Introduction

About this Manual

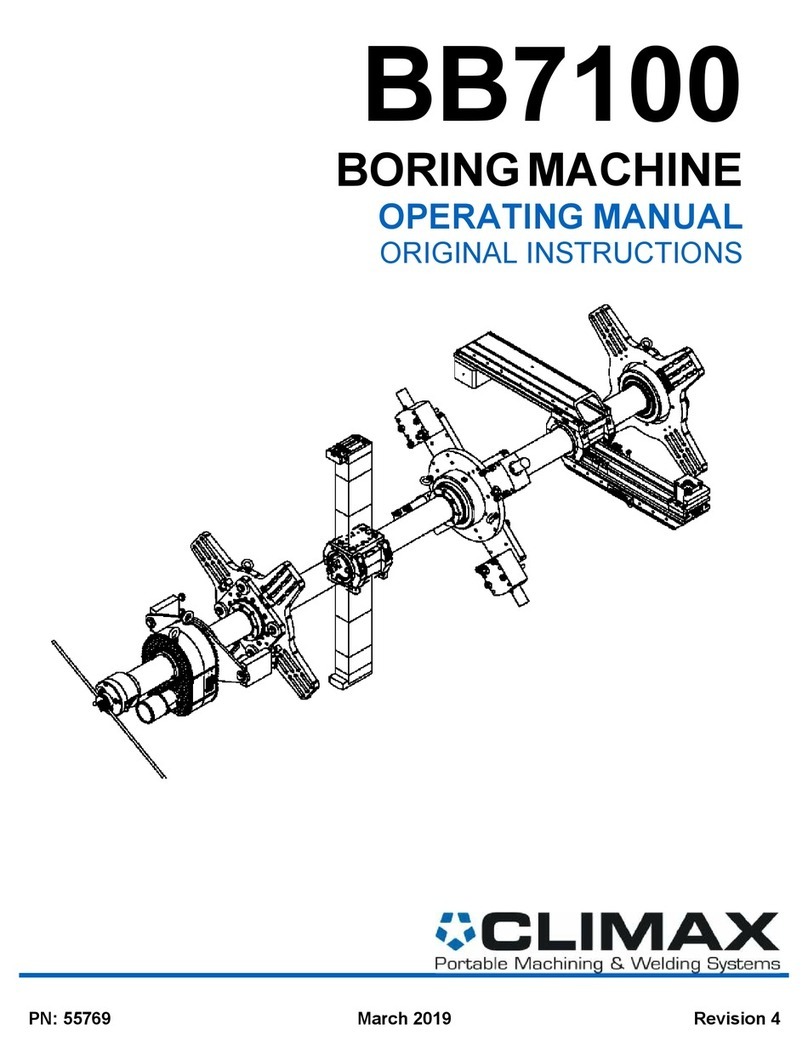

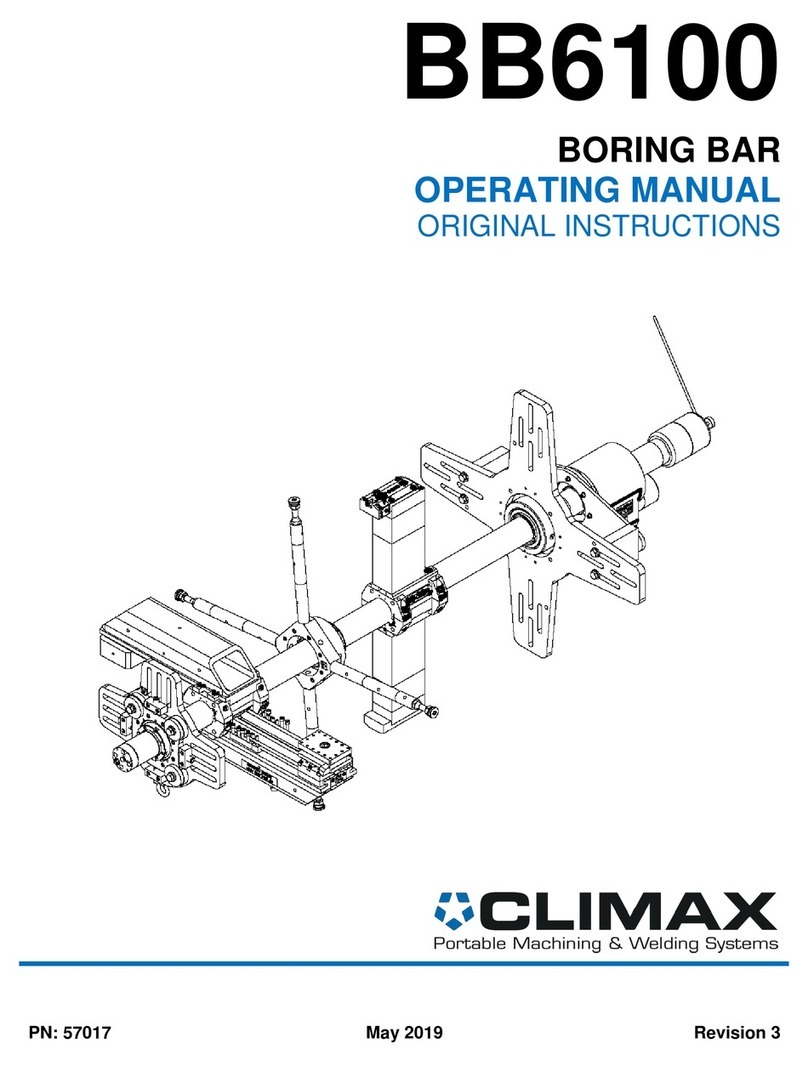

CLIMAX machines are highly configurable with many options and accessories. This manual

covers the use and operation of all of those possible options. The machine configuration

purchased by a customer may not contain all of the options and accessories in this manual. If

a specific machine application requires additional options or accessories, please contact

CLIMAX for assistance in obtaining the needed components.

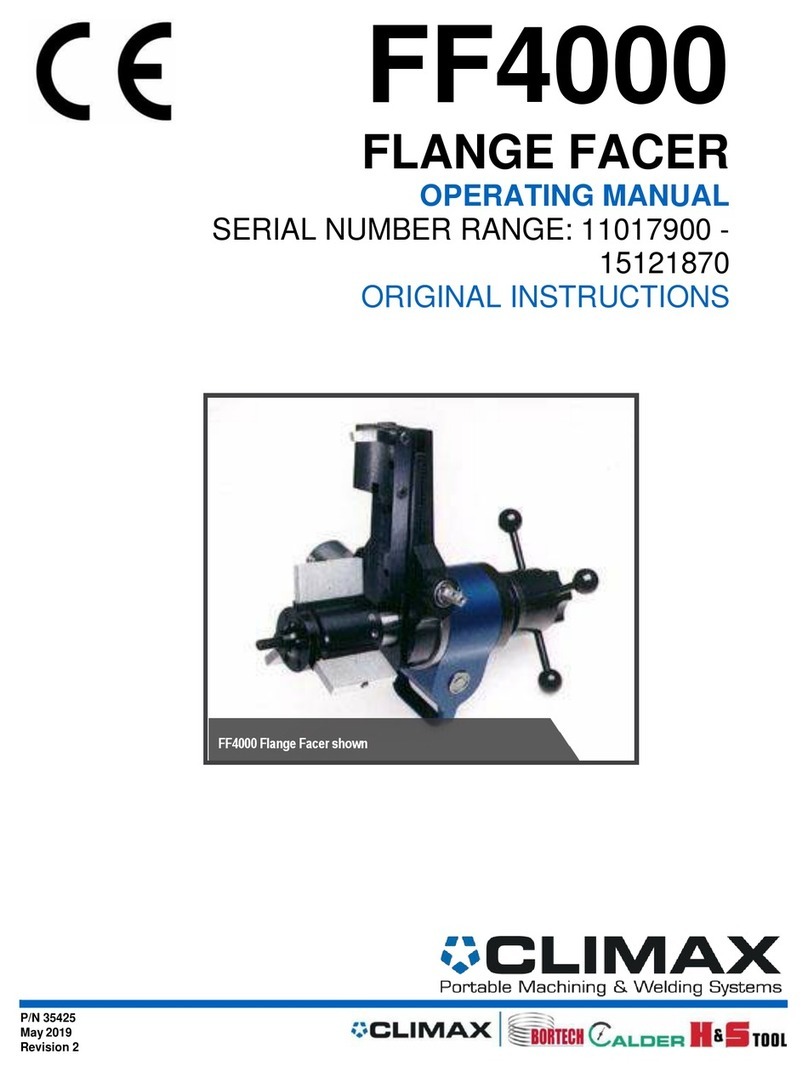

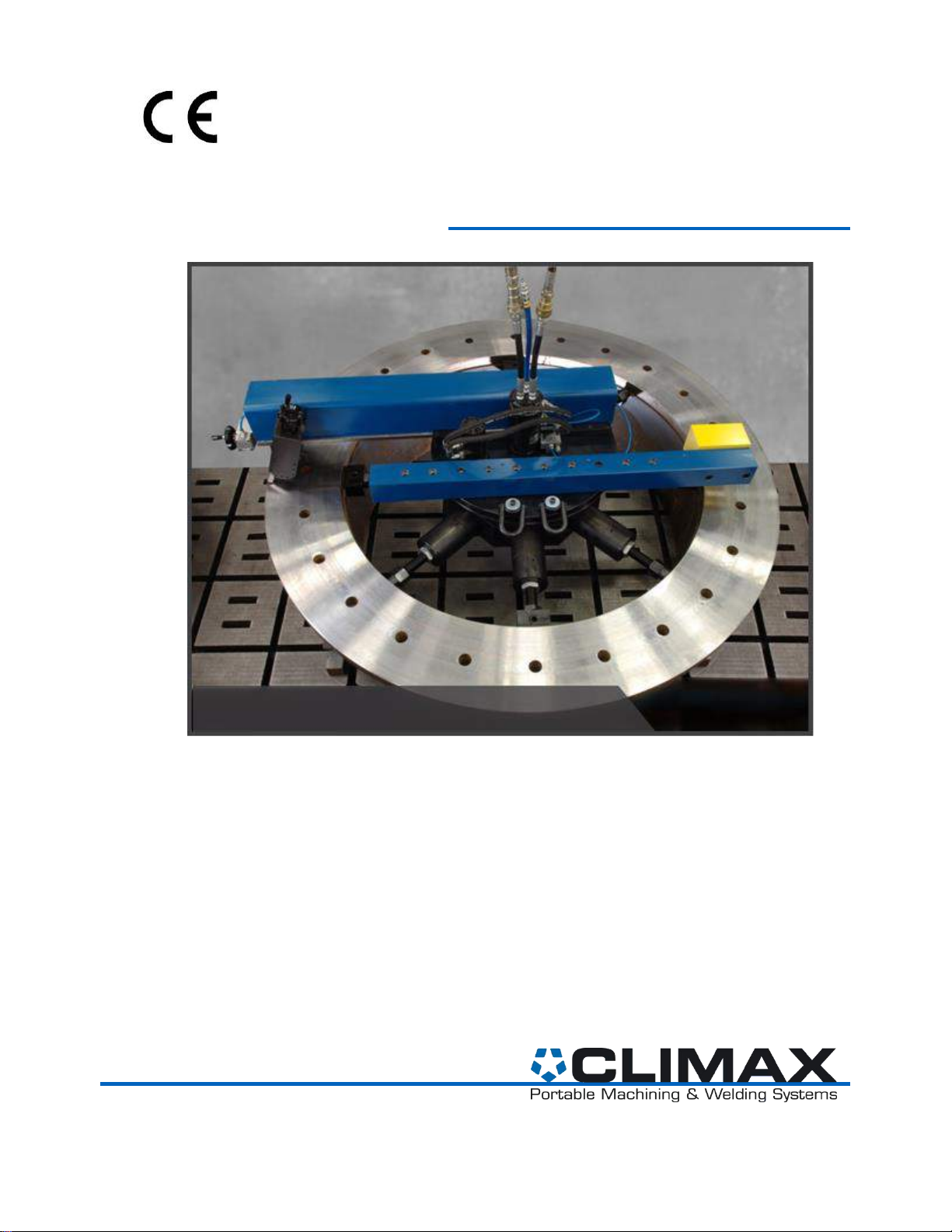

This manual describes the operation and maintenance of your flange facer. The machine is

designed for facing, beveling and grooving operations. All parts meet CLIMAX’s strict quality

standards. For maximum safety and performance, you must read the entire manual before

operating the machine.

Safety Guidelines

The primary safety challenge for most on-site maintenance is that repairs are often done under

difficult conditions.

CLIMAX leads the way in promoting the safe use of portable machine tools. Safety is a joint

effort. As the operator of this machine, you are expected to do your part by closely examining

the job site and following the operating procedures outlined in this manual, your own company

rules, and local regulations.

Observe the following safety precautions when operating or working around the machine.

Training –Before operating this or any machine tool, you should receive instruction from a

qualified trainer. Contact CLIMAX for machine-specific training information.

Risk assessment –Working with and around this machine poses risks to your safety. You,

the end user, are responsible for conducting a risk assessment of each job site before

setting up and operating this machine.

Intended use –Use this machine in accordance with the instructions and precautions in

this manual. Do not use this machine for any purpose other than its intended use as

described in this manual.

Personal protective equipment –Always wear the appropriate personal protective gear

when operating this or any other machine tool. Eye and ear protection are required

when operating or working around the machine. Flame-resistant clothing with long

sleeves and legs is recommended when operating the machine, as hot flying chips from

the workpiece may burn or cut bare skin.

Work area –Keep the work area around the machine clear of clutter. Keep all cords and

hoses away from the work area when operating the machine.

Lifting –Many CLIMAX machine components are very heavy. Whenever possible, lift the

machine or its components using proper hoisting equipment and rigging. Always use

designated lifting points on the machine. Follow all lifting instructions in the setup

procedures of this manual.

Lock out/tag out –Lock out and tag out the machine before doing maintenance.