D-EIMWC01308-16EN - 10/40

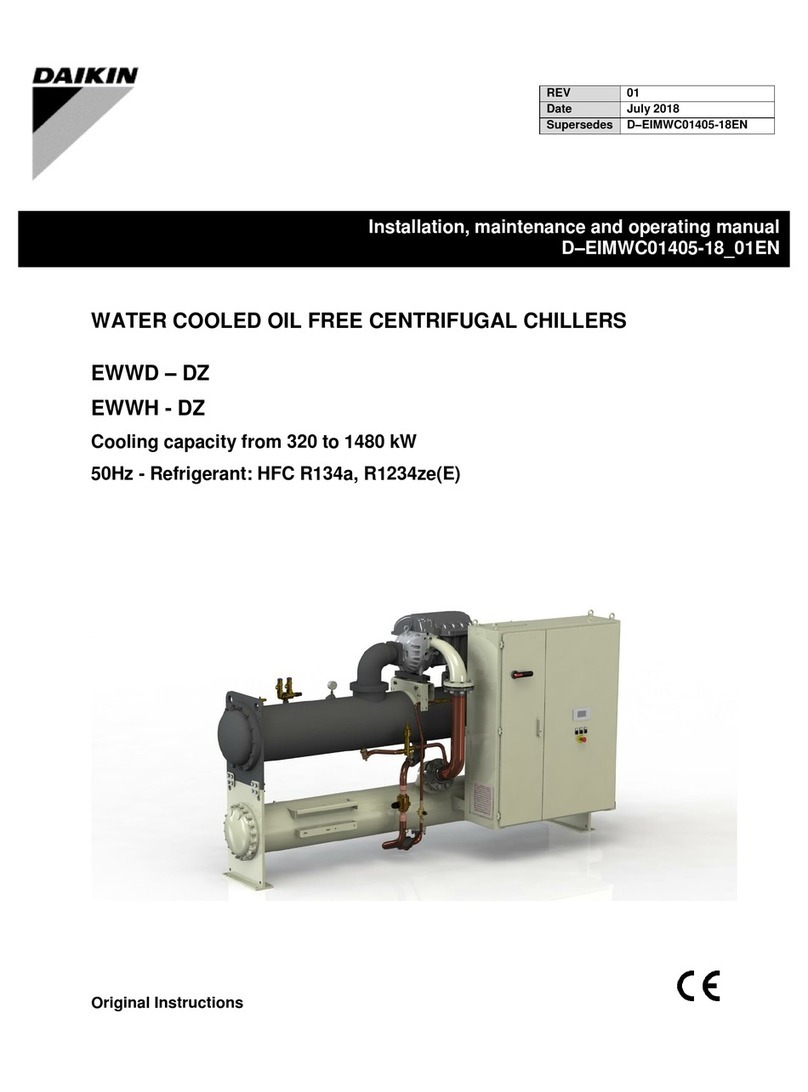

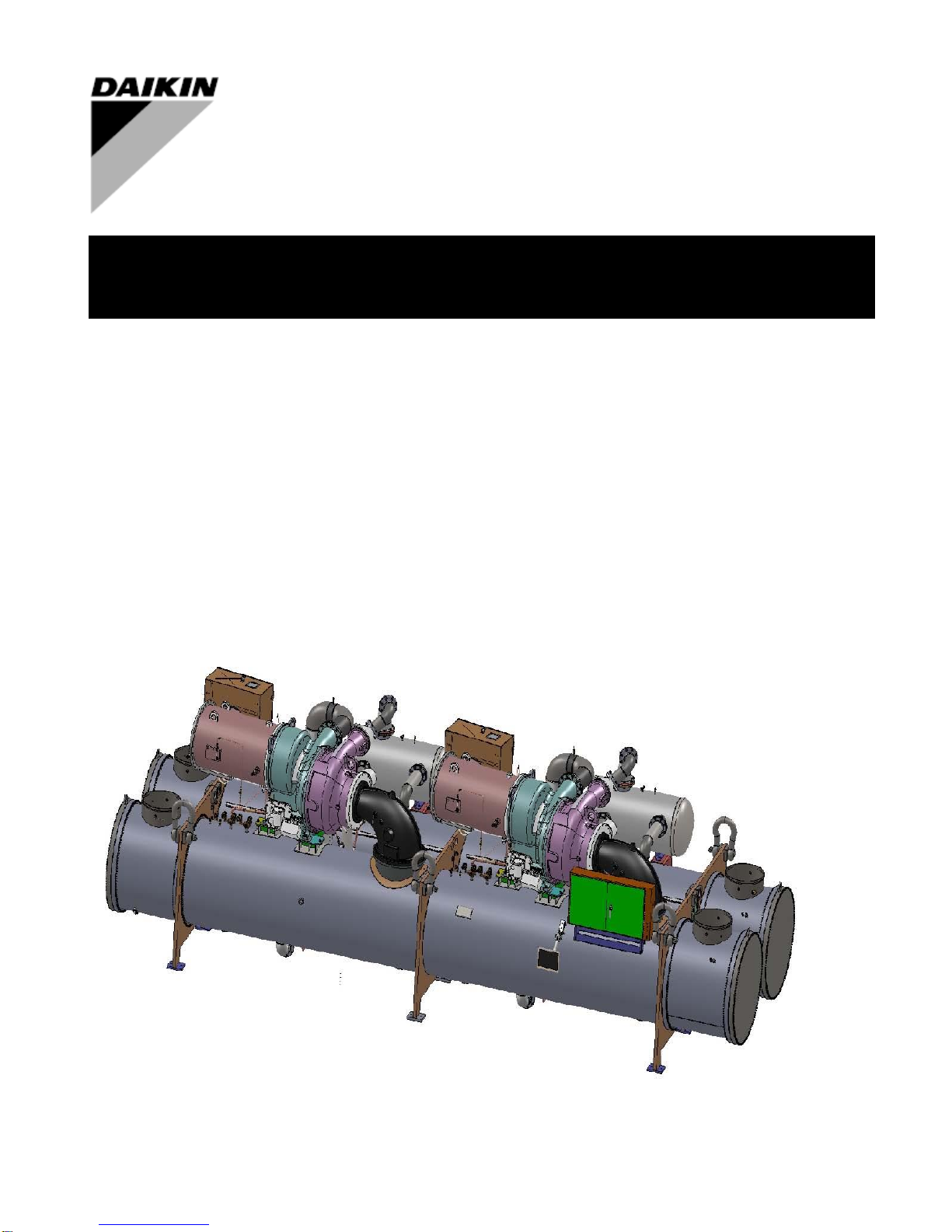

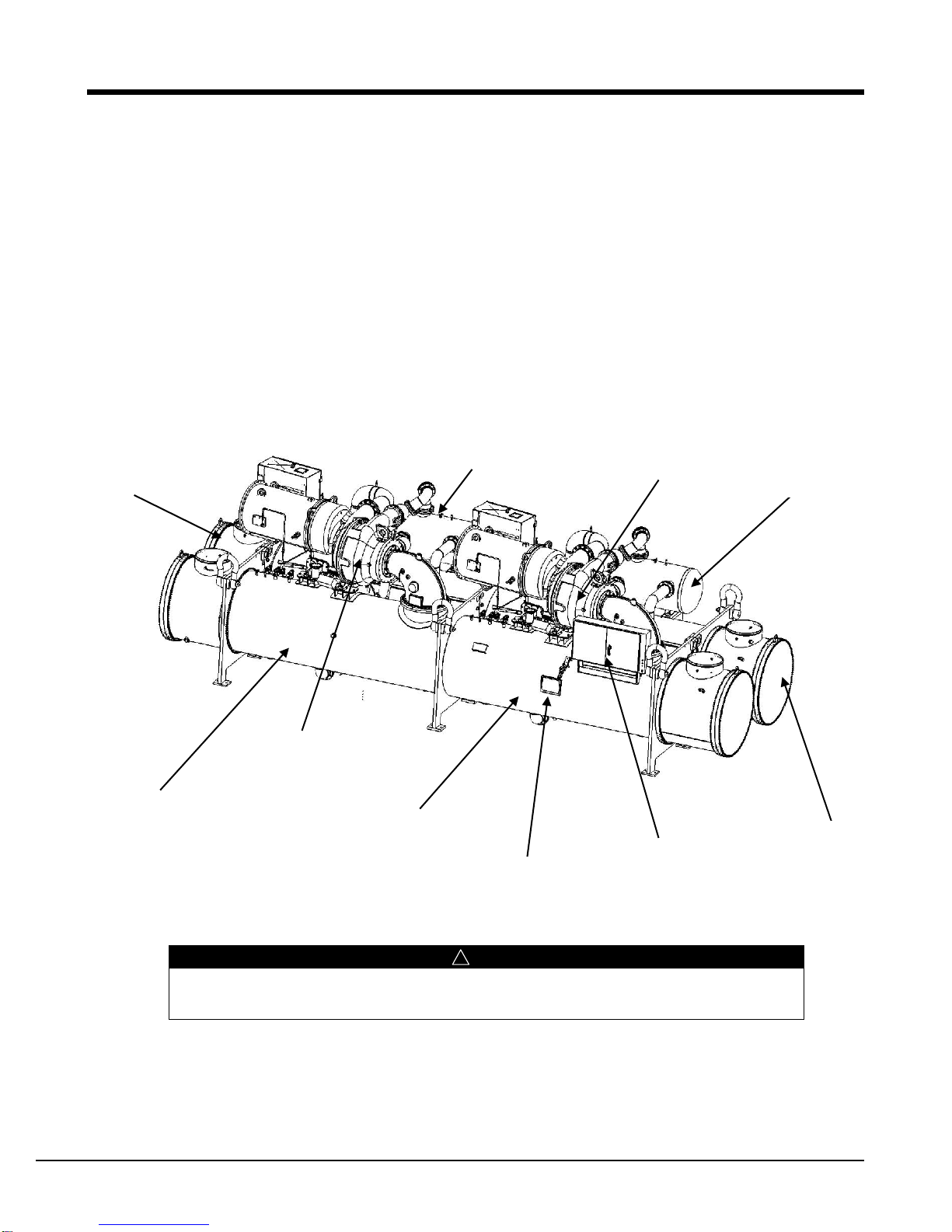

Location and Mounting

The unit must be mounted on a concrete or steel base which is level end-to-end to within ¼” (6.4 mm) and must

be located to provide service clearance at one end of the unit for possible removal and replacement of evaporator

and/or condenser tubes, and if necessary, to permit brush cleaning of evaporator and condenser tubes as

required. Doors, removable wall sections and piping should be arranged for ease of disassembly at the chiller for

tube clearance and cleaning. Minimum clearance at all other points, including the top, is 3 feet (1 meter). Local

regulation can require more clearance in and around electrical components and must be checked. These chillers

are intended only for installation in an indoor or weather protected area consistent with the NEMA 1 rating on

the chiller, controls, and electrical panels. Equipment room temperature for operating and standby conditions is

40°F to 104°F (4.4°C to 40°C) for storage at higher temperatures refrigerant may need to be removed.

Vibration Pads

The unit is shipped with neoprene vibration pads having a nominal 0.375 inch (9.5 mm) operating height. They

are to be placed under the steel foot supports for contact with the foundation, and to be flush with the sides and

outside edge of the foot supports affixed to the chiller tube sheets.

Mounting

Make sure that the floor or structural support is adequate to support the full operating weight of the complete

unit.

The pads should be located in accordance with the unit dimensional drawing. After the pads have been placed

into position on the floor, lower the unit onto the pads which are to be centered under the foot supports. When

the unit is in place, remove the rigging equipment and check that the chiller is level, both longitudinally and

transversely.

First, check the longitudinal alignment of the unit by placing a “level gage” at top center of the evaporator shell

which has more compressor/motor load. Second, check the transverse alignment by placing a level gage on top

of the tube sheets at both ends of the unit. Their alignment should be within ¼”(6.4 mm) and if not, lift the unit

and place shims between the neoprene pads and the foot supports.

It is not necessary to bolt the unit to the mounting slab but should this be desirable, 1-1/8" (28.5 mm) mounting

holes are provided in the unit feet. See dimension drawing for location.

Each pad deflection is around 0.06 inch (2 mm) and if necessary, shims should be placed between the unit foot

supports and pads to equally deflect all pads.

Units will be shipped with holding refrigerant charge and oil. All valves must remain open

until start-up by the authorized commissioning technician.