Blue Max Global Arf Operator's manual

1

Instructions for Final Assembly

Version V1.0 4-99 Kit # 232500 All Contents © Copyright 1999

Commemorate the Aviation's beginnings with the new Global Blue Max ARF.

A time when the nose skid was as important as the tail skid to safety minded

pilots landing on unprepared airfields, planes of this style used cutting edge

technology for their day. The Blue Max remembers those years long past. It's

open cockpit, wire spoke wheels and open framework capture a more experi-

mental time in aviation. The high lift wing and generous wing area mean

super slow stall speed and very forgiving flight characteristics. Don't be sur-

prised if you see beginners with this plane. Our test pilots say this plane is

easier to fly than most .40 size trainer planes. And unlike the grossly under-

powered airplanes of yesteryear, the Blue Max is favorably powered using a

.40 size two stroke or a .52 size four stroke. So put on your scarf and your

goggles and get ready to go back into time. Oh, and don't forget to load that

cannon!

40 - 46 Size Almost Ready to Fly

2

TABLE OF CONTENTS

To make your modeling experience totally enjoyable, we recommend that you get experienced, knowledgable help

with assembly and during your first flights. Your local hobby shop has information about flying clubs in your area

whose membership includes qualified instructors. You can also contact the AMA at the address below.

Academy of Model Aeronautics

5151EastMemorialDrive

Muncie,IN. 47302-9252

(800)435-9262

www.modelaircraft.org

Global guarantees this kit to be free from defects in both material and workmanship, at the date of purchase. This does

not cover any components parts damaged by use, misuse or modification. Inno caseshall Global'sliability exceedthe

originalcostof thepurchasedkit.

In that Global has no control over the final assembly or material used for final assembly, no liability shall be assumed for

any damage resulting from the use by the user of the final user-assembled product. By the act of using the final user-

assembled product, the user accepts all resulting liability.

Kit Contents...................................................3

Additional Items Required................................3

Tools and Supplies Needed..............................3

Field Support Equipment Needed......................3

Metric Conversion Chart.................................3

Wing Assembly...............................................4

Install the Dihedral Braces.........................4

Joining the Wing Halves.............................5

Wing Mounting................................................5

Install the Wing Hold Down Dowels...........5

Aligning the Wing to the Fuselage...............6

Install the Wing Struts................................6

Horizontal Stabilizer Mounting..........................6

Align the Horizontal Stabilizer.....................6

Mounting the Horizontal Stabilizer...............7

Vertical Stabilizer Mounting..............................8

Align the Vertical Stabilizer........................8

Mounting the Vertical Stabilizer..................8

Control Surface Installation..............................8

Hinge the Ailerons....................................8

Hinge the Elevator....................................9

Install the Tail Wheel Wire.........................9

Hinge the Rudder......................................9

Mounting the Tail Wheel Bracket.............10

Installing the Tail Wheel...........................10

Main Landing Gear........................................10

Aligning the Main Gear Assembly............10

Installing the Main Gear Assembly...........10

Installing the Main Gear Wheels...............11

Engine Mounting............................................11

Mounting Engine to Motor Mount.............11

Aligning the Motor Mount........................11

Mounting the Engine to Firewall...............12

Nose Skid.....................................................12

Align the Nose Skid.................................12

Installing the Nose Skid............................12

Fuel Tank......................................................13

Fuel Tank Assembly................................13

Fuel Tank Installation...............................13

Throttle Linkage............................................14

Installing the Throttle Linkage..................14

Servo Installation...........................................14

Installing the Fuselage Servo Tray............14

Installing the Aileron Servo Tray...............14

Installing the Aileron Servo......................15

Installing the Fuselage Servos..................15

Throttle Connector........................................15

Installing the Throttle Connector...............15

Rudder Pushrod............................................16

Installing the Rudder Control Horn...........16

Installing the Rudder Pushrod..................16

Elevator Pushrod..........................................17

Installing the Elevator Control Horn..........17

Installing the Elevator Pushrod.................17

Aileron Linkage............................................18

Installing the Aileron Linkage...................18

Pilot and Cannon...........................................19

Barrel Seat Assembly..............................19

Pilot and Cannon Assembly......................19

Barrel Seat Installation.............................20

Pilot Installation.......................................20

Cannon Installation..................................20

Final Assembly..............................................21

Installing the Receiver and Battery...........21

Installing the Switch................................21

Installing the Fuel Lines...........................21

Installing the Propeller.............................21

Balance........................................................21

Lateral Balance......................................22

Control Throws.............................................22

Flight Preparation..........................................22

Preflight Check.......................................23

Basics of Flight.............................................23

Product Evaluation........................................26

3

KIT CONTENTS

Thisinstruction manualis designedto helpyou builda straight,great flyingairplane. Please readthis

manual thoroughly before beginning assembly of your new Blue Max. Use the parts listing below to

identifyand separate all partsbeforebeginningassembly.

**KITCONTENTS**Wehaveorganizedthepartsastheycomeoutoftheboxforbetteridentification

duringassembly. Werecommendyouregroupthepartsinthesamemanner. Thiswillensureyouhaveall

ofthepartsrequiredbeforeyoubeginassemblyandwillalsohelpyoufamiliarizeyourselfwitheachpart.

o{2} NylonClevises w/2mm I.D. Hole

o{2} 2mmx150mm ThreadedRod

o{2} Nylon Snap Keepers

o{2} Nylon Adjustable Control Horns

o{1} 2mmx300mmPushrodWire

o{1} Adjustable Servo Connector Assembly

o{2} Nylon Motor Mount Beams

o{4} 3mmx25mm MachineScrews

o{4} 3mmx20mm MachineScrews

o{4} 3mm Nylon Insert Nuts

o{4} 3mm Blind Nuts

o{12}3mm Flat Washers

o{1} AileronServo Tray (W-39)

o{1} ForwardDihedral Brace (W-40)

o{1} Rear Dihedral Brace (W-41)

o{2} WingHold Down Dowels (W-43)

o{1} Fuselage Servo Tray (D-47)

o{6} 3mmx10mm MachineScrews

o{6} 3mm Flat Washers

o{4} 3mmx12mm WoodScrews

o{2} Wing Halves w/Ailerons and Hinges

o{1} Fuselage

o{1} HorizontalStabilizer w/Elevator and Hinges

o{1} VerticalStabilizer w/Rudder and Hinges

o{2} Wing Struts

o{1} Wire Main Gear Assembly

o{1} Wire Nose Skid

o{2} Nylon Mounting Straps w/4mm Slot

o{5} Nylon Mounting Straps w/3mm Slot

o{2} 127mm Diameter Wire Spoke Wheels

o{2} Nylon Axle Spacers

o{2} Wheel Collars w/3mm x 6mm Machine Screws

o{14}3mm x 12mmWoodScrews

o{1} Tail Wheel Wire w/ Mounting Bracket

o{1} 25mm Diameter Tail Wheel

o{2} Wheel Collars w/3mm x 6mm Machine Screws

o{3} 3mmx12mm WoodScrews

o{1} 990mmNylon Pushrod

o{1} 1.5mm x 50mmThreadedWirew/Z-Bend

o{1} 1.5mm x 45mmWire ThreadedEachEnd

o{1} Nylon Clevis w/1.5mm I.D.Hole

o{1} Nylon Control Horn

o{1} Nylon Control Horn Backplate

o{2} 2mmx15mm MachineScrews

o{1} Molded Fuel Tank

o{1} 20mmFront Squash Plate

o{1} 18mmRear Squash Plate

o{1} Rubber Stopper

o{1} 70mmLength of Fuel Tubing

o{1} Metal Weighted Pick-Up

o{3) Aluminum Tubes

o{1} 3mmx20mm MachineScrew

o{1} 990mmNylon Pushrod

o{1} 1.5mm x 50mmThreadedWirew/Z-Bend

o{1} 1.5mm x 45mm Wire Threaded Both Ends

o{1} Nylon Clevise w/1.5mm I.D. Hole

o{1} Nylon Control Horn

o{1} Nylon Control Horn Backplate

o{2} 2mmx15mm MachineScrews

RUDDERCONTROL SYSTEM

ELEVATORCONTROLSYSTEM

TAILWHEELASSEMBLY

MAINGEARASSEMBLY

AIRFRAMEASSEMBLIES AILERON CONTROLSYSTEM

MOTOR MOUNT ASSEMBLY

MISCELLANEOUSITEMS

FUELTANK

THROTTLECONTROLSYSTEM

PILOTAND CANNON ASSEMBLY

o{1} Prepainted Balsa Cannon Mount

o{2} Plastic Body Halves

o{2} Plastic Cannon Halves

o{2} Plastic Head Halves

o{1} BalsaBarrel Seat Platform

o{1} PlasticBarrel Seat

o{1} PlasticBarrel Seat Back

4

ADDITIONAL ITEMS REQUIRED

o{1}Hitec4 orMore ChannelRadio w/4 Servos

o{1}Dubro Foam Rubber # 513

o{1}GlobalFuel Line# 115923

o{1}Arco # 64 Rubber Bands # 24649

FOR2-STROKE ENGINE

o{1}MagnumXL .40-.46Two Stroke

o{1}Magnum1/4” SpinnerNut# 237310

o{1}PropellerToSuitEngine

o{1}ThunderboltGlowPlug# 115493

FOR4-STROKE ENGINE

o{1}MagnumXL .52RFSFour Stroke

o{1}Magnum1/4” SpinnerNut# 237310

o{1}PropellerToSuitEngine

o{1}ThunderboltGlowPlug# 115490

TOOLS AND SUPPLIES NEEDED

oKwikBond ThinC/A #887500

oKwikBond Thick C/A# 887510

oKwikBond 5Minute Epoxy# 887560

oKwikBond 30Minute Epoxy# 887565

oWilholdSilicon Sealer# 00684

oElectricDrill

oAssortedDrillBits

oModelingKnife

oWireCutters

oMachineOilorVaseline

oStraightEdgeRuler

oDremelToolw/AssortedBits

oPhillipsScrewdriver

oZ-BendPliers

o3mmHexWrench

oBuildersTriangle

o220Grit Sandpaper

oMaskingTape

oPaperTowels

oRubbingAlcohol

FIELD SUPPORT EQUIPMENT NEEDED

oMagnum12VElectricStarter(#361006)

oMagnum12V FuelPump(# 237377)

oMagnumLockingGlowClip (# 237440)

oGlobal12V Battery (# 110171 )

oGlobal 12V Charger (# 110270 )

oMagnumPower Panel(# 237390)

oGlobalFieldBuddyFlightBox(#233072)

oMagnum4-WayWrench(#237420)

TOFINISHPILOT ANDCANNON

oTestors ContourPutty #3511X

o320Grit Sandpaper

oFind&MediumPaintBrushes

o3MFine Line Masking Tape# 218-06300

oCoveriteFlat ClearPaint #COVR1280

oPaintThinner

oTan, White,Brown andOrange -Mix to

makeskincolor andlip color

oFlatBlack - Eyebrows,Mustache, Hair

andCannon

oWhiteandBlue -Eyes

oLightBlue-Body

oGold- SimulateButtonsandStrapsofJacket

oBrass-CannonTrim

oBrown- CannonBarrel Seat

METRIC CONVERSION CHART

Toconvert inches intomillimeters: Inchesx25.4= MM

1/64” = .4mm

1/32” = .8mm

1/16” = 1.6mm

3/32” = 2.4mm

1/8” = 3.2mm

5/32” = 4.0mm

3/16” = 4.8mm

1/4” = 6.4mm

3/8” = 9.5mm

1/2” = 12.7mm

5/8” = 15.9mm

3/4” = 19.0mm

1” = 25.4mm

2” = 50.8mm

3” = 76.2mm

6” = 152.4mm

12” = 304.8mm

18” = 457.2mm

21” = 533.4mm

24” = 609.6mm

30” = 762.0mm

36” = 914.4mm

5

**SUGGESTION** To avoid scratching your new airplane, do not unwrap the pieces until they are

needed for assembly. Cover your workbench with an old towel or brown paper, both to protect the aircraft

and to protect the table. Keep a couple of jars or bowls handy to hold the small parts after you open the

bags.

**NOTE** Please trial fit all the parts. Make sure you have the correct parts and that they fit and are

aligned properly before gluing! This will assure proper assembly. Since the Blue Max is hand made from

natural materials, every plane is unique and minor adjustments may have to be made. However, you

should find the fit superior and assembly simple.

If you should find a part missing or have questions about assembly, please call or write to the address below:

CustomerService Center

18480Bandilier Circle

FountainValley, CA. 92728

Phone:(714) 963-0329

Fax:(714)964-6236

E-Mail:[email protected]

o3) Test fit thedihedral bracesinto their re-

spectiveboxesineach wing half. W-40fitsinto

theforwardbox andW-41fits into therearbox.

Thebracesshouldslideintoeachwinghalfupto

thecenterlines. Iftheydonot, remove themand

lightlysandtheedgesandtipofeachoneuntilthe

proper fit is obtained. Seephoto# 2below.

PARTSREQUIRED

WING ASSEMBLY

INSTALLTHEDIHEDRALBRACES

o{2} Wing Halves w/Ailerons and Hinges

o{1} Forward Dihedral Brace (W-40)

o{1} Rear Dihedral Brace (W-41)

o1) Lookat thefaceof eachrootribon both

winghalves. Noticehowtheexcesscoveringma-

terialoverlapsontothem. Usingamodelingknife,

carefullycutawaythecoveringfrom both ofthe

root ribs. Leave about 1/16” of covering over-

lappingsoitdoes not pullaway.

Itisimportantthatthecoveringberemoved

fromthe rootribs. This willensure an ad-

equate wood-to-wood glue joint and prevent

wingfailureduringflight.

o2) Usinga ruler and a pen, locateandmark

the center section of the forward and reardihe-

dral braces(W-40 and W-41). Draw a vertical

line at this location on both braces. Seephoto

# 1below.

Thedihedral bracesare cut inthe shapeof

a"V". Theyshouldbeinstalledwiththe"V"

shapefacingupright to formtheproperdihedral

anglewhenthewingsarejoined.

o4) Test fitbothof thewinghalves together

withthedihedralbracestemporarilyinstalled. Do

notgluetheminatthistime! Thewing halves

shouldfittogethertightlywithlittleornogapsinthe

centersection joint. If thecentersection jointis

nottight,removethewinghalvesandlightlysand

the edges and tips of each brace. Reinstall the

winghalvesandbracesandtestthefituntilyouare

satisfied thatthecentersectionjointistight.

o5) When satisfied with the fit of the wing

halves,removethe dihedral braces.

Photo # 1

Photo # 2

FORWARD

DIHEDRAL

BRACE

REAR

DIHEDRAL

BRACE

DRAW CENTERLINE

DRAW CENTERLINE

SLIDE IN UP

TOCENTERLINE

SLIDE IN UP

TOCENTERLINE

6

o8) Once the epoxy has cured, trial fit both

winghalvestogethertodoublecheckthatthewing

halvesstillfitcorrectly.

o9) MixagenerousamountofKwikBond30

MinuteEpoxy. Applyathinlayerofepoxytothe

exposedhalvesofbothdihedralbraces,theinside

ofbothdihedral braceboxesinthesecondwing

halfandtheentiresurfaceofbothrootribs. Make

suretouse enough epoxytofillany gaps.

o10) Slidethetwo winghalvestogether and

carefullyalignthemattheleadingandtrailingedges.

Wipeawayanyexcessepoxyusingapapertowel

andrubbingalcohol. Usemaskingtapetoholdthe

winghalves inplace untilthe epoxy cures. See

photo#4 below.

JOININGTHEWINGHALVES

o6) Mix a generous amount of Kwik Bond

30MinuteEpoxy. Working withonlyonewing

half for now, apply a thin layer of epoxy inside

both dihedral brace boxes and on only half of

eachdihedral brace. Make suretocover thetop

andbottom as well as the sides anduse enough

epoxytofillanygaps.

o7) Slidethedihedral bracesinto theboxes

uptothecenterlines. Removeanyexcess epoxy

before it dries using a paper towel and rubbing

alcohol. Allow the epoxy to cure before pro-

ceeding. Seephoto# 3below.

Photo # 4

Photo # 3

PARTSREQUIRED

WING MOUNTING

INSTALLTHEWINGHOLDDOWNDOWELS

o{1} Fuselage

o{2} WingHold Down Dowels (W-43)

o{2} Wing Struts

o{6} 3mmx10mm MachineScrews

o{6} 3mm Flat Washers

o1) Usingamodelingknife,carefullyremove

thecoveringfromoverthefourpredrilledholesin

thefuselagesides. Twoholesarelocatedoneach

side of the fuselage. Seephoto#5below.

Photo # 5

o2) Slideonewingholddowndowelthrough

thetwo forward holesin thefuselage sidesand

thesecond dowel throughthe tworear holesin

the fuselage sides. Adjust the dowels so both

ends of each dowel protrude from the fuselage

sides an equal amount. See photo#6below.

Photo # 6

o3) Whensatisfiedwiththefit,useapenand

place a mark on each dowel at the point where

theyexit the fuselage sides.

o4) Remove the dowels and mix a small

amountofKwikBond30MinuteEpoxy. Apply

athinlayerofepoxytotheinsideedgesofallfour

holesinthefuselage. Carefullyslide the dowels

intoplace upto the marksmade. Double check

thatthey arecentered anduse papertowels and

rubbingalcoholtoremoveanyexcess epoxy be-

foreitcures.

MASKING

TAPE

MASKING

TAPE

REMOVE COVERING

(both sides)

REMOVE COVERING

(both sides)

WINGHOLD

DOWNDOWEL

7

o5) Usingarulerand a pen,locateandmark

thecenterlineofthefuselageatboththefrontand

rear of the wing saddle. Place a mark at both

locations. Seephoto # 7below.

Thesetwomarkswillhelpyoualignthewing

whenyouinstallitonthefuselage. Youmay

wish to make these marks in permanent ink so

youcan align the wing correctly each timeyou

installthewing. Thiswillensurethewingisaligned

properlyeachtimeyouflytheairplane.

o6) Therearetwopreinstalledblindnutsthat

areused to mountthe wing struts to the bottom

of the fuselage. Using a modeling knife, care-

fullyremovethecoveringfromoverthetwoblind

nut holes on the bottom of the fuselage. The

holesarelocated 1/2”infrom the fuselagesides

and 8-1/4” back from the front of the firewall.

See photo # 8 below.

o8) Placethewingintothewingsaddle. Align

thecenterlineofthewingatboththeleading and

trailingedges with thetwo marksyou madeon

thefuselage.

o9) Using a couple of # 64 rubber bands,

temporarilysecurethewinginplacemakingsure

itisaligned. Tocorrectlyinstalltherubberbands,

hookone overone ofthe frontwing holddown

dowels,carefully pull itback over thetop of the

wingandhook itoverthe rear holddowndowel

on the same side. Install two rubber bands on

eachside for now.

o10) Bolt the wing struts to the wing and to

thefuselageusing thesix3mm x 6mmmachine

screws and six 3mm flat washers. It may be

necessaryto move thewing slightly toproperly

align the holes in the struts with the blind nuts.

See photo # 10 below.

ALIGNINGTHEWINGTOTHEFUSELAGE

Photo # 7

INSTALLTHEWINGSTRUTS

Photo # 8

o7) Therearealsotwoblindnutspreinstalledin

eachwinghalf. Theyarelocatedinplywoodgus-

sets,20”outfromthecenterlineofthewing. The

rearblindnutis2-3/4”forwardofthetrailingedge

andthefrontblindnutis3”backfromtheleading

edge. Usingamodelingknife,carefullyremovethe

coveringfromoverthetwoblindnutholesineach

winghalf. Seephoto#9attopright.

Photo # 9

Photo # 10

PARTSREQUIRED

HORIZONTAL STABILIZER

MOUNTING

ALIGNTHEHORIZONTALSTABILIZER

o{1} HorizontalStabilizer w/Elevator and Hinges

o1) Removetheelevatorfromthehorizontal

stabilizerand set it asidefornow. Turnthestabi-

lizerupsidedownonyourworksurface. Thebot-

tomsideistheflatsideandshouldbefacingup.

MARK

CENTERLINE MARK

CENTERLINE

REMOVE

COVERING 8-1/4”

WINGTIP

REMOVE COVERING AILERON

3mm FLAT

WASHER

3mm x

6mm

SCREW

3mm x 6mm

SCREW

3mm FLATWASHER

8

o3) Usingaruleranda pen, locateand place

amarkatthecenterlineofthefuselageatthefront

andrearofthestabilizermountingplatform. These

markswill beused toline upthe stabilizerwith

the fuselage. See photo#12 below.

o2) Usingarulerandapen, locate andmark

the centerline of the horizontal stabilizer at the

trailing edge and place a mark. Use a triangle

andextend this mark,fromback tofront,across

the bottom of the stabilizer. Alsoplace center-

linemarksonthetopofthestabilizerattheleading

andtrailingedges only. Seephoto #11below.

Photo # 11

Photo # 12

o4) Attach the wing to the fuselage and re-

movebothailerons. Setthehorizontalstabilizer

ontothestabilizermountingplatformonthefuse-

lage. Align the centerline marks on top of the

stabilizerwith the centerline marks at the front

andrearofthestabilizermountingplatform. When

themarksarealigned hold thestabilizerinposi-

tionusingacoupleofT-pins.Alignthehorizontal

stabilizerwiththewing. Whenviewedfromthe

rear,thehorizontalstabilizershouldbelevelwith

the wing. If it is not level, use sandpaper and

sanddownthehigh side ofthestabilizermount-

ingplatformuntiltheproperalignmentisachieved.

Thetipsofthestabilizershouldalsobeequaldis-

tancefrom thetips of thewing. Seefigures#1

and# 2 attop right.

Figure# 1

Figure# 2

o5) Whenyouaresatisfiedwiththealignment,

holdthestabilizerinplacewith T- pinsor mask-

ingtape, but donotglue atthistime.

o6) Withthestabilizerheldfirmlyinplace,use

a pen and draw aline on the stabilizerwhere it

and thefuselage sides meet. Do thison both the

rightandleftsidesonthebottomofthestabilizer.

o7)Removethestabilizer. Usingthelinesyou

justdrewasaguide,carefullyremovethecovering

frombetweenthem,usingamodelingknife. See

photo# 13below.

MOUNTINGTHEHORIZONTALSTABILIZER

Photo # 13

When cutting through the covering to re-

moveit, cut withonly enoughpressure to

onlycutthroughthecoveringitself. Cuttinginto

thebalsastructuremayweakenitandcausepos-

siblefailureinflight.

DRAW

CENTERLINE

DRAW

CENTERLINE

DRAW

CENTERLINE

A

BA1 B1

CC1

REMOVE

COVERING

9

Figure# 3

o8) Whenyou are satisfied thateverythingis

alignedcorrectly, mix up agenerous amountof

KwikBond30MinuteEpoxy. Applyathinlayer

tothebottomofthestabilizer mounting areaand

tothetop ofthestabilizer mounting platformon

the fuselage. Set the stabilizer in place and re-

align. Double check all of your measurements

oncemore before theepoxycures. Holdthesta-

bilizerin place withT-pins or maskingtape and

removeanyexcessepoxyusingpapertowelsand

rubbingalcohol.

PARTSREQUIRED

VERTICAL STABILIZER

MOUNTING

ALIGNTHEVERTICALSTABILIZER

o{1} VerticalStabilizer w/Rudder and Hinges

o1) Remove therudder from the stabilizer.

Slidethe stabilizerinto theslot inthe topof the

horizontalstabilizer. Therearedgeofthevertical

stabilizershouldbeevenwiththerearedgeofthe

horizontalstabilizerandfuselage. Itshouldalso

bepusheddowncompletely into theslot.

o2) Usinga pen,draw alineon eachside of

theverticalstabilizerwhereitmeetsthetopofthe

slotonthehorizontalstabilizer.

o3) Removethestabilizer. Usingamodeling

knife,removethecoveringfromjustbelowthelines

youdrew. Alsoremovethecoveringfromthebot-

tomedgeofthestabilizer. Seephoto#14below.

Photo # 14

When cutting through the covering to re-

move it, cut with only enough pressure to

onlycutthroughthecoveringitself. Cuttinginto

the balsa structure may weaken it. There may

alsobe coveringmaterial overlappedon the in-

sideedges oftheverticalstabilizermountingslot

inthehorizontalstabilizer. Usingamodelingknife,

carefullyremovethiscoveringalso. Thiswillhelp

insureagoodgluejoint.

o4) Set the vertical stabilizer back in place.

Usingatriangle,checktoensurethatthevertical

stabilizerisaligned90ºtothehorizontalstabilizer.

See figure # 3 below.

MOUNTINGTHEVERTICALSTABILIZER

o5) Whenyouaresatisfiedthateverythingis

alignedcorrectly, mixup a generousamount of

KwikBond30MinuteEpoxy. Applyathinlayer

tothemountingslotinthetophorizontalstabilizer

andtothe sidesandbottom of theverticalstabi-

lizer mounting area. Set the stabilizer in place

andrealign. Double check allofyour measure-

mentsonce more beforethe epoxycures. Hold

thestabilizerinplacewithT-pinsormaskingtape

andremove anyexcessepoxy usingpapertow-

elsandrubbingalcohol. Allowtheepoxytofully

curebeforeproceeding.

PARTSREQUIRED

CONTROL SURFACE

INSTALLATION

HINGETHEAILERONS

o{2} Ailerons w/Hinges

o{1} Elevator w/Hinges

o{1} Rudder w/Hinges

o{1} Tail Wheel Wire w/Mounting Bracket

o{1} 25mm Diameter Tail Wheel

o{2} Wheel Collars w/3mm x 6mm Machine Screws

o{3} 3mmx12mm Wood Screws

o1) TheC/A hingeshavealreadybeenglued

intothetwo ailerons. Workingwith oneaileron

atatime,slidetheaileronandit'shingesintotheir

precuthingeslotsinthetrailingedgeofthewing,

makingsure the torque rodisfirmlyseatedinthe

precutholeintheleadingedgeoftheaileron. Slide

theaileron in untilit istight against thetrailing

edgeofthewing. Themaximumhingegapshould

beno morethan 1/32”and thetip ofthe aileron

shouldbe flush with thetipofthewing.

REMOVE

COVERING

90º

10

o2) Whensatisfiedwiththefit,removetheai-

leronandslide a smallpieceofwaxed paper be-

tweentheailerontorquerodandthetrailingedge

ofthe wing. See photo#15 below.

Photo # 15

Thewaxed paper willprevent epoxy from

gluingthetorquerodto the trailingedge of

thewing.

o3) MixupasmallamountofKwikBond30

MinuteEpoxy. Applyathinlayerofepoxytothe

ailerontorquerod. Alsouseatoothpickandpack

epoxyintothepredrilledholeintheaileron.

o4) Slidetheaileronandit'shingesintotheir

precuthingeslotsinthetrailingedgeofthewing,

makingsure the torque rodisfirmlyseatedinthe

precutholeintheleadingedgeoftheaileron. With

theailerontightagainstthe wing, rotatethe aile-

ron down about 45º. Apply six drops of Kwik

BondThinC/Atotheexposedareaofeachhinge.

Allow the glue to cure for about ten minutes.

Oncecured,theaileronmaybestiffanddifficult

tomove. Thisisnormal. Gentlymovetheaileron

upanddown about fivetotentimes to freeitup.

o5) Repeat steps # 1 - # 4 for the second

aileron. HINGETHEELEVATOR

o6) TheC/A hingeshavealreadybeenglued

intotheelevator. Slidetheelevatorandit'shinges

intotheir precuthingeslotsinthetrailingedgeof

thehorizontalstabilizer. Slidetheelevatorin until

it is tight against the trailing edge of the stabi-

lizer. Themaximumhingegapshouldbenomore

than 1/32”. See photo # 16 below.

Photo # 16

o7) Withtheelevatortight againstthestabi-

lizer,rotate theelevatordownabout 45º. Apply

sixdrops ofKwikBondThinC/Atotheexposed

area of each hinge. Allow the glue to cure for

aboutten minutes. Once cured, theelevatormay

be stiff and difficult to move. This is normal.

Gentlymovetheelevatorupanddownaboutfive

toten timestofree itup.

INSTALLTHETAILWHEELWIRE

o8) Usingarulerandapen,measureup3/4”

fromthebottomoftherudder,attheleadingedge,

andplace a mark.

o9) Usinga3/32”drillbit,drillaholeintothe

rudderatthemarkmade. Usingamodelingknife,

cutagroovefromthehole,downtothebottomof

therudder. Maketheholedeepenoughforthetail

wheelwiretoset flush in. Seefigure#4 below.

Figure# 4

o10) MixupasmallamountofKwikBond5

Minute Epoxy. Apply the epoxy to only those

partsof thetail wheelwire thatwill beglued to

therudder. Pack epoxyintothehole you drilled

intheleading edge oftherudderalso.

o11) Insertthetailwheel wireintotherudder.

Cleanupanyexcessepoxyusingapapertoweland

rubbing alcohol. See photo # 17 below.

Photo # 17

HINGETHERUDDER

o12) The C/A hinges have already been

glued into the rudder. Slide the rudder and it's

hingesintotheirprecuthinge slots inthe trailing

edge of the vertical stabilizer. Slide the rudder

in untilit istightagainst thetrailingedge ofthe

stabilizer. Themaximumhingegapshouldbeno

morethan 1/32”.

TORQUEROD

WAXED PAPER

1/32” ELEVATOR

STABILIZER

DRILL

HOLE

CUT

GROOVE

TAIL WHEEL

WIRE

11

o13) With the ruddertight againstthe stabi-

lizer,rotatetheruddertoonesideabout45º. Ap-

plysix drops ofKwikBond ThinC/Ato theex-

posedareaofeachhinge. Allowthegluetocure

for about ten minutes. Once cured, the rudder

maybestiffanddifficulttomove. Thisisnormal.

Gentlymovetherudderbackandforthaboutfive

toten times tofree it up.

MOUNTINGTHETAILWHEELBRACKET

o14) Alignthe tailwheel mountingbracket

with the centerline of the fuselage. Use a pen

and mark the three mounting locations on the

fuselage.

o15) Movethe mounting bracketto the side.

Usinga1/16”drillbit,drillthreepilotholesthrough

thebottom ofthe fuselage atthe marksyou just

made.

o16) Securethemountingbracketinplaceus-

ingthree3mmx12mmwoodscrews. Seephoto

#18below.

Photo # 18

o17) Slide the wheel collar that has been

preinstalled onto the tail wheel wire tight up

against the bottom of the bracket. Tighten the

3mm x 6mm machine screw tohold itin place.

o18) Installthe25mmdiametertailwheelonto

thetailwheelwire. Securethetailwheelinplace

usingonewheelcollarandone3mmx6mmma-

chinescrew. Slidethewheelcollaronenough so

itisupagainstthetail wheel, butnot so tightthat

thetail wheelwon't turn. The tailwheel should

rotatewithoutbinding.

PARTSREQUIRED

MAIN LANDING GEAR

ALIGNINGTHEMAINGEARASSEMBLY

o{1} Wire Main Gear Assembly

o{2} Nylon Mounting Straps w/4mm Slot

o{2} Nylon Mounting Straps w/3mm Slot

o{2} Nylon Axle Spacers

o{2} Wheel Collars w/3mmx6mmMachineScrews

o{8} 3mmx12mm Wood Screws

o{2} 127mmDiameter WireSpokeWheels

INSTALLINGTHETAILWHEEL

o1) Inspecteachofthenylonmountingstraps.

Somestrapshave 4mmmoldedslots and others

have3mm moldedslots. To attachthemaingear

assembly you will need two straps with 4mm

moldedslots and two straps with 3mm molded

slots.

o2) Set the main gear assembly in place on

thebottom of thefuselage. The larger diameter

wire(4mm)should faceto therearand the front

edgeofthe forward gearwireshouldbe 4” back

fromthe firewall. Seephoto#19below.

Photo # 19

o4) Withthegearheldfirmlyinposition,place

two3mmnylonmountingstraps, equal distance

apart,overthefrontwire. Place two 4mmnylon

mounting straps, equal distance apart, over the

rearwire.

o5) Using a 1/16” drill bit, drill pilot holes

throughthefuselageforthemountingscrews. Use

thenylonstrapsasa guide forcorrect placement

oftheholes.

o3) Whileholding thegearassembly inthis

position, center it side-to-side on the fuselage.

Whensatisfiedwiththealignmentuseacoupleof

piecesofmaskingtapetoholdthegearinposition.

INSTALLINGTHEMAINGEARASSEMBLY

MOUNTING

BRACKET

3mm x 10mm

WOODSCREWS WHEEL

COLLAR

TAILWHEEL

GEAR

WIRE

FRONT

12

o6) Securethegearassembly in placebyin-

stalling the eight 3mm x 12mm wood screws

through the mounting straps and remove the

masking tape. Seephoto#20 below.

Photo # 20

INSTALLINGTHEMAINGEARWHEELS

o7) Slide one nylon spacer onto each axle.

Slideone127mmdiameterwirespokewheelonto

eachaxle andup against thenylon spacers. Se-

curethewheelsinplacebyslidingonewheelcol-

lar onto each axle and up against the wheels.

Tighten the 3mm x 6mm machine screw in the

wheelcollars. The wheels shouldbe able toro-

tatewithoutbinding.

PARTSREQUIRED

ENGINE MOUNTING

MOUNTINGENGINETOMOTORMOUNT

o{2} Nylon Motor Mount Beams

o{4} 3mmx20mm MachineScrews

o{4} 3mmx25mm MachineScrews

o{12}3mmFlatWashers

o{4} 3mm Lock Nuts

o{4} 3mm Blind Nuts

o1) Usingaclamporavise,alignthetwomotor

mountbeamsandclampthemtogether. Thebeam

halvesareuniversalandthewebbingshouldface

theoutside edges. Seephoto# 21 below.

Photo # 21

o2) Mark the locations of the four engine

mountingholes on the beamsusingapencil. For

theengine toalign properly, it is important that

the front edge of the engine's drive washer be

3-3/4”forwardfromthe rear edgeofthemount-

ingbeams.

o3) Whensatisfied with the alignmentofthe

engine, remove the beams from the clamp and

drill1/8” holes through the mounting beams at

thefour enginemounting hole locations.

o4) Mounttheenginetothemountingbeams

usingthefour3mmx25mmmachinescrews,eight

3mmflatwashersandfour3mmlocknuts. Tighten

thescrewsandnutscompletely.

Ifusing anengineequipped witharemote

needlevalvewerecommendmounting the

needlevalve to theengine prior toinstalling the

engineonthemotormountbeams.

ALIGNINGTHEMOTORMOUNT

o5) Theengineismounteduprightonthefire-

wall. Usingarulerandapen,measureanddraw

averticalcenterlineandahorizontalcenterlineon

thefirewall. See photo# 22below.

Photo # 22

o6) Usinga rulerandapen, measure 1/8”to

therightofthevertical centerline (lookingat the

firewall)anddrawasecondverticalline. Measure

1/2”upfromthehorizontalcenterlineanddrawa

secondhorizontalline. Measure7/8”downfrom

thehorizontalcenterlineanddrawathirdhorizon-

talline. Seephoto #23below.

Photo # 23

MOUNTING

STRAPS

3mm x10mm

WOODSCREWS

ALIGN

EDGES

ALIGN

EDGES

1/2”

7/8”

13

o7) Withyourenginestillinstalledonthemo-

tormountbeams,usearulerandmeasurethewidth

betweenthepredrilledmountingholesinthemotor

mountbeams. Thisdistancewillvarydepending

onthebrandandsizeoftheengineyouhavecho-

sen. See photo # 24 below.

Photo # 24

o8) Divide the measurement found in step

#7 inhalf. Measure thisresulting distanceand

draw one vertical line to the right and one to

the left of the second vertical line. Seephoto

#25below.

Photo # 25

o9) Holdthemotormountassemblyuptothe

firewallanddoublecheckthatthefourintersect-

inglinesline upwith thefourpredrilled holes in

themotormountbeams.

Themotor mountassemblyis offsettothe

airplane'sleftside(lookingfromtherear)to

compensatefor the 2º ofrightthrustbuiltintothe

firewall. Offsettingtheenginewillallowthecrank-

shaftto alignwiththecenterlineofthefuselage.

MOUNTINGTHEENGINETOFIREWALL

o10) Usinga1/8”drillbit,drillthefourmount-

ingholesthroughthefirewallforthemotormount.

o11) Mountthemotormountassemblytothe

firewall using the four 3mm x 20mm machine

screws,four3mmflatwashersandfour3mmblind

nuts. Tightenthescrewscompletelyuntiltheblind

nutshave been completelyseated in theback of

the firewall. See photo#26 attop right.

Photo # 26

PARTSREQUIRED

NOSE SKID

ALIGNTHENOSESKID

o{1} Wire Nose Skid

o{3} Nylon Mounting Straps w/3mm Slot

o{6} 3mmx12mm Wood Screws

o1) Setthenoseskidontothefrontofthefire-

wall. Thevertical wireoftheskidshouldbe1/8”

totheleftofthecenterlineofthefirewall(looking

atthefirewall). Toachievethecorrectheight,the

loweredgeofthehorizontal wire shouldbe 3/8”

upfromthebottomofthefuselage.

o2) Whensatisfiedwiththe alignmentuse a

coupleofpiecesofmaskingtapetoholdtheskid

inposition. See photo# 27below.

Photo # 27

o3) Withthenoseskidheldfirmlyinposition,

placeonenylonmountingstrapoverthehorizon-

tal wire and one over the shorter vertical wire,

next to the motor mount. Place the third nylon

strap over the rear section of the nose skid, on

thefuselage bottom.

o4) Using a 1/16” drill bit, drill pilot holes

throughthefirewall and fuselagebottomforthe

sixmounting screws. Usethe nylonstraps asa

guideforcorrectplacement of theholes.

INSTALLINGTHENOSESKID

D

D = DISTANCE

BETWEEN

MOTOR

MOUNT

BEAMS

NOSE

SKID

3/8”

ENGINE MOUNT

REMOVED FOR

CLARITY. FUSELAGE

SHOWN UPSIDE DOWN.

14

PARTSREQUIRED

FUEL TANK

FUELTANKASSEMBLY

o{1} Molded Fuel Tank

o{1} Rubber Stopper

o{1} 20mmDiameter Front Squash Plate

o{1} 18mmDiameter Rear Squash Plate

o{1} 3mmx20mmMachineScrew

o{1} Weighted Metal Pick-Up

o{3} Aluminum Tubes

o{1} 70mm Silicon Fuel Tube

o1) Thefueltankassemblyincudes3 differ-

entlengthaluminumtubes. Discardthe shortest

ofthe three. Itwill notbe used.

The40mm length tube is used for thefuel

linepickup andthe 70mmtube isused for

thevent/pressure line.

o2) Using 220 grit sandpaper carefully

smootheachendofthetwo tubes. This willpre-

ventthefuellinefrombeingcut.

o3) Pushthetwoaluminumtubesthroughthe

rubberstopperuntil1/2”protrudesfromthefront

of the stopper. Slide the 20mm diameter front

squash plate over the tubes at the front of the

stopperand slidethe18mmdiameterrearsquash

plate over the tubes at the rear of the stopper.

Insertthe3mm x20mmmachine screw intothe

centerholeinthefrontsquashplate,thenscrewit

throughthestopperandintotherearsquashplate.

Donotcompletelytightenthescrewatthistime.

Photo # 29

o6) Testfitthestopperassemblyintothetank.

Itmaybe necessaryto removesomeof the plas-

ticflashingaroundthetankopeningusingamod-

elingknife. Ifflashingispresent,makesurenone

fallsintothetankwhenyouremoveit.

o7) With the stopper assembly in place the

weightedpickupshouldbeabout3/8”awayfrom

the rear of the tank and move freely inside the

tank. Theventtubeshould be justbelowthetop

ofthe tank,but notrub against thetank. Adjust

thetubesaccordingly.

o8) Whensatisfiedwiththealignmentofthe

stopperassemblytighten the3mmx 20mm ma-

chinescrew until the rubberstopperexpandsand

seals the tank opening. Do not overtighten the

assemblyasthis couldcausethe tank tosplit.

FUELTANKINSTALLATION

o9) Slidethefueltankintothefueltankcom-

partmentin thefront ofthe airplane. The topof

the tank should face the top of the fuselage and

thestopperassemblyshouldalsoengagethepre-

drilledholeinthefirewall.

o5) Securethenose skidin place byinstall-

ingthe six3mm x12mm woodscrews through

themountingstrapsandremovethemaskingtape.

See photo # 28 below.

Photo # 28

o4) Carefullybendthelongerofthetwotubes

up at a 45º angle. This tube is the vent tube.

Whenthestopperassemblyisinstalledinthetank,

thetopoftheventtubeshouldrestjustbelowthe

topof thetank.

You can determine the top of the tank by

looking at the front of it. Notice that the

holein the frontof the tankis not centered. The

tallside isthetop ofthetank.

o5) Slide the silicon fuel tubing, with the

weighted pickup attached to one end, onto the

fuel pickup tube. See photo#29 below.

MOUNTING

STRAPS

3mm x 10mm

WOODSCREWS

VENTTUBE

PICKUP

TUBE

RUBBER

STOPPER

SILICON

TUBING

WEIGHTED

PICKUP

REARSQUASH

PLATE

FRONT

SQUASH

PLATE

15

o10) Securethefuel tank inplaceusingsev-

eral pieces of foam rubber. Seal any gaps be-

tweenthe stopper assemblyand the firewallus-

ingsilicon sealer. Becarefulnot togetanysealer

insidethealuminumtubing.

PARTSREQUIRED

THROTTLE LINKAGE

INSTALLINGTHETHROTTLELINKAGE

o{1} 1.5mm x 300mmWireThreadedOneEnd

o1) Locateanddrilla3/32”holethroughthe

firewall for the throttle pushrod wire to pass

through(youmayneedtotemporarilyremovethe

engine). Theholeshouldbelevelwiththethrottle

arm,but may needto be movedslightly to clear

thefueltankdependingontheengineused.

o2) Slide the plain end of the pushrod wire

throughthehole andinto thefuselage. Remove

the throttle arm from the carburetor and attach

theZ-bend totheouter holeinthe arm.

o3) Reattachthe throttlearmtothe carbure-

toranduseapairofplierstomakeanynecessary

bends in the wire so it does not bind when the

carburetorismoved fromidleto the fullthrottle

position. Seephoto# 30below.

Photo # 30

PARTSREQUIRED

SERVO INSTALLATION

INSTALLINGTHEFUSELAGESERVOTRAY

o{1} AileronServo Tray (W-39)

o{1} Fuselage Servo Tray (D-47)

o{4} 3mmx12mm Wood Screws

o1) Install the rubber grommets and brass

colletsontothree servos. Testfit theservosinto

the precut servo holes in the servo tray.

Becausethe sizeof servos differ,you may

need to adjust the size of the precut open-

ings. Youmayalsoneed to use a modeling knife

andcutagroovetoallowroomfortheservowires.

o2) Removetheservos fromthe servotray.

Usinga ruler anda pen, locateand mark thepo-

sitionofthefourservotraymountingholesonthe

topof thetray. Two holes arelocated 3/8”back

fromthe frontedge ofthe trayand 1/8”in from

each side. Two holes are also located 3/8” for-

wardofthe rearedgeand 1/8” infromthe sides.

See photo # 31 below.

Photo # 31

o3) Using a 1/16” drill bit, drill pilot holes

throughtheservo trayat thefourmounting hole

locations.

o4) Set the servo tray onto the preinstalled

supportrailsjust tothe rearofthe forward bulk-

head. The front of the tray should be pushed

firmlyupagainsttheforwardbulkhead.

o5) Usinga1/16”drillbitandthepilotholes

intheservotrayasaguide,drillfourholesthrough

thesupportrails.

o6) Securethetrayinplaceusingfour3mmx

12mm wood screws. See photo # 32 below.

Photo # 32

INSTALLINGTHEAILERONSERVOTRAY

o7) Install the rubber grommets and brass

collets onto the fourth servo. Test fit the servo

intothe aileron servotray(W-39).

Becausethe sizeof servos differ,you may

need to adjust the size of the precut open-

ings. Youmayalsoneed to use a modeling knife

andcutagroovetoallowroomfortheservowire.

PUSHROD

WIRE

THROTTLE

ARM

3/8”

1/8”

3/8”

1/8”

MAKE

MARKS

MAKE

MARKS

SERVO TRAY

3mm x 12mm

WOOD

SCREWS

16

o8) Placetheservotray,withtheaileronservo,

intotheprecutopeninginthebottomofthewing.

Theservoshouldbeorientatedwiththeoutputshaft

towardsthetrailingedgeofthewing.

o9) Removetheservotrayandusingamodel-

ingknife,carefullycutanotchinthewingtoallow

roomfortheservowire. Seephoto#33below.

Photo # 33

o10) Set the tray back in place and trace

arounditusingapen. Removethetrayandusing

amodelingknife,removethecoveringfromjust

insidethelines.

o11) Mix a small amount of Kwik Bond 5

MinuteEpoxyandgluethetrayinplace. Becare-

fulnotto getanyepoxy on theservo. Allowthe

epoxytocurecompletely.

There will be some gaps around the outer

edgesofthetray. Useenoughepoxytocom-

pletelyfillanygapsbetweenthetrayandwing.

INSTALLINGTHEAILERONSERVO

o12) Install the servousing thewood screws

providedwithyourradiosystem. Drill1/16” pi-

lot holes through the tray before installing the

screws. This will help prevent the wood from

splitting. Seephoto #34 below.

Photo # 34

INSTALLINGTHEFUSELAGESERVOS

o13) Install the three fuselage servos using

thewood screws provided with your radio sys-

tem. Drill1/16” pilot holesthrough the traybe-

foreinstallingthescrews. Thiswillhelpprevent

thewood fromsplitting. Install theservos with

the output shafts in the orientation shown. See

photo # 35 below.

Photo # 35

PARTSREQUIRED

THROTTLE CONNECTOR

INSTALLINGTHETHROTTLECONNECTOR

o{1} Adjustable Servo Connector Assembly

o1) Install one adjustable servo connector

throughthesecondholeoutfromthecenterofone

servoarm. Youmayhavetoenlargetheholeinthe

servoarmto accommodate theservoconnector.

Removetheexcess materialfrom theservoarm

usingwirecutters. Seefigure#5below.

Figure# 5

Afterinstallingtheadjustableservoconnec-

torapply asmall dropof Kwik BondThin

C/Ato thenut. This willprevent theconnector

fromlooseningduringflight.

o2) Turn onthe radiosystem. Check toen-

surethatthethrottleservooutputshaftismoving

inthecorrectdirection.

CUT NOTCH

PRECUT SERVO

OPENING

SERVO TRAY

TRAILING

EDGE

TRAILING

EDGE

T

R

E

E = ELEVATOR

T = THROTTLE

R = RUDDER

SERVO ARM NUT

SET SCREW

CONNECTOR

FRONT

17

o3) Slide the adjustable servo connector/

throttlearmassemblyovertheendofthethrottle

pushrodwire. Positionthe throttlestickand the

throttletrimattheirlowestpositions.

o4) Manuallypushthecarburetorbarrelfully

closed. Angletheservoarmforwardabout30ºfrom

centerandattachittotheservo. Thearmshouldface

therightsideoftheairplane(lookingfromtherear).

Withthecarburetorbarrelfullyclosed,tightentheset

screwintheadjustableservoconnector.

o5) Removetheexcessthrottlepushrodwire

usingwire cutters. Seephoto #36 below.

Photo # 36

o6) Test the movementof thethrottle push-

rod. Fullforwardstickandfullforwardtrimshould

resultinthecarburetorbarrelopeningcompletely.

Fullbackstickandfullforwardtrimshouldresult

inthe approximate idle setting. Full back stick

andfulldowntrimshouldresultinthecarburetor

barrelclosingfully.

o7) Whensatisfied thatthepushrod linkage

is adjusted correctly and no binding is present,

installtheservoarm set screw.

PARTSREQUIRED

RUDDER PUSHROD

INSTALLINGTHERUDDERCONTROLHORN

o{1} Nylon Control Horn w/Nylon Back Plate

o{2} 2mmx15mm MachineScrews

o{1} 990mmNylon Pushrod

o{1} 1.5mm x 45mm Wire Threaded Both Ends

o{1} 1.5mm x 50mmThreadedWirew/Z-Bend

o{1} Nylon Clevis w/1.5mm I.D.Hole

o1) Thecenterline of the ruddercontrolhorn

islocated onthe leftside ofthe rudder(looking

from behind) 1-3/8” up from the bottom of the

rudder. Position the control horn so the clevis

attachmentholesaredirectlyin-linewiththehinge

line. Thecontrolhornshouldalsobeparallelwith

thehinge line. Seefigure #6attopright.

Figure# 6

o2) Whensatisfiedwiththealignment,usea

3/32”drillbitandthecontrolhornasaguideand

drillthemountingholesthroughtherudder.

o3) Mountthe controlhorn to therudderby

inserting the 2mm x 15mm machine screws

throughthe control horn mountingbase,through

the rudder and into the backplate. Tighten the

screws,butdonotovertightenthem. Youdonot

wantto crushthe wood.

o4) Threadthe1.5mmx45mmthreadedwire

into one end of one nylon pushrod. For safety,

threadthewirenolessthan5/16”intothepushrod.

o5) Thread the nylon clevis onto the oppo-

siteendof the1.5mmx 45mm threadedwire. It

should be threaded no less than 5/16” onto the

wirealso.

o6) Usingamodelingkniferemovethecov-

ering from over the rudder pushrod exit slot.

Lookingfromthebackoftheairplane,theslot is

located on the left side of the fuselage, 1-7/8”

forwardofthe rudderhingeline and 3/4”below

thehorizontalstabilizer.

o7) Inserttheplainendofthenylonpushrod

intothefuselage fromtheback. Snap the clevis

onto the rudder control horn. Move the rudder

backandforthtoensurethereisnobinding. See

photo# 37below.

INSTALLINGTHERUDDERPUSHROD

Photo # 37

PUSHROD

WIRE

SERVO

ARM

SERVO

CONNECTOR

NYLON

PUSHROD

NYLON

CLEVIS

NYLON

CONTROL

HORN

PUSHROD

WIRE

CONTROL HORN

BACKPLATE

MACHINE

SCREW

RUDDER

18

o8) Usea couple ofpieces ofmasking tape

toholdtherudderin neutral.

o9) Locatealongservoarm. Usingwirecut-

ters,remove all butone ofthe arms. Installthe

Z-bendin the 1.5mm x50mmwireintotheouter

holeintheservoarm.

o10) Withtherudderandrudderservoinneu-

tral,installtheservoarmontotheservo. Thearm

shouldbe positionedperpendicular tothe fuse-

lageside and pointout towards theside.

o11) Usinga pen,placeamark onthenylon

rudderpushrodwherethetipofthethreadedwire

overlapsit. Useamodelingknifeand cut offthe

nylonpushrod5/16”infrontofthemark. This

willleaveenoughspacesothethreaded wirecan

threadintothepushrodatleast5/16”.

o12) Remove the servo arm from the servo

and thread the wire into the pushrod. You can

thread it in further or back it out to achieve the

correctlength.

o13) Whensatisfiedwiththealignment,install

theservoarmsetscrewandremovethemasking

tape from the rudder. Seephoto #38 below.

Photo # 38

PARTSREQUIRED

ELEVATOR PUSHROD

INSTALLINGTHEELEVATORCONTROLHORN

o{1} Nylon Control Horn w/Nylon Back Plate

o{2} 2mmx15mm MachineScrews

o{1} 990mmNylon Pushrod

o{1} 1.5mm x 45mm Wire Threaded Both Ends

o{1} 1.5mm x 50mmThreadedWirew/Z-Bend

o{1} Nylon Clevis w/1.5mm I.D.Hole

o1) The centerline of the elevator control

horn is located on the bottom right side of the

elevator,3/4” outfrom thefuselage side. Posi-

tion the control horn so the clevis attachment

holesare directlyin-linewiththehingeline. The

control horn should also be angled slightly

Figure# 7

o2) Whensatisfiedwiththealignment,usea

3/32”drillbitandthecontrolhornasaguideand

drillthemountingholesthroughtheelevator.

o3) Mount the control horn to the elevator

byinserting the 2mm x 15mm machine screws

throughthe controlhornmountingbase,through

theelevator andintothe backplate. Tightenthe

screws,butdonotovertightenthem. Youdonot

wantto crushthe wood.

o4) Threadthe1.5mmx45mmthreadedwire

into one end of the second nylon pushrod. For

safety, threadthe wire noless than 5/16”into the

pushrod.

o5) Thread the nylon clevis onto the oppo-

siteendof the1.5mm x45mmthreaded wire. It

should be threaded no less than 5/16” onto the

wirealso.

o6) Usingamodelingkniferemovethecov-

ering from over the elevator pushrod exit slot.

Lookingfromthebackoftheairplane,theslot is

locatedon the right side of the fuselage,1-7/8”

forwardofthe rudderhingeline and 1/2”below

thehorizontalstabilizer.

o7) Inserttheplainendofthenylonpushrod

intothefuselage fromtheback. Snap the clevis

ontotheelevator controlhorn. Movethe eleva-

tor up and down to ensure there is no binding.

See photo # 39 below.

INSTALLINGTHEELEVATORPUSHROD

Photo # 39

PUSHROD

WIRE NYLON

PUSHROD

PUSHROD

TUBE

towardsthepushrodexitinthefuselageside. See

figure # 7 below.

NYLON

CLEVIS

PUSHROD

WIRE

NYLON

PUSHROD

CONTROL

HORN

CONTROL HORN

BACKPLATE

MACHINE

SCREW

ELEVATOR

19

o8) Usea couple ofpieces ofmasking tape

toholdtheelevatorinneutral.

o9) Locatea longservo armand using wire

cutters, remove all but one of the arms. Install

theZ-bend in the1.5mm x50mm wireinto the

outerholein the servoarm.

o10) With the elevatorandelevator servo in

neutral,installtheservoarmontotheservo. The

armshouldbepositionedperpendiculartothefu-

selageside and pointout towards theside.

o11) Usinga pen,placeamark onthenylon

elevatorpushrod where thetipof thewireover-

lapsit. Useamodelingknifeandcutoffthenylon

pushrod 5/16” infront ofthe mark. This will

leave enough space so the threaded wire can

threadintothepushrodatleast5/16”.

o12) Remove the servo arm from the servo

and thread the wire into the pushrod. You can

thread it in further or back it out to achieve the

correctlength.

o13) Whensatisfiedwiththealignment,install

theservoarmsetscrewandremovethemasking

tape from the elevator. Seephoto# 40below.

Photo # 40

PARTSREQUIRED

AILERON LINKAGE

o{2} 2mmx150mm ThreadedWire

o{2} NylonClevises w/2mm I.D. Hole

o{2} Nylon Snap Keepers

o{2} Nylon Adjustable Control Horns

INSTALLINGTHEAILERONLINKAGE

o1) Threadonenylonadjustablecontrolhorn

onto each aileron torque rod. Thread them on

until they are 7/8” above the bottom surface of

the wing. See figure #8at top right.

Figure# 8

o2) Threadonenylonclevisatleast5/16”onto

eachof thetwo 2mmx 150mm threadedrods.

o3) Withtheservo centered, installonedual

takeoffservoarmontotheservo. Thearmshould

beinstalledso it isparallelwiththe trailing edge

ofthewing.

o4) Useacouple ofpiecesof maskingtape,

tapedbetween the aileronsandthe trailingedge

ofthewing,tohold the twoailerons inneutral.

o5) Snaptheclevisesontotheadjustablecon-

trolhorns. Withthe servo armandaileronscen-

tered, use a pen and mark on the wires where

theycross over theouter holes inthe servo arm.

o6) Usingpliers,makeanL-bendineachwire

atthe marksmade. Use wire cuttersand cutoff

allbut 1/4” oftheexcess wire.

o7) PushtheL-bendsdownthroughtheholes

inthe servoarm. Adjust thelength ofthe wires

by turning the nylon clevises in or out until the

correct length is achieved. Hold the wires in

placeusing two nylonsnap keepers. See photo

# 41 below.

Photo # 41

PUSHROD

WIRE

NYLON

PUSHROD

PUSHROD

TUBE

7/8”

PUSHROD

WIRE

NYLON

CLEVIS

ADJUSTABLE

CONTROL

HORN

SNAPKEEPER

ADJUSTABLE

CONTROL HORN

WING

TORQUE

ROD

20

PARTSREQUIRED

PILOT AND CANNON

BARRELSEATASSEMBLY

o{1} Prepainted Balsa Cannon Mount

o{2} Plastic Body Halves

o{2} Plastic Cannon Halves

o{2} Plastic Head Halves

o{1} BalsaBarrel Seat Platform

o{1} PlasticBarrel Seat

o{1} PlasticBarrel Seat Back

o1) Using a modeling knife or Lexan

Canopy Scissors, trim off the upper section of

the barrel seat at the molded scribe line. Using

220 grit sandpaper with a sanding block, care-

fullysandtheedgessmooth,beingcarefultokeep

theradiusflat.

o2) Gluethebalsabarrelseatplatformintoplace

inthetopofthebarrelseatusingKwikBondThick

C/A. Theprecoveredsideshouldfaceupandthe

topoftheplatformshouldbeflushwiththetopsides

ofthebarrel seat. Seephoto#42below.

Photo # 42

o3) Test fit the barrel seat into the fuselage.

Theseatrestsontopofthetwoangledbalsastand-

offspregluedtothefuselagefloor. Itisorientated

withthesmalldiameterportionfacingdown.

o4) UsingamodelingknifeorLexanCanopy

Scissors cut out the barrel seat back along the

moldedscribelines. Leaveabouta1/8”liparound

thebottom of theseat fora gluingsurface. See

photo# 43below.

Photo # 43

o5) Test fitthe seat backonto the barrelseat,

insidethefuselage. Using apenplace marks on

the seat back where the pushrod tubes contact

it on either side. Remove the seat back and cut

outonlythose areas thatinterferewiththe push-

rod tubes. Test fit the seat back once more and

makeany furtheradjustments untilyou aresat-

isfiedwiththefit.

o6) Removetheseat back andthe seat from

the fuselage. If you wish to detail the cockpit

areainthe fuselage,doso at thistime.

o7) Paintthebarrelseat and barrelseatback

totasteusingTestorspaints. We painted theout-

sideof thebarrelseat andtheoutside ofthe seat

back brown. The inside of the seat back was

paintedblack.

PILOTANDCANNONASSEMBLY

o8) UsingamodelingknifeorLexanCanopy

Scissors, trim off the rounded edges on the re-

mainingplasticparts. Theseincludethe cannon

halves, body halves and head halves. Use 220

gritsandpaperwith a sandingblockandsand all

oftheedgessmooth,flat and straight.

Pay careful attention to keeping all of the

edgesstraight. This willmake joining the

halvesmucheasier.

o9) Usingscissors, cutout smalltabs about

1/8”wide and1/4”long fromtheexcess plastic

thatwas trimmed off intheprevioussteps. Bend

eachofthe tabsat themiddleinto a shallow"V"

shape.

o10) Usingthin C/Agluetabs intoonlyone

half of each shape (head, body and cannon) at

several locations along the edges. See photo

# 44 below.

Photo # 44

BARREL

SEAT

BARRELSEAT

PLATFORM

MAKE

FLUSH

BARREL

SEATBACK

LEAVE

1/8”LIP

TABS

TABS

Table of contents

Popular Toy manuals by other brands

Hot Wheels

Hot Wheels TRACK BUILDER UNLIMITED instructions

LaserPegs

LaserPegs Speed record PB216OB Assembly instruction

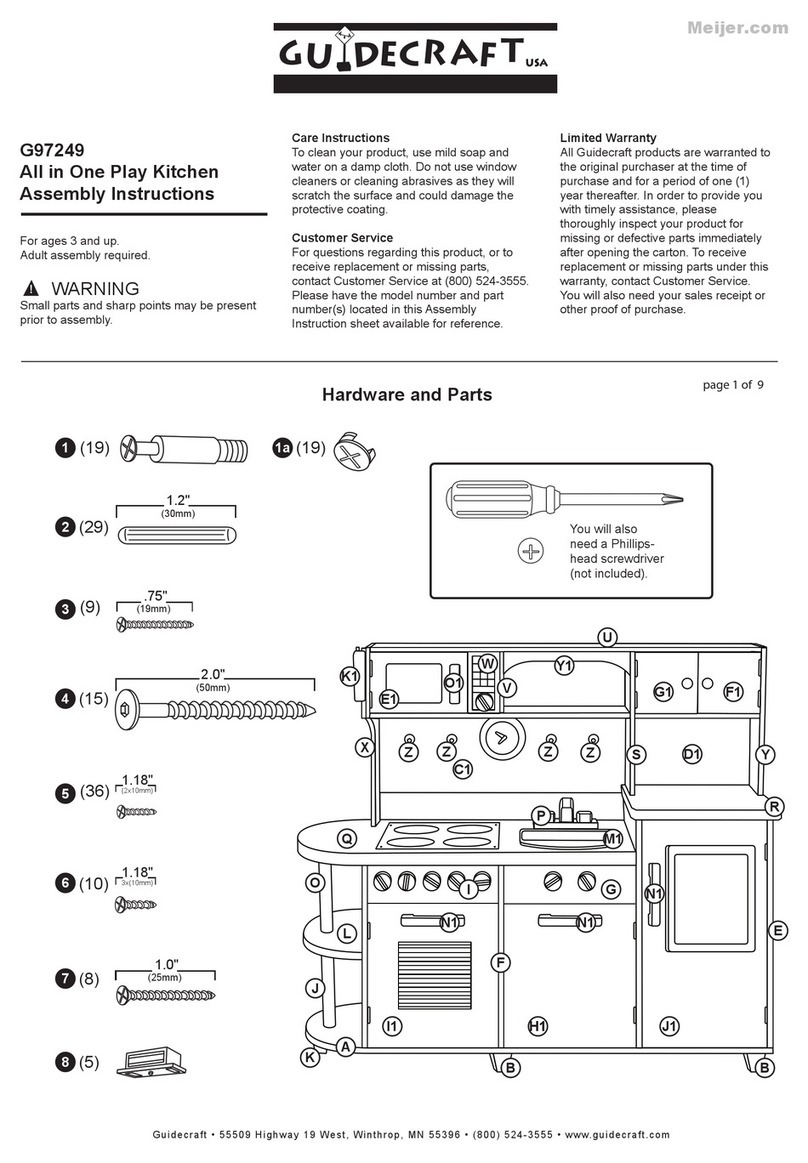

guide craft

guide craft G97249 Assembly instructions

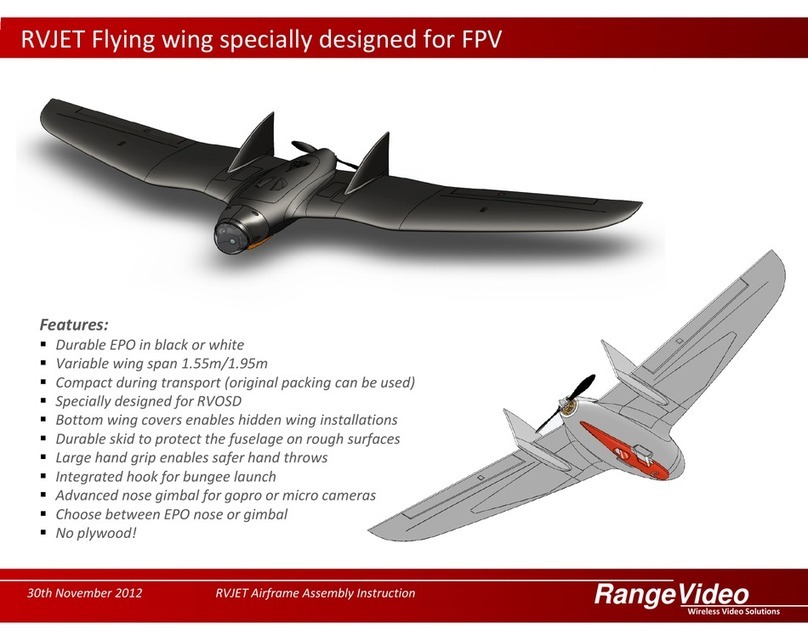

Range Video

Range Video RVJET Airframe Assembly instruction

V-tech

V-tech Create-A-Story: Cars user manual

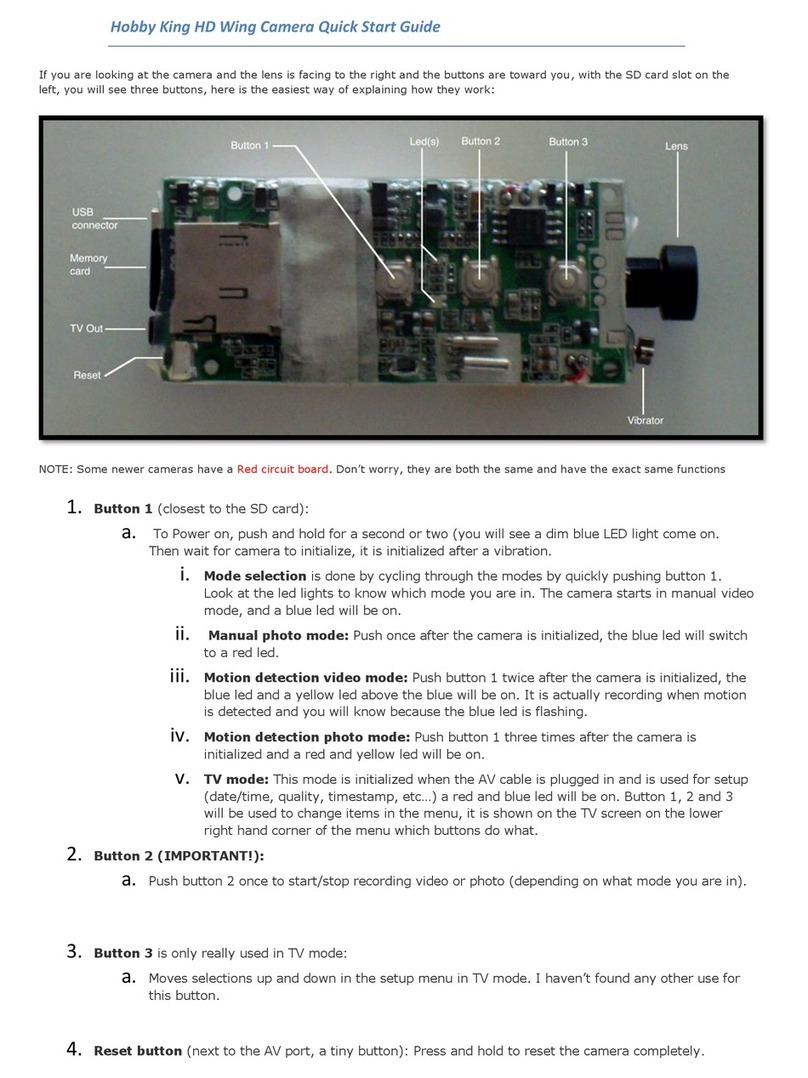

Hobby King

Hobby King HD Wing Camera quick start guide