-7-

Revision 4/F3544

Convection Oven © Moffat Ltd, April 2005

this is not carried out, uneven cooking could

occur). The feet/legs used with bench or floor

mounting are adjustable and will require

adjusting in levelling the unit. It should be

positioned so the operating panel and oven

shelves are easily reachable for loading and

unloading.

BEFORE USE

Operate the oven for about 1 hour at 200°C

(400°F) to remove any fumes or odours which

may be present. Operate the element on HI

for about three minutes. This will produce

some smoke which will soon disappear.

ELECTRICAL CONNECTION—OVEN

E9311 convection ovens are supplied with

pre-fitted cords. Ensure unit is fitted with the

correct cord and plug for the installation.

Refer specifications section.

It is most important that the oven is installed

correctly and that the operation is correct

before use. Installation shall comply with local

electrical, health and safety requirements.

BEFORE CONNECTION TO POWER

SUPPLY

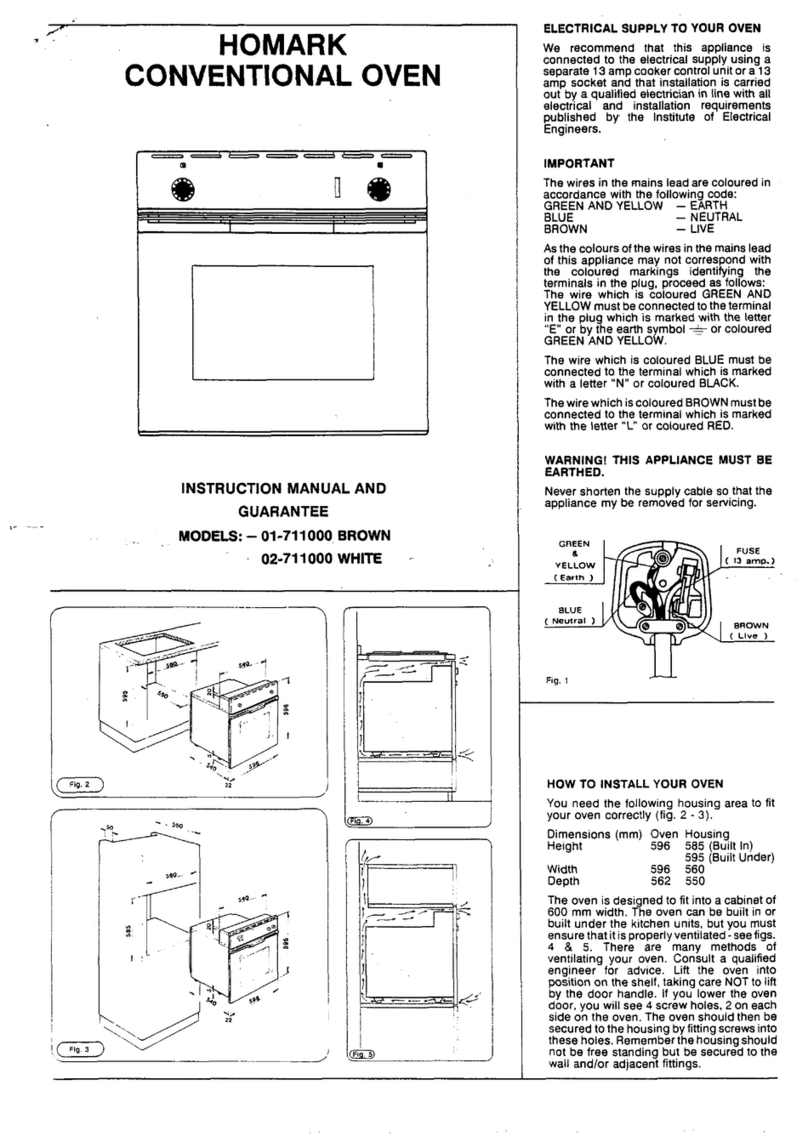

Unpack and check unit for damage and report

any damage to the carrier and dealer. Report

any deficiencies to your dealer. Fit the legs

which are packed inside the oven. Fit door

handle to oven door. Check that the available

power supply is correct to that shown on the

rating plate located on the right-hand side

panel (figure 2.3).

Oven

230-240 V AC, 50 Hz, 13.0 A, 3.1kW @ 240 V

Hob

230-240 V AC, 50 Hz, 13.0 A, 6.5kW @ 240 V

2. INSTALLATION

IMPORTANT: THE OVEN VENT

LOCATED ON THE CABINET TOP

MUST NEVER BE OBSTRUCTED.

WARNING: THIS APPLIANCE MUST BE GROUNDED.

LOCATION

To ensure correct ventilation for the motor,

and controls the following minimum

installation clearances are to be adhered to:

Rear 25mm / 1”

Left-hand side 25mm / 1”

Right-hand side 25mm / 1”

Figure 2.1

WARNING: THIS APPLIANCE HAS

INDEPENDENT ELECTRICAL CIR-

CUITS FOR THE OVEN AND HOB.

SEPARATE POWER CONNECTIONS

ARE REQUIRED.

Should changing of the cord be necessary,

gain access to the electrical connection

terminal block and strain relief by removing

the back panel (four screws).

ELECTRICAL CONNECTION—HOB

To access the electrical connection terminal

block, remove the back panel of the hob (six

screws).

WARNING: ALL INSTALLATION AND SERVICE REPAIR WORK MUST BE CARRIED

OUT BY QUALIFIED PERSONS ONLY.

Position the oven in its allocated working

position. Use a spirit level to ensure the oven

is level from side to side and front to back. (If

L1 L2 Ground

Phase Neutral

RED

BROWN

BLACK GREEN/YELLOW

GREEN

WARNING: THIS APPLIANCE MUST

BE GROUNDED / EARTHED

BLACK

BLUE

WHITE