MECHAPRO Slider SFX User manual

Manual Slider SFX Page 1

All in one

stepper motor driver

Slider SFX

Control factory automation

machinery and

CNC machine tools

by use of stepper motors

© Copyright mechapro GmbH, 2010

Page 2 Manual Slider SFX

The present stepper motor driver board was developed taking all common and established

rules into account. It has undergone extremely thorough testing. Nevertheless, it is impos-

sible to give a guarantee for completely fault-free operation. Furthermore, no responsibility

can be accepted for damage caused as a result of using Slider SFX. The developers ensu-

re that Slider SFX in combination with appropriate controls and appropriate mechanical

components for the purpose of this description and manual is in principle appropriate for

the intended use.

Each liability for associated consequential losses, such as loss of use, production and loss

of profits is excluded. Slider SFX is a component that can only be used together with a

power supply and an adequate control or control software on a personal computer. It is no

independent control under any circumstances.

Despite the most strenuous efforts, it is never possible to completely eliminate all faults.

Consequently, we would be grateful to receive feedback from users.

mechapro GmbH

Roermonder Str. 63

52134 Herzogenrath

Tel.: 0241/4091800

Fax: 0241/4091803

March 2013

All products mentioned by name are trademarks or registered trademarks of their corre-

sponding companies.

Manual Slider SFX Page 3

The structure of this manual…

This manual provides you with all information necessary to use your Slider SFX. It is divi-

ded into different chapters, the contents of which are summarised below:

Chapter 1: Short introduction and technical details

Chapter 2: Procedure for initial operation, pin out

Chapter 3: Safety instructions

Table of content

1 What is Slider SFX used for?...........................................................................4

1.1 Versions of Slider SFX.....................................................................................5

1.2 Optional 4th axis............................................................................................6

2 Start of operation........................................................................................... 7

2.1 Base settings on delivery ................................................................................8

2.2 Mounting and ventilation...............................................................................8

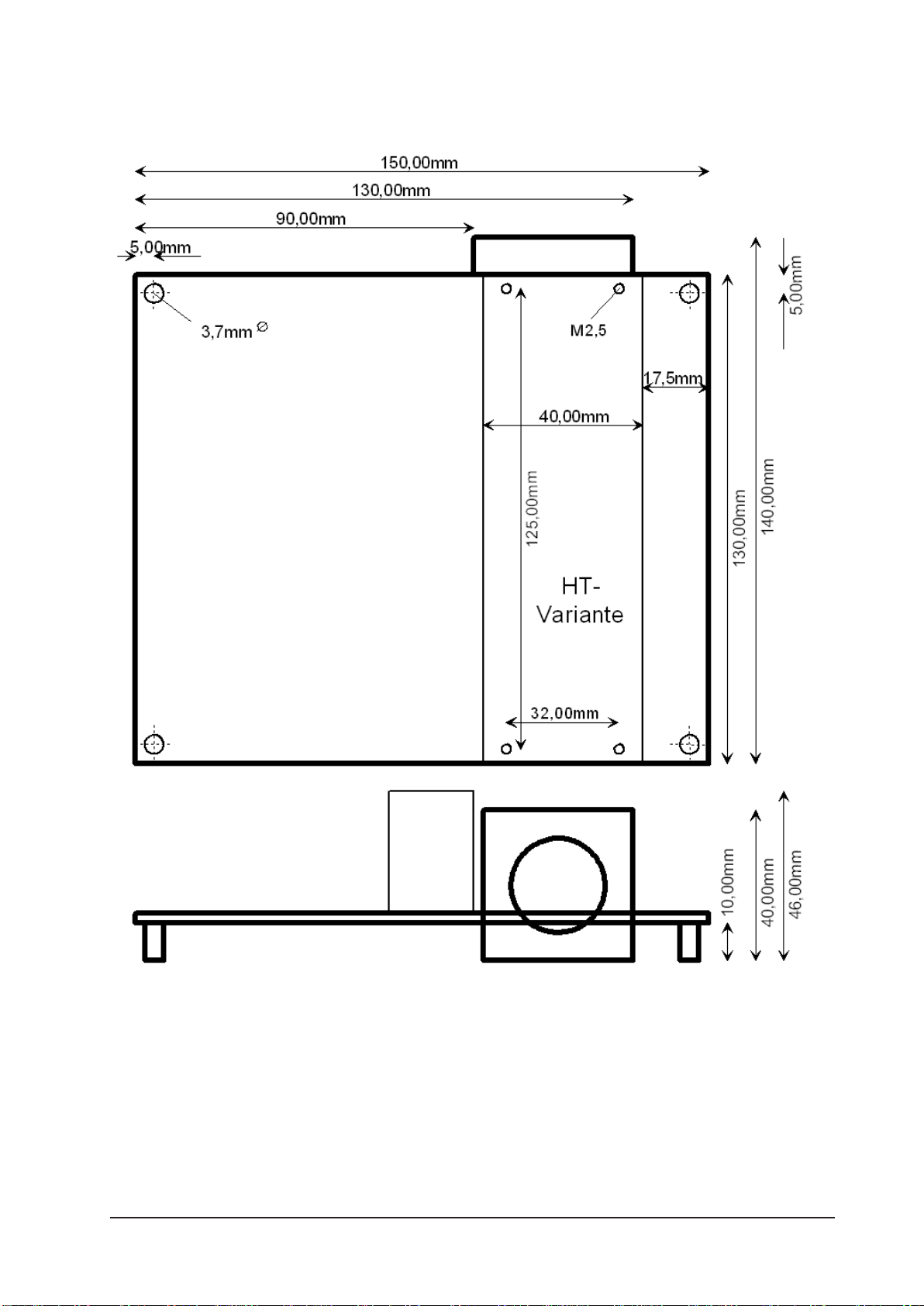

2.3 Mounting dimensions ....................................................................................9

2.4 X4 – Power supply .........................................................................................9

2.5 X10 – Control signals..................................................................................... 10

2.6 JP1-JP8 – Jumper settings, signal assignment.................................................. 11

2.7 JP6 – Pin14 drives relay 2 or PWM logic.......................................................... 12

2.8 JP10 – Toggle signal, safety function ..............................................................12

2.9 JP11 – Start up time ......................................................................................13

2.10 JP12 – Invert relay signals............................................................................... 13

2.11 X3(1/2) – Emergency stop ..............................................................................13

2.12 X7 – Inputs for limit and reference switches ................................................... 14

2.13 X2 – Switching outputs.................................................................................. 14

2.14 X3(3/4) – Analogue output signal for spindle control......................................15

2.15 X6, X8, X11 – Motor connectors.................................................................... 16

2.16 X5 – Additional capacitor............................................................................... 17

2.17 S1/S2/S3/S5 – Setup of motor current and step width ....................................17

2.18 LED’s / status signals.......................................................................................18

2.15 X13 – Connector for external LED’s................................................................19

2.20 X1 – Fan connector........................................................................................ 19

2.21 X9/X14 – Extension for 4th axis......................................................................20

3 Safety instructions..........................................................................................22

Page 4 Manual Slider SFX

1 What is Slider SFX used for?

The stepper motor driver Slider SFX is a sophisticated circuit, which includes power drivers

for three or four 2-phase stepping motors and some other useful components. The signals

to drive the board are connected to a 25-pin D-Sub type female connector, which can be

driven by appropriate controls or directly by a LPT printer port of a personal computer with

appropriate control software.

Slider SFX can be used ideally with the software products PC-NC and WinPC-NC that are

also available on our shop. The signals are fully compatible to these control programs.

A three or four axes mechanic can be used for a wide range of applications. Some examp-

les are….

• Engraving signs

• Milling 3D reliefs

• Milling negative matrices and casting moulds

• Cutting sticky foils

• Milling and drilling prototype PCBs

• Apply and dispense glues

• Cut and machine front plates

• Turning and shaping

• Gas and Plasma cutting

• Pick&Place or robot applications

• ...and many more

Manual Slider SFX Page 5

The technical data of the Slider SFX board are...

• Connection of three 2-phase stepping motors direct on the board

• Optional 4th axis as a plug-in board

• Single supply with AC or DC voltage without external stabilisation, meaning easy

supply with a transformer

• Control signals via 25-pin D-Sub type connector (female), e.g. directly from a PC prin-

ter port (LPT)

• Full-, half-, quarter, 8th- to 16th-step, 2.5th to 10th-step also possible (sinusoidal

micro step)

• Phase current up to 3.0A

• Individual setup of phase current for each axis with DIP switches, additional current

reduction input (reducing current to 50%)

• Protected against short windings and shorts to ground

• Ready switch acts as enable signal directly to power stages and relays, can be used

e.g. on a protection hood

• Three relays (240V~/10A) for switching outputs, e.g. main spindle, coolant pump,

chuck etc., also capable of switching DC current

• LED’s to signal supply voltage and other states, additional connector makes it possible

to integrate LED’s into front plate of housing etc.

• 5 free assignable inputs (N.O. or N.C. contacts), e.g. for limit or reference switches

• Protection circuit with toggle or ready signal to disable motors and relays

• Connector for additional 4th axis

• Standard version for ambient temperatures up to 50°C, special HT version for ambi-

ent temperatures of up to 70°C

• Analogue output 0-5V or 0-10V to drive speed controlled milling/drilling spindles,

interpretation of a PWM signal

• Control of a relay depending on PWM value, threshold level 10%

• Emergency signal, N.C. contact

• Dimensions: 150*130*52mm

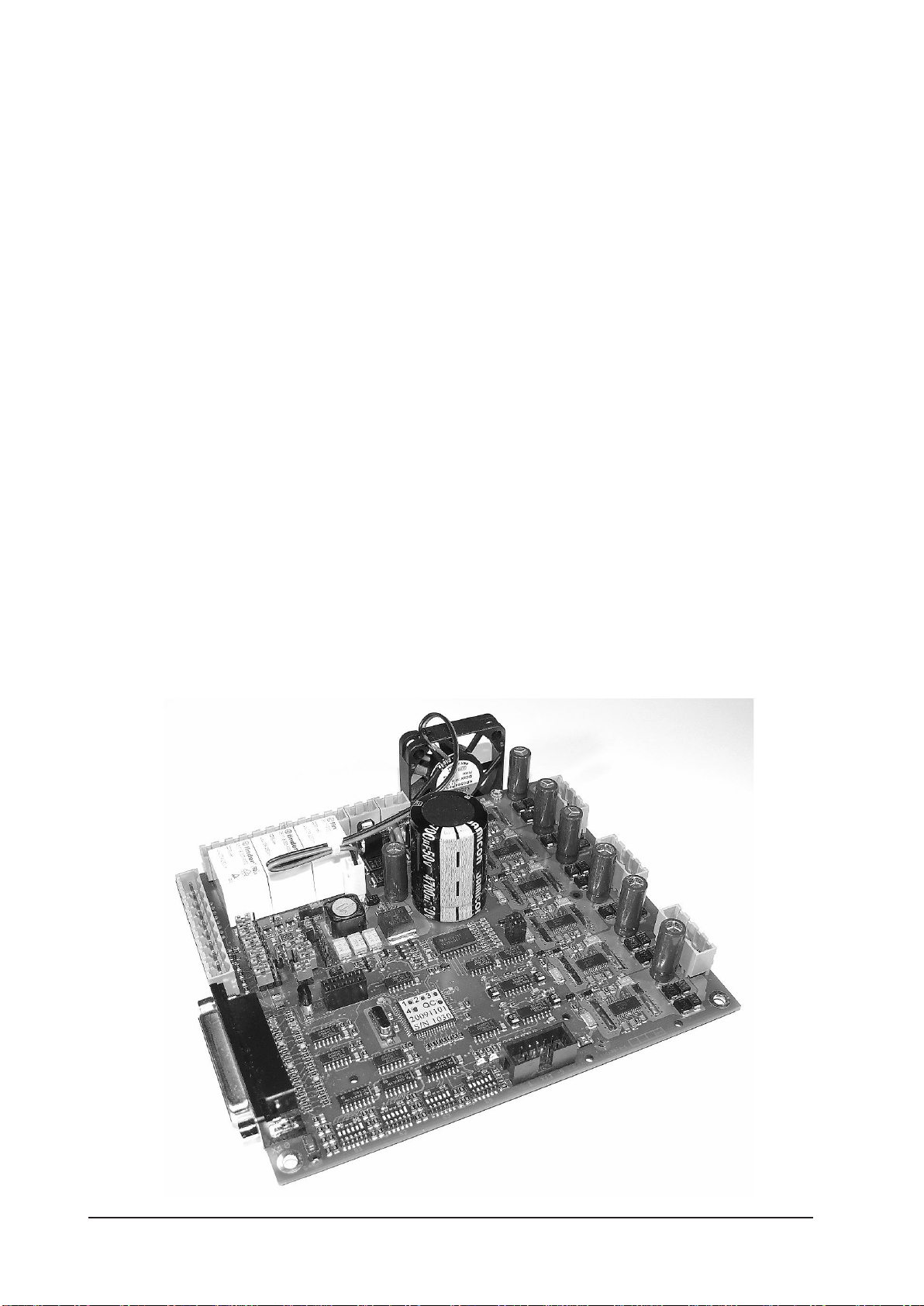

1.1 Versions of Slider SFX

The stepper motor driver Slider SFX is available in two versions and with optional 4th axis.

The standard version is designed for ambient temperatures up to 50°C and has to be used

in housings and machines where this ma-

ximum temperature is not exceeded. A fan

mounted to the side of the board or a case

fan ensures proper cooling. A filter with 30

ppi or higher is required.

The version Slider SFX HT is designed for

ambient temperatures up to 70°C and is

equipped with passive heat sinks on both

top and bottom side. A fan should be

used in a similar way than on the standard

version.

Page 6 Manual Slider SFX

Although the drivers are protected by an excess temperature protection, proper cooling has

to be clarified with the manufacturer.

Special fan less OEM versions or with other special and customer specific options can be

supplied on demand. We are looking forward to your requests.

1.2 Optional 4th axis

With an addon board, SliderSFX is

capable of driving 4 axies. The plug-

in position with two connectors and

mounting holes is placed directly

abouve the DIP switches.

The add-on moduleSliderSFX-4

can be ordered together with the

main board or later as a single part

including mounting material. It can

be easily installed by the user.

Manual Slider SFX Page 7

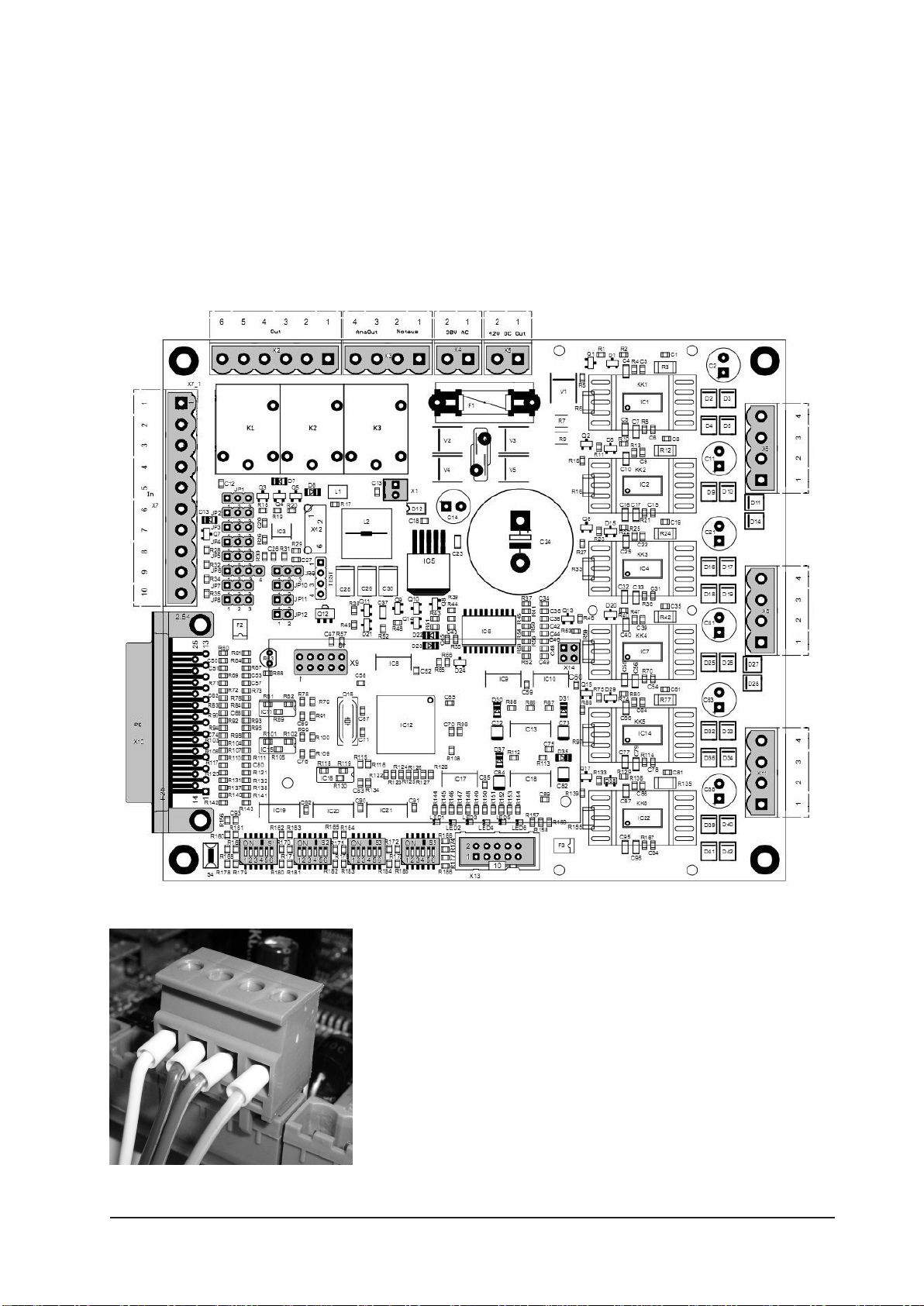

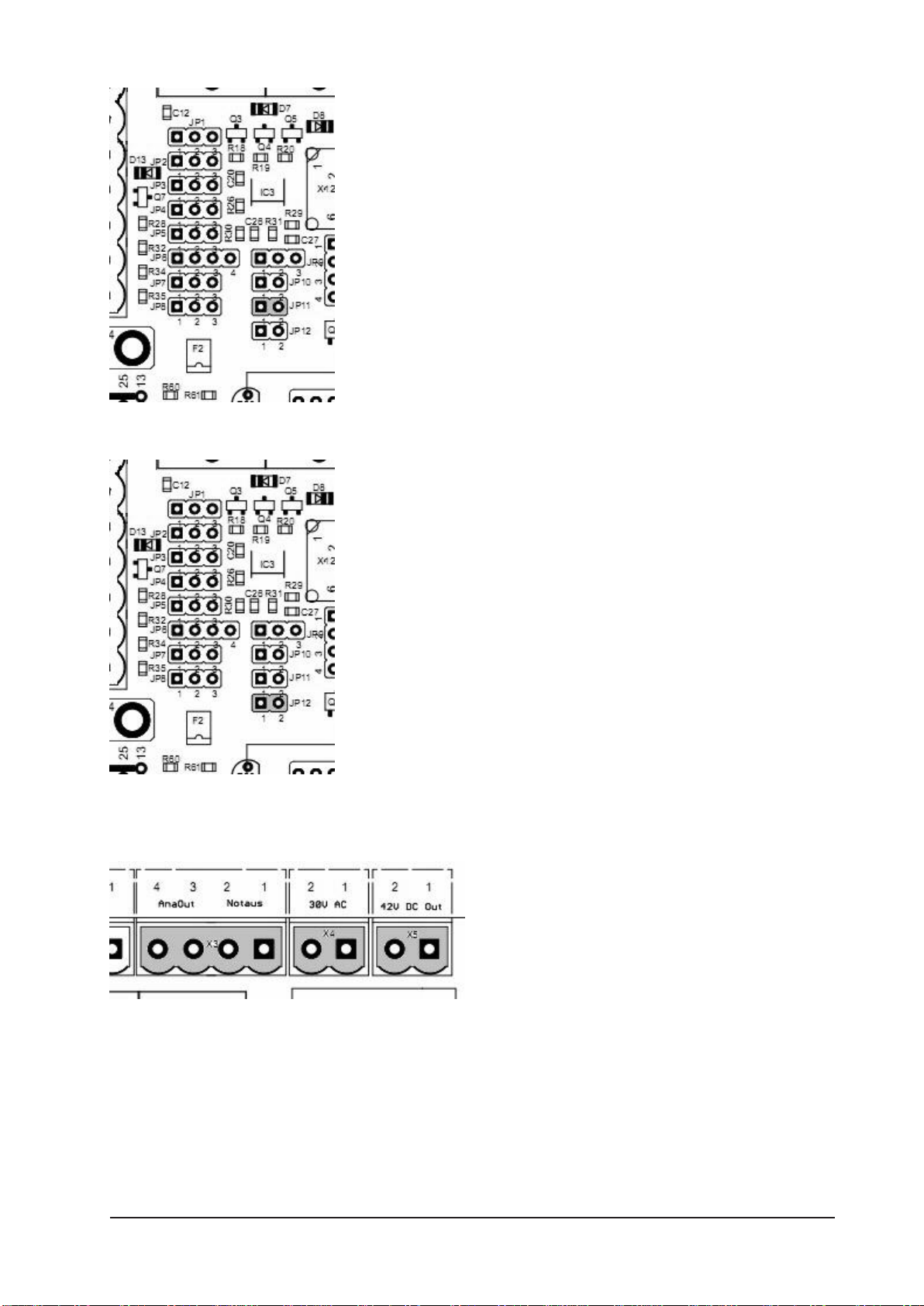

2 Start of operation

Please make sure to follow all protective regulations before the first initial operation of the

board and before connecting or switching on the supply voltage.

On the Slider SFX board all connections are equipped with pluggable cage clamps. All

connectors will be described in the following sections. The sketch gives a first overview. All

relevant connections and settings are marked in grey.

On all connections care should be taken to achieve the

best possible contact. All signal and motor wires should be

be equipped with core cable ends. To avoid disturbances

especially on the switch inputs on X7, shielded and/or

twisted pair wires have to be used.

Page 8 Manual Slider SFX

2.1 Base settings on delivery

The board is shipped in a base setting, were all jumper are set to position 1-2, JP10 and

JP11 are open, JP12 is closed. This results in the following functional assignment on the

interface X10 (input from the parallel port of a PC):

Pin 14 switches relay 2

Pin 15 is general input

Pin 16 switches relay 3

Pin 17 controls the current reduction of the motors (low active)

For a complete description of the interface X10 please refer to section 2.5.

The voltage range on the analogue output (to control a main spindle) is set to 0-10V. The

monitoring of the toggle signal is disabled. Relays are not inverted and the start up time is

aprox. 3 seconds.

The DIP switches are set in a way that all motors are driven with 1.0A and in quarter step

mode, meaning with 800 steps/rev for a standard 1.8° motor.

2.2 Mounting and ventilation

Slider SFX is tested for ambient temperatures of up to 50°C. An HT version is available

for ambient temperatures of up to 70°C. When mounting the board into a case, sufficient

ventilation has to be provided, e.g. by placing adequate ventilation slots in the case hood.

The fan that is mounted on the side of the Slider SFX board can be used on both sides of

the board, according to assembly and ventilation in the case. If a case with integrated fan

is used, the air stream should pass the 6 drivers (IC’s 1, 2, 5, 7, 12 and 17). The direction of

the board’s fan air stream should be adjusted in the same direction as the case fan. If the

ventilation of the case is sufficient, the fan on the board might be redundant.

Warning:

Ventilations slots (for active or passive cooling) should be covered with filter pads

of at least 30 ppi to protect them against intrusion of chips. Intruding chips and

metal parts can influence the function of the board and may also completely dest-

roy it!

The HT version for ambient temperatures up to 70°C is equipped with a 10mm thick alu-

minium heat sink on the bottom side. This heat sink has to be mounted to the bottom

plate of the case with its full surface. This ensures optimal heat conduction.

Manual Slider SFX Page 9

2.3 Mounting dimensions

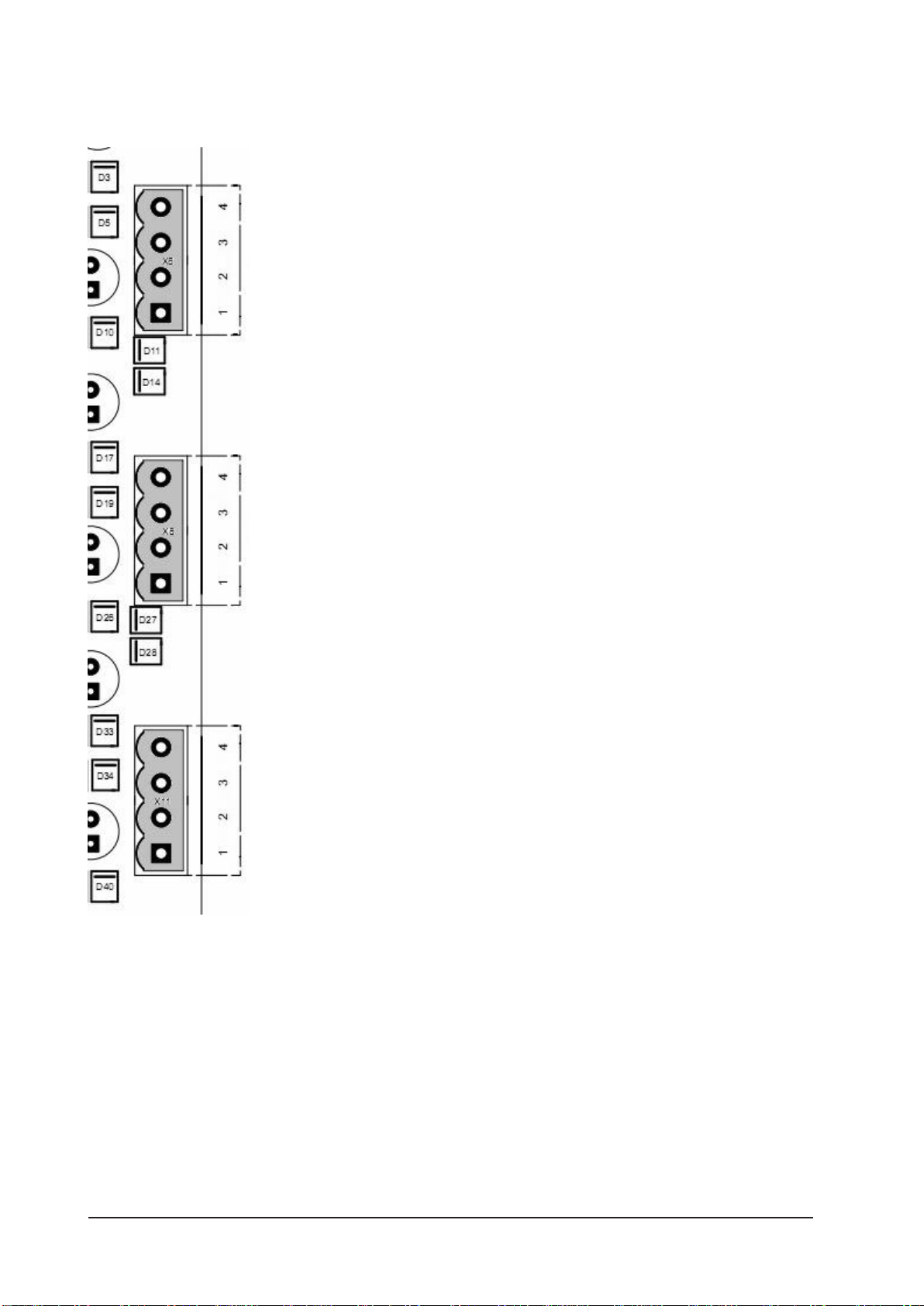

2.4 X4 – Power supply

The stepper motor board Slider SFX can be supplied with either AC or DC voltage. When

using AC power, the lower threshold is 12V~ while the upper threshold is 30V~. For DC

power the thresholds are 15V= and 42V=, the polarity is irrelevant. The supply input is pro-

tected by a glass fuse (6.3A fast blow). Blown fuses must always be replaced by the same

rated current and characteristic!

Page 10 Manual Slider SFX

We recommend a transformer or power

supply rating of 100VA to 160VA, depen-

ding on the employed motors and the volta-

ge level of the supply. We would be happy

to give you an advice. To follow the EMC

regulations an adequate supply filter has to

be used in addition the transformer used in

your application.

Attention:

When decelerating a stepper motor acts as a generator. This causes the supply

voltage to increase. The voltage should not exceed 45V= to avoid damaging the

drivers. This danger is more likely with higher supply voltages.

2.5 X10 – Control signals

All control signals are feed in by the 25-pin female D-Sub type connector. The signals are

switched to ground and are designed in a way that also weak ports on modern computers

are able to drive them.

The pin out is...

Pin 1 Relay 1, e.g. main spindle on/off

Pin 2 Direction motor X

Pin 3 Clock motor X

Pin 4 Direction motor Y

Pin 5 Clock motor Y

Pin 6 Direction motor Z

Pin 7 Clock motor Z

Pin 8 Direction motor 4 (option) or relay 2

Pin 9 Clock motor 4 (option) or relay 3

Pin 10-13Forwarded inputs, e.g. for signals from limit and

reference switches

Pin 14 PWM signal or relay 2, e.g. coolant pump on/off

Pin 15 Output for ready signal or signal from limit

or reference switches

Pin 16 Toggle signal or relay 3, e.g. chuck for tool changer

Pin 17 Current reduction input (active low), toggle or PWM

signal

Pin 18-25Signal ground (0V, GND)

Together with our CNC control software PC-NC CNC-Control, WinPCNC and X4Step

there are no compatibility problems driving a 3 or 4 axes mechanic. Of course any other

software with pulse and direction output signals can be used.

Manual Slider SFX Page 11

2.6 JP1-JP8 – Jumper settings, signal assignment

Some pins (8, 9, 14, 16 and 17) on Slider SFX can be used for different functions. Section

2.5 gives an overview about all inputs and their functions. The settings are made with jum-

pers, while setting connection pins 1-2 is the standard stetting (except for JP10).

• JP1: Pin15 forwards general input (jumper 1-2) or outputs ready signal (low active)

of Slider SFX (jumper 2-3).

• JP4: Pin16 switches relay 3 (jumper 1-2) or drives toggle signal (jumper 2-3).

• JP6: Pin14 switches relay 2 (jumper 1-2) and/or drives PWM signal (jumper 3-4). To use

both functions, two jumpers are necessary.

• JP7: Pin8 switches direction of motor 4 (jumper 1-2) or switches relay 2 (jumper 2-3).

• JP8: Pin9 switches clock of motor 4 (jumper 1-2) or switches relay 3 (jumper 2-3).

To evaluate the ready signal with WinPCNC the signal “I247 NReady” has to be assigned

to Pin15.

The ready signal is disabled (meaning set to logic high) by Slider SFX when the contact X3

(emergency switch) is opened or when an error occurs on the board (e.g. shorted coil of a

motor). With this signal is can be avoided that the board continues operation after clearing

an error, although the position of the motors doesn’t comply with the position that is assu-

med by the CNC software.

Caution:

Never configure two pins for the same function, as

this may result in a short of the outputs on the printer

port. This concerns all jumper settings from JP2 to JP8.

To avoid damages by unintended touching of nearby

components, it is highly recommended to change jum-

per settings only when the board is powerd down.

Function of Pin17 JP2 JP3 JP5

Current reduction 1-2 1-2 Any

Toggle 2-3 2-3 1-2

PWM 2-3 2-3 2-3

When using WinPCNC with the current reduction signal on Pin17, Signal “Q251 axis run-

ning” has to be set to “Pin 17 inverted”.

Page 12 Manual Slider SFX

2.7 JP6 – Pin14 drives relay 2 or PWM logic

Jumper JP6 is intended as a double contact and selects two

functions.

If set to position 3-4, the signal coming from Pin14 is fed

to the PWM logic and converted to an analogue signal

with 0-5V or 0-10V range. If a jumper is set to position 1-2,

Pin14 controls relay 2. When both jumpers are set, Pin14 is

fed to the PWM logic and relay 2 is switched automatically

depending on the PWM value.

The threshold includes a hysteresis of aprox. 5%. At PWM

values higher than 10%, the relay is switched on. When

the PWM value falls under 5%, the relay is switched of

again.

• Jumper JP6 set to 1-2 only Pin 14 controls relay 2

• Jumper JP6 set to 3-4 only Pin 14 controls PWM logic which outputs the analogue

value

• Jumper JP6 set to both 1-2 and 3-4 Pin 14 controls PWM logic and relay 2 is switched

depending on PWM value.

2.8 JP10 – Toggle signal, safety function

On power up and caused by plug&play routines of the

operating system, the pins on the parallel port may change

their logic levels before the port is under control of the CNC

software (e.g. WinPCNC). To prevent unintended switching

of relays and unintended movements of the motors, Win-

PCNC supports the output of a safety signal (“Q219 Toggle/

Ready”). In other products this is sometimes referred to as

“charge pump signal”. If enabled, Slider SFX will enable

relays and motors only when a valid toggle signal (minimum

frequency of 250 Hz) is recognised.

When using a control software that doesn’t support this

signal, e.g. PCNC (DOS), the monitoring of this signal has to

be disabled by setting JP10 open (default setting).

• JP10: Toggle signal monitored (jumper closed) or not (jumper open).

Manual Slider SFX Page 13

2.9 JP11 – Start up time

Jumper JP11 influences the start up time of the board.

When the jumper is left open, it takes aprox. 3 seconds after

power on until the board is ready and the motors are under

current. With JP11 set, this time is extended to aprox. 10

seconds. This may help to ensure, that the primary control or

the PC with control software is ready and all signals are in a

defined condition.

On each boot up, the board signals the version number of

the firmware on LED1, before ready is indicated.

• JP11: Start up time 3 seconds (jumper open) or

10 seconds (jumper closed)

2.10 JP12 – Invert relay signals

Depending on the signal level to control the relays, it may

be, that the behaviour of the relays is inverted compared to

the driving logic. Additionally, during power on or boot up

of the PC the relays may be switched unintended. With JP12

closed, the control signals for all three relays are inverted.

• JP 12: Relay control signals inverted (jumper closed) or

normal (jumper open).

2.11 X3(1/2) – Emergency stop

The ready or emergency signal on clamp

X3, contacts 1/2, activates the three power

drivers for the motors and also acts as ena-

ble signal for the relays. The signal is routed

to the enable input of the power drivers

and can therefore be used as an emergency

signal or as a contact of a protection hood.

The switch has to be an N.C. contact. With the contact opened, all three motors are cur-

rent less and can not be driven by the board. Same applies for the relays.

Caution:

Current less motors do have a very small holding toque. If they are in motion, they

continue running due to the inertia of the axis. A current less Z-axis may fall down

on the table or to the mechanical limit due to its mass.

Page 14 Manual Slider SFX

If no switch is used, the contact must be closed by a wire strap to ensure proper operation

of the board.

Pin out on X3:

Pin 1 Emergency contact

Pin 2 GND

2.12 X7 – Inputs for limit and reference switches

The stepper motor board Slider SFX has 5 inputs that are forwar-

ded to signals on the 25 pin D-Sub type connector. These are ex-

actly the signals, which are used as inputs on the PC parallel port.

Switches with both N.O. or N.C. can be used. For each input, two

cage clamp contacts are present.

The pin out is as follows...

• Clamp X7.1 Pin 10

• Clamp X7.2 GND

• Clamp X7.3 Pin 11

• Clamp X7.4 GND

• Clamp X7.5 Pin 12

• Clamp X7.6 GND

• Clamp X7.7 Pin 13

• Clamp X7.8 GND

• Clamp X7.9 Pin 15

• Clamp X7.10 GND

Depending on the interpretation in the control or in the control

software, these inputs can be used for limit switches, reference

switches or other sensors.

Please note:

Depending on setting of JP1, Pin 15 forwards input X7.9 or signals the operational

status of the boards

2.13 X2 – Switching outputs

Slider SFX is equipped with 3 relays which are cont-

rolled over the 25-pin D-Sub type port. Depending on

the configuration of the board, the pins 1, 8, 9, 14

and 16 are possible inputs, which can be controlled

by PCNC or WinPCNC as outputs for main spindle,

coolant pump and chuck for tool changer or other

purposes.

The assignment between pins and relays is done with jumpers (see chapter 2.5).

Manual Slider SFX Page 15

The assignment is as follows...

• Clamp X2.1/2 relay 3 - pin 16 (alternative pin 9)

• Clamp X2.3/4 relay 2 - pin 14 (alternative pin 8)

• Clamp X2.5/6 relay 1 - pin 1

All relays can switch up to 10A at max. 240VAC. DC currents can be switched also.

2.14 X3(3/4) – Analogue output signal for spindle control

Slider SFX can convert a PWM input signal (min. PWM

frequency 200 Hz) to an analogue output signal. Many fre-

quency converters accept such a signal as reference value for

the rotational speed of synchronous or asynchronous main

spindle motors. Consult the manual of your converter to see

how the reference input has to be parameterised.

The output of Slider SFX supports either a signal range

from 0V to 10V (default setting) or from 0V to 5V, where 10V (or 5V respectively) equals

the maximum rotational speed. Pre-condition to use this feature is to select an input pin for

the PWM signal and a matching configuration of the control software, e.g. our Win-PCNC

(signal “Q218 rotational speed PWM”).

The PWM signal can be evaluated from pin 14 or pin 17. The mapping of the signals is

done by jumpers JP2, JP3, JP5 and JP6.

• JP9: analogue output (main spindle) 0-10V (jumper 1-2) or 0-5V (jumper 2-3).

Page 16 Manual Slider SFX

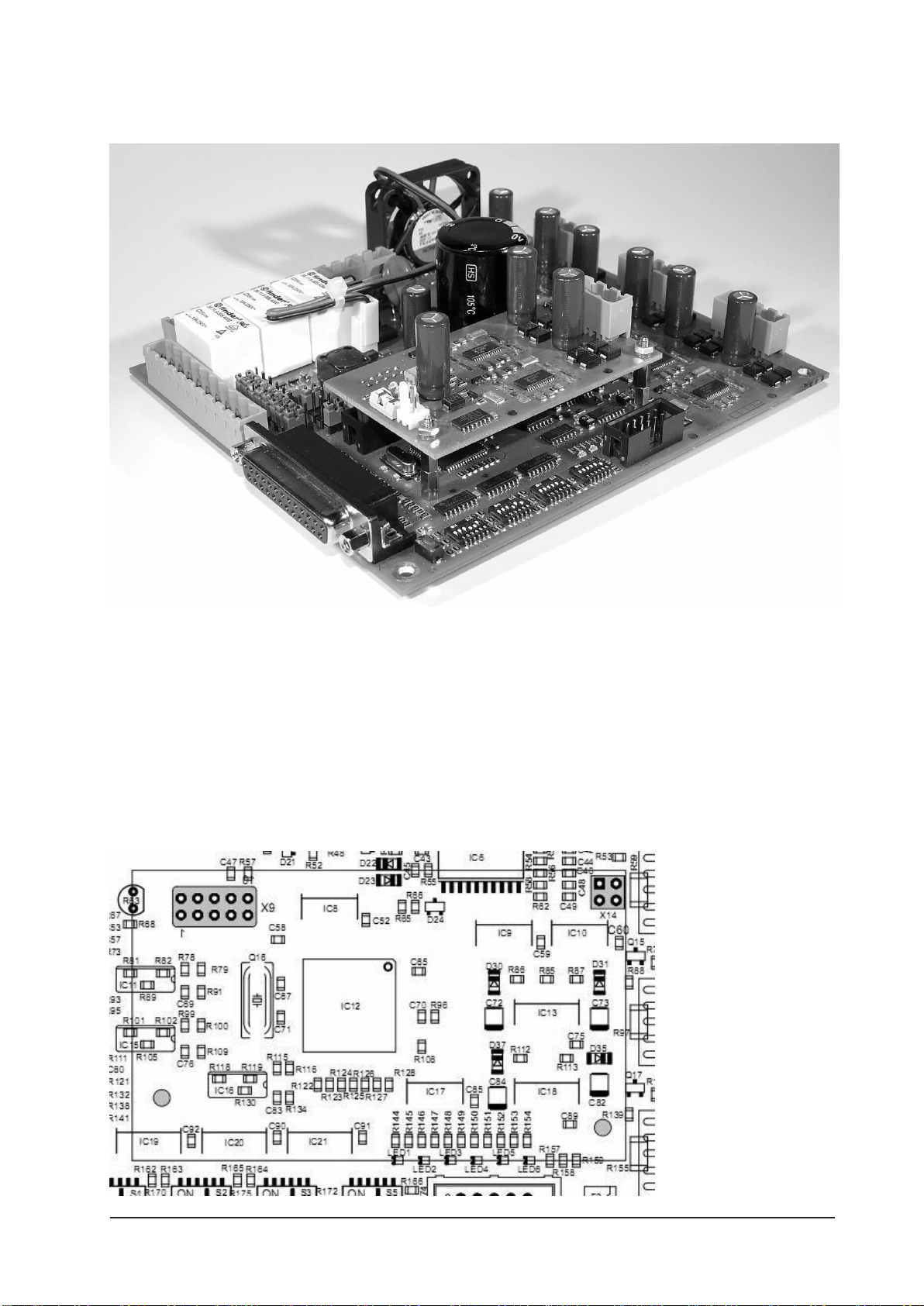

2.15 X6, X8, X11 – Motor connectors

Slider SFX is designed for 2-phase stepping motors only. It can

be used with both bipolar and unipolar motors. If no datasheet is

available to your motors, you have measure which connectors be-

long to which winding of the motor.

Bipolar motors have 4 connections, where each winding has two

connections. These can be found easily with an Ohm meter. Both

ends of one winding have to be connected to the board as phase

A1/A2, while the other one are connected as phase B1/B2.

Unipolar motors come with 5 or 6 connections, where both win-

dings have an additional contact in the middle of the coil. Also with

this motors, the endings of whe coils can be found easily by measu-

ring the resistance of the different connections. Leave the centre

taps unconnected and isolate them to prevent any contact with

conductive materials. The connection to the board is then the same

as before, connecting one coil to phase A1/A2, the other one to

phase B1/B2.

When the motor connections are correct, the motors should move

smooth and without jerk in both directions. A wrong connection

leads to jerky movement or in a dithering movement of the motor.

The direction of the motor’s movement can be changed by crossing

the connections on one of the phases, e.g. changing A1 with A2.

The connections are assigned as follows:

• X11 (1+2) – X axis phase A

• X11 (3+4) – X axis phase B

• X8 (1+2) – Y axis phase A

• X8 (3+4) – Y axis phase B

• X6 (1+2) – Z axis phase A

• X6 (3+4) – Z axis phase B

Attention:

Do not connect a motor phase to positive supply voltage under no circumstances.

This would inevitably lead to a break down of the power driver.

Manual Slider SFX Page 17

2.16 X5 – Additional capacitor

When decelerating, a stepper motor acts as

a generator and supplies current back to the

power supply. This will temporarily cause

the supply voltage to increase significantly.

To prevent rising above 45VDC, an electro-

lytic capacitor can be connected to clamp

X5 in addition to the capacitor in the pow-

er supply. Especially when using large and powerfull motors and high supply voltages, an

additional capacitor is recommended.

Assignment on X5:

Pin 1 GND

Pin 2 +42V

Please note:

In most circumstances, the use of an additional, external capacitor is not necessary.

2.17 S1/S2/S3/S5 – Setup of motor current and step width

The stepping motor drivers support mi-

crostep operation. They produce a sinu-

soidal course of motor currents. The step

width can be set individually for each

motor with the left three DIP switches

according to the following table.

Beside the dividers that are common for

2-phase motors down to 1/16th (3,200

steps per revolution) it is also possible to use dividers 1/2.5th to 1/10th commonly used

with 5-phase motors (500, 1,000 and 2,000 steps per rev.).

Furthermore the right three DIP switches are used to set the phase current of the power

drivers in 0.25A steps. In addition, pin 17 can be used to activate a current reduction down

to 50% of the selected set value. See section 2.5 for details. If clock pulses are applied to

the board with current reduction activated, the onboard controller will automatically disab-

le the current reduction until all steps are processed.

Changes on the DIP switches are taken over within less than 1 second without rebooting

the board. Changes to the step width may result in a position error of up to 4 full steps, so

it is recommended to do a reference movement after changing this setting.

The axes are allocated to the switches as follows:

• S1 – X axis

• S2 – Y axis

• S3 – Z axis

• S5 – optional 4th axis

Page 18 Manual Slider SFX

For each axis (n=1, 2, 3, 4) there exist 6 DIP switches. The switches Sn.1-n.3 are used for

setting the set value for the motor current, while the switches Sn.4-n.6 define the step

width according to the following tables:

Sn.1 Sn.2 Sn.3 Current

0 0 0 1.0 A (default setting)

0 0 1 1.5 A

0 1 0 1.75 A

0 1 1 2.0 A

1 0 0 2.25 A

1 0 1 2.5 A

1 1 0 2.75 A

1 1 1 3.0 A

Sn.4 Sn.5 Sn.6 Step width

0 0 0 ½

0 0 1 ¼ (default setting)

0 1 0 1/8

0 1 1 1/16

1 0 0 1/1

1 0 1 1/2,5

1 1 0 1/5

1 1 1 1/10

2.18 LED’s / status signals

There are some LED’s placed above the connector X13, that are used to signal the current

operating condition of the Slider SFX board.

LED1: Status indication

LED2: Toggle signal (safety function) recognised

LED3: Short detected, the blink code identifies the faulty axis

LED4: Shutdown due to over voltage

LED5: Power supply present

LED6: 5V (Logic supply) present

Explanation to the meaning of the LED’s:

LED1 signals errors on the board. A continuous, slow blinking LED signals that contact X3

(pins 1-2) was opened. A fast, 4-times blinking with following pause signals a short conditi-

on on one of the outputs.

LED2 shows, if a valid toggle signal was detected. If the evaluation of the toggle signal is

activated (JP10 set to 1-2), and LED7 is not lit (meaning no valid signal is applied to the

board), the drivers are switched of and the board is not ready.

Manual Slider SFX Page 19

LED3 signals a short on one of the axes and has to be cleared by the reset button S4. LED3

blinks once for a short on the X axis, twice for a short on the Y axis, three times for a short

on the Z axis. The blink code will be repeated after a short pause. For a fault on the optio-

nal 4th axis, LED3 is lit continuously.

If the supply voltage rises above 44V, the power supply shuts down the logic voltage

(5VDC), which leads to a shut down of the power stages. This is signalled by LED4.

2.15 X13 – Connector for external LED’s

If Slider SFX is mounted into a case, so that the on board LED’s can not be seen from the

outside, it is possible to connect some additional LED’s to connector X13, which then can

be mounted into the front plate of the case. The pinout of X13 is:

Pin 1 LED1, Status (Vcc)

Pin 2 VMotor (used for LED4)

Pin 3 LED4, over voltage (VMotor)

Pin 4 (not used)

Pin 5 LED5, motor supply voltage (GND)

Pin 6 LED3, short detected (Vcc)

Pin 7 LED6, VCC (GND)

Pin 8 LED7, Toggle (GND)

Pin 9 GND

Pin 10 VCC/+5VDC

With except to LED 1, 3 and 4, all LEDs are connected to ground. LEDs 1 and LEDs 3 is con-

nected to VCC/+5VDC, while LED4 is connected to VMotor.

2.20 X1 – Fan connector

On the connector X1 5VDC are supplied for the

fan mounted to the side of the board. This fan

can be mounted on the upper or lower side of

Slider SFX, depending on mounting situation

and ventilation in the case. If a case with integra-

ted fan is used, the air stream should pass the 6

drivers (IC’s 1, 2, 5, 7, 12 and 17). The direction

of the board’s fan air stream should be adjusted

in the same direction as the case fan. In this case

the fan mounted to the board may be redundant.

Manual Slider SFX Page 20

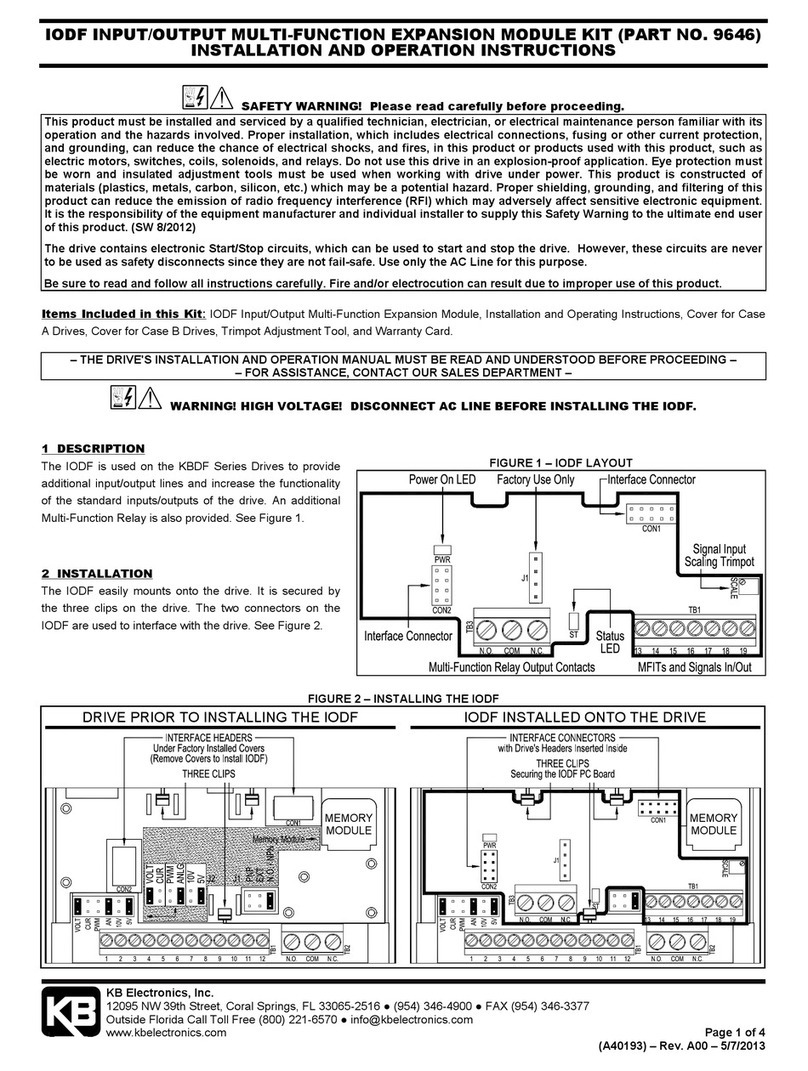

2.21 X9/X14 – Extension for 4th axis

To upgrade Slider SFX to a 4 axes driver, connectors X9 and X14 provides the necessary

control signals. The upgrade is done with a small add on board, that includes all com-

ponents including the connector for the 4th motor.

Please follow these instructions when mounting the add on board:

• Mount distance bolts with retaining washers

• Torque the bolts with a 4mm socket wrench

• Plug in the add on board

• Screw the board with screws and retaining washers

Table of contents

Popular Control Unit manuals by other brands

Allen-Bradley

Allen-Bradley ArmorBlock 1732E-16CFGM12M12LDR User manua

KB Electronics

KB Electronics 9646 Installation and operation instructions

Smartgen

Smartgen CMM366-4G user manual

urmet domus

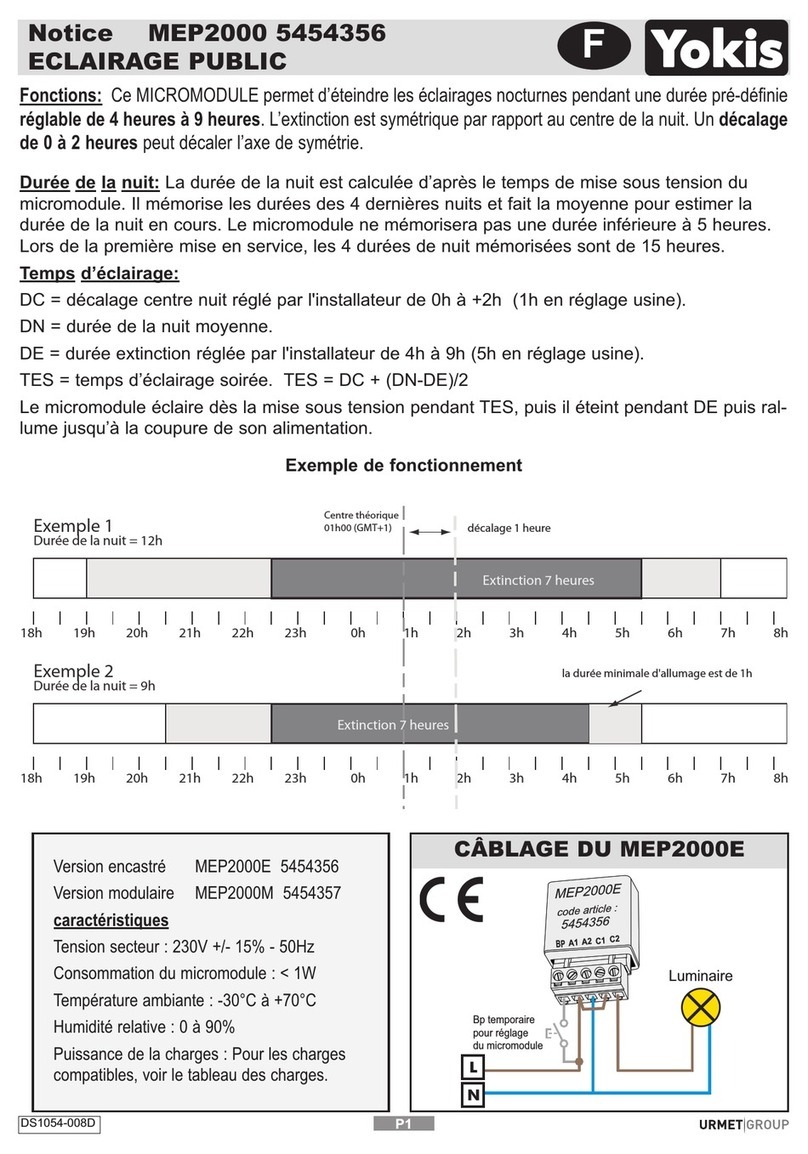

urmet domus Yokis MEP2000E manual

Victaulic

Victaulic 317 Series Installation and maintenance instructions

WAREMA

WAREMA GA Kompakt Operating and installation instructions