Blue BLUE 120 User manual

BLUE Professional Poolware

Positioning control for pool cover

1 Manufacturer’s Address

BLUE Professional Poolware bv

Korenmijt 1, 5741 PP Beek en Donk

Tel. +31 (0)85 076 88 85

Mail : info@blueppw.com

BLUE Professional Poolware tube motor / 2016-01 Seite 1

Table of contents

1 Manufacturer’s Address........................................................................................................................ 0

2General information.......................................................................................................................... 2

2.1 Important information ............................................................................................................. 2

2.2 Technical data........................................................................................................................ 2

2.3 Symbols legend and description.................................................................................................... 3

2.5 Hazard information................................................................................................................. 3

2.6 Validity.................................................................................................................................... 3

2.7 Intended use .......................................................................................................................... 4

2.8 General safety and usage information................................................................................... 4

2.9 Disposal.................................................................................................................................. 5

2.10 Delivery contents................................................................................................................... 5

2.11 Additional information............................................................................................................. 5

3Operation.......................................................................................................................................... 5

3.1 Optional stop switch............................................................................................................... 5

3.2 Key switch operation.............................................................................................................. 5

3.2.1 Key switch with automatic reset......................................................................................... 5

Hold mode .................................................................................................................................... 6

3.3 Pushbutton operation............................................................................................................. 6

3.4 Optional remote control operation.......................................................................................... 7

5 Assembly of BLUE.............................................................................................................................. 9

6 Electrical connection......................................................................................................................... 10

6.1 Wiring diagram............................................................................................................................. 10

6.2 Cable inlets .................................................................................................................................. 10

6.3 Power connection ........................................................................................................................ 10

6.4 Terminals ..................................................................................................................................... 10

6.5 BLUE motor connection............................................................................................................... 11

6.5.1 7-wire connection cable, standard design............................................................................. 11

6.5.2 7-wire standard cable, 5-wire motor connecting................................................................... 12

6.6 Key switch connection ................................................................................................................. 13

6.7 Pushbutton connection touch control........................................................................................... 13

6.8 Water level monitoring connection............................................................................................... 13

7 Start-up............................................................................................................................................. 13

7.1 Select language ........................................................................................................................... 14

7.2 Programming the final positions .................................................................................................. 14

7.2.1 Activation............................................................................................................................... 14

7.2.2 Testing the motor's rotation direction.................................................................................... 15

7.2.3 Programming the OPEN position.......................................................................................... 15

7.2.4 Programming the CLOSED position ..................................................................................... 15

7.3 Information shown on display 16 ................................................................................................. 16

8 Maintenance and upkeep................................................................................................................ 16

9 Error messages ............................................................................................................................... 17

10 PC connection (USB interface) ...................................................................................................... 17

10.1 Relays connection functions...................................................................................................... 18

10.1.2 "Drive" function.................................................................................................................... 18

10.2 Drive mode configuration........................................................................................................... 18

10.2.1 MODE EU 1, Standard configuration.................................................................................. 18

10.2.2 MODE EU 2, France ........................................................................................................... 18

10.2.3 MODE EU 3, Stop operation in both directions................................................................... 18

10.2.4 MODE EU 4, TOUCH CONTROL....................................................................................... 18

10.2.5 MODE EU 5, external 1-channel remote control................................................................. 18

11 Commissioning certificate ............................................................................................................. 19

BLUE Professional Poolware tube motor / 2016-01 Seite 2

2 General information

2.1 Important information

Operation

Guarantee

Observance of these operating instructions is essential to ensure trouble-free

operation and in order for any warranty entitlements to be honoured. Read the

operating manual carefully before working with the BLUE control unit.

Proper use

The BLUE control unit is designed for use in privately-used pools. It may not be

used in public swimming pools.

Note

This operating manual contains instructions for the operation, storage, setup and

maintenance of the BLUE control unit.

Start-up

Maintenance

Setup

The personnel entrusted with the handling, storage, installation, start-up,

inspection and maintenance of the machine must be qualified for industrial,

mechanical and electrical equipment.

Disposal

The current and regional regulations must be observed for disposal.

The electronic components and plastic components are to be disposed of in

accordance with environmental protection regulations.

2.2 Technical data

Model

BLUE 120

BLUE 150

BLUE 180

BLUE 250

BLUE 300

Supply voltage

230V AC

Frequency range

50/60Hz

Rated current

2.5A

Rated power

160VA

160VA

160VA

200VA

300VA

Power-on time

Maximum of 15 min. (S2 –15 min)

Motor voltage

24VDC

Motor current

limit

5.8A

6.8A

7.0A

8.0A

9.0A

Motor fuse

7.5A

7.5A

7.5A

7.5A

7.5A

Ambient

temperature

-10°C to +60°C

Site altitude

up to 1000 m above sea level

Humidity

Max. 90%, no condensation

Protection class

IP54, Protection classification I

Break connection

24V DC, maximum 1.0A

Voltage impulse

transmitter

5V DC –24V DC

Switching level

4.5V < High < 24V 0V < Low: <1.0V

Dimensions

240mm x 465mm x 100mm

Weight

2.9 kg

BLUE Professional Poolware tube motor / 2016-01 Seite 3

2.3 Symbols legend and description

DANGER DUE TO ELECTRICAL CURRENT

Failure to observe this can result in death, serious injury or property damage.

DANGER

Failure to observe can result in personal injury or material damage.

) NOTE

Note supplementary information.

2.4 Information for the user, target group

This documentation contains the necessary information for proper use of the products described

therein. It is intended for technically qualified personnel. Qualified personnel are persons who -

because of their education, experience, instructions, and knowledge about corresponding standards

and regulations, rules for the prevention of accidents, and operating conditions - are authorised by the

person responsible for the safety of the machine to perform the required actions and who are able to

recognise and avoid potential hazards (definition of qualified personnel according to IEC 364).

2.5 Hazard information

The following directions are for the safety of the service personnel as well as for the safety of the

described products as well as any connected devices.

Warning! Dangerous electrical voltage.

Failure to observe this can result in death, serious injury or property damage.

•Isolate supply voltage before installation or removal work as well as in case of fuse

replacement or modifications of the setup.

•Observe the accident prevention and safety regulations that apply to the specific area of use.

•Before putting the machine into operation, check whether the rated voltage coincides with the

local mains voltage.

•Emergency stop devices must remain operational in all modes of operation. Disabling the

emergency stop devices may not cause an uncontrolled restart.

•The electrical connections must be covered!

•Ground wire connections must be checked for fault-free function after installation!

•The conditions described in DIN VDE 0100-702:2003-11 must be observed.

2.6 Validity

This document applies to the BLUE control unit from the BLUE series

Safety Information

Adherence to this information is the prerequisite for trouble-free operation and the fulfilment of any

guarantee claims.

BLUE Professional Poolware tube motor / 2016-01 Seite 4

2.7 Intended use

)Note: The devices described here are electrical equipment for use in swimming pools and other

pools and may only be used under the following conditions:

Exceptions: the manufacturer has designed the product specifically for other applications and ambient

conditions.

The BLUE control unit …

•...must only be used for the intended purposes and those confirmed in the shipping

documents.

•... must only be operated under the operating conditions stipulated in the operating

instructions and within the power limits.

•... complies with the valid standards and regulations.

•... is a component designed for use in privately-used swimming pools.

•Improper use

•Use in potentially explosive areas

•Use in harsh environments (acids, gases, vapours, dust, oil)

•Use in a sewage area

•Control unit use in 0 zone as per DIN VDE 0100-702:2003-11

2.8 General safety and usage information

At the time of delivery, the BLUE control unit and its components are considered to be state of the art

and fundamentally safe to operate.

) All transport, storage, installation/assembly, connection, commissioning, maintenance and

servicing work may only be performed by qualified personnel.

During such work, qualified personnel must observe:

· the supplementary safety instructions in the individual chapters of this documentation.

· the safety instructions in attached supplementary sheets and further documents from

subcontractors.

· this documentation and the circuit diagrams.

· the warning and safety signs on the devices.

· the machine-specific regulations and requirements.

· the national and regional regulations for safety and accident prevention.

) The BLUE control unit can pose a risk to persons, the machine itself and other property

belonging to the operator

· ... if unqualified personnel work on or with the drive system.

· ... if the drive system is used improperly.

· ... if the drive system is installed and operated incorrectly.

· ... if the following information is disregarded:

oOnly operate the control unit when it is in perfect working order.

oAs a general rule, any retrofitting, changes or reconstruction of the drive system is prohibited.

The above work may only be performed after consultation with the manufacturer.

oDuring operation and for an extended period afterwards, the components may have live

parts, moving parts and potentially hot surfaces.

BLUE Professional Poolware tube motor / 2016-01 Seite 5

oStart-up (start of proper operation) may only be carried out once there it has been confirmed

that the machine complies with EMC Directive 2004/108/EC and that the machine conforms to

Machinery Directive 2006/42/EC.

oEN 60204 must be observed.

Should you have any questions or problems, please contact your BLUE representative.

2.9 Disposal

The control unit must be disposed of in compliance with the currently valid regulations of the

respective country. Electronic elements and components must be disposed of through a certified

specialised company.

2.10 Delivery contents

· Pre-wired control unit with mains supply line, shock-proof plug and options as per

specification.

· Additional accessories in accordance with the accompanying papers.

After receiving the delivery, check the delivery contents against the accompanying papers to make

sure they are complete. The manufacturer does not offer warranty for claims regarding missing parts

submitted at a later date. Any transport damage that is discovered must be reported to the shipping

agent without delay.

2.11 Additional information

) NOTE

The customer is responsible for professional installation and setup of the machine. Safety devices and

other safety-relevant components are to be installed at the machine site.

3 Operation

The operator must have an unobstructed view of the pool. There may not be any people in

the pool when opening and/or closing the pool cover. Objects and hoses in the pool can

become caught in the cover and potentially destroy the drive motor. If the water level is too

low, the cover or motor may also be damaged.

Operation is carried out by a switched installed near the pool. The switch may be either a pushbutton

or a key switch. An optional remote control is available for purchase.

3.1 Optional stop switch

If an optional stop switch exists, the motor can be stopped at any time by actuating the switch.

3.2 Key switch operation

3.2.1 Key switch with automatic reset

Touch control

By briefly (less than 1 s) turning the key switch in the desired direction for "opening" or "closing", the

pool cover moves to the selected final position and the control unit switches the motor off. This

movement can be stopped at any time by turning the key switch (less than 1 s) in the opposite

direction or by actuating the optional stop button. By turning the key switch once again in a particular

direction, the motor restarts and the moves in the selected final position.

BLUE Professional Poolware tube motor / 2016-01 Seite 6

Hold mode

If the key switch is held in the desired direction for a longer period (longer than 1 s), the drive returns

to the final position and stops. If the operator releases the switch during the movement, the drive stops

immediately and must be restarted.

3.2.2 Key switch with manual reset

By briefly turning the key switch in the desired direction for "opening" or "closing", the pool cover

moves to the selected final position and the control unit switches the motor off. The movement can be

stopped at any time be turning the key switch to the neutral position. By turning the key switch once

again in a particular direction, the motor restarts and moves to the selected final position. After arriving

at the final position, turn the key switch back to the neutral position.

3.3 Pushbutton operation

3.3.1.1 Touch control

By briefly (less than 1 s) pressing the pushbutton in the desired direction for "opening" or "closing", the

pool cover moves to the selected final position and the control unit switches the motor off. This

movement can be stopped at any time by pressing the pushbutton (less than 1 s) in the opposite

direction or by actuating the optional stop button. By pressing the pushbutton once again in a

particular direction, the motor restarts and moves to the selected final position.

3.3.1.2 Hold Mode

If the pushbutton is held in the desired direction for a longer period (longer than 1 s), the drive returns

to the final position and stops. If the operator releases the switch during the movement, the drive stops

immediately and must be restarted.

BLUE Professional Poolware tube motor / 2016-01 Seite 7

3.4 Optional remote control operation

)

The device can be retrofitted with a remote control unit. Please notify the BLUE if desired.

The pool cover is activated by the two top buttons on the hand-

held remote control unit.

Upper button:

press once

to open

press once

to stop

press once

to open

Second button:

press once

to close

press once

to stop

press once

to close

3.5 Operation with buttons 6 and 7

3.5.1 Touch control

By briefly (less than 1 s) pressing the pushbutton in the desired direction for "opening" or "closing", the

pool cover moves to the selected final position and the control unit switches the motor off. This

movement can be stopped at any time by pressing the pushbutton in the opposite direction or by

actuating the optional stop button. By pressing the pushbutton once again in a particular direction, the

motor restarts and moves to the selected final position.

3.5.2 Hold mode

If the pushbutton is pressed down in the desired direction for a longer period (longer than 1 s), the

drive returns to the final position and stops. If the operator releases the pushbutton during the

movement, the drive stops immediately and must be restarted.

4 Installation site, dimensions

BLUE Professional Poolware tube motor / 2016-01 Seite 8

· Observance of DIN VDE 0100-702 (Installation of low voltage units, section 702: Swimming

pools and other pools) is mandatory.

· Installation in area 2 in accordance with DIN VDE 0100-702 is only allowed if the required

power outlet is protected by a residual current device (RCD) with a rated differential current of

≤ 30mA.

· Installation in a dry room in which other technical equipment for operating the swimming pool

is installed. The room should be a maximum of 10m from the pool.

· The control unit is designed for wall mounting. It is mounted by means of 4 screws, Ø 4 mm

(not included in delivery). It must be fixed in such a way that the cable entries are on the

bottom.

Figure 1

Drill hole pattern for BLUE

BLUE Professional Poolware tube motor / 2016-01 Seite 9

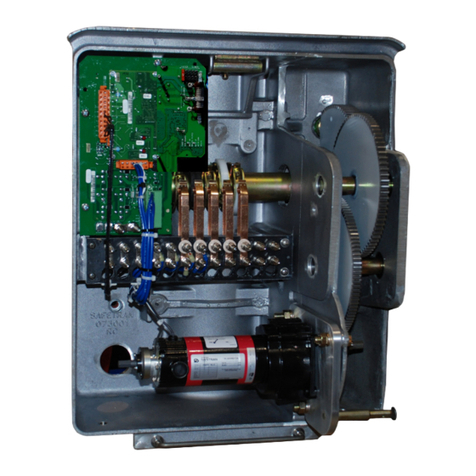

5 Assembly of BLUE

Figure 2

Assembly

1

power switch with control lamp

11

Motor terminal

2

cable inlets M20 x 1.5

Blade fuse ISO 8820-3

12

Motor fuse

3

control panel

13

Terminal 24VDC

4

Dip switch (do not change Off position)

14

LED voltage 24VDC

5

Programming button with LED

15

Rectifier

6

Movement direction open with LED

16

Display

7

Movement direction close with LED hidden

under the control panel:

8

Safety transformer 230/24V

17

Circuit board power connection

9

Terminals labelled 1 - 14

18

Mains fuse 5 x 20 mm, IEC 60127-2

10

Brake resistance

BLUE Professional Poolware tube motor / 2016-01 Seite 10

6 Electrical connection

6.1 Wiring diagram

Figure 3

Wiring diagram (switch is not included in delivery)

6.2 Cable inlets

All cables must be fed through the plastic cable inlets in the terminal section.

· M25 screw connection for cable diameters from 9mm to 17mm.

) Compliance with IP54 protection class is only assured if

· … the cables have been properly clamped in the cable inlets.

· …all cable inlets not in use are sealed with dummy plugs.

6.3 Power connection

The BLUE control unit comes ready for connection with a 1m feed line and shock-proof plug.

6.4 Terminals

· Motor connection (11) screw clamps maximal 4 mm²

oScrew driver 4 x 0.5, 1.0Nm

· All other spring-loaded clamps for maximum 2.5 mm²

) To release the clamps, press the plastic lever towards the control panel.

BLUE Professional Poolware tube motor / 2016-01 Seite 11

To actuate the lever, use appropriate tools. Levers can break if subjected to too much force. If the

terminal or a component on the control panel is damaged, a warranty claim is no longer valid.

6.5 BLUE motor connection

The BLUE motors for pool covers come with an orange connection cable.

)

•Do not open the motor if the motor feed line requires lengthening!

•Only use a matching cable for lengthening.

•The junction boxes must be sealed watertight with a moulding compound.

•Do not shorten the motor feed line. If shortened, all warranty claim are invalid!

6.5.1 7-wire connection cable, standard design

The wires are color-coded or labelled with numbers as shown in the table.

•Motor connection 2 x 2,5mm²

Terminal label (11)

Cable number

Colour

Polarity

24VDC

Blue ……

Changes depending

on rotation direction

of motor

Black ……

•Brake coil connection 2 x 0,5mm²

Terminal number (9)

Cable number

Colour

Polarity

24VDC

1

1

Blue ……

Plus +

2

2

Black ……

Minus –

•Impulse transmitter connection 3 x 0.5mm² with mutual shielding (shielding is not connected to

the device)

Terminal number (9)

Cable number

Colour

Polarity

3

3

White ____

Minus –

4

4

Red ____

Plus +

5

5

Green ____

Signal

BLUE Professional Poolware tube motor / 2016-01 Seite 12

Figure 4

Centre: Motor connection cable 7-wire

6.5.2 7-wire standard cable, 5-wire motor connecting

Special model or for third party manufacturers. Motor and brake are connected in parallel. No separate

brake connection necessary. The wires in BLUE motors are color-coded or labelled with numbers as

shown in the following table.

•Motor connection 2 x 2,5mm²

Terminal label (11)

Cable number

Colour

Polarity

24VDC

without number

Blue ……

Changes depending

on rotation direction

of motor

without number

Black ……

•Brake connection 2 x 0,5mm2 (without pin)

Terminal number (9)

Cable number

Colour

Polarity

24VDC

1 (not occupied) plus +

1 (without pin)

Blue ……

Plus +

2 (not occupied) minus -

2 (without pin)

Black ……

Minus –

•Impulse transmitter connection 3 x 0.5 mm² with mutual shielding (shielding is not connected to

the device)

Terminal number (9)

Cable number

Colour

Polarity

3

3

White ____

Minus –

4

4

Red ____

Plus +

5

5

Green ____

Signal

Figure 5

Centre: Motor connection cable

5-wire

Special model or for third party motors.

BLUE Professional Poolware tube motor / 2016-01 Seite 13

6.6 Key switch connection

Terminal number (9)

Function

Colour

11

Common (0V)

Customer-specified

connection

6

To open

7

To close

6.7 Pushbutton connection touch control

Terminal number (9)

Function

Colour

11

Common (0V)

Customer-specified

connection

6

To open

7

To close

8

To stop

6.8 Water level monitoring connection

The pool cover may only be opened or closed when the water level is sufficient. For switching off if the

water level is not sufficient, a potential-free contact for water level monitoring is required. The contact

must be closed if the water level is too low. The connection is carried out at terminal 11 and 8 on the

strip terminal (9), parallel to the stop button.

7 Start-up

DANGER DUE TO ELECTRICAL CURRENT

Before starting the machine up, check the operation of the residual current device (RCD) on the

machine side! Check all lines for damage and make sure the electrical connections are secure.

DANGER

Before switching the machine on, make sure that there are no swimmers in the swimming pool!

BLUE Professional Poolware tube motor / 2016-01 Seite 14

7.1 Select language

The language can only be selected during the initial start of operation and will remain until the unit is

subjected to a power outage or switched off. If the language is selected after the final positions have

been programmed, the selected positions are saved.

· Plug in the shock-proof plug.

· Press and hold the Open button (6) and turn on the power switch (1).

· Hold the Open button (6) down until the "Language" message is shown in the display.

· Release the Open button (6).

· By pressing the close button (7), the desired language (German, English, French, Dutch,

Spanish, Italian, or Portuguese) can be selected

· When the desired language is shown in the display, it can be saved by pressing the Open

button (5).

· The message "ready" appears on the display in the selected language.

Figure 5:

Select language

7.2 Programming the final positions

)

•When programming the final positions, the operator must have an unobstructed view of

the pool.

•There is no automatic switch-off.

•Movement to the final positions can be actuated by an external switch or with the Open

(6) and close (7) button on the control panel, or by using the optional remote control.

•We recommend programming with an external switch, and the following is based

only on this recommendation.

7.2.1 Activation

Plug in the shock-proof plug.

•Press the power button (1)

•Control lamp in the power switch is on

oLED (14) on the control panel is lit

oLED´s for buttons 7, 6 and 5 flash briefly

oAfter approximately 5 seconds, the "ready" message appears in the display.

oThe control unit is ready for additional programming

BLUE Professional Poolware tube motor / 2016-01 Seite 15

7.2.2 Testing the motor's rotation direction

The rotation direction can be tested by the open (6) and close (7) buttons on the control

panel. If the pool cover is not within sight, two people are required.

•Press the open button (6).

•The closed cover must begin opening.

•If the cover moves in the wrong direction, exchange the motor connections at terminal 11.

•The rotation direction should then also be tested with the external switch. If the rotation direction

is incorrect when the external switch is activated, correct the connections at terminals 11, 6 and

7.

7.2.3 Programming the OPEN position

The OPEN position indicates that the water surface of the pool is exposed and the cover is completely

rolled back.

1. Press and hold the red programming button (5) until "Programming mode" appears on the

display. The red LED next to the red button (5) is flashing rapidly.

2. Press the external "open" switch. The red LED next to the OPEN button (6) is lit.

3. When the cover has arrived in the OPEN position, turn off the motor by briefly pressing the

switch in the opposite direction. The desired position can be corrected in either direction by

means of the pushbuttons. When switching directions, a time delay of 4 seconds must be

observed.

4. Turn off the power to the mains switch (1) at the control unit. The final position OPEN is now

programmed.

7.2.4 Programming the CLOSED position

The CLOSED position indicates that the water surface of the pool is covered and the cover is

extended completely across the water surface.

1. Turn on the power switch (1) The "ready" message is being displayed.

2. Press and hold the red programming button (5) for 3 seconds until "Programming mode"

appears on the display.

The red LED next to the red button is flashing rapidly.

3. Press the external "close" switch. The red LED next to the CLOSE button (7) is lit.

4. When the cover has arrived in the CLOSED position, turn off the motor by briefly pressing

the switch in the opposite direction. The desired position can be corrected in either direction by

means of the pushbuttons. When switching directions, a time delay of 4 seconds must be

observed.

5. Press the red program button (5) one time.

• "Position 1" will appear in the display and the LED next to button (5) is flashing

slowly.

6. Press the red program button (5) once again.

• "Position 2" will appear in the display and the LED next to button (5) is flashing more

rapidly.

7. Press the red program button one more time.

• The desired position is saved.

• The word "saved" is displayed and the LED next to the red programming button (5)

goes off.

• Both positions are saved and the unit is ready for operation.

BLUE Professional Poolware tube motor / 2016-01 Seite 16

7.3 Information shown on display 16

A variety of information is shown on the display, depending on operating mode.

• In standard operating mode, the motor parameters are displayed.

Figure 6 Figure 7:

Display information

• In programming mode, information pertaining to programming are displayed.

• In the event of malfunction, information regarding the possible cause are displayed. See the

section on error messages.

8 Maintenance and upkeep

Only use a damp cloth to clean the control unit. Ensure that the control unit is not covered by objects

and is always accessible. The cables must always be fastened in the intended cable inlets. If the

housing or cover becomes discoloured, this indicates exposure to excessive temperatures. Pull the

shock-proof plug from the mains and contact an expert.

BLUE Professional Poolware tube motor / 2016-01 Seite 17

9 Error messages

An error is indicated when the LED's next to the programming buttons 5,6, and 7 flash simultaneously.

The display will show an error message in accordance with the following table.

LED error code

Error in display

Possible cause

Remedy

All 3 LED's are

flashing

KEY SWITCH BLOCK

Key switch is in the

OPEN or CLOSE

position

Turn the key switch to

the 0 position. The

word "ready" appears

in the display.

All 3 LED's are

flashing

SENSOR ERROR

Decoder not functioning.

Have the unit

inspected by a

professional

technician. The drive

runs out of control in

this instance.

All 3 LED's are

flashing

MAXIMUM CURRENT

Motor is blocked or is

rough-running. Items in

pool

Remove the items.

Have the unit

inspected by a

professional

technician.

none

none

The unit only moves in

one direction

Connect the key

switch properly.

Connect the cable

from terminal 6 to

terminal 11, or from

terminal 7 to terminal

11.

LED for voltage

display is not lit

No display

Shock-proof plug has no

power. Residual current

circuit breaker was

activated. Power switch

(1) not turned on

mains fuse ( ) on the

power supply board

defective

Check house fuse,

have unit inspected by

a professional

technician. Turn on

power switch, check

fuse / replace if

needed

10 PC connection (USB interface)

)

The operational data of the BLUE can be evaluated and the parameters changed via the USB

interface and a Windows PC (Laptop). The required software must be installed on the PC.

After changing the parameters, the BLUE must be switched off and back on by the power

switch (1).

Changing the default values may cause damage or destroy the motor and the control unit.

Therefore, changes should only be carried out by persons trained by BLUE!

The following functions of the BLUE can be changed via the USB interface:

•Relays connection stable and drive

•Behaviour of control unit when actuating operating switches, drive mode configuration

BLUE Professional Poolware tube motor / 2016-01 Seite 18

10.1 Relays connection functions

10.1.1 "Stable" function, delivery state

The relays switch when the final position has been reached.

•Cover reaches the closed position: Contact 13 –14 closed, 12 –13 open

•This switching status remains until the final open position has been reached.

•The cover reaches the open position: Contact 12 –13 closed, 13 –14 open

•This switching status remains until the final closed position has been reached.

10.1.2 "Drive" function

The relays switch as soon as the motor begins to turn.

•The control unit switched the motor off: Contact 13 –14 closed, 13 –12 open

•The control unit switched the motor on: Contact 12 –13 closed, 13 –14 open

10.2 Drive mode configuration

10.2.1 MODE EU 1, Standard configuration

Control unit behaves as described in section 6 "Operation".

10.2.2 MODE EU 2, France

There are special safety regulations which must be observed in France. During the closing process,

the button (key switch) must be held in place (dead man switch). The opening process can be started

by briefly pressing the corresponding button as with configuration EU 1.

10.2.3 MODE EU 3, Stop operation in both directions

Opening and closing transpire as long as the button or key switch are held in place (hold-down mode).

10.2.4 MODE EU 4, TOUCH CONTROL

Opening and closing are done automatically, after the button or key switch was actuated for at least 1

second.

10.2.5 MODE EU 5, external 1-channel remote control

Is used for buttons with external 1-channel remote control.

•press once = open

•press once = stop

•press once = close

•press once = stop

•press once = open

BLUE Professional Poolware tube motor / 2016-01 Seite 19

11 Commissioning certificate

BLUE recommends documenting the start of operation. The following information should be noted:

Date of startup:

Installer:

Motor serial number:

Motor current listed on type plate: A

Control unit serial number:

Control unit power listed on type plate: A

Measurement values

Motor current before reaching "Closed" position: A

Motor current before reaching "Open" position: A

Impulse counter when "closed":

Impulse counter when "open":

Travel time from "open" -> "closed": S

Travel time from "closed" -> "open": S

This manual suits for next models

4

Table of contents

Popular Control Unit manuals by other brands

Unitronics

Unitronics Uni-I/O UIS-04PTN installation guide

Festo

Festo MPYE-5-***-B series operating instructions

Telit Wireless Solutions

Telit Wireless Solutions M.2 N930 Series Hardware user's guide

MS Sedco

MS Sedco Commander PTM installation instructions

Hach

Hach sc200 user manual

Solera

Solera R24R/3 Instructions for use and safety