BLUE JAY BJ-PR240 Series User manual

User Manual

Tel: +0086-023-67628702 Email:tech@cqbluejay.com

www.cqbluejay.com

Add: 1802,Building 2,No.88,Jianxin East Road,Chongqing,400020,China

BJ-PR240 series

Motor Protect Relay

User Manual

Version 3.7

Revision 2022-8

User Manual

Tel: +0086-023-67628702 Email:tech@cqbluejay.com

www.cqbluejay.com

Add: 1802,Building 2,No.88,Jianxin East Road,Chongqing,400020,China - 1 -

Read me

When you use BJ-PR240 series intelligent motor protection relay, be sure to read this user

manual carefully, and be able to fully understand the implications, the correct guidance of

operations in accordance with user manual, which will help you make better use of BJ-

PR200 series motor protector, and help to solve the various problems at the scene.

1. Before the meter turning on the power supply, be sure that the power supply within the provisions

of the instrument;

2. When installation, the current input terminal must non-open, voltage input terminals must Non-

short circuit;

3. Communication terminal (RS232/RS485 or Ethernet) is strictly prohibited to impose on high

pressure;

4. Be sure the instrument wiring consistent with the internal system settings;

5. When communicating with the PC, instrument communication parameters must be consistent

with the PC.

●Please read this user manual carefully

●Please save this document

User Manual

Tel: +0086-023-67628702 Email:tech@cqbluejay.com

www.cqbluejay.com

Add: 1802,Building 2,No.88,Jianxin East Road,Chongqing,400020,China - 2 -

Directory

1. - SUMMARIZE.................................................................................................................................- 4 -

2. - FEATURES ...................................................................................................................................- 4 -

3. - SPECIFICATIONS ........................................................................................................................- 5 -

4.- INSTALLATION AND START-UP ..................................................................................................- 9 -

4.1.- INSTALLATION ............................................................................................................................ - 9 -

4.1.- TERMINAL DEFINITION ...............................................................................................................- 11 -

TERMINAL DEFECATION .....................................................................................................................- 11 -

5. OPERATION MODE......................................................................................................................- 12 -

5.1- LCD DISPLAY SCREEN ............................................................................................................... - 12 -

5.2- PANEL LED INDICATOR ............................................................................................................. - 12 -

5.3- MOTOR CONTROL BUTTONS ...................................................................................................... - 13 -

5.3- CONFIGURATION BUTTONS ........................................................................................................ - 14 -

5.4- MEASUREMENT INTERFACE ....................................................................................................... - 15 -

5.5- CONFIGURATION INTERFACE ...................................................................................................... - 16 -

6. - RS485 COMMUNICATION PORTOCOL....................................................................................- 23 -

6.1.- MODBUS © PROTOCOL .......................................................................................................... - 23 -

6.1.1- Modbus RTU Frame Format:...........................................................................................- 23 -

6.1.2.- Modbus function code ....................................................................................................- 24 -

6.2.- MOTOR STATUS PARAMETER (READ ONLY, CODE 04) ................................................................ - 26 -

6.3.- MOTOR BASIC CONFIGURATION (READ AND WRITE)................................................................... - 29 -

6.4.- MOTOR PROTECTION FUNCTIONS CONFIGURATION (READ AND WRITE)....................................... - 30 -

6.5.- MOTOR START MODE CONFIGURATION (READ AND WRITE)......................................................... - 32 -

6.5.- SEQUENCE OF EVENT RECORD (READ ONLY, CODE 04)............................................................. - 33 -

6.5.- MOTOR ADVANCED CONTROL (READ AND WRITE)...................................................................... - 34 -

7.- PORTECTION FUNCTION INTRODUCTION .............................................................................- 35 -

7.1- START OVERTIME PROTECTION ................................................................................................. - 35 -

7.2- OVERLOAD PROTECTION........................................................................................................... - 36 -

7.3- JAM IN RUNNING PROTECTION (STALL)...................................................................................... - 40 -

7.4- JAM IN STARTING PROTECTION (ROTOR LOCKED)....................................................................... - 40 -

7.5- PHASE FAILURE PROTECTION.................................................................................................... - 40 -

7.6- CURRENT IMBALANCE PROTECTION ........................................................................................... - 41 -

7.7- GROUND FAULT PROTECTION.................................................................................................... - 41 -

7.8- UNDER POWER PROTECTION .................................................................................................... - 42 -

7.9- OVER TEMPERATURE PROTECTION............................................................................................ - 42 -

7.10- SHORT CIRCUIT PROTECTION .................................................................................................. - 42 -

7.11- OVER VOLTAGE PROTECTION .................................................................................................. - 43 -

7.12- UNDER VOLTAGE PROTECTION ................................................................................................ - 43 -

User Manual

Tel: +0086-023-67628702 Email:tech@cqbluejay.com

www.cqbluejay.com

Add: 1802,Building 2,No.88,Jianxin East Road,Chongqing,400020,China - 3 -

7.13- ABNORMAL FREQUENCY PROTECTION ..................................................................................... - 44 -

7.14- ABNORMAL POWER FACTOR PROTECTION................................................................................ - 45 -

7.15.- TE PROTECTION .................................................................................................................... - 45 -

8- MOTOR START MODE INTRODUCTION....................................................................................- 47 -

8.1.- ONLY PROTECTION MODE ......................................................................................................... - 47 -

8.2.- FULL VOLTAGE START MODE...................................................................................................... - 49 -

8.3.- FORWARD AND REVERSE START MODE....................................................................................... - 50 -

8.4.- TWO-WINDING START MODE ..................................................................................................... - 51 -

8.5.- WYE-DELTA TRANSITION MODE................................................................................................. - 52 -

8.6.- AUTOTRANSFORMER CLOSED TRANSITION MODE ...................................................................... - 53 -

8.7- CIRCUIT BREAKER DIRECTLY START MODE .................................................................................. - 54 -

9. - SAFETY CONSIDERATIONS.....................................................................................................- 55 -

10. - MAINTENANCE........................................................................................................................- 55 -

User Manual

Tel: +0086-023-67628702 Email:tech@cqbluejay.com

www.cqbluejay.com

Add: 1802,Building 2,No.88,Jianxin East Road,Chongqing,400020,China - 4 -

1. - SUMMARIZE

PR240 motor protection relay is an all-in-one solution designed to continuously monitor 3-phase

power lines for abnormal conditions. It can use with motors less than 690V/820A. It can realize a

variety of control operation, as well as measurement, self-diagnosis, maintenance management,

field bus communication and other functions.

The series of products through the real-time monitoring of the scene signal, provide various

protection trip to avoid motor failure. Option RS485 communication port can upload the monitor

data and alarm status to remote control system.

Protection function

(Details please refer to chapter 7)

Real-time monitor parameter

Start Overtime (Max. Start time),

Over Load,

Phase Failure (Phase loss),

Jam in starting(Stall),

Current imbalance,

Under power,

Jam in running,

Ground fault,

Over temperature,

Short circuit,

Over voltage,

Under voltage,

Abnormal frequency,

Abnormal power factor,

tE protection (Increased safety motor

overload)

Automatic restart,

Three-phase current,

Three-phase line voltage,

Frequency,

Active power,

Reactive power,

Apparent power,

Power factor,

Electrical energy,

Ground residential current

2. - FEATURES

-. Various electrical parameter real-time detect, Dot matrix LCD display.

-. Built-in 4-channels relay, provide various start methods: Direct start, positive & negative start,

star - delta start, autotransformer start, 2-speed motor start, circuit breaker direct start and

protection trip logic.

-. User free to set each protection function act off, alarm or trip.

-. Build in Sequence of Event function, can logger last 100 trip records.

-. With programmable analog output function, user option RS-485 communication interface.

User Manual

Tel: +0086-023-67628702 Email:tech@cqbluejay.com

www.cqbluejay.com

Add: 1802,Building 2,No.88,Jianxin East Road,Chongqing,400020,China - 5 -

3. - SPECIFICATIONS

Working environment:

Motor rated voltage:

AC380V / AC660V

Motor rated current:

0.5-820A

Working temperature:

-10C ~ +55C

Storage temperature:

-25C ~ +70C

Relative humidity:

< 93% RH

Elevation:

not more than 3000 m

Atmospheric conditions:

installation site does not allow the explosive medium,

containing gas to corrode metal and damage the insulation

and conductive medium.

Measuring accuracy:

Current:

±0.5% @ 10% to 200% of Ie

Voltage:

±0.5% @ 10%~150%Ue

Frequency:

±0.1% @ 45 ~ 65Hz

Power factor:

±1.0% @ 0 ~ 1.000

Active Power

±1.0% @ 0 ~ 500kW

Leakage current:

± 1% @10% to 100% of Ir

Analog Output:

±1% @4 ~20mA

Electrical parameters:

Auxiliary Power:

AC90-240Vac/dc

Power consumption:

<10 VA

Insulation resistance:

>100MΩ

Relay:

Alarm relay @ 5A / 250VAC, 5A / 30VDC (NO node)

User Manual

Tel: +0086-023-67628702 Email:tech@cqbluejay.com

www.cqbluejay.com

Add: 1802,Building 2,No.88,Jianxin East Road,Chongqing,400020,China - 6 -

Electrical test:

IEC 61000-4-2

level III

IEC 61000-4-4

level III

IEC 61000-4-5

level III

IEC 61010-1

AC2kV/1min Between power / input / output

Product standards

GB / T 14048.1

(IEC 60947-1)

Low-voltage switchgear and control equipment General Provisions

GB /T14048.4

(IEC 60947-4)

Low voltage electromechanical contactors and motor starters

requirements

JB / T 10613-2006

General specification for digital motor combined protection

equipment

JB /T10736-2007

Low voltage motor protection

User Manual

Tel: +0086-023-67628702 Email:tech@cqbluejay.com

www.cqbluejay.com

Add: 1802,Building 2,No.88,Jianxin East Road,Chongqing,400020,China - 7 -

Product selection guide

PR240- □-□□□-□-□

HMI cable

(Chart 3.3)

Optional function

(Chart 3.2)

Rated

current/volt(Power)

(0.5-820A)

Motor start method

(Chart 3.1)

SN

Preset Motor Start method

Code

1

Protect only

A

2

Full voltage

B

3

Forward and reverse start

C

4

Two-Winding start

S

5

Wye-Delta Transition

D

6

Autotransformer Closed Transition

G

Chart 3.1

HMI cable length

Code

1-meter cable

D1

3-meters cable

D3

3-meters cable

D5

Chart 3.3

External protection CT selection guide, typical in 380V grid:

Motor rated

power (Kw)

Rated

current (A)

Internal

CT range

0.06

0.22

10A

0.12

0.42

0.37

1

0.55

1.5

0.75

2

1.1

2.5

2.2

5

3

6.5

5.5

11

100A

7.5

14.8

11

21

15

28.5

18.5

35

22

42

30

57

37

69

45

81

55

100

Motor rated

power (Kw)

Rated

current

(A)

Internal

CT

External

CT

75

135

10A

500/5

90

165

110

200

132

240

160

285

200

352

220

420

250

480

Notes: If motor rated current over 100A, need to connect

an external CT, Blue Jay suggest use 500/5A CT. In

Configuration menu-[CT ratio] set to 100.(See chapter

5.6.2)

SN

Optional function

Code

1

With Zero sequence CT

L

2

4 ~ 20mA analog port

M

3

Temperature probe

T

4

SOE record

R

Notes: Standard type without additional function,

If need multiple additional functions the coded

arranged in sequence after main code.

Chart 3.2

User Manual

Tel: +0086-023-67628702 Email:tech@cqbluejay.com

www.cqbluejay.com

Add: 1802,Building 2,No.88,Jianxin East Road,Chongqing,400020,China - 8 -

Residual current sensor

If PR240 choose ground fault protection, need external LCT05/30 series CT for detect leakage

current.

LCT05 rated current of 500mA, the current range (50 ~ 500mA)

LCT30 rated current of 30A, the current range of (3 ~ 30A)

Each PR240 need 1pcs, please contact sales team for purchase issue.

Wiring core for cable type

Current

range

Dimension (mm)

φ

A

B

C

D

E

F

G

H

16-100A

45

77

85

24

38

54

9

64

54

100-250A

80

112

122

28

56

80

14

89

80

250-400A

100

131

136

24

66

96

14

108

107

400-800A

150

200

209

28

100

145

16

184

177

Wiring core for cooper bar type

Current

range

Dimension (mm)

A1

B1

A

B

C

D

E

F

G

0-63A

100

20

133

50

16

144

140

3

2.0

0-100A

100

25

133

60

24

154

143

9

2.5

0-225A

140

32

172

72

24

189

184

9

2.5

0-250A

180

32

212

72

24

229

224

9

2.5

0-400A

220

45

254

86

24

269

264

11

2.5

0-630A

260

45

294

86

24

309

304

11

2.5

0-1600A

300

45

334

86

24

349

344

11

2.5

0-4000A

420

45

454

86

24

469

464

11

2.5

Notes: Protection function please refer Chapter 7.7

User Manual

Tel: +0086-023-67628702 Email:tech@cqbluejay.com

www.cqbluejay.com

Add: 1802,Building 2,No.88,Jianxin East Road,Chongqing,400020,China - 9 -

4.- INSTALLATION AND START-UP

The manual you hold in your hand contains information and warnings that the user

should respect in order to guarantee a proper operation of all the instrument functions

and keep it in safety conditions. The instrument must not be powered on and used until

its definitive assembly is on the cabinet’s door.

If the instrument is not used as manufacturer’s specifications, the protection of the

instrument will be damaged.

When any protection failure is suspected to exist (for example, it presents external visible

damages), the instrument must be immediately powered off. In this case contact a qualified

service representative.

4.1.- Installation

Mounting

PR240 series motor protection relay designed as separate 2 parts, one for din-rail mounting body,

another is panel mounting HMI.

Note that with the instrument powered on, the terminals could be dangerous to touch and cover

opening actions or elements removal may allow accessing dangerous parts. Therefore, the

instrument must not be used until this is completely installed.

Note: This connection drawing is for reference only; the actual connecting terminal please refer to

the label on the rear part.

User Manual

Tel: +0086-023-67628702 Email:tech@cqbluejay.com

www.cqbluejay.com

Add: 1802,Building 2,No.88,Jianxin East Road,Chongqing,400020,China - 10 -

User Manual

Tel: +0086-023-67628702 Email:tech@cqbluejay.com

www.cqbluejay.com

Add: 1802,Building 2,No.88,Jianxin East Road,Chongqing,400020,China - 11 -

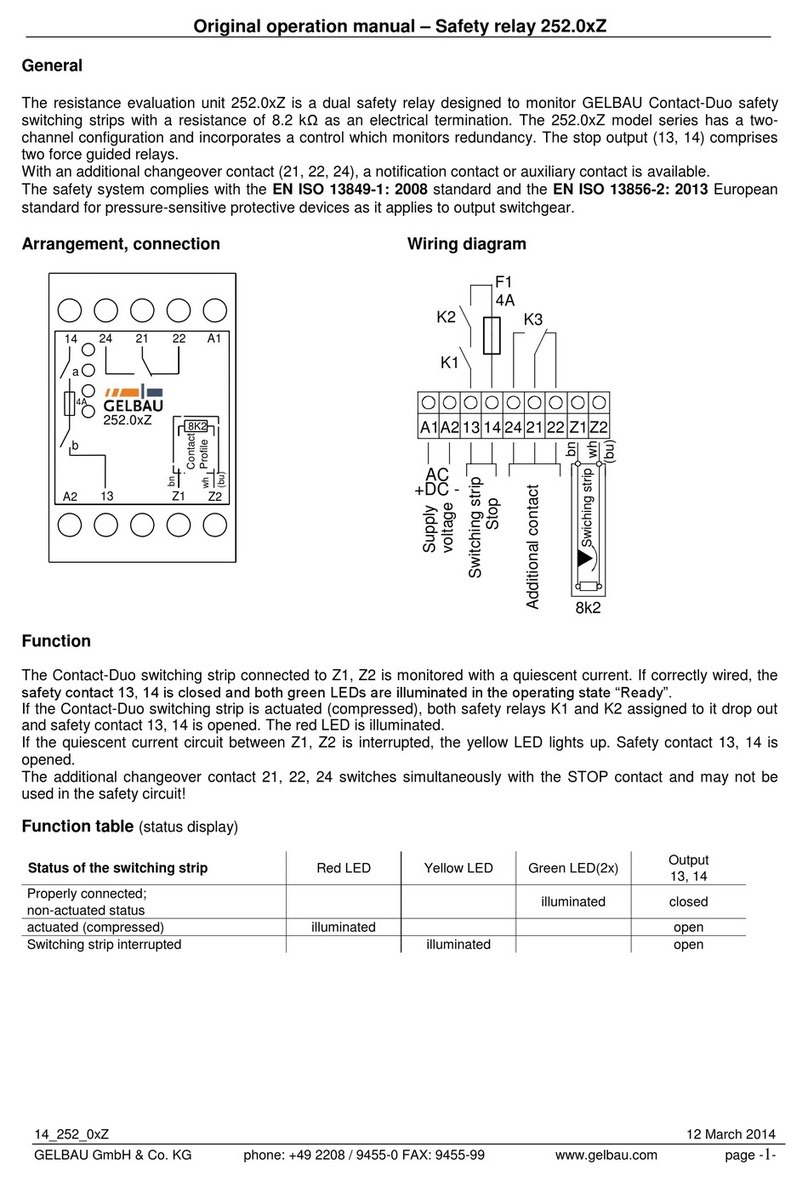

4.1.- Terminal Definition

LED indicator Introduction

Run/Stop:

Always ON when motor stopped;

Flicker when motor running.

COMM:

Flicker when RX/TX.

Alarm/Failure

Always ON when device have failure;

Flicker when motor in alarm threshold trigged.

Notes:

1. PR240 provide 7 digital input terminals, external signal sampling interval >= 100ms. 15Vdc

internal feeder, external can be controlled by passive contacts.

2. DI status can be set in NO or NC.

3. PR240 provide 4 relay outputs, DO status can be set in NO or NC, support Level output or

Pulse output.

Caution:

1. Forbidden to connect external feed voltage to DI terminals!

2. Do not wire the DI terminal in the same tube or twist it with high voltage cable!

3. If distance more than 2 meters must use shielded cable! The maximum distance of the DI

pinout should not exceed 300 meters!

Terminal defecation

Terminal No.

Description

11

A-phase voltage

12

B-phase voltage

13

C-phase voltage

4

A-phase current

6

B-phase current

8

C-phase current

10

Zero sequence current input

42

Leakage current input+

43

Leakage current input-

44

NTC -

45

NTC +

58

RS485A

59

RS485B

19-20

DO1

21-22

DO2

23-24

DO3

25-26

DO4

15

4~20 mA-

16

4~20mA +

70

DI COM Terminal

71

DI 1

72

DI 2

73

DI 3

74

DI 4

75

DI 5

76

DI 6

77

DI 7

1

Aux - L

90~240Vac/dc

2

Aux - N

User Manual

Tel: +0086-023-67628702 Email:tech@cqbluejay.com

www.cqbluejay.com

Add: 1802,Building 2,No.88,Jianxin East Road,Chongqing,400020,China - 12 -

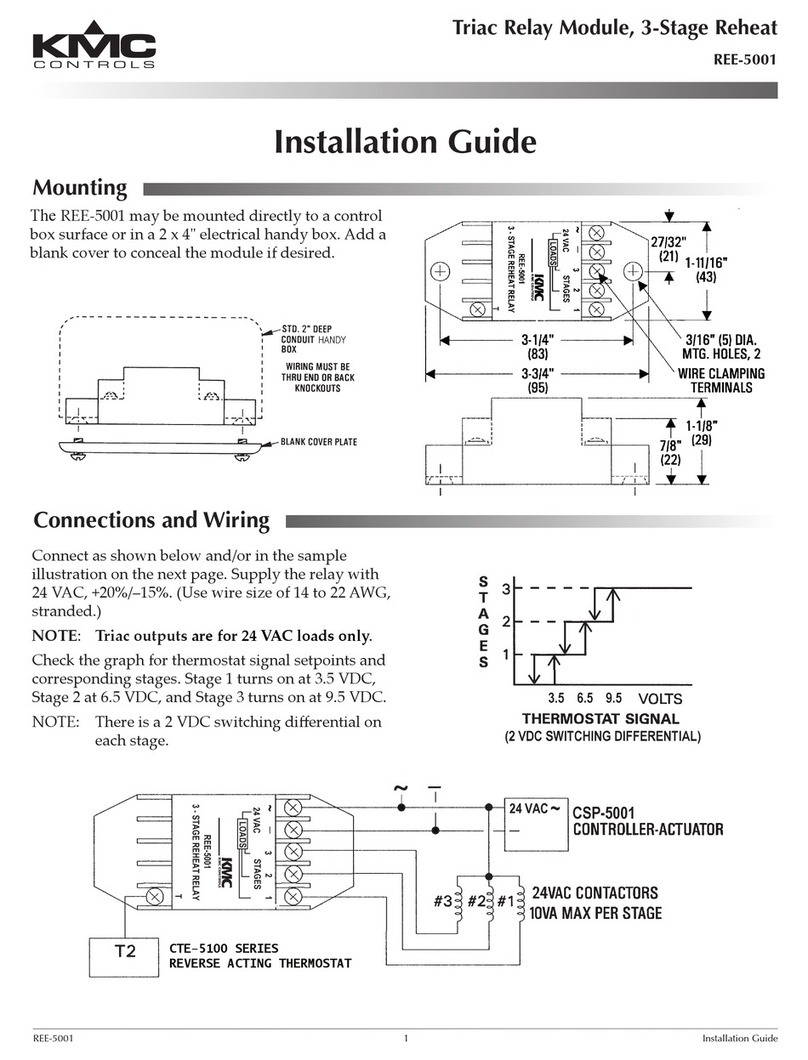

5. OPERATION MODE

PR240 have a HMI, wired to relay

body by DB9 cable;

It used for parameter display and

configuration, also can use operation

button to control motor working or

stop.

LED indicator show motor status.

5.1- LCD display screen

Screen area adopts a large size dot-matrix LCD, backlight is gray. The backlight time free to

configuration. When there is a key operation, the backlight will be re-lit, and will go out after the set

interval.

After device be powered, HMI default screen is measurement interface. In this interface, pressing

the " " button can enter password and switch to configuration interface.

In this configuration menu, user can set the protection mode, system parameter, view fault alarm

record, operation information etc.

5.2- Panel LED Indicator

Indicator mark

Description

Stop

Motor in working status

Motor stopped

Start

Motor in non-start status

Motor in starting period

Runs

Motor in non-runs status

Motor in running

Alarm

Motor in normal status

Alarm threshold trigged

Failure

DO in non-trip status

DO tripped

User Manual

Tel: +0086-023-67628702 Email:tech@cqbluejay.com

www.cqbluejay.com

Add: 1802,Building 2,No.88,Jianxin East Road,Chongqing,400020,China - 13 -

5.3- Motor Control Buttons

There have 4 key buttons for motor operation:

Local direct control

Under remote

control mode

In “Protect only” mode

Invalid

In “Panel control start/stop” mode

Motor start

Invalid

In “Forward and reverse start” mode

Motor start in forward rotation

Invalid

In “Two-Winding start” mode

Motor start in low winding-1(low speed)

Invalid

In “Wye-Delta Transition” mode

Motor start

Invalid

In “Autotransformer Closed Transition” mode

Motor start

Invalid

Local direct control

Under remote

control mode

In “Protect only” mode

Invalid

In “Panel control start/stop” mode

Motor start

Invalid

In “Forward and reverse start” mode

Motor start in reverse rotation

Invalid

In “Two-Winding start” mode

Motor start in low winding-2(high speed)

Invalid

In “Wye-Delta Transition” mode

Invalid

Invalid

In “Autotransformer Closed Transition” mode

Invalid

Invalid

Local direct control

Under remote

control mode

In “Protect only” mode

Invalid

In “Panel control start/stop” mode

Stop motor immediately

Invalid

In “Forward and reverse start” mode

Stop motor immediately

Invalid

In “Two-Winding start” mode

Stop motor immediately

Invalid

In “Wye-Delta Transition” mode

Stop motor immediately

Invalid

In “Autotransformer Closed Transition” mode

Stop motor immediately

Invalid

Press to release alarm and reset DO port to non-tripped status when motor in Stopped status.

User Manual

Tel: +0086-023-67628702 Email:tech@cqbluejay.com

www.cqbluejay.com

Add: 1802,Building 2,No.88,Jianxin East Road,Chongqing,400020,China - 14 -

5.4- Configuration Buttons

In HMI right are have 4 buttons for configuration operations:

Under measurement interface: Switch to former parameter displayed.

Under configuration interface: Move cursor to left and increase value.

Under measurement interface: Switch to next parameter displayed.

Under configuration interface: Move cursor to right and decrease value.

Under measurement interface: Switch to configuration interface (password requested).

Under configuration interface: Exit or switch to measurement interface.

Confirmed the enter value or setting changes.

5.4.1- Enter configuration menu

In normal monitor status, press , screen will ask Password,

Press into password screen, use and to enter password

Notes: Default user password is 0001),

Then press key to confirm enter, in password correct can into the menu screen,

Notes: If password changed and enter error, screen still ask password again.

5.4.2- Exit configuration menu

After parameter set, press , protector screen show “SAVE”, then press for save the

change and exit, press key for exit without save.

User Manual

Tel: +0086-023-67628702 Email:tech@cqbluejay.com

www.cqbluejay.com

Add: 1802,Building 2,No.88,Jianxin East Road,Chongqing,400020,China - 15 -

5.5- Measurement Interface

Notes:

1. Thermal resistance parameter is only valid when access temperature probe;

2. Symbol of DI/DO status:

Hollow circle means no digital input or no relay trigged;

Solid circle means digital signal looped in or relay be trigged;

3. When the measured current > 1.3 * Protect CT, the display value of measurement error will be

increasing.

4. Press Enter button can switch to Motor status screen:

User Manual

Tel: +0086-023-67628702 Email:tech@cqbluejay.com

www.cqbluejay.com

Add: 1802,Building 2,No.88,Jianxin East Road,Chongqing,400020,China - 16 -

5.6- Configuration Menu

5.6.1- Protection mode configuration

There have 15 different protection mode can configuration, detail function descriptions please refer

to Chapter 7:

Start over time (chapter 7.1):

Over time (chapter 7.2):

User Manual

Tel: +0086-023-67628702 Email:tech@cqbluejay.com

www.cqbluejay.com

Add: 1802,Building 2,No.88,Jianxin East Road,Chongqing,400020,China - 17 -

Jam in running (chapter 7.3):

Jam in running (chapter 7.4):

Phase failure (chapter 7.5)

Current imbalance (chapter 7.6)

Ground fault (chapter 7.7)

Under power (chapter 7.8)

User Manual

Tel: +0086-023-67628702 Email:tech@cqbluejay.com

www.cqbluejay.com

Add: 1802,Building 2,No.88,Jianxin East Road,Chongqing,400020,China - 18 -

Over temperature (chapter 7.9)

Short circuit (chapter 7.10)

Over voltage (chapter 7.11)

Under voltage (chapter 7.12)

Abnormal Frequency (chapter 7.13)

User Manual

Tel: +0086-023-67628702 Email:tech@cqbluejay.com

www.cqbluejay.com

Add: 1802,Building 2,No.88,Jianxin East Road,Chongqing,400020,China - 19 -

Abnormal Power factory (chapter 7.14)

tE protection (chapter 7.15)

Table of contents

Other BLUE JAY Relay manuals