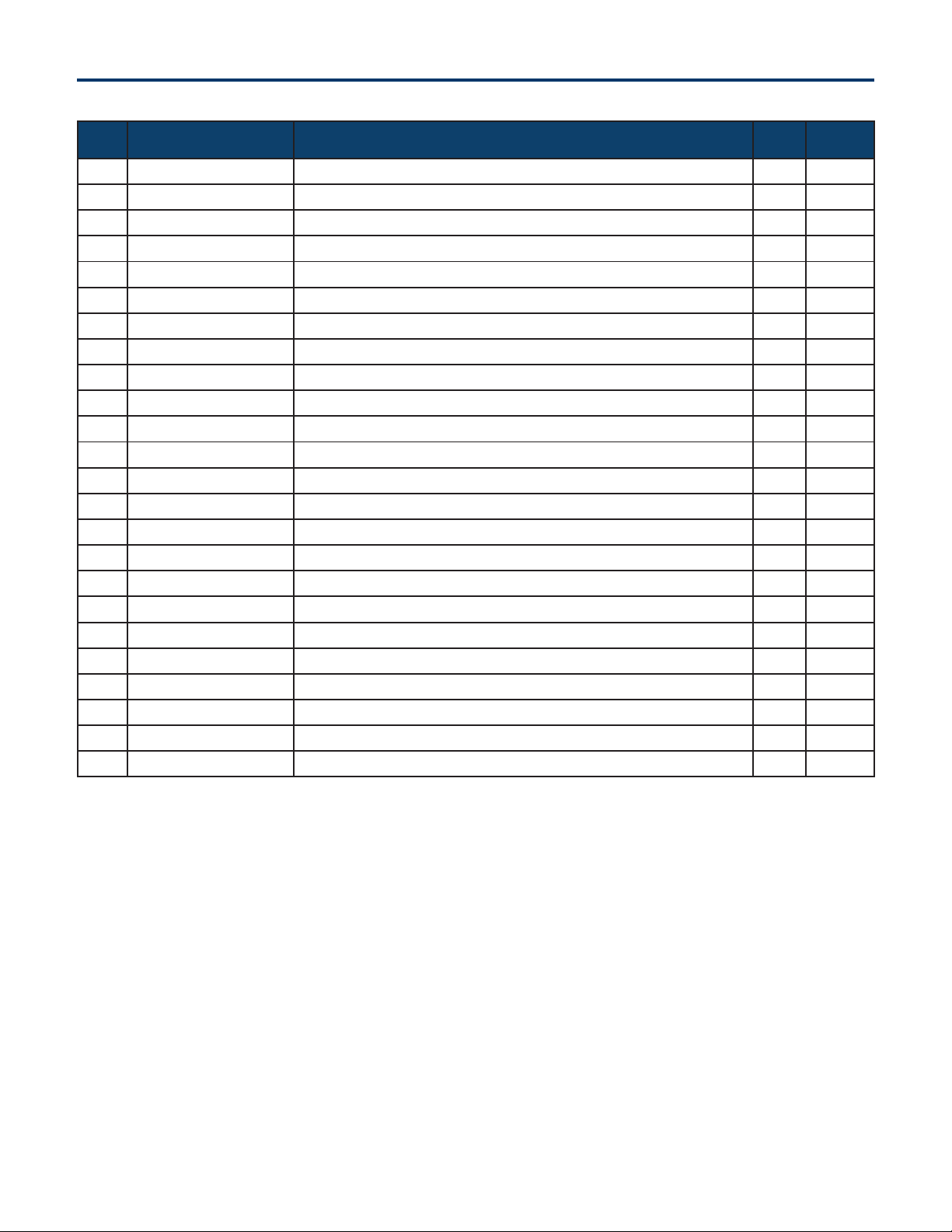

5. Parts

5.4 Manifold

ITEM PART NUMBER DESCRIPTION QTY

1 204437 Spool-Type 4-Way 3-Position Tandem Center Valve 2

2 204438 Relief Dierential Area Poppet-Type Relief Valve 1

3 204439 Relief Direct-Acting Poppet-Type Relief Valve 1

4 204440 Piloted Spool-Type Logic Element 1

5 204441 Pilot-Operated Check Valve 1

6 204442 Check Valve 1

7 204443 Coil Spacer 3

8 204487 Solenoid Valve Coil 6

9 204444 Spool-Type 4-Way 3-Position Open Center Valve 1

8

7

8

1

9

1

5

6

2

4

3

Blue Diamond® Attachments20

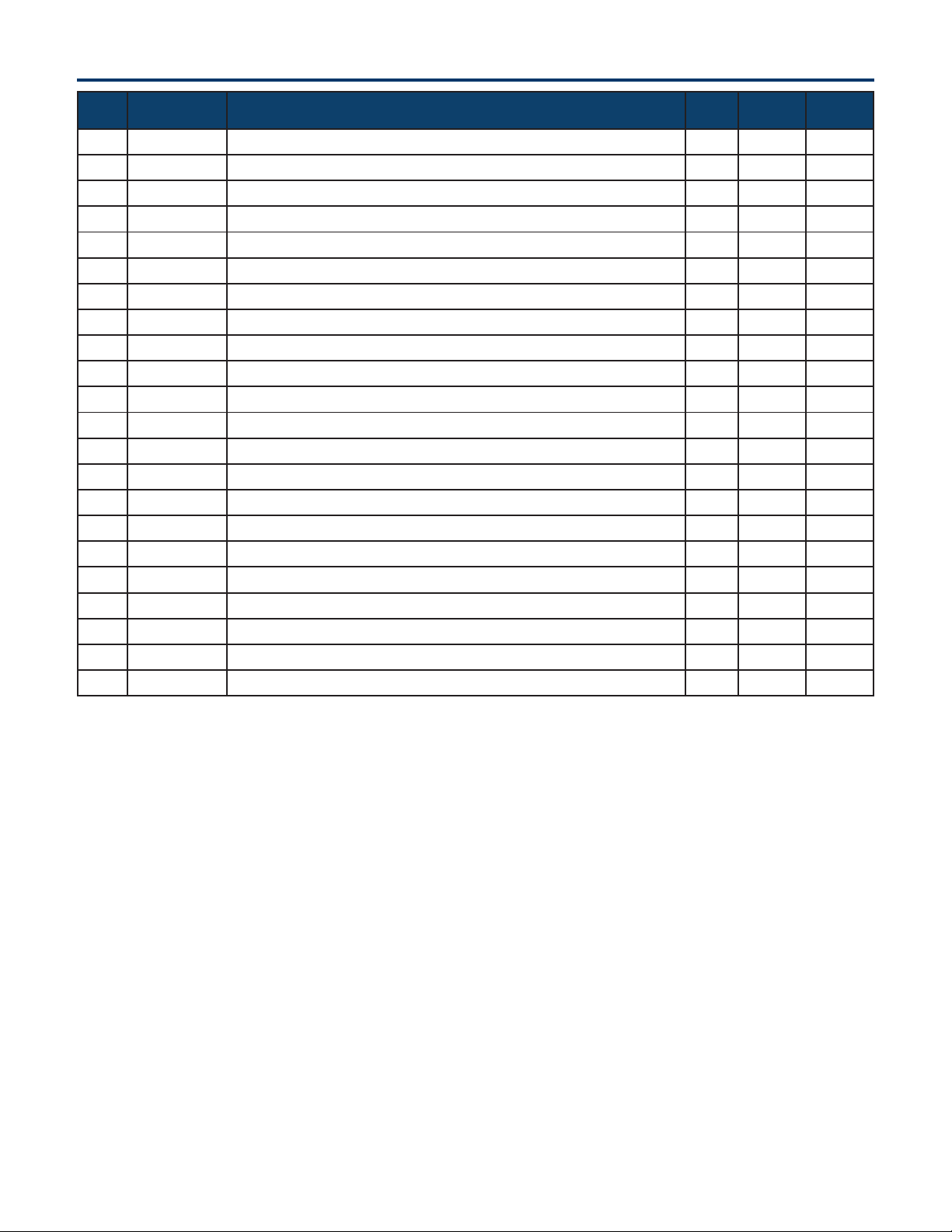

5. Parts

5.5 Manifold Deck Assembly

ITEM PART NUMBER DESCRIPTION QTY

1 295010-M16ORB-M16JIC 1 MOR X 1 MJIC, Adapter 2

2 295010-M04JIC-M06ORB 1/4" MJIC X 3/8" MORB, Fitting 5

3 295050-M04JIC-M04JIC-M06ORB 1/4" MJ X 1/4" MJ X 3/8" MORB, Tee 1

4 295050-M04JIC-F04JIC-M04JIC 1/4" MJ X 1/4" FJ X 1/4" MJ, Tee 1

5 295030-M04JIC-F04JIC 1/4" MJIC X 1/4" FJIC-90deg, Fitting 1

6 224012 1/2" Male Quick Coupler X 3/4" SAE, Flat Face, No Spill 1

7 224011 1/2" Female Quick Coupler X 3/4" SAE, Flat Face, No Spill 1

8 295010-M16ORFS-M16ORB -16 MOR X -16 MOFS 2

9 290320 Adapter, -16 MFS X -12 MOR 2

10 204489 Hose 1/4" X 21" (1/4" FJIC X 1/4” FJIC) 2

11 204490 Hose 1/4" X 28" (1/4" FJIC X 1/4” FJIC) 1

12 204491 Hose 1/4" X 36" (1/4" FJIC X 1/4” FJIC) 1

13 204492 Hose 1/4" X 26" (1/4" FJIC X 1/4” FJIC-90deg) 1

14 204493 Hose 1/4" X 21" (1/4" FJIC X 1/4” FJIC-90deg) 1

15 204494 Hose 1/4" X 25" (1/4" FJIC X 1/4” FJIC-45deg) 1

16 204495 Hose 1/4" X 30" (1/4" FJIC X 1/4” FJIC) 1

17 204497 Motor to Manifold Pressure Hose 1 X 67” 4000 PSI (–16 FFS X –16FFS) Kevlar 2

18 204498 Hose 1" X 67 3000 Psi (1" Fjic X -16s) Kevlar 2

19 204436 Manifold, Valve Assemply 1

19

14

15

2

13

11 4

10

3

1

1

2

7

6

9

9

17

18

1

8

10

2

7 8

19

12

18

17

This manual suits for next models

2

Table of contents

Other Blue Diamond Grinder manuals