Blue Diamond PN 104605 Manual

Swing Arm Stump Grinder

Operation & Maintenance Manual

Date Purchased: ____________________________________

Purchased From: ___________________________________

Model Number: _____________________________________

Serial Number: _____________________________________

REMEMBER: Register your product! No claims for warranty shall be

considered unless your product registration is completed online within

30 days of purchase.

To Register: www.bluediamondattachments.com/warranty-registration/

2

The list below shows all revisions

of the Stump Grinder Operations

and Maintenance Manual

Summary of

Changes First

Revision

Publication Date:

September 2018

Document Revision

First Publication

Corporate Headquarters

Blue Diamond Attachments, LLC.

4512 Anderson Rd.

Knoxville TN, 37918

toll free 800-376-7027

local 865-246-2006

fax 865-246-2007

www.bluediamondattachments.com

Forward

Congratulations on the purchase of your Blue Diamond Stump Grinder!

Blue Diamond Stump Grinders are designed by people with years of experience in the landscape business. You can be

sure that the quality and innovation of Blue Diamond is our first priority. Getting to know your new stump

grinder should be the first step in learning its features and limitations. This manual is designed to assist you in the

operation and maintenance of your grinder.

Document History

3

Contents

Forward

Blue Diamond Safety

About This Manual

Terminology & Hazard Notices

Safety Notices

Modifications of Equipment

About the grinder

Grinders

Attaching the grinder

Removing the grinder

Operation

Equipment Inspection

Usage Guidelines

How to Grind Stumps

Maintenance

Detailed Parts Diagrams

Parts Identification List

Specifications

Manufacturer’s Warranty

2

4

4

4

4

4

5

5

6

6

7

7

7

8

9

10

11

12

13

4

Blue Diamond Safety

ABOUT THIS MANUAL

Read this manual and follow safety instructions before operating the grinder. Learn to operate the stump grinder and its

controls properly. Never let anyone operate without instruction. This manual contains information about the usage

and maintenance required for the equipment. This document must be available for review by the operator before

using the attachment to ensure proper safety, maintenance, and usage.

TERMINOLOGY & HAZARD NOTICES USED IN THIS MANUAL

CAUTION

WARNING

DANGER

Cautions are used to indicate a potentially hazardous situation which, if not avoided, may result

in damage to the equipment or other property.

Warnings are used to indicate a potentially hazardous situation which, if not avoided, could

result in serious injury or death.

Danger is used to indicate a potentially hazardous situation which, if not avoided, will result in

serious injury or death.

Prime Mover The Blue Diamond Stump Grinder can be attached to many different pieces of equipment;

therefore the term “prime mover” will be used. A prime mover is any loader, tractor or

equipment providing power to the attachment.

SAFETY

Safety Notices

Before operating or conducting maintenance on this equipment, it is important to wear proper protection.

Recommended safety equipment when operating and maintaining this equipment include close fitting

clothing, earplugs, eye protection, and a hard hat. Additional safety equipment may be required depending on

the operating environment and worksite conditions.

Only qualified and trained personnel should operate, maintain, and service this attachment. It is recommended that this

equipment be inspected regularly for leaks, cracks, or other conditions that may impair proper usage of the equipment.

Verify that all repairs have been completed and inspected prior to using the attachment under load.

It is the responsibility of the user to follow all local, state, and federal safety regulations. Improper use of this

equipment may result in personal injury, property damage, and/or damage to the equipment.

AVOID

WARNING

high pressure fluids. Escaping fluid under pressure can penetrate the skin and cause serious

injury. Relive pressure BEFORE disconnecting hydraulic lines. Tighten all connections before

applying pressure. IF AN ACCIDENT OCCURS, SEE A DOCTOR IMMEDIATELY. Any

fluids injects into the skin must be surgically removed within a few hours or gangrene may

result.

Do not operate the grinder if any of the safety guards are not in place.

Modifications to Equipment

Any modifications made to this equipment may void any warranty and relieve the manufacturer of liability of

any resulting injury or damage

5

Grinders

The Blue Diamond Stump Grinder attachment is a necessity for

tree companies, landscapers, agricultural producers and

rental companies looking to increase their productivity

and efficiency when stump grinding.

The grinder is designed by people with years of experience with

attachments for machinery. You can be sure that the quality of

the Blue Diamond Stump Grinder is our first priority.

The grinder has been designed to deliver the productivity of a

dedicated machine,but it costs four to five times less. This

grinder is engineered for skid steers with high flow

hydraulics(30-45 GPM). A hydraulic grinder motor for

maximum productivity, heavy weight for increased stability,

and super high efficiency cutting performance are just a few

features that combine to bring you the world’s finest stump

grinder!!

About the grinder

The stump grinder attachment is intended for use in stump grinding. Use if this equipment in any other manner

is considered to be contrary to the intended use of the attachment.

6

Attaching the grinder to the Prime Mover

NOTE

Before attempting to attach the grinder to the

prime mover, verify that all hydraulic

couplers are compatible.

CAUTION

Hydraulics should operate in an even and

smooth manner. Hydraulic movement that is

not even and smooth may indicate that air is

in the hydraulic lines.

WARNING

Improper attachment to the prime mover may

cause personal injury.

CAUTION

All hydraulic connections must be clean and

free of debris before making any connection.

WARNING

Improper disconnection may result in

personal injury or damage to the attachment

and prime mover.

CAUTION

All hydraulic connections must be clean and

free of debris before disconnection

NOTE

Hydraulic connections must be disconnected

before disengaging latches to prevent damage

to the prime mover or the attachment.

1. Place the grinder attachment on a level surface.

2. Position and align the prime mover to the rear of the

attachment, within proximity of the front of prime mover.

3. Insert and connect the prime mover into the attachment.

4. Connect the hydraulic lines from the attachment to the prime

mover.

5. Close latches (or other locking mechanism) to secure the

attachment to the prime mover.

6. Using the prime mover withtheMultifunction controllerand

harness, raise the attachment and move the attachment to

ensure hydraulic lines are clear of air and operate properly.

7. Lower the attachment to ground level.

8. Route hoses away from pinch areas –install cable ties if

necessary to assure extended hose life.

9. Inspect that the attachment is mounted properly and securely.

If the attachment does not meet this requirement, follow the

instructions to remove the grinder and re-attach using the

instructions above.

1. Using the prime mover, lower the attachment to the

ground.

2. Relieve the pressure in the hydraulic system by

following these instructions:

a. Turn the ignition to off.

b. Turn the ignition back to the on position without

starting the machine.

c. Move the auxiliary hydraulic function lever back

and forth to relieve the pressure in the hydraulic lines

(this will greatly assist you when hooking the unit

back up so that the hydraulic couplers connect easily).

3. Disconnect the hydraulic connection between the

attachment and the prime mover. To prevent

contamination, remove any dirt and debris from the

couplers.

4. Disengage the prime mover latches (or other locking

mechanism) from the attachment.

5. Remove the prime mover from the attachment.

Removing the grinder from the Prime Mover

7

Operation

NOTE

Replace any damaged hardware, hoses and

fittings before using the equipment.

WARNING

Do not use hands to check for hydraulic

leaks. Keep body parts away from the

leaking hydraulic lines and couplers that are

under pressure.

DANGER

Keep all body parts away from the grinder

when in use. The pivoting blade is

dangerous and hazardous and could

potentially cause serious bodily injury or

death.

CAUTION

Always be aware of what is overhead when

operating the grinder

Inspection Checklist

Are all safety notices and warning

stickers in proper locations and

visible?

Are there any visible hydraulic

leaks?

Are any cracks visible in structure of

the grinder?

Is the cutting wheel bent?

Are bolts holding teeth secure and

tight?

Has the prime mover been properly

inspected for hydraulic leaks and

proper tire inflation?

Has the prime mover been properly

maintained?

Equipment Inspection

It is recommended to inspect the equipment for damage and wear

before use. Use the following list as a guideline during equipment

inspection.

Check all hardware connections to the prime mover for

damage or fatigue such as cracks or other structural flaws

Check that all latches or locks are closed

Check that all hydraulic fittings are tight and free of leaks

Check that all hydraulic lines are free of leaks, holes or

cracks

Check that the tires on the prime mover are in good

condition and have proper load ratings

Usage Guidelines

Before each use of the stump grinder, do the following:

Perform the equipment inspection by performing a walk

around

Perform daily inspection as indicated on the Inspection

Checklist

Verify that the proper attachment is being used for the

task

As with any power attachment, safety is critical. An

enclosed cab prime mover with the operation wearing

safety protection is required

Never operate the grinder with persons within 100 feet of

range

Disengage grinder and shut off the engine before

leaving the cabin of the prime mover

Keep all body parts away from the grinder when in use

Use caution on slopes and uneven terrain

Never carry passengers

Never leave the machine running unattended

Never leave grinder off the ground when out of the

operator’s seat

Never allow children or untrained personnel operate the

grinder

8

Operation Continued

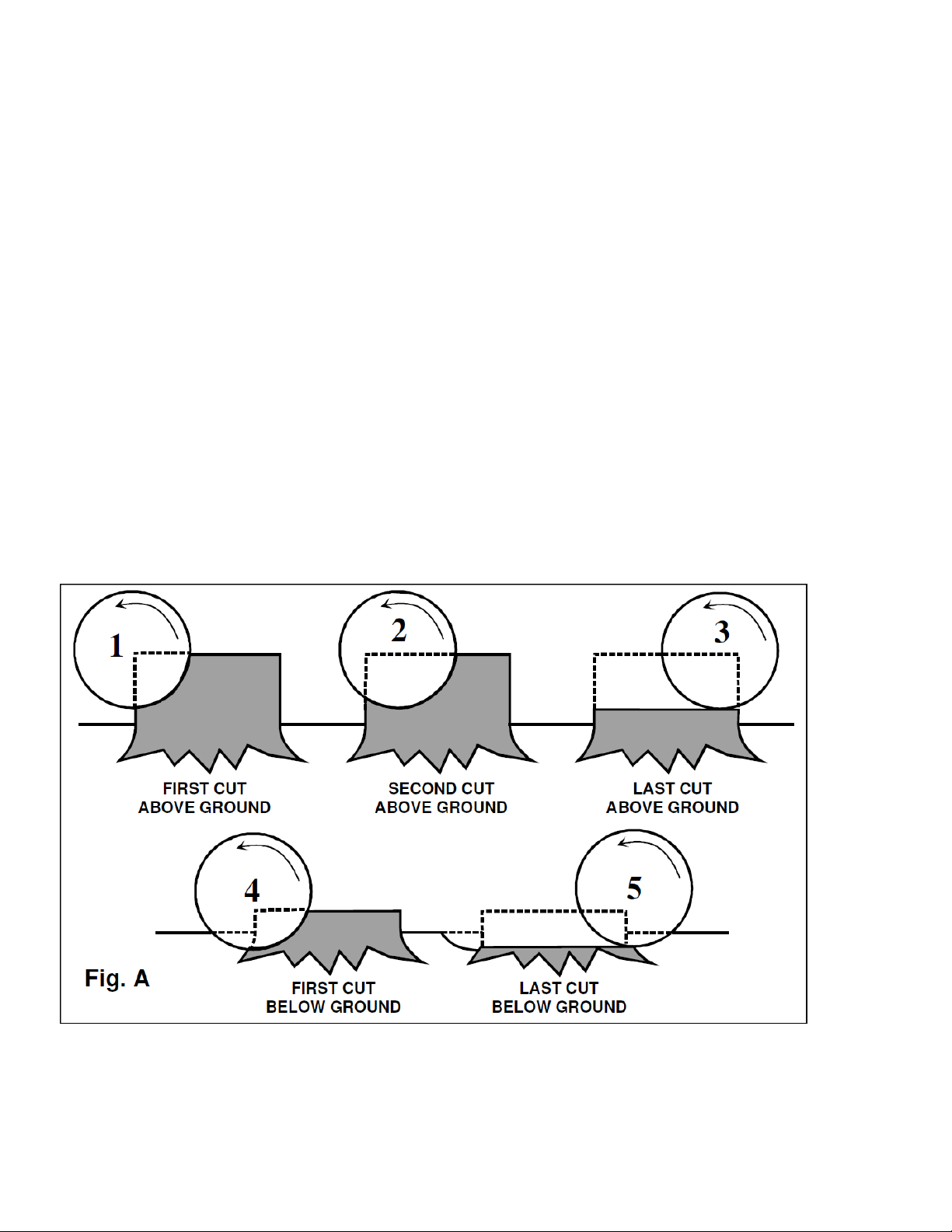

How to Grind Stumps

Align the cutter wheel with the left side of the stump (viewed from the machine control area) and position the machine so

that it will cut about 4-6 inches off the top of the stump and 8-12 inches from the left side of the stump. See FIGURE A.

The rate of cut will depend on the type of tree, condition of the wood, and the condition of the cutters. Too light a feed

will produce sawdust. The ideal feeding rate produces heavy wood chips, some of which may be about 1/16” thick by

approximately 6-8 inches long, as well as chunks of wood. After completing the first cut through the stump, move the

machine to the right (again as viewed from the control area) so the wheel can cut another 8-12 inches. Proceed with

anther cut. Additional passes, when the tree stump is very large, are made in the same manner as described above.

Repeat the procedure until the stump is cut to ground level.

Before cutting below the ground level, make certain that all rock or stone is removed from the immediate area of the

cutting wheel. When you are cutting below the ground level, the feed rate should be reduced and the operator should be

alert to the possibility of cutting hidden rock. Extra care used in this part of the operation can avoid costly damage to the

cutting wheel and teeth.

The wheel is designed so that it can “saw” or cut its way into solid wood by dropping straight down on it. This operation

works well for cutting off large roots.

NOTE:DO NOT operate grinder with safety guards removed

9

NOTE

Disconnect the hydraulic connection between

the attachment and the prime mover before

performing any type of maintenance on the

grinder.

GREASE POINTS

Cutting Wheel

Be certain to check carbide cutting teeth for wear. Replace teeth

as necessary.

Hoses

Check hoses occasionally for abrasion damage. This may save you

from downtime. If in doubt, replace with genuine Blue Diamond

parts.

Pivot Pins

Pivot pins may be lubed with moly-type grease, same as what is

used on your machine. Please check the cotter pins that

retain all pivot/anchor pins after each use. If missing, replace!

Severe damage could be caused by losing a pin.

Grease Points

There are 6 grease points on the grinder. Each grease point

should have new grease applied daily when being used.

Approximately every 8 hrs. Please refer to the pictures for the

6 grease points.

Storage

Lubrication of pivot pins is recommended if unit is stored outside.

Be certain hydraulic quick couplers are cleaned and joined together

to keep dirt out. A light coating of oil film or diesel fluid is

recommended to prevent corrosion. Touch-up paint should be used

on all scratches to prevent further rust.

Maintenance

10

Detailed Parts Diagram

Swing arm stump grinder –Parts Diagram

11

Parts Identification List

Item #

Part#

Description

23008

Bracket, Lift

34001

WHEEL, STANDARD,

35052

HARNESS, 6 FUNCTION

54227

3/8" PROOF COIL SELF COLOR,

69001A

1/4" Polycarbonate 75SS Shield

FK0008

FITTINGS KIT, PRO75 SS

FK-5014

FASTENER KIT FOR PRO75SS

FS15HDA31302713A0D316ADBM

HYDRAULIC GRINDER MOTOR –130 - 2933

FS15HDA31502713A0D316ADBM

HYDRAULIC GRINDER MOTOR –150 - 3339

FS15HDA31702713A0D316ADBM

HYDRAULIC GRINDER MOTOR –170 - 3945

GB3236-024

Garlock Bushing, 2" X 1.5""

GB3236-032

Garlock Bushing, 2" x 2""

HK0008

HOSE KIT, PRO75 SS

MFJC

CONTROLLER, MULTI-FUNCTION

P25010

OMNI GEAR MDH40 W/CASTLE NUT

P25022

CHECK VALVE, CASE DRAIN

P25039

WASHER, PLASTIC

P25047

O-RING FOR STUMP GRINDER

P25058

WHEEL,8 TOOTH HIGH PERFORMACE

P25059

WHEEL, REVOLUTION HD-26"

P25060

COUPLER,1/4" FEMALE CASE DRAIN

P25061

COUPLER,3/8" FEMALE CASE DRAIN

P25062

COUPLER, 3/8" MALE CASE DRAIN

P25200

MANIFOLD, VALVE ASSEMBLY FOR

P25507

CYLINDER, SWING, 2.5 X 6,

P25508

CYLINDER, EXTEND, 2.5 X 12,

P25510

CYLINDER, LIFT, 4.5 X 8

P25511

UHMW PLASTIC SLIDE

P25512

PIN, LIFT, BASE END

P25513

PIN, LIFT, ROD END

P25516

WASHER, MACHINED

P25517

SNAP RING, EXTERNAL

P25545

DECAL KIT, WARNING

P25546

HARNESS, CAT 14 PIN

P25547

HARNESS, CAT 8 PIN

P25548

HARNESS, UNIVERSAL 14 PIN

P25549

HARNESS, UNVERSAL 8 PIN

P25550

PIN, TELESCOPIC BASE

P25551

PIN, CENTER ROTATION

P25553

PIN, CENTER TILT

P50010F

FLAT FACE COUPLER, FEMALE

P50010M

FLAT FACE COUPLER, MALE

65

65

65

17

16

18

20

21

12

P80010F

FLAT FACE COUPLER 5/8" FEMALE

P80010M

FLAT FACE COUPLER 5/8" MALE

P90010F

FLAT FACE COUPLER 3/4" FEMALE

P90010M

FLAT FACE COUPLER 3/4" MALE

STEEL KIT 75SS

STEEL KIT FOR 75SS

T100HB

Hardened Bolt

T100HW

Hardened Washer

T100L

LEFT SIDE TOOTH

T100R

RIGHT SIDE TOOTH

T100S

STRAIGHT TOOTH

T100TMB

THREADED MOUNT BLOCK

Specifications

Model Number

PN 104605 PN 104610 PN 104615

Requirements:

SkidSteer Lifting

Capacity(lbs.)

2,400

2,400

2,400

Hydraulic HP

55-77

70-91

68-105

Hydraulic Flow

29-33GPM

33-39GPM

39-45GPM

Hydraulic Pressure

3,000-4061 PSI

3,000-4061 PSI

3,000-4061 PSI

Case Drain

Yes

Yes

Yes

Product Data:

Cutting Wheel Diameter

26”

26”

26”

Cutting Wheel

Thickness

1.25”

1.25”

1.25”

Number of Teeth

32

32

32

Weight(lbs.)

1,640

1,640

1,640

Available Upgrades:

6 Tooth Low Flow

Wheel

NO

NO

NO

8 Tooth High Flow

Performance Wheel

Yes

Yes

Yes

5 Hose Control Upgrade

Yes

Yes

Yes

Universal Controller with

Harness

Yes

Yes

Yes

13

Six-Month Limited Warranty

Warranty Claim

Exclusions of Warranty

Remember: Register your product! No

claims for warranty shall be considered

unless your product registration has

been submitted online within 30 days of

purchase.

To Register Product Go To:

bluediamondattachments.com/warranty-registration/

Blue Diamond Attachment, warrants new Blue Diamond Stump

GRINDERS at the time of delivery to the original purchaser, to be free

from defects in material and workmanship when properly set up and

operated in accordance with the recommendations set forth by Blue

Diamond. Blue Diamond's liability for any defect with respect to

accepted goods shall be limited to repairing the goods at a Blue

Diamond designated location or at an authorized dealer location, or

replacing them as Blue Diamond shall elect. The above shall

be in accordance with Blue Diamond warranty adjustment

policies. Blue Diamond's obligation shall terminate

six (6) months after the delivery of the goods to original purchaser.

This warranty shall not apply to any machine or attachment which shall

have been repaired or altered outside the Blue Diamond factory or

authorized Blue Diamond dealership or in any way so as in Blue

Diamond's judgment, to affect its stability or reliability, nor which has

been subject to misuse, negligence or accident beyond the Company

recommended machine rated capacity.

To submit a warranty claim, a return authorization from Blue Diamond

must be obtained. The failed part may then be returned. Tampering with

the failed part may void the warranty. This warranty may not include

freight or delivery charges incurred when returning machinery for

servicing. Dealer mileage, service calls, and pickup/delivery charges are

the customers’ responsibility.

Except as otherwise expressly stated herein, Blue Diamond Attachments

makes no representation or warranty of any kind, expressed or implied,

AND MAKES NO WARRANTY OF MERCHANTABILITY IN

RESPECT TO ITS MACHINERY AND/OR ATTACHMENTS ARE

FIT FOR ANY PARTICULAR PURPOSE. Blue Diamond shall not be

liable for incidental or consequential damages for any breach of

warranty, including but not limited to inconvenience, rental of

replacement equipment, loss of profits or other commercial loss. Upon

purchase, the buyer assumes all liability for all personal injury and

property resulting from the handling, possession, or use of the goods by

the buyer.

No agent, employee, or representative of Blue Diamond has any

authority to bind Blue Diamond to any affirmation, representation or

warranty concerning its machinery and/or attachments except as

specifically set forth herein.

This warranty does not cover abuse, modifications by others, or

leaking hoses due to improper routing, abrasion, or pinching.

This warranty policy supersedes any previous documents.

No claims for warranty shall be considered unless warranty registration

is submitted to Blue Diamond within 30 days of purchase.

Manufacturer’s Warranty

This manual suits for next models

2

Table of contents

Other Blue Diamond Grinder manuals

Popular Grinder manuals by other brands

Meterk

Meterk S1M-GW20-115 Translation of the original instructions

U.S.SAWS

U.S.SAWS SX65000C operating manual

Parkside

Parkside PWS 230 C3 Translation of the original instructions

SUHNER ABRASIVE

SUHNER ABRASIVE ASC 9 Technical document

PTA

PTA P1322 Operation manual

Craftsman

Craftsman CMCG400 instruction manual