Blue Torrent Sand Shark User manual

10475

INCLUDES BASE FOR FILTER AND PUMP

TOOLS

REQUIRED

•Phillips head screwdriver

•Flat head screwdriver

•O-ring lube

SAND SHARK

UNIVERSAL

INSTRUCTIONS

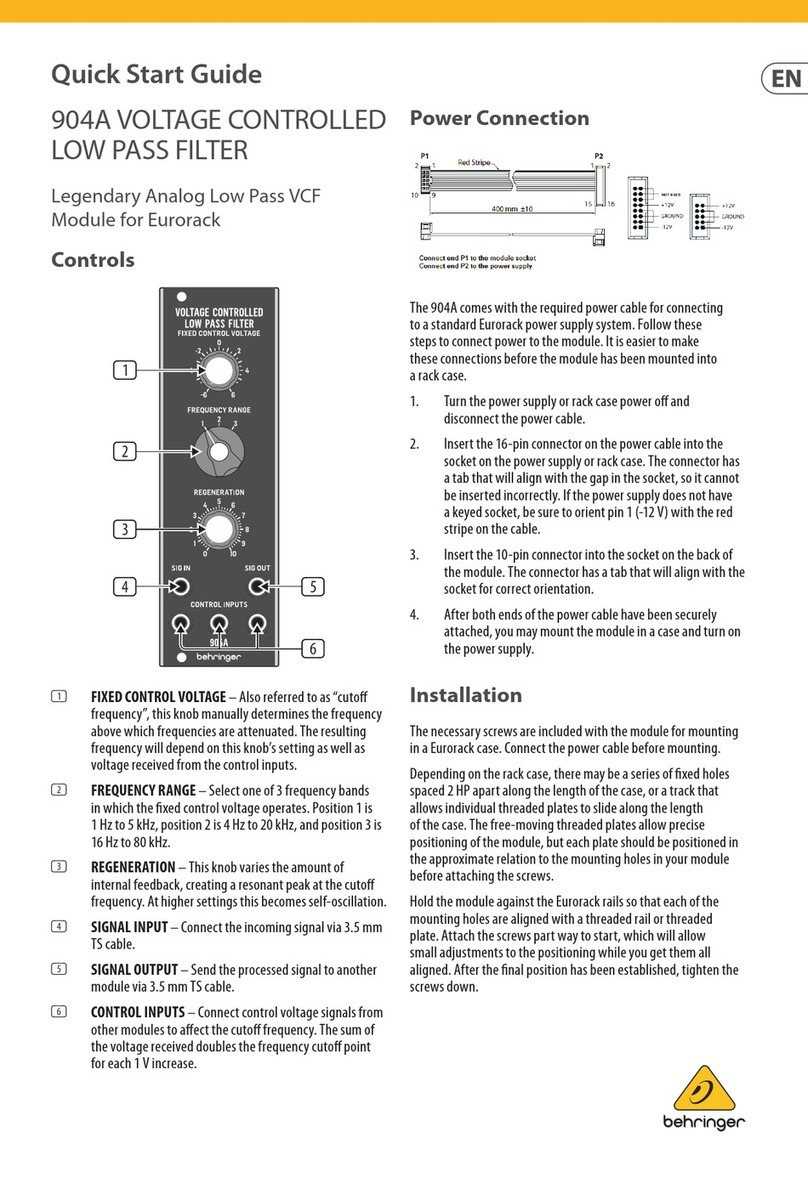

PARTS FOR SAND FILTER

FILTER

TANK

CLOSURE CLAMP STAND PIPE VALVE O-RING

4 WAY VALVE

NOTE

See breakdown on following page for model specific part lists.

DRAIN PLUG

HOSE CLAMPS (6)

STRAIGHT FITTING (3)

TEFLON TAPE

SHORT HOSE (1) LONG HOSE (2)

BASE

2

PRESSURE GAUGE

HOSE ADAPTERS (2)

3

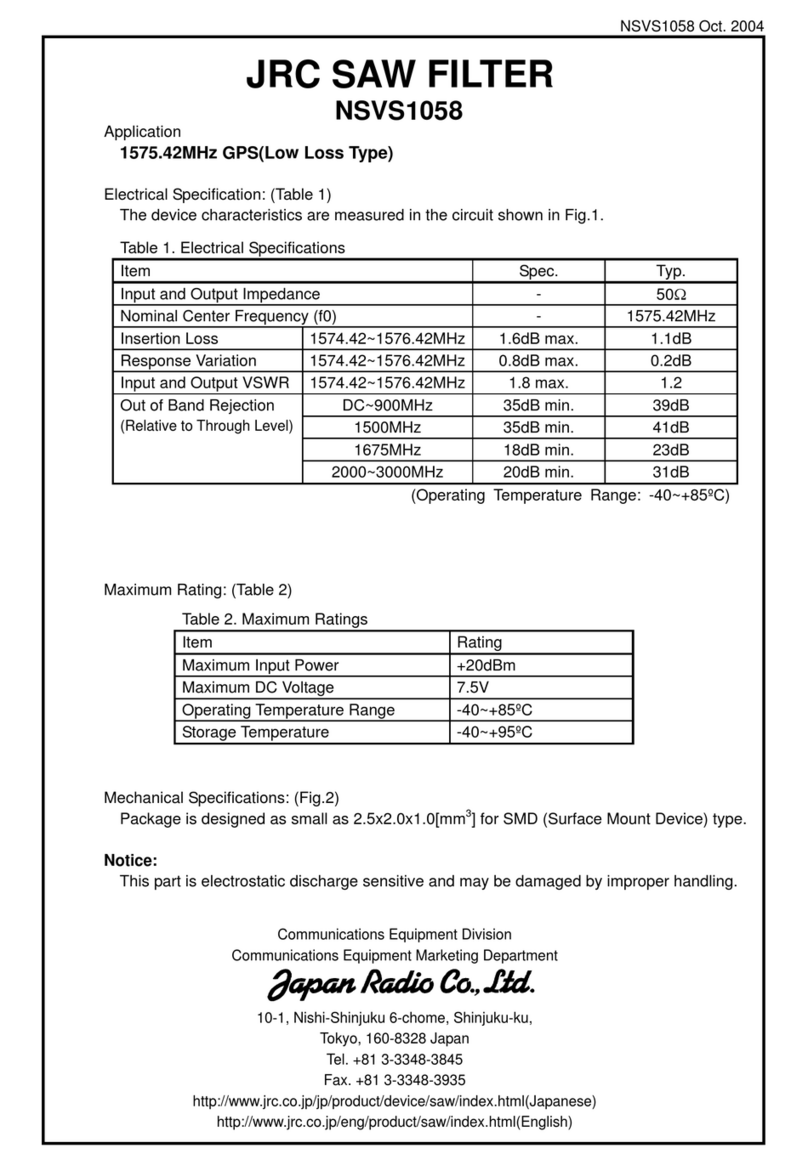

FILTER PARTS BY MODEL

PART #

MODEL # DESCRIPTION QTY

1 AC 85685 Filter Base 1

2 AC 83402 Drain Plug 1

3 AC 83380 Stand Pipe 1

4 AC 83399 Filter Tank 1

5 AC 83348 O-Ring 1

6 AC 83364 Flange Clamp 1

7 AC 83321 4 Way Valve 1

8 AC 84514 Bolt Kit 1

9 BS 40061 Straight Fitting 3

10 BS 35815 Clamps 6

11 AC 52221 1.25” x 24” Hose 1

12 BS10014 1.5”x3’Hose 2

13 AC 76473 Rear Mount Pressure Gauge 1

STEP 1

•Remove the valve from the box and place it to the side until instructed to attach it.

ASSEMBLY INSTRUCTIONS

FOR SAND FILTER

•Inside the tank you will find the standpipe and

a plastic bag containing various parts, remove

from tank and set aside.

NOTE

Filter may be partially assembled; however, nothing has been

properly tightened. DO NOT operate filter system without

completing assembly instructions.

4

STEP 2

ATTACHING THE DRAIN ASSEMBLY

If drain assembly is all together, take it apart.

Take one rubber gasket and put over threaded

part of the drain assembly. Flat part of gasket

must be flush against sealing plate.

From inside the tank insert drain

assembly through hole in bottom of

tank, you will see the threaded part on

the outside of the tank.

5

Place other gasket on threaded part of the

drain assembly that is outside of tank flat

side to the tank.

Place locking nut on threaded part and

thread until snug. Hand tighten only. Be

sure to hold drain assembly from inside

while tightening locking nut.

1

2

3

4

Place drain cap over threaded port on outside of

tank. Hand tighten only.

5

STEP 3

•The filter and pump should be attached to the base prior to filling the filter with sand as it

will be difficult to maneuver after the tank is full.

A. CRADLE STYLE MOUNT

•Pumps with cradles located directly under the motor should be aligned

with the 4 holes that match up to the cradle. This type of mount will

require the use of four mounting bolts and nuts from the hardware

supplied with the base.

•Place nuts underneath the base, in

the properly aligned hole

6

•Bolt the housing of the pump through the base

and tighten.

•Cover the threads of each straight fitting with

teflon tape and thread one fitting into the front of

the motor and one fitting to the top of the motor.

•Attach the 1 1/4” hose with a clamp on each

fitting.

STEP 4

•Before filling tank with sand, place nub on bottom

of tank into notched out piece of the base, twist to

the right till snug.

7

NOTE

Sand should be filled no less than 1/2 way up the tank and no more

than 3/4. Over-filling will result in permanent damage to your

Filter System.

•Add filter grade sand (sold separately) to

filter tank around standpipe.

12” Tank ...... 50 Lbs.

•Remove plastic protector and fill tank with water until the tank is filled right below

opening of standpipe.

NOTE

NEVER FILL SAND TANK MORE THAN 1/2 TO 3/4 OF THE

WAY.

•Place standpipe inside the filter, cover standpipe

with the round plastic standpipe protector to

prevent sand from entering standpipe.

STEP 4 — CONTINUED

•Lubricate with o-ring lube to ensure proper seal

on tank.(O-Ring lube not included)

•Push o-ring against the lip of the valve.

It MUST sit flat against the lip to protect from

leaking at the valve.

•Clean off any sand or debris on top lip of filter and

position valve over the opening of the standpipe.

•Valve will slide ONTO standpipe when positioned

properly in tank (as shown). Push down firmly to make

sure valve slides on all the way.

NOTE

You CANNOT pull standpipe up to secure the valve.

Pulling up can damage the hub and cause sand to get

sent back with water flow to pool.

8

•Place valve so that pump port is directly

over the pump.

STEP 4 — CONTINUED

•Make sure that the screws of the clamp are lined up with the

seams of the tank. Tighten two screws on clamp a little at a time.

Alternating from side to side so that both sides are tightened

equally. Failure to follow these instructions will result in

a leak at the clamp.

•Cover threads of pressure gauge with Teflon tape.

Remove temporary plug from valve and thread

gauge into opening.

9

STEP 5

•The valve ports are labeled “RETURN”, “POOL” and

“WASTE” with raised letters next to or on the the openings.

•Attach one long hose to the bottom of the thru-wall skimmer

and to the front of the pump with hose clamps on each

fitting.

•Attach second long hose to the fitting on the “RETURN”

and to the pools return fitting with hose clamps on each

fitting.

•“WASTE” port will accept a standard fitting and a backwash

hose

(sold separately) which will be used during maintenance.

•Check drain plug at bottom of filter to ensure that it is

screwed on tight.

•Once valve is in place, hold clamp as shown and

position clamp around lip of filter and over edge

of valve. 2 long screws and nuts are provided

to put clamp together.

•The clamp should sit flat around the lip of the tank

and valve. If it is not sitting flat the clamp will leak.

HOSE CONNECTIONS FOR STANDARD ABOVEGROUND POOLS

HOSE CONNECTIONS FOR TEMPORARY ABOVEGROUND POOLS

AC 124EZ5G and FILTERS EQUIPPED WITH AC 22764 FITTINGS

10

1. Take the short hose. Place a clamp onto each end of the short

hose. Leave loose. Slide one end of the short hose over the

exhaust port of you pump. This is the port opening at the top

of the pump not the one in front of the pump. Once in place

tighten that clamp. Take the other end of the short hose and

slide it onto the port of the multiport valve labeled PUMP.

This port is identified by the word “PUMP” embossed on the

side of the port on the vale itself. Tighten the clamp.

2. Take one of the long hoses. Place a clamp onto each end of

the hose. Again leave them loose. Slide one end of the hose

over the intake port of the pump. This is the port at the very

front of the pump. Tighten the clamp. Take the other end of

the6’hoseandslideitovertheportofthepoolsthruwall

skimmer.Once in place tighten the clamp.

3. Take the remaining long hose. Place a clamp over each end

of the hose, again loosely. Slide one end of the hose over the

port on the multiport valve labeled “POOL”. The word “POOL

“is embossed next to the correct port on the valve. Once in

placetightenclamp.Taketheotherendofthe6’hoseand

slide it over the pools return fitting connection on the outside

of the pool wall. Once in place tighten the clamp.

1. Take the short hose. Place a clamp onto each end of the short

hose. Leave loose. Slide one end of the short hose over the

exhaust port of you pump. This is the port opening at the top of

the pump not the one in front of the pump. Once in place tighten

that clamp. Take the other end of the short hose and slide it onto

the port of the multiport valve labeled PUMP. This port is identified

by the word “PUMP” embossed on the side of the port on the vale

itself. Tighten the clamp.

2. Take one of the long hoses. Place a clamp onto each end of the

hose. Again leave them loose. Slide one end of the hose over the

intake port of the pump. This is the port at the very front of the

pump.Tightentheclamp.Taketheotherendofthe6’hoseand

slide one of the AC 22764 fittings onto the end and tighten the

clamp. Attach the fitting (now connected to the hose) to the

suction/intake port of your temporary pool. Hand tighten fitting.

3. Take the remaining long hose. Place a clamp over each end of

the hose, again loosely. Slide one end of the hose over the port

on the multiport valve labeled “POOL”. The word “POOL”

is embossed next to the correct port on the valve. Once in place

tighten clamp. Take the other end of the long hose and slide the

other AC 22764 fitting into the end and tighten the clamp. Attach

the fitting to the pools return port on the outside of the pool wall.

Hand tighten fitting.

AC 22764

PUMP

POOL WASTE

PUMP

11

OPERATING YOUR FILTER

NOTE

Your filter cannot be run if the water is not at the proper level in the

pool. Running the filter without water can cause serious damage to

your pump and filter.

NOTE

NEVER move selector handle while pump is on. Pump MUST be

switched off to change the position of the valve. Failure to comply

will cause damage to your valve and is not covered by WARRANTY.

•Prime filter prior to starting up filter system. DO NOT turn motor on until system has been primed,

you can damage your pump.

•Make sure water in pool is up to middle of skimmer(s) and that there is nothing blocking water

flow from return(s) and skimmer(s) (i.e. plug, plate).

•Push down selector handle on valve and turn to notch labeled BACKWASH. Let go of handle

and the valve is now in backwash position. Make sure backwash hose (sold separately) is

attached to the waste port so water will not spray all over you once pump is started.

•Remove lid of strainer basket on pump (if applicable) and fill with water. Skimmer and return lines

should be filled with water as well (when water level is in proper place in pool this will happen

naturally).

•Place cover back on basket and plug in/switch on pump. When pump starts up, water will come

out through the backwash hose. If the pump is properly primed, the water in the strainer basket

will fill completely and air pocket will be eliminated.

•Repeat above until all air is purged from the system then turn off the pump. If this does not get

air out of system, double check all connections to make sure they are properly tightened and try

again.

•To use filter, with pump OFF, push down selector handle on valve and turn to notch labeled FILTER.

•Connect pump to power to start filter operation.

•Note pressure gauge reading at this time.

•When pressure through return fades and pressure gauge reads 5 psi above starting pressure,

you will need to backwash the filter system to remove debris.

•Turn pump off before moving selector to BACKWASH position. Once in backwash, turn pump

back on.

•Water will come out through the waste port, so position backwash hose where you would like

water to run out.

•NEVER backwash for longer than ONE MINUTE at a time. Backwashing longer than one minute

will cause sandblasting of internal components and can lead to damage of standpipe and/or

hub and VOIDS WARRANTY.

•Turn pump off and move selector to RINSE position. Rinse will allow water to flow through to

clear out the lines and prevent a puff of sand or debris back into the pool after backwashing.

•Rinse for approximately 15 seconds and turn off pump again. Move selector back to filter and

turn pump back on. You are now filtering water.

TROUBLESHOOTING

WINTERIZING

•At the end of the season once you disconnect filter system, remove the valve from the tank. Valve

selector handle should be positioned BETWEEN any of the notches to allow for air ventilation

through the valve to protect from cracking.

•Remove drain plug from bottom of sand tank to drain water out of the filter tank. Keep this plug off

for the winter to allow any potential water build-up to escape from the tank.

•Empty ALL sand from the filter system and dispose of as it is recommended to replace sand

EACH season.

•Rinse out inside of tank and air dry. Remove standpipe from tank.

•Store tank in an area where it will be protected from the elements and keep valve and tank stored

APART to protect from condensation forming and causing cracks in the tank or valve.

•Run hose water through pump to rinse out and store in a warm, dry place for the winter.

NOTE

Failure to winterize your filter properly may result in damage to the

tank and pump which is NOT covered under any warranty.

1. Check skimmer and pump

strainer baskets for debris.

2. Check for restrictions in intake

and discharge lines.

3. Check for air leak in intake

line (indicated by bubbles

returning to pool).

4. Backwash filter.

5. Bring sand level in filter down

to 1/2 full.

LOW

WATER FLOW SHORT

FILTER CYCLES POOL WATER

WON’T CLEAR UP

1. Check for algae in pool and

superchlorinate as required.

2. Be sure chlorine and pH levels

are in proper range.

Adjust as required.

3. Check surface of filter sand for

crusting or caking. Remove

1” of sand if necessary.

4. Check hair and lint basket on

pump for possible air leak,

lubricate basket lid O-Ring as

necessary.

1. Check chlorine, pH and total

alkalinity levels and adjust as

required.

2. Be sure flow rate through filter

is sufficient.

3. Operate filter for longer

periods.

4. Be sure valve is set on

“Filter” position.

5. Be sure sand is between

1/2 and 3/4 full in tank.

12

Blue Torrent warrants its Pumps and Filters to be free of defects in

material and/or workmanship for a period of one year from the original date of

purchase and/or installation.

WARRANTY CLAIM EXCLUSIONS:

• Damage caused by improper installation as specified in owner’s manual

• Damage caused by improper handling

• Damage due to misuse, abuse and/or failure to operate item per owner’s

manual

• Damage caused by improper water chemistry

• Damage caused by improper winterization of equipment

• Damage caused by not using original Blue Torrent replacement parts

• Damage caused by improper wiring or use of extension cords

• Accidental damage, fire, acts of God or other circumstances outside of

Blue Torrent’s control

Please return any and all defective items to your local authorized

Blue Torrent dealer for inspection.

The customer is responsible for all shipping charges to and from the nearest

Factory Warranty Center. For more information. Please visit www.btwarranty.com

Should a defect in material or workmanship appear the product will be repaired

or replaced at our discretion. Neither Blue Torrent nor any authorized dealer

is responsible for any charges related to the installation of the new item or part.

Nor are they responsible for any incidental charges incurred including, but not

limited to, water, chemicals, landscaping or any other associated expenses.

NOTE:

• Customer must retain the original sales invoice as proof of purchase along

with the installers invoice (to establish date of installation)

• Commercial facilities are not covered by warranty

Blue Torrent manufactures all of its products using cutting-edge technology

with the best materials and workmanship available.

Blue Torrent’s PUMPS AND FILTERS are warranteed as follows:

Mfg. by Asia Connection LLC, NY

1 YEAR LIMITED WARRANTY

Table of contents

Popular Water Filtration System manuals by other brands

Filtreco

Filtreco Drum 100 user manual

Atlas Filtri

Atlas Filtri Micro Instructions for installation, use and maintenance manual

Spectra Watermakers

Spectra Watermakers Catalina 340 Z Installation and operating manual

GE

GE RPWFE quick start guide

aeropur

aeropur ecomax 100 operating instructions

Highland Tank

Highland Tank Ultra Clear Service manual