bluelab PeriPod M3 Guide

English

2

1.0 Introduction & Overview:

1.1 Features 3

1.2 What’s in the box? 3

1.3 How the Bluelab®PeriPod™4

works

2.0 Safety Precautions:

2.1 General safety precautions 5

2.2 Chemical safety precautions 5

3.0 Installing the Bluelab®PeriPod™:

3.1 Mounting the Bluelab®6

PeriPod™

3.2 Setting up the inlet and 6

outlet tubes

3.3 Bluelab®PeriPod™ 8

connection panel

3.4 Connecting to a Bluelab® 8

Pro Controller

3.5 Connect power adapter 8

4.0 Set up and Operation:

4.1 Manual pump priming 9

4.2 Calibrating nutrient pumps 10

5.0 Multi-part Nutrient Dosing

with Bluelab®PeriPods™

5.1 Reservoir size 13

5.2 Starting with multi-part 14

nutrient dosing

5.2.1 Setting up the PeriPods 14

5.2.2 Setting up Connect 15

5.2.3 Calculating the on time 16

with multi-part nutrients

6.0 Maintenance, Troubleshooting

& Specications:

6.1 Maintenance 17

6.2 Firmware upgrading 17

6.3 Troubleshooting guide 17

6.4 Technical specications 19

6.5 Material specication 19

for tubing

6.6 pH adjuster compatibility 19

for tubing

7.0 Accessories, Parts & Guarantee:

20

21

Bluelab®accessories & parts

Bluelab®limited warranty

Contact details 22

page page

Contents

PLEASE FOLLOW THE MANUAL STEP BY STEP BEFORE FIRST USE

English

3

1.2 What’s in the box?

Please check and verify the box contents match the below list:

1.1 Features

Bluelab®PeriPod™M3 & M4 Bluelab®PeriPod™L3

3 or 4 120ml/min peristaltic pumps which

can be set to dose pH adjuster or nutrient

stock solutions.

3 x 1200ml/min peristaltic pumps which can be set

to dose pH adjuster or nutrient stock solutions.

Rugged wall mount design.

Individual pump calibration and pump priming.

4 metres / 13 feet of acid / alkaline resistant food grade tubing for dosing pH correction solution.

3x 4 metres / 13 feet per pump of tubing for dosing nutrient stock solution.

Replaceable peristaltic pumps and tubing.

Compatible with most modern growing systems including recirculating and drain to waste systems.

Compatible with Bluelab®Pro ControllerTM and most Bluelab®Dosetronic™models1.

1

Bluelab

®

PeriPod

™

is compatible with Bluelab

®

Dosetronic

™

s manufactured after 2010. Contact Bluelab

®

Customer Support

for more information.

Bluelab®PeriPod™L3Bluelab®PeriPod™M3

24V DC 2Amp

power supply

24V DC 2Amp

power supply

(24V DC 5A on limited stock)

Dosing

cable

Dosing cable4 metres / 13 feet

pH Tubing

4 metres / 13 feet

pH Tubing

4 metres / 13 feet

Nutrient Tubing

per pump

3x

4 metres / 13 feet

Nutrient Tubing

1.0 Introduction & Overview

Mounting

Screws

Mounting

Screws

Inlet Tube Cap - ts on

Bluelab®pH Up or Down

500ml or 1Litre Bottles

112 mm

4.4 in

M3: 220 mm / 8.7 in

M4: 285 mm / 11.3 in

154 mm

6 in

392 mm / 15.4 in

Pump 1 is set as pH by default. All pumps can be set as

pH or nutrient in Bluelab®Connect.

Pump 1 is set as pH by default. All pumps can be set

as pH or nutrient in Bluelab®Connect.

English

4

1.3 How the Bluelab®PeriPod™works & installation example

The Bluelab®PeriPod™is designed to be connected to a Bluelab®Pro Controller with inlet tubes

placed into pH adjuster and nutrient stock solutions, and the outlet tubes placed into the reservoir.

The Bluelab®PeriPod™can be integrated into a variety of growing systems including but not limited to

recirculating and drain to waste systems. Up to three M3 or M4 PeriPods™can be connected together

(max. 12 pumps) to dose multi-part nutrients. They are not designed for use as an inline doser.

PeriPod M3

Dosing

The Bluelab®PeriPod™responds to electrical dosing 'triggers'

received from the Bluelab®Pro Controller, and pumps the

pH adjuster and nutrient stock solutions into the reservoir as

needed through peristaltic pumps.

Peristaltic pumps work by compressing a exible tube between

rollers and the inside wall of the pump housing. When these

rollers are rotated, liquid is squeezed through the tube and

pushed out of the pump outlet. At the same time, as the

rollers move past a section of tube, the tube opens, creating a

suction that pulls liquid into the pump inlet for the next roller to

squeeze out of the outlet. Chemical resistant tube allows acids

and alkalis to be pumped direct from their containers, through

the pumps, and into the nutrient reservoir.

The amount of liquid that is pumped through a peristaltic pump can vary due to a number of factors

including:

• Age and condition of peristaltic tubing.

• Pump mounting height and tube length.

• Viscosity and specic gravity of the liquid being pumped.

• Environmental temperature.

To counteract these variations each EC peristaltic pump can be individually calibrated to help

ensure the desired amount of solution is dosed relative to that being dosed by the other EC

pumps in the Bluelab®PeriPod™ chain.

pH adjuster and nutrient stock solutions. Up to three M series

PeriPods™ dosing up to 12 nutrient parts can be connected

pH ECA ECB

Outlet dosing

tubes

seperate

Inlet dosing

tubes

Reservoir / tank

RECOMMENDED

To avoid precipitation of nutrients, tubes

into reservoir should be separated.

pH Nutrient A Nutrient B

(Default settings -

Can be set as pH

or nutrient pumps

in Connect)

English

5

2.0 Safety Precautions

IMPORTANT

BEFORE installation and rst use - read this section. To ensure safe setup and operation of

the Bluelab®PeriPod™follow all precautions in this manual. All the safety instructions and/or

warnings given throughout this manual relate to the specic features of the Bluelab®PeriPod™.

2.1 General safety precautions

Follow all generally accepted safety practices and procedures required when working with and

around electricity, including the following;

WARNING

•This product is designed for pumping liquids only.

•Never use in or around ammable gases. Doing so creates risk of smoke, re, or explosion.

•Never use a voltage that is different from that specied on the product.

•Do not touch the pump motor when removing it shortly after running. The motors get hot

when operating and could cause serious burns.

•Never take the product apart or modify it except as described in this manual.

•Never leave any dangerous liquids inside the tubing when replacing or disconnecting tubing or

pumps. Remaining dangerous liquids may cause serious injury. Always ush with water.

•Remove dangerous liquids from pumps and tubing when storing, or if product is not to be

used for extended periods.

•Always ush tubing with water before changing from one dosing solution to another.

CAUTION

•Peristaltic tubing can degrade in certain conditions of use. Always check for signs of

degradation and leaks, and replace tubing as required to ensure safe operation.

2.2 Chemical safety precautions

Bluelab®recommend that you DO NOT handle concentrated acids or alkalis, however if you do,

ensure that ALL generally accepted safety practices and procedures required when working with

acidic and alkaline solutions are followed.

WARNING

•Follow all Manufacturer's storage, safety instructions and precautions when handling

chemicals.

•ALWAYS neutralise acids and alkalis before cleaning up a spill or disposing of them.

English

6

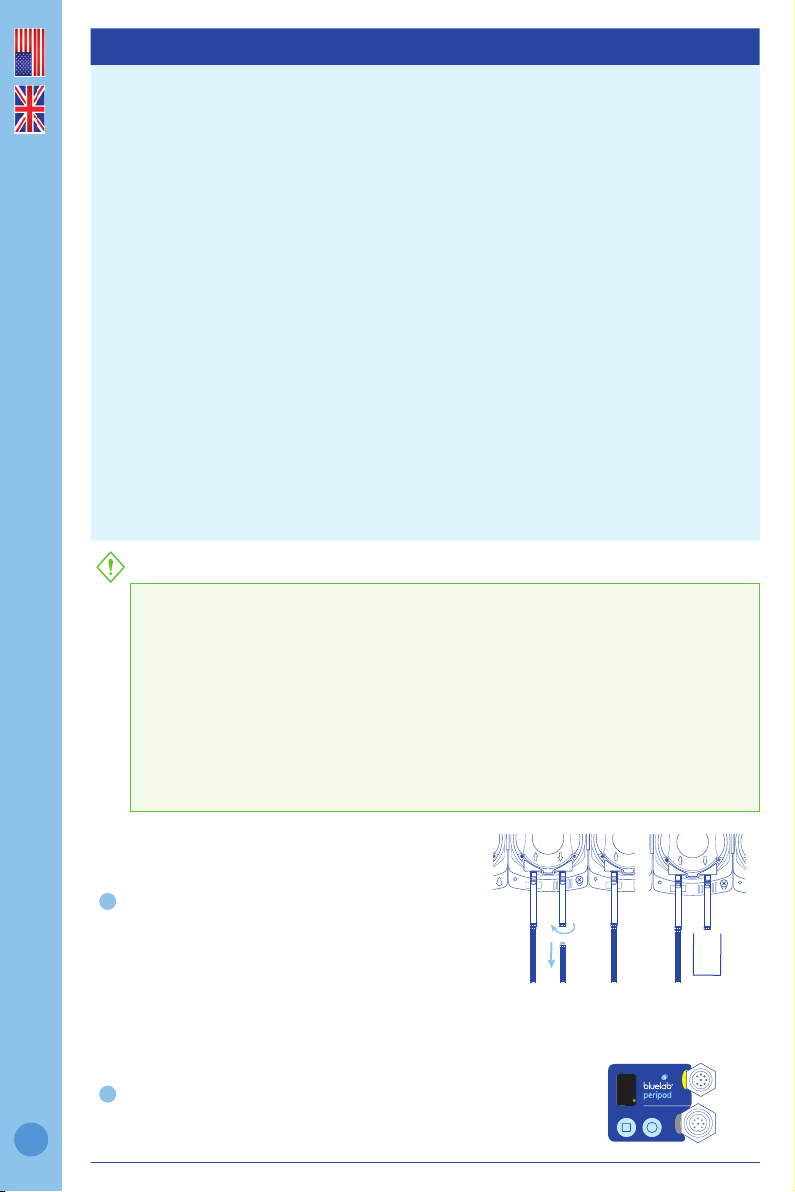

3.2 Setting up the inlet & outlet tubes

Straighten the dosing tubes before connecting. Bend tube in the opposite direction to its curve

and straighten by running through closed ngers.

Each 4 metre / 13 foot length of tube requires cutting to be used as both inlet and outlet

dosing tubes with connectors. Before cutting, ensure there is enough length for each. Cut the

tubing on a 45° angle. This is important to avoid the tube becoming blocked due to suction at

the bottom of the adjuster and nutrient solution bottles.

CAUTION

•Ensure you use the pH dosing tube with the pH adjuster solution. pH adjuster solution could

damage nutrient tubing.

Set up the pH inlet dosing tube.

M Version: Insert the pH dosing

tube connector into the LEFT pH

pump tube.

L Version: Push one end of the

pH dosing tube over the LEFT pH

pump barb.

3.0 Installing the Bluelab®PeriPod™

3.1 Mounting the Bluelab®PeriPod™

Select a suitable location that is:

• Higher than both the reservoir and the pH and nutrient

solutions. This will avoid siphoning from one to the

other in the event of peristaltic tube failure.

• NOT directly above the reservoir. This will avoid

leaked solution entering the reservoir in the event of

peristaltic tube failure.

• Less than 1.5m from an electrical mains outlet.

• Less than 400mm from the next PeriPod, if being used

in a chain.

• Less than 2m from the reservoir so that pump outlet

tubing can reach easily.

• Ideally less than 1.5m above pH adjuster and nutrient

stock solutions. This will ensure pump suction is

adequate to pump solutions. For heavy or viscous

solutions a lower mounting height may be required.

CAUTION

•Direct sunlight may result in increased damage

to tubing and plastic components of the

Bluelab®PeriPod™.

Attach to the wall by securing the screws through the

mounting holes in the top and bottom of the case. It is

recommended to place screws as indicated in the diagram.

1

2

1

Inlet ‘’

arrow on

pump cover

Inlet ‘’

arrow on

pump cover

Connector

Left pump

tube Left pump

barb

Inlet dosing

tube

Inlet dosing

tube

M Version L Version

Mounting holes at bottom

Recommended mounting conguration:

Mounting holes at top

English

7

3.2 Setting up the inlet & outlet tubes continued

Ensure the inlet dosing tube will

reach the bottom of the pH adjuster

container. Cut the inlet dosing tube

to desired length.

Set up the pH outlet dosing tube.

M Version: use the remaining

dosing tube with the connector,

and insert the connector into the

RIGHT pH pump tube.

L Version: Use the remaining dosing

tube and push it onto the RIGHT pH

pump barb.

Cut the outlet dosing tube so that

the tube sits above the maximum

solution level of the reservoir. The

pH adjuster and nutrient solutions

must drip into the nutrient reservoir.

Note: If the outlet dosing tubes are

immersed in the reservoir it could

create a siphon. This could possibly

cause the solutions to ow into the

reservoir or vice versa.

To set up nutrient tubing and pumps, repeat steps 1-4 using the darker nutrient solution

tubing. For the L Version: Insert and twist each connector of the nutrient dosing tube into each

nutrient pump tube connector.

Note: If pH adjuster or nutrient stock solution being used has solid particles suspended in

it, then a sieve lter should be placed on the end of the tube to prevent tube blockages and

potential damage to the peristaltic pumps.

A suitable sieve lter should suit tubing with 3mm or 1/8in ID for the M version, 8mm or 1/3in

ID for the L version. The lter should be made from a material that is compatible with the pH

adjuster or nutrient stock solution being used.

2

3

4

5

Dosing tube reaches

bottom of container

Cut tubing on 45° angle

pH

adjuster

Nutrient solution

reservoir / tank

Inlet dosing

tube

pH

pump

Nutrient

pumps

Outlet dosing

tube

pH

adjuster

Connector

Outlet ‘’ arrow

on pump cover

Right pump tube

Right pump barb

Outlet dosing tube

Nutrient pumps

Inlet dosing tubes

Outlet dosing tubes

M Version

M Version

L Version

L Version

English

8

3.3 Bluelab®PeriPod™ connection panel

The interface panel is located on the right hand side of the Bluelab®PeriPod™and provides the

user interface to access its features.

3.4 Connecting to a Bluelab®Pro Controller

For ease of use Bluelab®dosing cables are colour coded. Each end matchs up with colours on

the connector panel of the Bluelab®PeriPod™.

To connect the Bluelab®PeriPod™to

the Bluelab®Pro Controller™, align

pins and push the connector onto

the GREY connector.

Once pushed in turn the threaded

collar of the connector clockwise to

secure the connector in place.

Then connect the other end

(YELLOW end) to the doser

connector of the Bluelab®

Pro Controller.

Connect the next PeriPod in the

chain (if used) to the upper YELLOW

connector of the previous PeriPod. Line up connector pins, push and turn

Grey connector

(To the Pro Controller

Doser connector)

Yellow connector

(To the next PeriPod

in the chain)

LED display

screen

Select / Save button

Start / Stop button

1

2

3

Doser

connector

Grey

connector

3.5 Connect power adapter

Connect the power adaptor into the power

receptacle in the base of the Bluelab®PeriPod™.

Plug the adaptor into the mains power supply.

Switch on the power adaptor at the mains. The

Bluelab®PeriPod™will complete a display test

sequence. A GREEN dot in the lower right hand

corner of the display indicates that the Bluelab®

PeriPod™is powered ON, in stand-by mode and

ready to dose.

1

2

connect power

adaptor

stand-by

mode

English

9

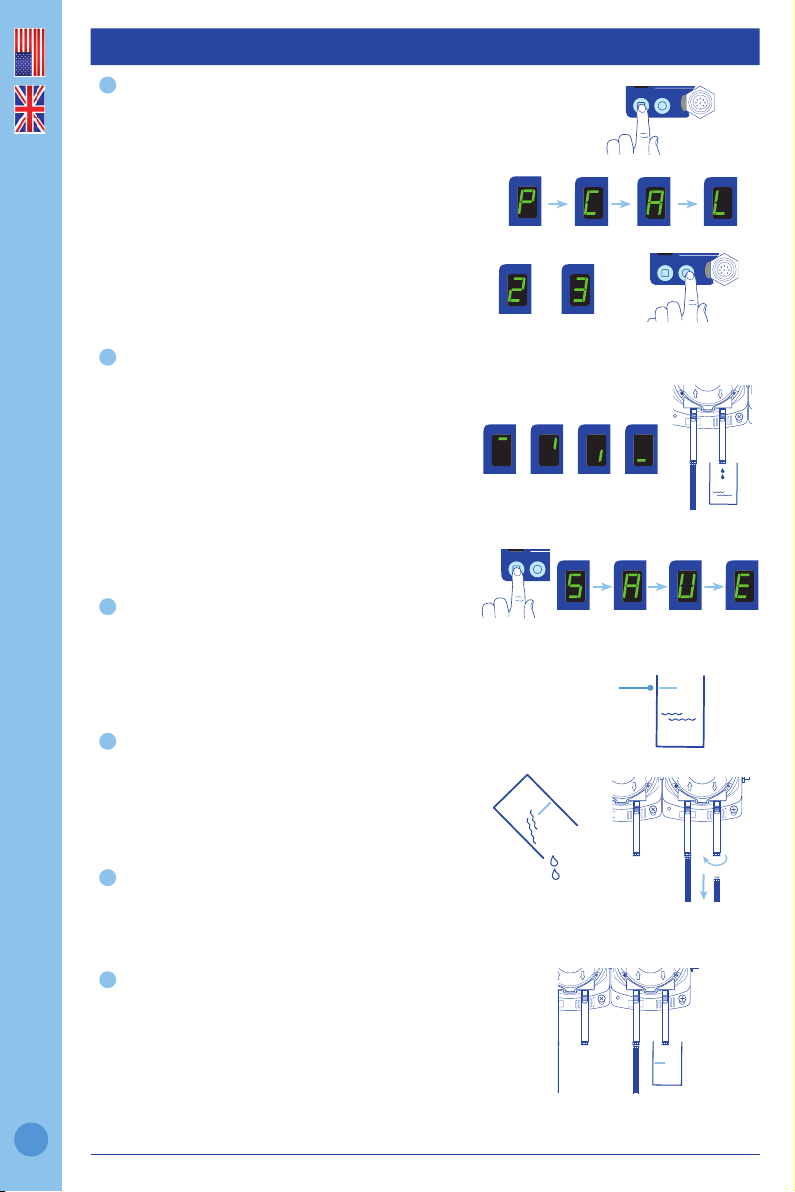

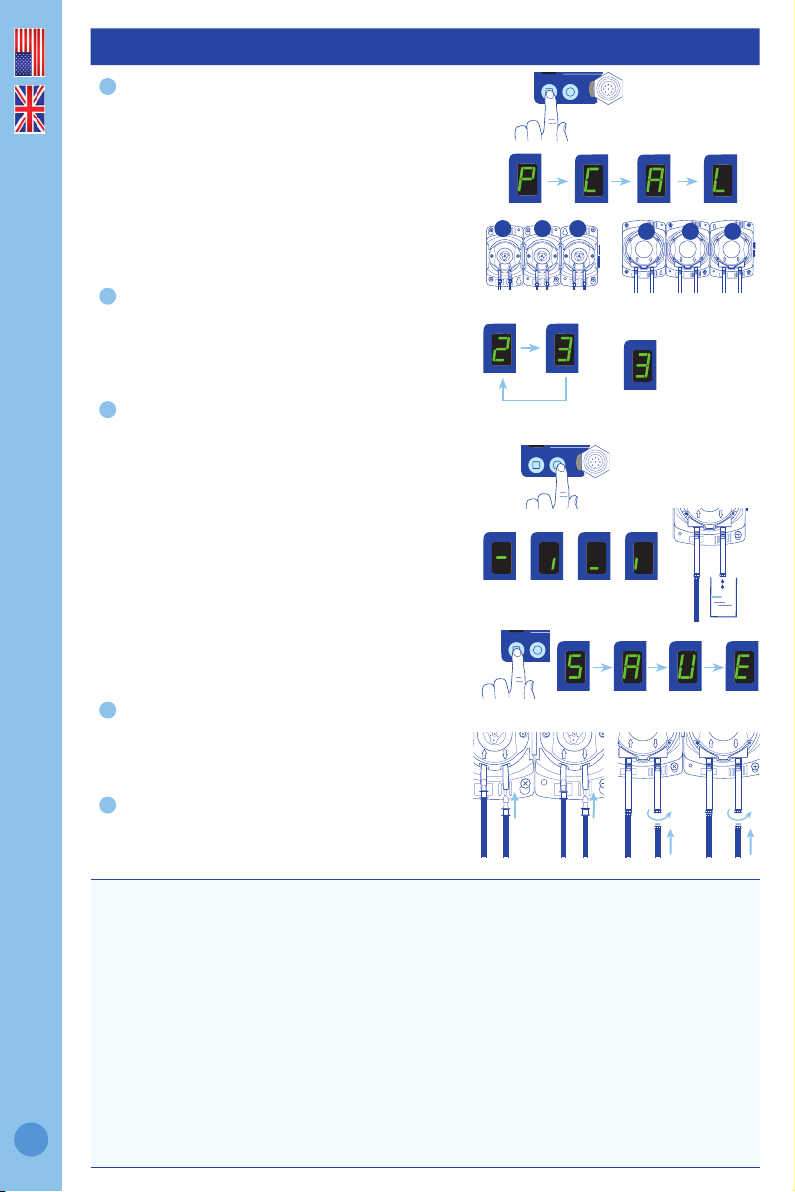

4.1 Manual pump priming

It is recommended that after setup and before automatic dosing begins all pumps are manually

primed with the solutions that they will dose during normal operation. This is done for each pump

individually by following the process below.

Ensure that all dosing tubes are correctly

installed, see Section 3.2, and the

Bluelab®Pro Controller (if connected) is

in monitor mode.

Short press the Select / Save button ''

to enter pump priming mode.

The LED display will show the letter P

to indicate that priming mode has been

entered then either a 1, 2 or a 3 will

be displayed to indicate which pump is

selected.

Change the selected pump by short

pressing the Select / Save button ''.

This will change the displayed number

between 1, 2 and 3.

To begin priming the selected pump

short press the Start / Stop button ''.

The pump will begin running and the

LED display will show a DOT in the

bottom right corner (along with the pump

number) to indicate that the pump is

being primed.

Note: As a safety precaution the pump

will stop after around two minutes,

and return to standby mode. If further

priming is required, simply re-enter

priming mode, select the pump again,

and start priming as before.

Once the pump is primed short press

the Select / Save button ''to return to

standby mode.

To prime another pump repeat steps 1

to 5 above.

Note: The pump can be paused and

restarted at any time during priming by

short pressing the Start/Stop button ''.

1

2

3

4

5

6

M Version

M Version pump selection

L Version

Priming

mode

Pump to be primed

Change pump

Pump being primed

Press Select /

Save button ''

Press Select /

Save button ''

Press '' selection

button once pump

is primed

Press Start / Stop

button ''

4.0 Set up and operation

1 2 3

L Version pump selection

1 2 3

English

10

4.2 Calibrating nutrient pumps

Bluelab®recommends that pumps are calibrated on initial set up, whenever it is observed that

different quantities of solution are being dosed, when changing nutrient type, and every 30 days.

A pump set as a pH pump cannot be calibrated.

Dose rates of peristaltic pumps can vary for many reasons, including:

• Temperature of solution.

• Temperature of operating environment.

• Vertical mounting distance (height) from stock solutions.

• Age and condition of peristaltic tubes.

• Age and condition of pumps.

• Specic gravity and viscosity of stock solutions.

For these reasons the Bluelab®PeriPod™has a pump calibration feature that is designed to reduce

these effects by providing a user calibration for each pump. Pump calibration is not required,

however it does improve the dosing accuracy of each pump relative to the others, which is important

when accurate dosing of several nutrient stock solutions into the reservoir is required.

The pump calibration is a simple process where equal volumes of solution are pumped through

each nutrient pump. The time taken to deliver this volume of solution is measured by the Bluelab®

PeriPod™which will then adjust each pump’s running time during dosing in order to deliver the same

quantity of solution from each pump.

To complete calibration you will need; an empty transparent container that is able to hold

approximately 300ml / 10oz for M versions, or 3000ml / 100oz for L versions, a marker pen, and a

stop watch or similar.

CAUTION

•If calibrating pumps, ensure ALL pumps in the PeriPod™chain are calibrated.

•To ensure calibration accuracy, the solution used during the calibration of each pump MUST

be the same solution that will be dosed by that specic pump during normal operation.

•Pump calibration should be done with the Bluelab®PeriPod™and inlet tubing fully installed

and primed as it would be during normal operation.

•The maximum running time for a pump during calibration is 3 minutes. If this time is

exceeded the calibration will fail (the PeriPod will display “F” then “A”,”I,” “L”, leave calibration

mode and return to standby). It will not save calibration for that pump. If a pump takes longer

than three minutes to deliver the required amount of solution it is likely there is a problem

with the pump. See Section 5.3 Troubleshooting.

With the Bluelab®PeriPod™and dose tubing fully

installed and primed, and the Bluelab®Pro Controller

in monitor mode (if connected):

Select the rst nutrient pump to be calibrated, remove

the outlet dosing tube from the pump outlet and place

your empty transparent container underneath the

pump outlet tube so that nutrient pumped through the

pump will ow into the empty transparent container

and NOT into the reservoir.

Note: Carefully remove the outlet dosing tube from the

connector to remove for M3 version.

Power up the Bluelab®PeriPod™. The LED Display

should show a dot in the lower left hand corner of the

display indicating it is in standby mode.

1

2

Remove outlet

dosing tube

Power up in

standby mode

Put empty container

under pump outlet tube

English

11

4.2 Calibrating nutrient pumps continued

Enter pump calibration mode with a

long press of the Select / Save button ''

(long press = ~2 seconds).

The LED display will initially show the letter P, then C,

A, L, once pump calibration mode has been entered.

A 2 or 3 will be displayed to indicate which pump

will be calibrated.

Note: Press the Select / Save button '' to switch

between pumps 2 or 3 and select the pump you

will calibrate rst. Remember, pH pumps cannot be

calibrated.

To begin calibrating start the stop watch, or note the

time, and short press the Start / Stop button ''.

The pump will begin running and the LED display

will show a rotating bar to indicate that the pump

is running.

Allow the pump to run for approximately two

minutes, then short press the Start / Stop button

again to stop the pump. The LED display will show

a dash.

Press the Start / Stop button '' to save the

calibration for this pump. The LED display will show

S A V E to conrm that the calibration has been

saved.

Take the marker pen and draw a line on the

side of the transparent container to indicate the

solution level within the container. This will be the

reference quantity that all of the other pumps will

be calibrated to.

Empty the transparent container.

Select the second nutrient pump to be calibrated,

remove the outlet dosing tube from the pump

outlet and place your empty transparent container

underneath the pump outlet tube so that nutrient

pumped through the pump will ow into the empty

transparent container and NOT into the reservoir.

Note: Carefully remove the outlet dosing tube from

the connector to remove for M3 version.

4

5

6

Press '' selection button to save calibration

Mark solution

level in container

Press ''

selection button

Indicates pump

being calibrated

OR

Let pump run for 2 minutes

3

Long press ''

selection button

7

8

Remove outlet

dosing tube

Empty the container

Put empty container

under pump outlet tube

English

12

4.2 Calibrating nutrient pumps continued

Enter pump calibration mode again with

a long press of the Select / Save button ''

(long press = ~2 seconds).

The LED display will show the letter P, then C, A, L,

once pump calibration mode has been entered.

A 2 or 3 will be displayed to indicate which pump

will be calibrated.

If required, press the Select / Save button ''

to switch to the next pump to be calibrated.

Repeated presses will cycle through all of the

nutrient pumps in that PeriPod.

To begin calibrating the pump short press the

Start / Stop button ''.

The pump will begin running and the LED display

will show a rotating bar to indicate that the pump

is running.

This time stop the pump with a short press of the

Start / Stop button ''once the solution level has

reached the mark made on the container in STEP

6 above. The LED display will show a dash.

Note: The pump can be paused at any time during

calibration by short pressing the Start / Stop

button. Push it again to restart the pump and

continue calibration.

Press the Select / Save button ''to save the

calibration for this pump. The LED display will

show S A V E to conrm that the calibration has

been saved.

When all of the nutrient pumps in the PeriPod

chain have been calibrated, calibration is

complete. Re-attach the nutrient dosing tubes to

the peristaltic pump tubes.

Note:

Pump calibration can be repeated at any time, however it is recommended that calibration is

done at least every 30 days.

Once the rst calibration has been carried out, calibration of any pump can be carried out at

any time using the marked solution container without the necessity of timing the rst pump,

however it is recommended that all all pumps in the PeriPod chain are calibrated whenever

calibration is carried out.

Once calibrated, the pumps will be turned on and off at intervals by the Bluelab®PeriPod™

while dosing in order to dose the correct amount, rather than both pumps continuously dosing.

This is normal operation.

Calibration times of greater than three minutes are not allowed, and will result in a failed calibration.

Resetting the Bluelab®PeriPod™to an un-calibrated state can be carried out by pressing and

holding both Select / Save ''and Start / Stop ''buttons while powering up. If any PeriPods™

in the pod chain are reset, it is recommended to recalibrate them all.

9

10

11

12

13

Press ''

selection button

Indicates pump

being calibrated

Press '' selection button to save calibration

Let pump run until solution reaches

the marker line

M Version L Version

M Version pump selection

Pump to be

calibrated

1 2 3

L Version pump selection

Long press ''

selection button

1 2 3

English

13

The Bluelab®PeriPods™can be used with the Bluelab® Pro Controller and Bluelab®Connect to dose

multi-part nutrients in varying proportions, according to a feed chart or feed schedule.

Overview of Multi-part nutrient dosing

Multi-part nutrient dosing allows dosing of nutrients into a reservoir according to a feed chart or

feed schedule. These are often provided by the nutrient manufacturer.

Multi-part nutrient dosing can be selected in Connect when a suitable Pro Controller/PeriPod™

combination is detected. It is enabled in the Pro Controller Nutrient Dosing screen.

Each pump in the PeriPod™or the PeriPod™chain of up to three PeriPods™can be set as a pH

pump, an EC (nutrient) pump, or it can be turned off if not currently needed.

The nutrient proportions are calculated automatically from the feed chart quantities directly

entered into Connect by the user.

When the Pro Controller initiates dosing, the PeriPods™use the calculated proportions to switch

individual pumps on and off on during dosing, so that they dose the nutrients in the correct

proportions. For example, if one pump is set to 10 ml/gal and another set to 5 ml/gal the rst

pump will dose for twice as long as the second pump.

When the nutrient proportions change (a new line or week in the feed schedule), the reservoir

should ideally be emptied, lled, and dosed up using the new ratio. This avoids unwanted nutrients

remaining in the reservoir, and smaller components taking too long to come to the correct

concentrations.

When the nutrient proportions change (a new line or week in the feed schedule), the reservoir

should ideally be emptied, lled, and dosed up using the new ratio. This avoids unwanted nutrients

remaining in the reservoir, and smaller components taking too long to come to the correct

concentrations.

5.0 Multi-part Nutrient Dosing with Bluelab®PeriPods

5.1 Reservoir size

Because 100 seconds total dosing time is required in order for the PeriPod to accurately dose, it’s

clear that there is a minimum reservoir size required. If the reservoir doses up to the required EC

before the 100 seconds dosing is up, the nutrients may not be properly balanced.

If the reservoir that will be used is less than about 25 gallons (100 litres)(for an M series PeriPod

chain), we suggest diluting all of the nutrient components by adding an equal volume of water.

This will double the dosing time, ensuring that 100 seconds dosing time is achieved. Remember

to label the containers to indicate that they are diluted.

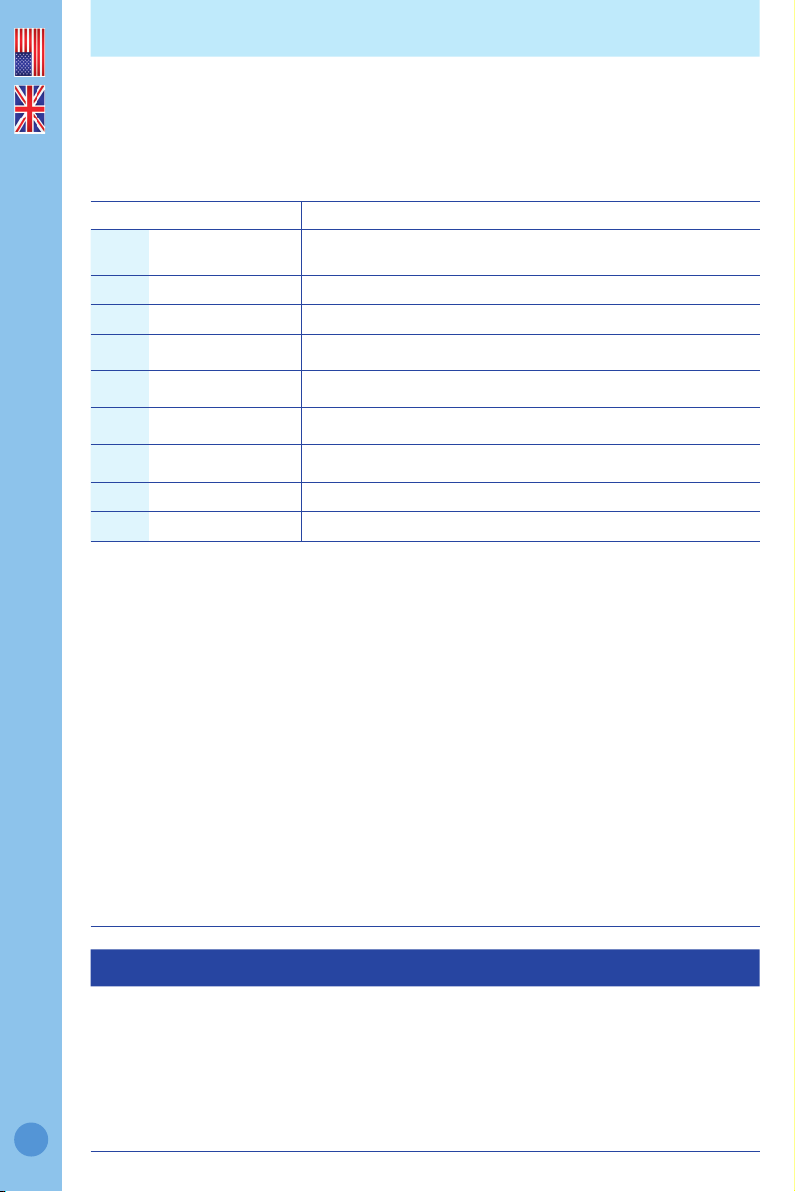

FRODO'S FEED CHART NUTRIENTS

Week Required

pH

Required

PPM Macro A Macro B Mini

Macros

Mega

Micro 1

Mega

Micro 2

Special

Sauce

15.8 450 8 ml 8 ml 2 ml 1 ml

25.8 650 10 ml 10 ml 4 ml 2 ml

35.8 650 12 ml 12 ml 5 ml 2 ml 1 ml

45.8 1400 14 ml 14 ml 5 ml 5 ml 3 ml

55.8 1100 14 ml 14 ml 5 ml 5 ml 3 ml

65.8 1100 14 ml 14 ml 5 ml 5 ml 3 ml

75.8 800 12 ml 12 ml 5 ml 5 ml 3 ml

85.8 450 10 ml 10 ml 5 ml 5 ml

*all measures in ml/US gal and ppm 500 scale

English

14

5.2 Starting with multi-part nutrient dosing

Setting up the PeriPods and Connect

Mount the PeriPods™as described in the PeriPod™Manual.

Ensure each pump is drawing from the correct nutrient part. Labelling the pumps

with the nutrient types in the feed chart is a good idea.

Connect the PeriPods™in a daisy chain with the dosing cables. The dosing cable

and the PeriPod™connectors are colour coded to make this easier.

Ensure the Pro Controller and all of the PeriPods™are

powered up. If it is the rst time the PeriPods™have been

connected to the Pro Controller, a “Pod Change – Accept”

message will be displayed on the Pro Controller. Check

that the all of the PeriPods™are correctly set up, powered

up and connected, with all required nutrient parts and pH

adjusters in place, then press the Pro Controller brightness

button to “accept” the pod chain. This prompts the Pro

Controller to “remember” the details of all of the pods and

pumps, so it can communicate with them correctly.

Prime and carry out a calibration of the PeriPod™pumps if desired (see section 4.2 of this

manual). Note: The “Pod Change” message does not need to be accepted during priming

or calibration.

1

2

3

4

5

IMPORTANT

The PeriPod™ doses small volumes of nutrient into the reservoir so results in less

precipitating nutrients, but to further ensure this is minimised:

• Separate all nutrient tubes where they enter into the reservoir

• Always have sufcient and continuous mixing in the reservoirs (more is better)

• Some nutrient components or additives (e.g. silicon) are extremely prone to precipitation.

Dilute precipitation prone nutrients or additives to very dilute levels before dosing. Multiply

the dose value (ml/gal) by the dilution rate and enter into Connect™to retain the same ratio.

Continuous addition in dilute form results in some of the nutrient/additive always being

available, even if precipitation over time is expected.

5.2.1 Setting up the PeriPods

English

15

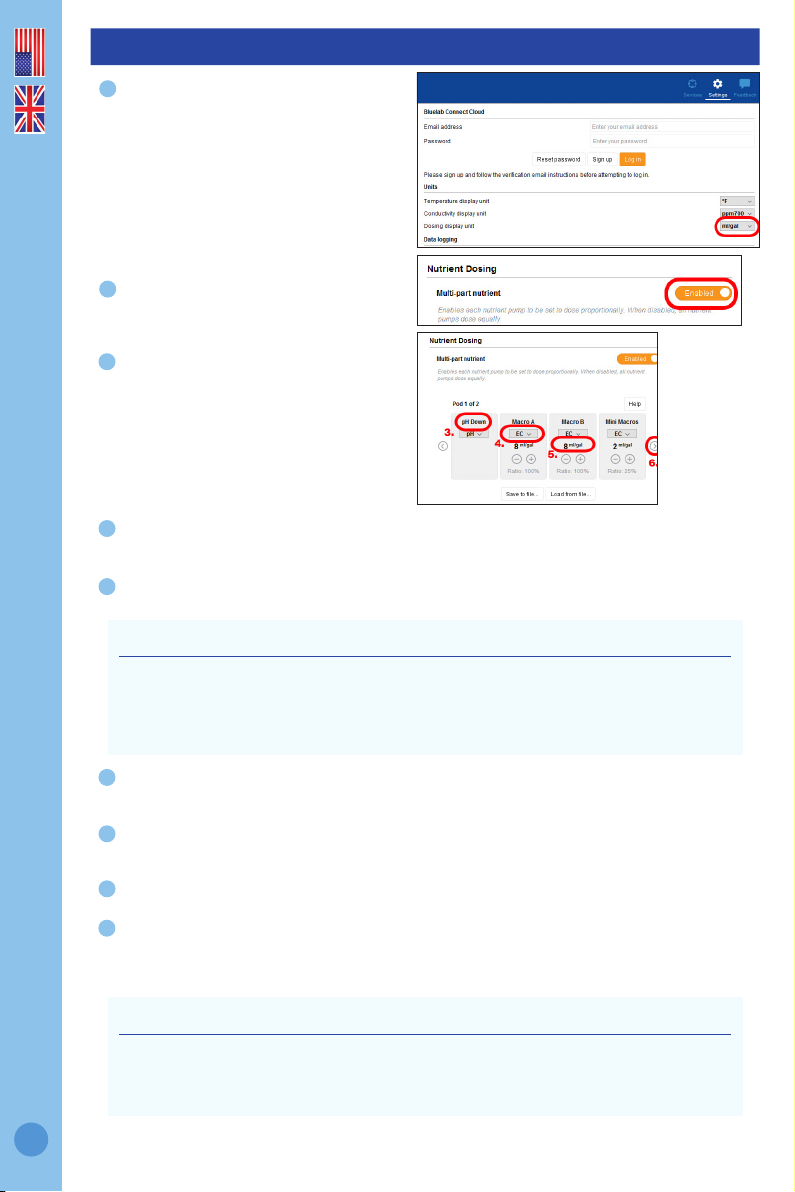

5.2.2 Setting up Connect

In the Connect global Settings screen,

select the units of the quantities that

will be entered in the multi-part nutrient

dosing screen (ml, ml/gal, ml/l are

available). This is likely to be the

units used in the nutrient feed chart

or schedule.

In the Connect™Pro Controller Nutrient

Dosing screen, enable Multi-part nutrient.

Click on the pump name of each nutrient

pump and enter the name of the nutrient

component it will be dosing (e.g., 5%

Nitric, Grow A, Grow B etc.).

Select the pump function – pH, Nutrient (EC) or Off - by using the drop-down box for each

pump. All pumps should be either set up or switched off.

Enter the nutrient quantities for each pump (probably taken from a nutrient feed schedule,

or feed chart).

Use the left and right arrows at the side of the screen to navigate between PeriPods™in order

to set up the pumps in each.

Save the setup to le, if it is likely to be used again. Click “Save to le…” and choose a location

for saved les. A saved setup can be loaded and used by clicking “Load le…”

Click “Apply” to send the information to the Pro Controller/PeriPods.

Check all equipment is correctly installed and set up, and enter Control mode to start

dosing. Nutrients will be dosed in the proportions entered from the feed chart line up to

the required EC value.

1

2

4

5

6

7

8

9

3

IMPORTANT

The Pro Controller will not use these numbers to dispense a particular quantity. Connect™uses

them to calculate nutrient proportions (these proportion are displayed as percentages, and can

be seen changing as new quantities are entered). The Pro Controller/PeriPods™will continue to

dose in these proportions until the correct EC is reached.

IMPORTANT

Remember to set or check the EC and pH required values, on/off times and alarms,

in Device Settings if loading a le, as these settings are not saved in the setup les.

See the Bluelab®Pro Controller manual for more information on setting dosing settings

English

16

5.2.3 Calculating the on time with multi-part nutrients

From the feed chart or schedule, nd the largest (by volume) nutrient component.

Example: MaxiVeg requires 18 ml/gal – all the others take less.

Then, work out how many doses are required to take a reservoir from newly lled to dosed

up. This is simply based on the required EC.

Example: 1.2 EC required = 12 (minimum) doses (We can only shift it 0.1EC with

each dose – otherwise, we’ll overshoot).

Work out how much of the nutrient component is used when fully dosing up the reservoir.

Example: Nutrient part A is added at the rate of 18 ml per gallon (from the schedule, above).

My reservoir is 100 gallons so I need: 1800mls (1.8 litres) total.

Now we can work out how big the maximum dose should be,

Example: 1800ml total divided by 12 doses (found earlier) equals 150ml per dose.

1800/12 = 150ml

Which gives us the on-time we need.

Example: My M3 pumps dose 120ml per minute, which is 2 ml per second, so

150/2 = 75 seconds.

Remember, this is the biggest we can have it, so we can reduce it a bit, to stop overshooting. So,

60 seconds would be a good starting point. It can be tweaked later, if needed.

Ensure that the nutrient / pH output tubes from the PeriPods™are separated where they enter

the reservoir to avoid precipitation problems.

1

2

3

4

5

FRODO'S FEED CHART

Week Required

pH

Required

EC Macro A Macro B MaxiVeg Mega

Micro 1

Mega

Micro 2

Special

Sauce

15.8 0.8 8 8 1 ml

25.8 0.8 10 8 8 2 ml

35.8 1.0 12 814 2 ml 1 ml

45.8 1.0 12 818 5 ml 3 ml

55.8 1.2 12 818 5 ml 3 ml

65.8 1.2 12 12 5 ml 3 ml

75.8 1.0 12 12 5 ml 3 ml

85.8 0.5 10 10 5 ml

*all measures in ml/US gal and ppm 500 scale

English

17

6.0 Maintenance, Troubleshooting & Specications

6.1 Maintenance

• Peristaltic pump tubing has a nite life and should be replaced periodically to maintain stable

performance. Refer to the Bluelab®website or the back of this manual for information on spare

parts.

• Flush pumps and tubing with water when product is going to be unused for more than one month.

• If re-installing after long periods of storage, initial setup procedures should be carried out.

• If you notice sudden or signicant changes in ow rate see the troubleshooting guide in section

5.3 and check for signs of damage or wear.

WARNING

Always ush tubing and pumps with clean water BEFORE performing any maintenance on

pumps or tubing. This ensures that all dangerous chemicals are ushed out of the tubing and

pump, reducing accidental harm or injury.

6.2 Firmware upgrading

When prompted by the Bluelab®Connect™ software that new rmware for the Bluelab®

PeriPod™is available, upgrade it to ensure optimum functionality and reliability. The computer

running Bluelab®Connect™ software must be connected to the internet to receive rmware

update information.

1

Computer & Connect

Stick with internet

Computer to

Bluelab®Pro Controller

Controller to

Bluelab®PeriPod™

Receive update

data via internet

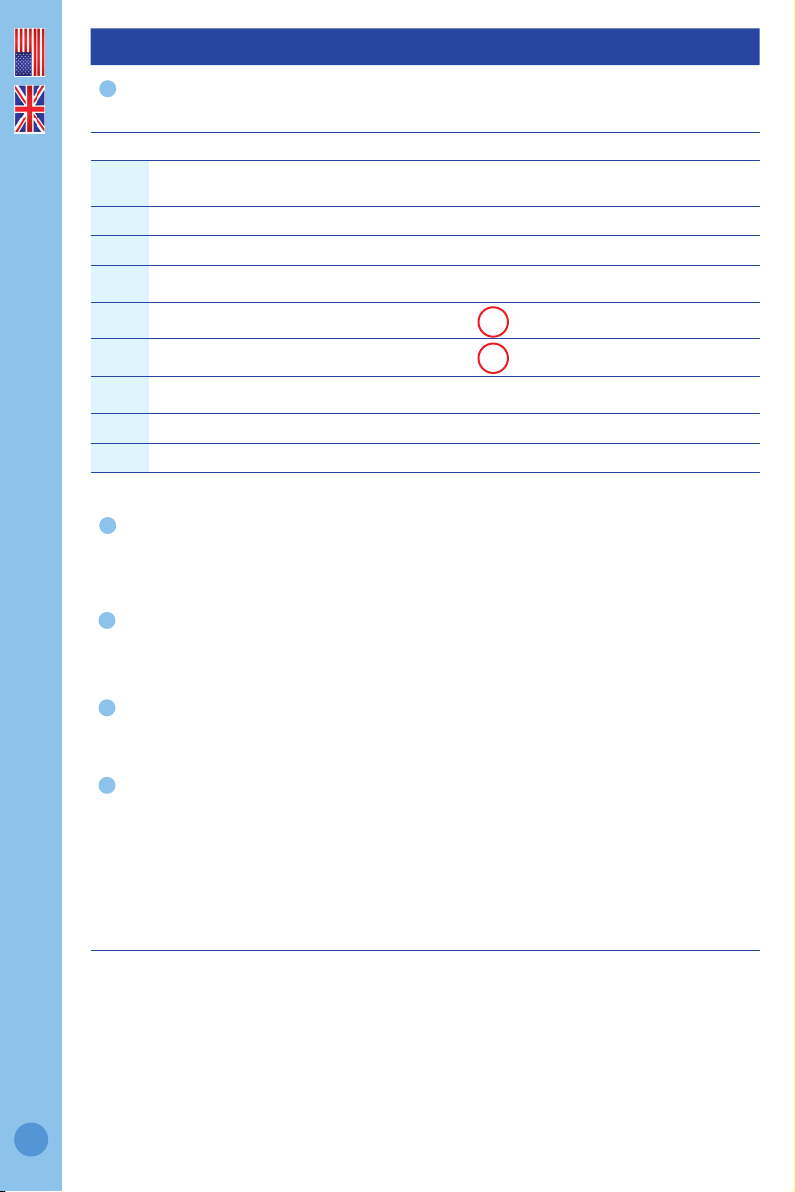

6.3 Troubleshooting guide

PROBLEM PROBABLE CAUSE CORRECTION

Pumps not

turning.

Pro Controller currently

in an off time

Wait until next on time starts.

Required EC/pH level met. No action required.

Bluelab®Pro Controller is in

alarm - dosing is locked out.

Check Pro Controller display or Connect to identify alarm

cause, and correct it.

Bluelab®Pro Controller not

set to control.

Ensure Bluelab®Pro Controller is in control mode

(refer to Bluelab®Pro Controller Manual).

Required dosing levels not

correctly set.

Ensure Bluelab®Pro Controller is set up with correct required

levels for EC/pH (refer to Pro Controller Manual).

Power not connected. Check power supply is plugged in. If there is a green dot in

the bottom right corner of the display the Bluelab®PeriPod™

is correctly powered.

Bluelab®PeriPod™not

connected properly.

Check the connections between the Bluelab®PeriPod™and

the Bluelab®Pro Controller.

Cassette is damaged. If you can hear the motor running, but the cassette isn’t

spinning, check cassette and motor spindle. Replace if

damaged.

Motor damaged. Replace motor.

English

18

6.3 Troubleshooting guide continued

PROBLEM PROBABLE CAUSE CORRECTION

Pump(s) not

pumping but

are turning.

Nutrient stock/pH adjuster

tank is empty.

Replenish nutrient.

Tube is blocked. Remove and unblock tube, rinse with water and reattach.

Tube is twisted. Go through all the tubing (including that going into the

cassette) and straighten out any kinks.

Tube is cut at and touching

the bottom of the nutrient

tank.

Cut the bottom of the tube at a 45° angle.

Split or hole in tubing. Replace tubing.

Damaged cassette/worn

peristaltic tube.

Replace cassette.

Pumps are

not pumping

the expected

quantities /

Pump(s) ow

rate decreased /

Pump(s) failing

calibration

Calibration is out of date. Re-calibrate pumps.

Nutrient has changed. Re-calibrate pumps.

Tube is blocked. Remove and unblock tube, rinse through with water

and reattach.

Nutrient levels very low. Ensure tube is always in the nutrient even when levels

are low.

Tube is twisted. Go through all the tubing (including that going into the

cassette) and straighten out any kinks.

Tube is cut at and touching

the bottom of the nutrient tank.

Cut the bottom of the tube at a 45° angle.

Split or hole in tubing. Replace tubing.

Damaged cassette/worn

peristaltic tube.

Check pump output (approx. 120ml/min, M series;

1,200ml/min L series). If low, replace cassette.

If cassette is damaged, replace cassette.

Damaged pump. Replace pump.

EC/pH not

changing.

Inlet dosing tube not in

nutrient stock solution/pH

adjuster.

Put dosing tube back in nutrient stock solution/pH

adjuster, and re-prime pump.

Outlet dosing tube not in

reservoir.

Put dosing tube back in reservoir.

Run out of nutrient/pH

adjuster.

Replace nutrient/pH adjuster, and re-prime pump.

Tube is twisted. Go through all the tubing (including that going into the

cassette) and straighten out any kinks.

Tube is cut at and touching

the bottom of the nutrient tank.

Cut the bottom of the tube at a 45° angle.

Split or hole in tubing. Replace tubing.

Damaged cassette/worn

peristaltic tube.

Check pump output (approx. 120ml/min, M series;

1,200ml/min L series). If low, replace cassette.

If cassette damaged, replace cassette.

Damaged pump. Replace pump.

Overshooting

required values

Poor mixing in reservoir. Add mixer to reservoir.

Off time too short. Increase off time (refer to Bluelab®Pro Controller Manual).

Too many doses

needed to change

measured value.

On time too short. Increase on time (refer to Bluelab®Pro Controller Manual).

Never reaching

desired EC/pH.

On time too short/off time

too long

Set on/off times correctly (refer to Bluelab®Pro Controller

Manual).

Pumps too small for reservoir. Move to the L3 version of the Bluelab®PeriPod™if possible

or add more Bluelab®PeriPod™(in a daisy chain) for larger

reservoirs. Contact customer support for advice.

EC/pH is never

dosing.

Bluelab®Pro Controller control

direction is set incorrectly

Change Bluelab®Pro Controller control direction setting

to the correct direction, and ensure the correct solution/

adjuster is being used.

English

19

6.4 Technical specications

M3 / M4 L3

Default Function (Can be changed in

Bluelab®Connect)

Pump 1: pH, Pump 2: EC A,

Pump 3: EC B, Pump 4 (M4): EC C.

Pump 1: pH, Pump 2: EC A,

Pump 3: EC B

Pump ow rate 120 ml/min11200 ml/min1

PeriPod size selection Refer to bluelab.com for discussion on pump sizing

Peristaltic tube lifetime >750hrs pump running time

Peristaltic pump motor lifetime >1500hrs pump running time

Solution Temperature 5 - 50°C / 41 - 122°F

Environment Temperature 5 - 40°C / 41 - 104°F

Flow rate accuracy at 20°C / 68°F ±10% 1,2

Pump Calibration Yes

Firmware upgradable Yes

Power Source Input: 100-240 Vac, 50-60 Hz, 5 VA

Output: 24Vdc 2 Amp, 24Vdc 5 Amp (on limited L3 stock)

Certications CE, FCC, IC.

1

Pump ow rate and dosing accuracy is dependent on, among other things; temperature, liquid being pumped, age and condition of tubing. Therefore the actual

ow rate achieved will vary between each setup and with time.

2

With no valid pump calibration.

6.5 Material specication for tubing

Peristaltic tubing pH tubing Nutrient tubing

Food Grade YES YES NO

Standards Met

USP Class VI, ISO 10993,

FDA CFR 21, FDA 3-A, NSF

51, REACH, RoHS

USP Class VI,

FDA CFR 21 RoHS

6.6 pH adjuster compatibility for tubing3

Peristaltic tubing (PharMed BPT) pH Tubing (PTFE) Nutrient tubing (LDPE)

Nitric Acid <35% Concentrated <10%

Phosphoric Acid <85% Concentrated <40%

Sulfuric Acid <30% Concentrated <50%

Citric Acid <20% Concentrated <10%

Potassium Hydroxide Concentrated Concentrated Concentrated

Potassium Carbonate Concentrated Concentrated Concentrated

Potassium Silicate Unknown Concentrated Concentrated

3

The chemical concentrations stated in the above table are just a guide. Variations in temperature, pressure, or UV exposure may cause tubing failure which

could lead to serious injury if proper safety precautions are not followed. For this reason it is recommended that the tubing be tested by the user with the desired

chemical in the specic application to determine ultimate suitability before using them. No warranty (neither express or implied) is given that the information in

these tables is accurate or complete or that any material is suitable for any purpose.

English

20

If your pH isn’t in the right range – and that’s 5.5-6.5 for most

plant varieties – your nutrients are likely wasted.

We say that’s a problem you don’t need. At Bluelab®, we want our

customers to have optimum growth and the best plants possible. So we’ve

made it easy to raise or lower pH levels, whenever you need, and keep them

just where they should be.

Bluelab®’s pH Up and pH Down are formulated to the highest standards.

Just add what’s required to lift or reduce growing solution acidity. Your

plants will thank you for it. The main thing is, you’ll see the difference in

your harvest. Optimum inputs. Optimum results. Simple.

Bluelab®pH Up and pH Down Solutions

Optimum growth needs optimum pH. And we make optimum simple.

› Bluelab®pH Up 500ml

› Bluelab® pH Up 1 Liter

› Bluelab®pH Up 1 Gallon

› Bluelab®pH Down 500ml

› Bluelab®pH Down 1 Liter

› Bluelab®pH Down 1 Gallon

Available in:

7.0 Accessories, Parts & Guarantee

Bluelab®Peristaltic Pumps

Replacement pump motor and

cassette for Bluelab®PeriPod™.

Quick and simple to replace when required.

All you have to do is order a replacement from your supplier!

Bluelab®Cassette

Replacement cassette for Bluelab®

Peristaltic Pumps.

Quick and simple to replace when required.

All you have to do is order a replacement from your supplier!

Bluelab®Dosing Tubing

Replacement pH and nutrient tubing, 4 meters /

13 feet in length.

For use with Bluelab®PeriPod™and pH adjuster or

nutrient solution.

Dosing tube is specic to version of Bluelab®PeriPod™, so

replacement is easy. Simply order pH or nutrient tubing to suit M

or L type. Bluelab®pH Dosing Tube can be used with undiluted

Bluelab®pH Up or Bluelab®pH Down. Replacement Tubing for

Bluelab®PeriPod M

This manual suits for next models

2

Table of contents

Popular Industrial Equipment manuals by other brands

Leader Evaporator

Leader Evaporator WSE manual

PCB Piezotronics

PCB Piezotronics 394C06 Installation and operating manual

Dover

Dover Marathon V-4224 Operation, maintenance and installation manual

schmersal

schmersal AZM300B-ST-SD2P-A-T Instructions for operation

ABB

ABB EVLunic Series installation manual

RUD

RUD VVGSCH Safety instructions