Belanger CUBE Installation manual

Cube® Installation & Startup Manual

1MANUAL963 Rev03

Cube®Installation and Startup

Belanger® Equipment Owner’s Manual

Cube® Installation & Startup Manual

Copyright 2022

Belanger, Inc®

This manual and the accompanying equipment are protected by United States trademark, copyright, and patent laws. You

may make one copy of this manual. Do not make additional copies of this manual or electronically transmit it in any form

whatsoever, in whole or in part, without the prior written permission of Belanger, Inc.®

The registered trademarks used in this document are the property of their respective owners. The use of such trademarks is

for reference purposes only and does not imply sponsorship or approval of Belanger, Inc.®by these companies or any

companies affiliated with their respective owners.

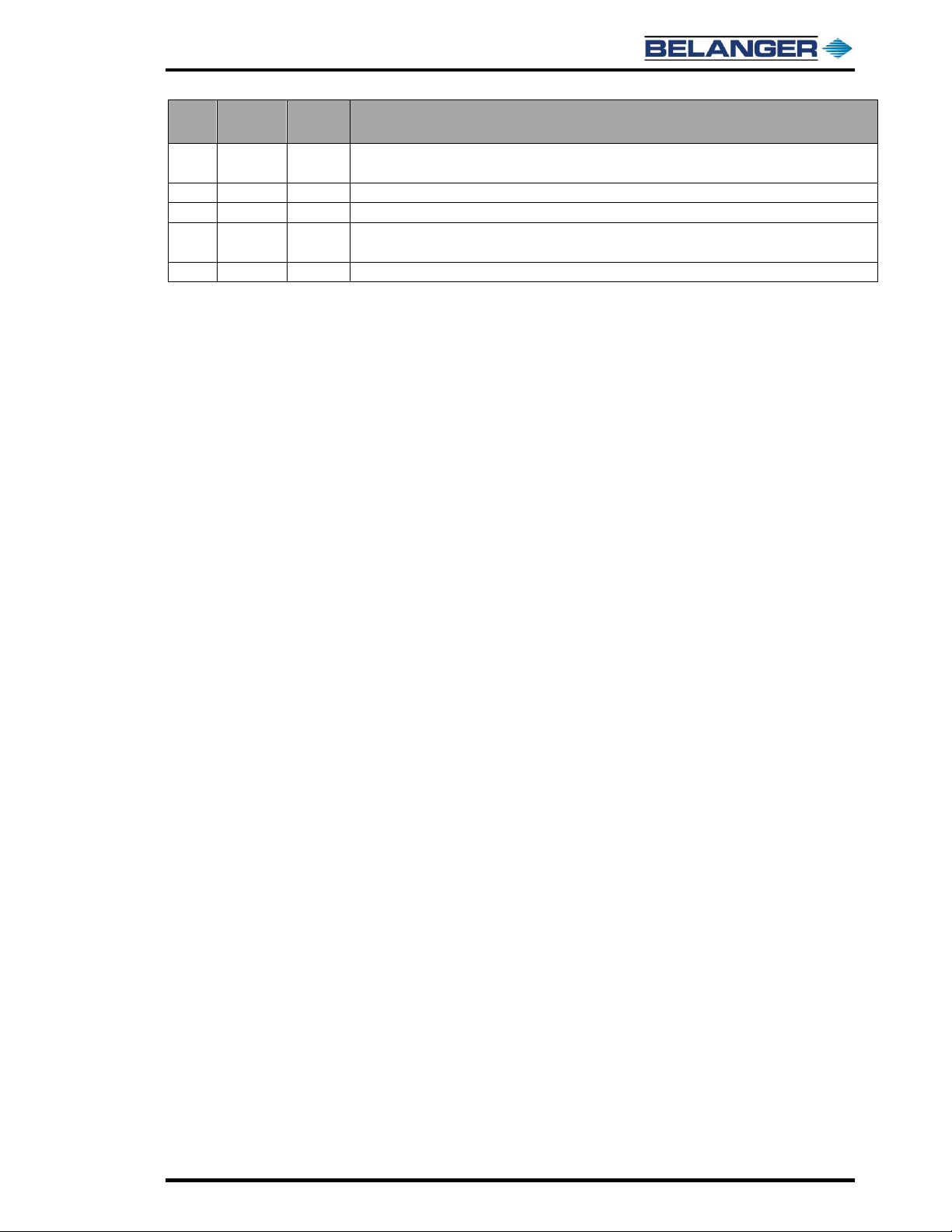

Current Revision Log

1MANUL963 Belanger, Inc. * PO BOX 5470. * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681

Rev

Release

Date

Page

Description

02

09/22/21

5-1

Added an Important Note about the installation of the radiant heating system (per Project

#10151)

03

04/26/22

7-4

Added to Step 10: and the four (4) bearing bolts (per Project #10151)

7-5

Inserted step between Step 13 & 14: Tighten the four (4) bearing bolts on the side wheel

hub assembly. (per Project #10151)

Cube®Installation & Startup

1MANUL963 Belanger, Inc. * PO BOX 5470. * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 iii

Table of Contents

Chapter 1 Introduction.................................................................................................1-1

Belanger Incorporated Limited Warranty .....................................................................................1-1

Operational Warning ....................................................................................................................1-2

Important Safety Information........................................................................................................1-3

Safety Symbols and Signal Words...............................................................................................1-3

IMPORTANT Safety Information –MUST READ ........................................................................1-4

UL Information..............................................................................................................................1-6

Scope of This Manual ..................................................................................................................1-7

Torque Values..............................................................................................................................1-8

Component Identification .............................................................................................................1-9

Chapter 2 Recommended Installation Sequence Checklist.......................................2-1

Main Checklist..............................................................................................................................2-1

Chapter 3 Trades..........................................................................................................3-1

Required Man Hours....................................................................................................................3-1

Scope of Work..............................................................................................................................3-1

Electrical Coordination Meeting ...................................................................................................3-1

Plumbing Coordination Meeting...................................................................................................3-2

Penetrating the Wall for Cube® Utilities.......................................................................................3-2

Chapter 4 Electrical Overview and Panels..................................................................4-1

General.........................................................................................................................................4-1

Electrical Standards Overview.....................................................................................................4-1

Best Practice Methods .................................................................................................................4-3

Cube® Carriage Electrical Cables ...............................................................................................4-5

Cube® Carriage Panel.................................................................................................................4-6

Cube® Building Panel..................................................................................................................4-7

Cube® HMI Panel........................................................................................................................4-8

Cube® Local Network ..................................................................................................................4-9

Cube Static IP Address: ........................................................................................................................4-9

Chapter 5 Getting Started ............................................................................................5-1

Installation Overview....................................................................................................................5-1

Skilled Trades...............................................................................................................................5-9

Equipment Locations....................................................................................................................5-9

Establishing an Origin in the Bay.................................................................................................5-9

Fastening Needs and Other Required Materials........................................................................5-10

Cube® Utility Supplies Recommendations................................................................................5-11

Chapter 6 Frame and Carriage Assembly...................................................................6-1

Frame Overview...........................................................................................................................6-1

Frame Assembly: Rails and Head Beams ...................................................................................6-1

Frame Assembly: Attaching Leg Assemblies.............................................................................6-13

Frame Assembly: Position Frame in Bay...................................................................................6-16

Establish Lines in Bay to Position the Frame Assembly......................................................................6-16

Place & Secure the Frame Assembly in Position.................................................................................6-19

Carriage Prep.............................................................................................................................6-21

Location of Equipment Room ..............................................................................................................6-21

Attach the CAT Track Support Assembly to the Frame.......................................................................6-21

Disengage the Roller Drive..................................................................................................................6-24

Carriage Placement on Frame Assembly: Overview.................................................................6-26

Carriage Placement on Frame Assembly: Preferred Method....................................................6-27

Carriage Placement on Frame Assembly: Alternate Method.....................................................6-32

Attach Safety Stops and Proximity Target to Entrance Rails.....................................................6-38

Attach the Utility Manifold to the Frame.....................................................................................6-39

Connect the Carriage Utility Lines to the Utility Manifold...........................................................6-40

Cube®Installation & Startup

ii Belanger, Inc. * PO BOX 5470. * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL963

Table of Contents

Chapter 6 Frame and Carriage Assembly (cont.) .....................................................6-47

Carriage Movement....................................................................................................................6-47

Re-Engage the Roller Drive ................................................................................................................6-47

Chapter 7 Side Wheel Hub Assemblies.......................................................................7-1

Attach Side Wheel Hub Assemblies to Carriage..........................................................................7-1

Chapter 8 Smart Spray Assemblies.............................................................................8-1

Mount the Smart Spray Assemblies onto the Carriage................................................................8-1

Connect Feed Manifolds to Smart Spray Manifolds.....................................................................8-4

Connect Airlines to Smart Spray Cylinders................................................................................8-10

Connect LED Cable to Smart Spray LED ..................................................................................8-11

Chapter 9 Photo-Eyes...................................................................................................9-1

Photo-Eye: Standard....................................................................................................................9-1

Photo-Eye: Available Add-on Options..........................................................................................9-1

Photo-Eye: Layout and Description Overview..............................................................................9-1

Photo-Eye: General Setup ...........................................................................................................9-3

Photo-Eye: Wiring ........................................................................................................................9-4

Photo-Eye: Undercarriage Wash & Short Bay Considerations....................................................9-5

Load Position Photo-Eyes............................................................................................................9-6

Chapter 10 Undercarriage Option..............................................................................10-1

Undercarriage Overview.............................................................................................................10-1

Undercarriage In-Ground Placement .........................................................................................10-2

Undercarriage In-Ground Connections ......................................................................................10-4

Chapter 11 Air Panels.................................................................................................11-1

Air Panels: Overview..................................................................................................................11-1

Main System Regulator Panel....................................................................................................11-2

Triple Foam Air Panel.................................................................................................................11-3

Single Foam Air Panel................................................................................................................11-4

Chapter 12 Injection Chemical System (ICS)............................................................12-1

ICS Assembly: Overview............................................................................................................12-1

ICS Assembly Installation...........................................................................................................12-1

Connect Chemical Lines from Utility Manifold to ICS ................................................................12-3

Select Metering Tips & Connect Suction Tubing to ICS Injectors..............................................12-5

ICS Assembly: Electrical Connections.......................................................................................12-8

Chapter 13 High-Pressure Pump Assembly..............................................................13-1

Overview.....................................................................................................................................13-1

Installation of High-Pressure Pump Assembly...........................................................................13-2

High-Pressure Pump Assembly Hose Connections...................................................................13-5

High-Pressure Pump Assembly Electrical Connections ............................................................13-8

Chapter 14 MixStir® for Chemical Tire Application..................................................14-1

Overview.....................................................................................................................................14-1

Mounting the MixStir® Assembly ...............................................................................................14-2

MixStir® Assembly Utility Connections ......................................................................................14-4

Chapter 15 Water Softener Option.............................................................................15-1

Water Softener ...........................................................................................................................15-1

Getting Started ...........................................................................................................................15-2

Water Softener Installation CP 213............................................................................................15-3

Model 213S OD / WA and WB Connections..............................................................................15-6

Component Functionality (Scanned)........................................................................................15-10

Water Softener Conversion Charts ..........................................................................................15-12

Cube®Installation & Startup

1MANUL963 Belanger, Inc. * PO BOX 5470. * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 iii

Table of Contents

Chapter 16 Spot Free Rinse (RO) Option..................................................................16-1

Specifications.............................................................................................................................16-1

Safety Warnings.........................................................................................................................16-5

Utility Requirements and Dimensions........................................................................................16-6

Installation..................................................................................................................................16-7

Storage Tank Connections.........................................................................................................16-8

Plumbing and Electrical Connections ........................................................................................16-9

Install Pur-Clean Auto Back Wash Head .................................................................................16-11

Pump Water Hose Connection to Utility Manifold....................................................................16-12

RO Installation Final Check List...............................................................................................16-12

Chapter 17 Signage Options......................................................................................17-1

Wait/Go Sign..............................................................................................................................17-1

Navigational Sign .......................................................................................................................17-1

Combination Sign.......................................................................................................................17-2

Floor Mount................................................................................................................................17-2

Signage for Position Loading Photo-Eyes .................................................................................17-3

Chapter 18 Pneumatic Connections..........................................................................18-1

Main Air to Pneumatic Manifold Assembly.................................................................................18-1

Side Wheel Head Cylinder Circuit Overview..............................................................................18-1

Side Wheel Rail Assembly Cylinder Circuit Overview ...............................................................18-2

Smart Spray Pivot Cylinder Circuit Overview.............................................................................18-3

Smart Spray CTA Foam Generator Circuit Overview................................................................18-3

OverGlow™Pneumatic & Chemical Solution Overview............................................................18-5

Foam Rain Pneumatic & Chemical Solution Overview..............................................................18-6

Triple Foam Pneumatic Circuit Overview...................................................................................18-7

Triple Foam Chemical Solution Overview..................................................................................18-8

Single Foam Pneumatic & Chemical Solution Overview ...........................................................18-9

Chapter 19 Initial Startup Procedure of Cube®........................................................19-1

1) Initial Inspection and Power Up .............................................................................................19-1

2) Inspect and Adjust Axis Drives ..............................................................................................19-1

3) Load ShineMitt® Cleaning Material onto Hubs......................................................................19-3

4) Inspect and Adjust Pneumatics ...........................................................................................19-13

5) Inspect and Adjust the Carriage Assembly..........................................................................19-16

6) Inspect and Adjust Chemical and Water Delivery Systems.................................................19-27

7) Review All Bay and Equipment Room I/O ...........................................................................19-49

8) Configure Applications & Wash Packages to Match Menu Sign and Business Plan ..........19-49

9) Run Test Vehicles................................................................................................................19-49

Chapter 1 - Introduction

Chapter 1

Introduction

Cube®Installation & Startup

1MANUL963 Belanger, Inc. * PO BOX 5470. * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1-1

Chapter 1 Introduction

Belanger Incorporated Limited Warranty

LIMITED WARRANTY:

Equipment:

Subject to the limitations stated below, Seller warrants that the Equipment sold hereunder, which is fabricated by Seller,

shall be free from defects in workmanship and material under normal use and service for a period of 1 year plus 30

days from the date of invoice - CATPumps will be warranted for 2 years from the date of invoice.

Parts:

Subject to the limitations stated below, Seller warrants that the Parts sold hereunder, shall be free from defects in

workmanship and material under normal use and service for a period of 90 days from the date of invoice.

Limitations on All Warranties:

The warranties contained in this Section 13 are subject to the following limitations: (1) they are void if the factory

specifications for operation and maintenance, found in original equipment manuals, and component manuals, are not

followed, or if other than factory authorized erection, alterations or modifications are made to any Parts or Equipment;

(2) defective Parts are warranted to the Purchaser only for repair or replacement through an authorized Purchaser or

Distributor of Seller, or direct with Seller for a period of 13 months from the date of invoice; however, this warranty

excludes all claims for failure resulting from normal wear and tear, improper installation, omission of factory specified

preventative maintenance, misuse, abuse, negligence, third party damages, or acts of God and Purchaser agrees to

submit to and assist Seller or its authorized Purchaser or Distributor in conducting in-warranty inspections of the Goods

including inspection of any Equipment or Parts claimed to be defective by the Purchaser; (3) the cost of providing labor

or repair to replace Equipment and Parts warranted to Purchaser will be included within the warranty only if such claim

is made within 120 days from the date of invoice and then only during normal business hours through an authorized

Purchaser or Distributor of Seller, or direct with Seller, and labor and service provided beyond the labor warranty

period shall be subject to labor charges at the rates established by the local authorized Purchaser or Distributor or

direct with Seller; (4) the warranties shall be void for all Equipment failures and premature Part wear caused by the

use of corrosive chemicals in the wash process, and the following list includes some, but not all, of the particularly

corrosive chemicals that if used in conjunction with Equipment or Parts will void the warranty: Hydrofluoric Acid,

Ammonium Bi-fluoride, Bromic Acid, Muriatic Acid, Sulfonic Acid, Phosphoric Acid, Hydrogen Cyanide, Hydrochloric

Acid, Sodium Hydroxide and Chlorinated Solvents; (5) Seller makes no warranty, express or implied, with respect to

the design or operation of any entire system, in which Seller’s Equipment or Parts sold hereunder are mere

components;(6) in no event shall Seller be liable for any incidental, special, consequential, punitive or exemplary

damages resulting from the furnishing, performance or use of any Goods or services sold pursuant hereto, whether

due to a breach of contract, breach of warranty, negligence or any other claim at law or equity. Seller shall not be

liable for any damages of any kind, including, but not limited to, loss of business; inconvenience, or property damage

of any kind; nor for any damages of whatever nature resulting in any way from the Purchaser’s selection and use of

any chemicals not manufactured exclusively by Seller but used with the purchased Equipment or Parts; or for any

service not expressly provided herein related to or arising from the Equipment or Parts sold. Seller shall not be liable

for damages resulting from Purchaser’s use of any engineering recommendations, sales representations, technical

assistance, advice or data other than that information contained in Belanger manuals; (7) all warranties, express,

implied, or statutory, pertaining to the Equipment and Parts apply to the Purchaser only; are not transferable; are fully

set forth herein; and no addition to or modification thereto shall be binding upon the Seller, unless made in writing and

signed by a duly authorized employee of Seller.

No Other Warranties:

THIS LIMITED WARRANTY FOR EQUIPMENT AND PARTS IS EXPRESSLY IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, WHETHER STATUTORY OR OTHERWISE, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR

PURPOSE. THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR PARTICULAR

PURPOSE CONTAINED IN THE UNIFORM COMMERCIAL CODE –SALES ARE EXPRESSLY

DISCLAIMED.

Copyright ©2020 by Belanger, Inc. All rights reserved. No part of this work may be reproduced or transmitted in any

form or by any means, electronic or mechanical, including photocopying and recording, or by any information storage

or retrieval system, except as may be expressly permitted by the 1976 Copyright Act. Belanger reserves the right to

change or modify the Belanger Inc. Limited warranty without notice.

Cube®Installation & Startup

1-2 Belanger, Inc. * PO BOX 5470. * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL963

Chapter 1 Introduction

Operational Warning

Formulations containing the chemicals listed below are particularly dangerous and should not

be used even at low concentrations:

•Hydrofluoric Acid

•Ammonium Bi-fluoride

•Bromic Acid

•Muriatic Acid

•Sulfonic Acid

•Phosphoric Acid

•Hydrogen Cyanide

•Hydrochloric Acid

•Chlorinated Solvents

Belanger, Inc., does not endorse or condone the use of chemicals that are potentially dangerous

to human health, the environment or property. Belanger recognizes that it is the right and sole

decision of the end user operators of our equipment as to the type and dilution ratio of the

chemicals used in their facilities. We strongly recommend that the end user does not select

products containing any of the chemicals listed above as an ingredient in the wash solutions.

The chemicals listed above are potentially dangerous to human health, and have a detrimental,

deteriorating effect on the equipment and the facility. Be advised that a portion of, or all of your

warranty will be voided if you determine to use any of the chemicals listed above as an ingredient

in the wash solutions in conjunction with your Belanger automatic car wash equipment:

Limitation (4), of Paragraph (8), Limited Warranty, of the Belanger Terms and Conditions of

Sales describes the potential limitation of warranty due to your chemical selection:

(4) This warranty shall be void for all equipment failures and premature component wear

caused by the use of corrosive chemicals in the wash process. The following list includes

some, but not all, of the particularly corrosive chemicals that if used in conjunction with

Belanger equipment will void the warranty: Hydrofluoric Acid, Ammonium Bi-fluoride, Bromic

Acid, Muriatic Acid, Sulfonic Acid, Phosphoric Acid, Hydrogen Cyanide, Hydrochloric Acid,

and Chlorinated Solvents. The Purchaser also agrees to accept the responsibility and liability

for the selection and use of any chemicals listed above.

However, should the end user decide to use formulations containing any of the above

ingredients, the end user should institute a comprehensive training program and implement

detailed operational parameters within their organization for the proper handling and treatment

of such products to minimize the potential dangers involved. Consult your chemical supplier for

assistance in establishing operational guidelines in the use of their products. MSDS (Material

Safety Data Sheet) should be obtained from the chemical supplier before using any chemical

formulation.

CAUTION

During the installation process the installer is responsible for re-tightening

ALL lugs, set screws and terminals located in the electrical panels.

Components may vibrate loose during shipping.

Cube®Installation & Startup

1MANUL963 Belanger, Inc. * PO BOX 5470. * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1-3

Chapter 1 Introduction

Important Safety Information

This section introduces the hazard and safety precautions associated with installing, maintaining, or

servicing this product. Before performing any task on this product, read this safety information and

the applicable sections in this manual, where additional hazards and safety precautions for your task

may be found. Electrical shock could occur and cause death or serious injury if these safe service

procedures are not followed.

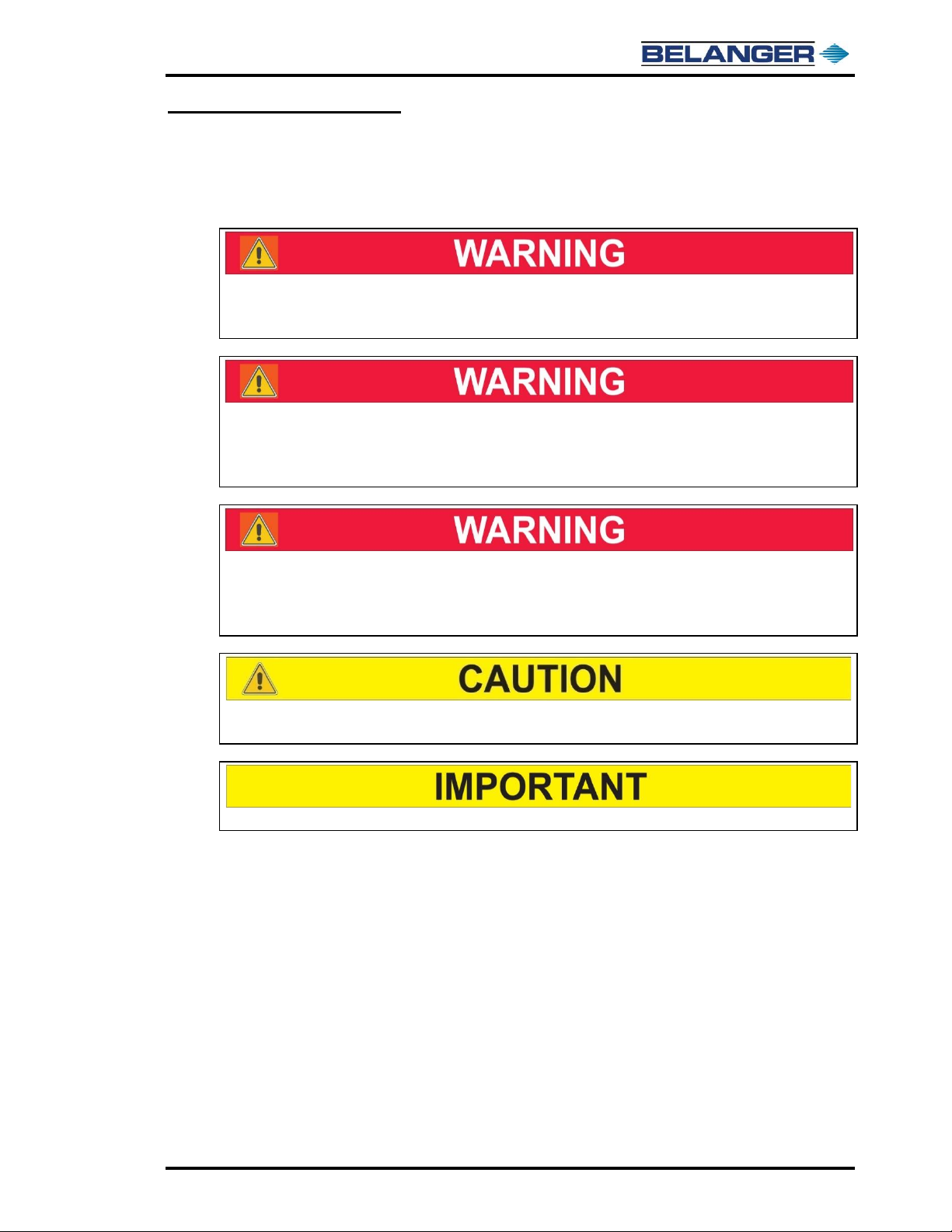

Safety Symbols and Signal Words

Alert Symbol

This safety alert symbol is used in this manual and on warning labels to alert you to

precautions, which must be followed to prevent potential personal safety hazards.

Obey safety directives that follow this symbol to avoid possible injury or death.

Signal Words

The signal words used in this manual and on warning labels tell you the seriousness of particular

safety hazards. The precautions that follow must be followed to prevent death, injury, or damage

to the equipment.

DANGER

This signal word is used to alert you to a hazard or unsafe practice which WILL RESULT IN

DEATH OR SERIOUS INJURY

This alerts you to a hazard or unsafe practice which COULD RESULT IN DEATH OR

SERIOUS INJURY

CAUTION

This signal word designates a hazard or unsafe practice which MAY RESULT IN MINOR

INJURY

CAUTION

When used by itself, CAUTION designates a hazard or unsafe practice, which MAY RESULT

IN PROPERTY OR EQUIPMENT DAMAGE

When used by itself, IMPORTANT designates information that should be followed exactly as

written.

Read the Manual

Read, understand, and follow this manual and any other labels or related materials supplied with

this equipment. If you do not understand the procedure, call a Belanger, Inc®. representative at

248-349-7010. It is imperative to your safety and the safety of others to understand the

procedures before beginning work.

Cube®Installation & Startup

1-4 Belanger, Inc. * PO BOX 5470. * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL963

Chapter 1 Introduction

IMPORTANT Safety Information –MUST READ

Safety Warnings

DISCONNECT THE MAIN POWER SUPPLY AND

DISSIPATE ALL POTENTIALLY HAZARDOUS

ENERGY SOURCES PRIOR TO SERVICING OR

MAINTAINING EQUIPMENT

Belanger® recommends that all workers observe the OSHA (U.S. Department of

Labor Occupational Safety & Health Administration) Lockout / Tagout procedure

to dissipate all potentially hazardous energy sources (i.e. - electrical, mechanical,

hydraulic, pneumatic, chemical, thermal, etc.) prior to performing service or

maintenance on machinery and equipment.

Note: Reference the OSHA standard for the Control of Hazardous Energy (Lockout/Tagout), Title 29

Code of Federal Regulations (CFR) Part 1910.147 and the example provided in 1910.147

Appendix A for practices and procedures necessary to disable machinery or equipment, thereby

preventing the release of hazardous energy while employees perform servicing and maintenance

activities. The standard outlines measures for controlling hazardous energies –electrical,

mechanical, hydraulic, pneumatic, chemical, thermal, and other energy sources.

Note: Reference the OSHA standard 29 CFR 1910.331 to 29 CFR 1910.335 for safe work practices to

protect employees working on electrical circuits and equipment. This section requires workers to

use safe work practices, including lockout and tagging procedures. These provisions apply when

employees are exposed to electrical hazards while working on, near, or with conductors or systems

that use electrical energy.

Note: Both referenced OSHA standards can be found at the following website:

http://www.osha.gov/law-regs.html. Browse to the General Industry tab under the Find an OSHA

Standard heading, scroll down to the link of interest and click on it.

Doing so will prevent unexpected energization, startup, or release of hazardous

energy while maintenance and servicing activities are being performed.

Cube®Installation & Startup

1MANUL963 Belanger, Inc. * PO BOX 5470. * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1-5

Chapter 1 Introduction

IMPORTANT Safety Information –MUST READ

Safety Warnings

BE SURE TO OBSERVE OPERATING ENVELOPE. EQUIPMENT MAY

START UNEXPECTEDLY. OVERHEAD, ROTATING AND/OR MOVING

COMPONENTS COULD RESULT IN SERIOUS INJURY OR DEATH.

BE AWARE OF FOREIGN OBJECTS IN THE AREA SURROUNDING A

ROTATING PIECE OF EQUIPMENT. OBJECTS MAY BECOME TANGLED

WITH EQUIPMENT AND COULD RESULT IN SERIOUS INJURY OR

DEATH.

CONSULT A TRAINED ELECTRICIAN. ONLY TRAINED OR AUTHORIZED

INDIVIDUALS KNOWLEDGEABLE IN THE RELATED PROCEDURES

SHOULD INSTALL, INSPECT, MAINTAIN OR SERVICE THIS

EQUIPMENT.

BE AWARE OF HAZARDS ASSOCIATED WITH EQUIPMENT INSTALLED

ON THE FLOOR THAT MAY BE A TRIP HAZARD.

BE SURE TO SAVE THESE INSTRUCTIONS.

It is imperative to your safety and the safety of others to always follow

safe work procedures.

Cube®Installation & Startup

1-6 Belanger, Inc. * PO BOX 5470. * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL963

Chapter 1 Introduction

UL Information

This applies when an optional door controller is installed

To reduce the risk of severe injury or death to persons all material and

instructions intended for Belanger® system and door operator shall be

read and comprehended. If materials/instructions are not present, they

must be obtained prior to beginning installation/modification.

The Door Control System shall not be installed at locations that don’t

provide a Service entrance. The service opening shall be labeled as an

exit and placards installed on vertical door indicating no pedestrians.

The Belanger® system is not intended for use as source of preventing

injury to persons, nor is it intended for entrapment or obstruction

protection as described in UL 325. This equipment is intended to

enhance the system by signaling the doors desired position but be

overridden by operator’s safety features. The operator that is in direct

control of the door must independently provide entrapment protection

in accordance with UL325. Installation of the Belanger® system shall

not interfere with primary or secondary entrapment protection, nor

interfere with any provided safety features of the door operator.

The installer shall evaluate the existing/new operator requirements for

maintaining UL325 compliance, Examples include loss of being in

accordance when parallel connections are made to up/down buttons,

or loss of being in accordance when upward motion brings door

within 2 feet of a solid object, etc.

Cube®Installation & Startup

1MANUL963 Belanger, Inc. * PO BOX 5470. * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1-7

Chapter 1 Introduction

Scope of This Manual

This Introduction Section is intended to:

•Address the installation portion only.

•Help you to understand how the installation manual is organized.

•Encourage planning and organization.

•Address safety issues.

Installation Manual

This is the manual that covers the installation and initial startup of a Cube®system. In this

manual there is very little content as to the operation, maintenance, troubleshooting and

replacement parts of the Cube® system. For those items please refer to the Cube®

Maintenance manual and any other supplied support documents.

How the Manual is Organized

The installation manual starts off with a "punch list" of activities that must be performed during

the installation phase. The list is fairly comprehensive and provides a general order in which

the tasks should be completed to minimize installation time.

This list also acts as a directory for the remainder of the manual. Now is a good time to review

the Recommended Installation Sequence checklist in chapter 2.

The last section of the installation manual is concerned with initial startup. A checklist format

is provided as a walk- through of starting up and fine tuning the Cube®system.

Planning and Organization

The installation manual assumes that your Belanger® Representative has already visited the

site, taken measurements, and quite possibly sent drawings showing equipment locations.

The installation manual also assumes that all these items have been thoroughly reviewed by

the site General Contractor and Owner. If that is not the case, now is the time to do so. For

your convenience, the "Getting Started" section reiterates some of the critical points of a

Cube®installation. Primarily, the “Getting Started” section addresses equipment placement

and electrical considerations to ensure the Cube®system is installed successfully. If there

is a planning question not covered in this manual, please contact your Belanger®

Representative immediately.

Ensure a Safe Work Environment

The job site can be a hectic place. Often deadlines control the pace. Please keep, Job Site

Safety, in mind at all times. Proper use of all safety gear (safety glasses, hard-hats, footwear,

shields, guards, etc.) is imperative. Be aware of electrical concerns (exposed conductors,

extension cords, proximity to water, power tool maintenance, etc.). Be sure to obey OSHA

Lockout/Tagout procedures (Refer to 29 CFR 1910.147 and the example in 29 CFR

1910.147 Appendix A) and that everyone on site understands this process. Rigging (forklift

operation) is another concern. Minimize slip, trip, and fall potentials consistently. In short, be

aware of OSHA considerations, in addition to rules and regulations put in place by your local

authorities.

It is imperative to your safety and the safety of others to always follow safe

work procedures.

Cube®Installation & Startup

1-8 Belanger, Inc. * PO BOX 5470. * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL963

Chapter 1 Introduction

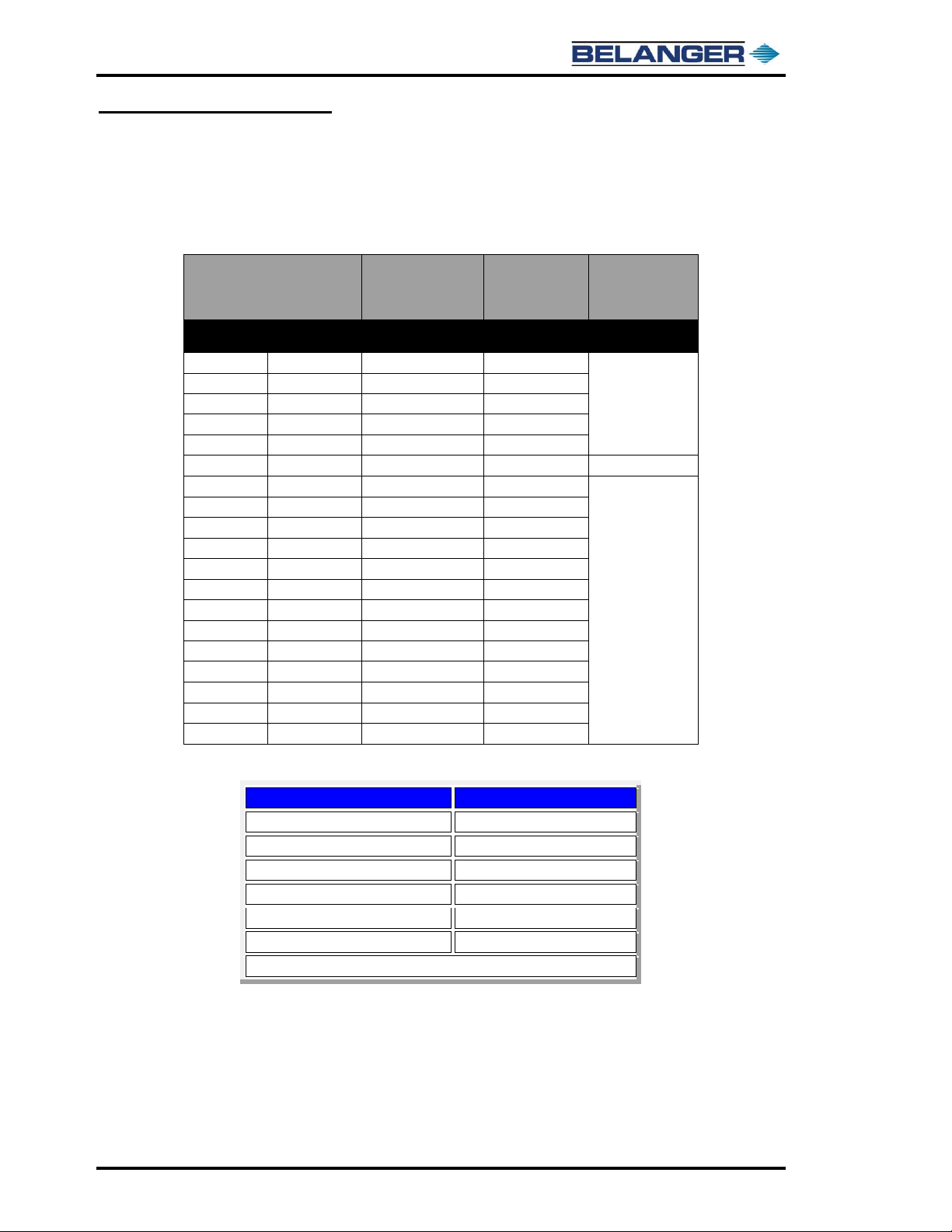

Torque Values

The following chart represents torque values for Grade-5, Stainless Steel Grade 18-8, and Grade-8

fasteners, which are the common fasteners used on Belanger® equipment.

Information provided by Engineers Edge

Torque Values = FT - lbs.

SAE Grade 5

120,000 PSI

Medium Carbon

Heat Treated Steel

Stainless Steel

Grade 18-8

SAE Grade 8

150,000 PSI

Medium Carbon

Alloy Steel

Bolt Size

Inches

Coarse

Threads/Inch

Torque Values

(FT*LBS)

Torque Values

(FT*LBS)

Torque Values

(FT*LBS)

#10

24

NA

2

1/4

20

10

6

5/16

18

19

11

3/8

16

33

20

7/16

14

54

31

1/2

13

78

43

120

9/16

12

114

57

5/8

11

154

93

3/4

10

257

128

7/8

9

382

194

1

8

587

287

1 1/8

7

794

NA

1 1/4

7

1105

NA

1 3/8

6

1500

NA

1-1/2

6

1775

NA

1 5/8

5.5

2425

NA

1 3/4

5

3150

NA

1 7/8

5

4200

NA

2

4.5

4550

NA

Bolt Torque Factors

LUBRICANT OR PLATING

TORQUE CHANGES

Oil / Anti-seize

Reduce torque 15% to 25%

Dry Film (Teflon™ or moly based)

Reduce torque 50%

Dry Wax (Cetyl alcohol)

Reduce torque 50%

Chrome plating

No change

Cadmium plating

Reduce torque 25%

Zinc plating

Reduce torque 15%

Information provided by raskcycle.com

Torque values should be reduced if using lubricants such as anti-seize.

Other manuals for CUBE

1

Table of contents

Other Belanger Industrial Equipment manuals