Bluelight Automatic Technology BL2000-QKB-V3 User manual

BL2000-QKB-V3

Destination Group Control System

User Manual

Ver: 1.6

Contents

1Introduction.................................................................................................................................... 1

2User Guide for Group Destination Control System ....................................................................... 3

2.1 System Block Diagram.............................................................................................................3

2.2 System Configuration.............................................................................................................. 3

2.2.1 Group Control Board .......................................................................................................3

2.2.2 LCD Floor Selector............................................................................................................ 3

2.2.3 Scope of Application........................................................................................................ 3

2.2.4 Port Definition and Specification of BL2000-QKB-V3.....................................................4

2.2.5 System Configuration ......................................................................................................4

2.2.6 Group Destination Control System Schematic Diagram ................................................5

2.3 Keypad Operation Description ...............................................................................................5

2.4 LCD Display Flowchart and Description.................................................................................. 6

2.5 LCD Keypad Display Description............................................................................................. 7

2.6 Group Control Status and Communication ............................................................................7

2.7 Each Elevator Status and Description..................................................................................... 7

2.8 Password Inputting .................................................................................................................8

2.9 Save Parameter ....................................................................................................................... 8

2.10 Password Changing .................................................................................................................9

2.11 General Parameter Settings.................................................................................................... 9

2.11.1 Group able set ................................................................................................................. 9

2.11.2 S.X.N quotient................................................................................................................10

2.11.3 Mode Select ...................................................................................................................10

2.11.4 Set System Time ............................................................................................................11

2.11.5 Set On Duty Time / Off Duty Time................................................................................11

2.11.6 Set Non-Stop Floor ........................................................................................................12

2.11.7 Set Homing Floor ...........................................................................................................13

2.12 Group Control Elevator Bottom Floor Setting......................................................................14

2.13 Group Control Elevator Passenger Full Setting .................................................................... 15

2.14 Regular Hall Operation Panel Configuration Option for Each Floor....................................16

2.15 Setting Group Control Floor Numbering ..............................................................................16

2.16 Setting Requirement for Group Control versus elevator numbers (A, B, C, …) ..................17

2.17 Controller Parameter Settings Requirement for Group Control ......................................... 17

3Destination Control Floor Selector Installation and Usage.........................................................18

3.1 SJT-MBC-V1 Destination Control Floor Selector Introduction.............................................18

3.1.1 Dimension......................................................................................................................18

3.1.2 Instruction......................................................................................................................19

3.2 SJT-EPAD-097-QK Touch Screen Destination Floor Selector (9.7-inch)...............................24

3.2.1 Dimension......................................................................................................................25

3.2.2 Instruction......................................................................................................................26

3.2.3 Wiring Description.........................................................................................................30

4Cabin Vertical Display Installation and Description ....................................................................31

4.1 Function Description............................................................................................................. 31

4.2 Product Appearance and Installation Dimensions ..............................................................31

4.3 Terminal Port Definition and Specification..........................................................................33

4.4 Floor Display Setting .............................................................................................................34

1

Shenyang Bluelight Automatic Technology Co., Ltd.

BL2000-QKB-V3 Destination Group Control System User Manual

1Introduction

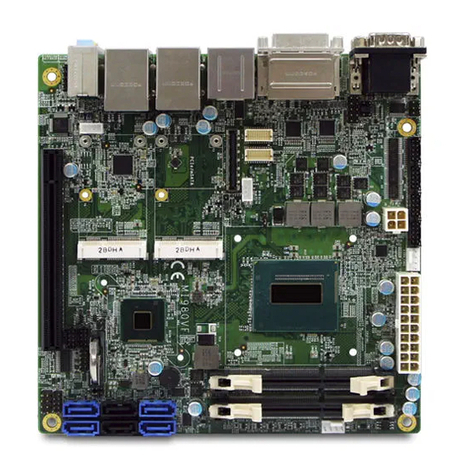

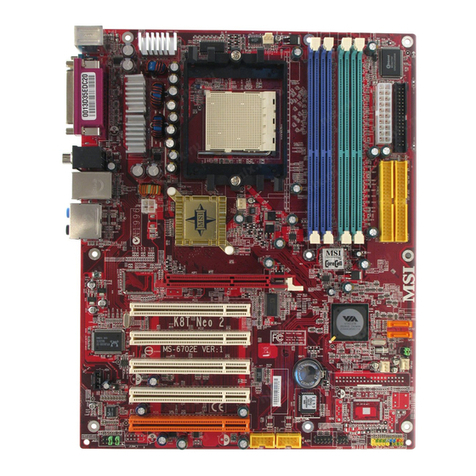

149mm

159mm

86mm

96mm

4-Φ3.5

Figure 1.1 Layout and dimension of Group Destination Control motherboard BL2000-QKB-V3

BL2000-QKB-V3 is an advanced and intelligent Group Destination Control System. The

advantages of group destination control system are:

1. Prior to assigning the elevator service, the target floors to be reached by the passenger

sand the number of passengers is already known, hence, the operational efficiency is

improved, and waiting time is reduced.

2. It has great advantage when using centralized scheduling for intensive crowded floors, it

can effectively divert passengers and to speed up the dispatching of passengers.

3. Immediately forecast passengers to take the elevator number, guiding passengers to

service elevators, delighting the passengers, avoiding passengers always monitor all the

elevator to service and the direction of operation and then choose to ride on the elevator.

Group Destination Control System has integrated the expert system and fuzzy logic control system,

and other optimization scheduling algorithm, based on CAN bus communication technology to

ensure that the Group Destination Control System is always in high efficient and safe operation.

2

Shenyang Bluelight Automatic Technology Co., Ltd.

BL2000-QKB-V3 Destination Group Control System User Manual

Group Destination Control System has five types of operation modes:

On Duty Mode –During the pre-set time, all elevators are given the highest priority to the up-travel

hall calls to serve the up-peak traffic effectively.

Off Duty Mode –During the pre-set time, all elevators are given the highest priority to the down-

travel hall calls to serve the down-peak traffic effectively.

Equalization Mode –Optimizing the allocation of the elevator calls as per the principle of the shortest

responding time to the hall the calls.

Standby Mode –During the Balance Mode operation, if no car call or hall call is made for 3 minutes,

the elevators will be assigned to standby at the first floor of each region, this is to increase the

efficiency of attending hall call registration.

Base Floor Mode –After starting the Base Floor mode, during the equalization mode, if the base floor

does not have an elevator, the system will allocate a nearest elevator to the base floor to standby.

The Group Destination Control System is composed of the group control panel and the LCD Floor

Selector. The floor selector sends the hall call information to the group control panel, the group

control board calculates the shortest time to reach the target floor and delivers the passengers to

the destination floor, and then the group control panel will broadcast the allocation of information

to the main control panel and LCD floor selector, the LCD floor selector will then prompt the

passengers to the assigned elevator number.

3

Shenyang Bluelight Automatic Technology Co., Ltd.

BL2000-QKB-V3 Destination Group Control System User Manual

2User Guide for Group Destination Control System

2.1 System Block Diagram

Destination Group

Controller

CAN1 CAN2

Elevator

Controller

Car Control Board and

Destination Floor Display

Nth floor display

panel

Nth floor hall call

3rd floor display

panel

3rd floor hall call

2nd floor display

panel

2nd floor hall call

1st floor display

panel

1st floor hall call

Elevator

Controller

Nth floor

selector

3rd floor

selector

2nd floor

selector

1st floor

selector

Nth floor

selector

3rd floor

selector

2nd floor

selector

1st floor

selector

Nth floor display

panel

Nth floor hall call

3rd floor display

panel

3rd floor hall call

2nd floor display

panel

2nd floor hall call

1st floor display

panel

1st floor hall call

Car Control Board and

Destination Floor Display

Figure 2.1 Group Destination Controller –Communication Network and System Block Diagram

2.2 System Configuration

2.2.1 Group Control Board

1. Using ST industrial control microcontroller;

2. Using CAN Bus for serial communication;

3. Equipped with RS232 port (connecting to PC through this interface, to check the call response

and each elevator status).

2.2.2 LCD Floor Selector

1. Using Philips 32-bit industrial control microcontroller;

2. Using CAN bus for serial communication;

3. Keyboard type of operation and LCD display.

2.2.3 Scope of Application

1. Control method: Elevator selective-collective control, 2 to 8 car group control;

2. Maximum number of floors: 64 floors

4

Shenyang Bluelight Automatic Technology Co., Ltd.

BL2000-QKB-V3 Destination Group Control System User Manual

2.2.4 Port Definition and Specification of BL2000-QKB-V3

Table 2.1 Group Control Board Port Definition and Specification

Port

Terminal

Position

Definition

Purpose

J1

GND3

J1-1

0V

Power Source and

Communication

J1-2

GND3

J1-3

0V

5V_IN

J1-4

5V Power Input

J1-5

H1

J1-6

Communication with main

control board group port

L1

J1-7

GND3

J1-8

0V

H2

J1-9

Communication port for

destination floor selector

L2

J1-10

2

+5V

J2-1

+5V Power Output

For RS485 (Spare)

DA+

J2-2

RS485+ Communication

DA-

J2-3

RS485- Communication

GND3

J2-4

0V

JP1

+5V

JP1-1

+5V Power Output

For RS232 (Programming)

RX

JP1-2

Transmitting

TX

JP1-3

Receiving

JP1-4

GND3

JP1-5

0V

JP1-6 to

J1-9

5V_IN has maximum load of 200mA.

2.2.5 System Configuration

Table 2.2 System Configuration

Component

Part Name

Configuration

Machine Room

Group Control Board

BL2000-QKB-V3

Must be configured

Elevator Main Control Board

BL3000-STB or BL6 Integrated

Must be configured

Landing Device

Destination Floor Selector

SJT-MBC-V1

Must be configured

(select from two options*)

Hall Operation Panel

Hall Lantern and Controller

BL2000-HQK-V9

Optional (recommended)

Arrival Chime

Optional

Destination Landing Dot

Matrix Display

BL2000-HBH-N3

Optional

Inside Cabin

Car Operating Panel

Optional (recommended)

Destination Vertical Dot

Matrix Display

BL2000-HBH-N4

Optional (recommended)

*Note: In destination group control system, it is applicable to use destination floor selector for

some floors and use the regular hall operation panel for the rest floors. For the floors that are

using destination floor selector, the number of installed destination floor selector is optional. For

the floors that are using hall operation panel, one hall operation panel is required for each

elevator, and the parameter IO GDCS Floor must be configured, refer to 2.14 for detail.

5

Shenyang Bluelight Automatic Technology Co., Ltd.

BL2000-QKB-V3 Destination Group Control System User Manual

2.2.6 Group Destination Control System Schematic Diagram

Power Supply 1

Group Control

Board

J1-3

J1-4

J1-6

J1-7

J1-8

J1-9

J1-10

GND

+5V

H1

L1

H1

L1

GND

GND

H2

L2

Power Supply 2

+5V

+24V

GND

Nth floor

destination

selector

PW-1

PW-2

PW-3

PW-4

+24V

GND

H

L

2nd floor

destination

selector

PW-1

PW-2

PW-3

PW-4

+24V

GND

H

L

1st floor

destination

selector

PW-1

PW-2

PW-3

PW-4

+24V

GND

H

L

Power Supply 3 +24V

GND

Nth floor

destination

selector

PW-1

PW-2

PW-3

PW-4

+24V

GND

H

L

2nd floor

destination

selector

PW-1

PW-2

PW-3

PW-4

+24V

GND

H

L

1st floor

destination

selector

PW-1

PW-2

PW-3

PW-4

+24V

GND

H

L

Destination Floor

Selector (depends

on the location,

every two elevators

have one selector

installed in the

middle of is

recommended)

Group Control

Cabinet

Group Control

Communication

Terminal

Elevator Controller

1~N

Hall Call and COP

Communication

Terminal

COP

Control

Board

Front and Rear

Cabin Display

Nth Floor Hall

Lantern/Chime

Controller

Nth Floor Hall

Call Board

Nth Floor

Display Panel

Elevator Control

Configuration Diagram

2nd Floor Hall

Lantern/Chime

Controller

2nd Floor Hall

Call Board

2nd Floor

Display Panel

1st Floor Hall

Lantern/Chime

Controller

1st Floor Hall

Call Board

1st Floor Display

Panel

Figure 2.2 Group Destination Control System Schematic Diagram

Remark: If cabin destination display is used, then landing destination display will not be used.

2.3 Keypad Operation Description

LCD Keypad has six keys, the arrangement and definition as below:

Figure 2.3 Key arrangement and definition

ESC

AB C D E F G H

-1 2 3 4 5 * * *

Menu

Λ

V

>

Enter

Running direction

Elevator number

Current floor

number

Elevator Group

Comm. Error

6

Shenyang Bluelight Automatic Technology Co., Ltd.

BL2000-QKB-V3 Destination Group Control System User Manual

Table 2.3 The functions of the keys

Key

Description

Menu

Unconditionally return to main menu.

Enter

To enter to the next level of menu, to confirm the modified value

Esc

To escape to the upper level of menu or to cancel the amendment.

>

Right scrolling cursor or to view communication or group status in main menu.

Λ

To scroll up one screen, to increase parameter value by one or to select YES (ON).

V

To scroll down one screen, to decrease parameter value by one or to select NO (OFF).

Group control board (QKB) uses the LCD display and keypad operation to set the group control

system operating modes, hall call up and down, car call availabilities, system date and time, On duty

and Off duty times, and to view each elevator running status.

2.4 LCD Display Flowchart and Description

Figure 2.4 LCD Display and Set Flowchart

A B C D E F G H

-1 2 4 15 * * * *

Balance mode

Sys: Ok

Elevator state

Enter

Logic state

Enter

Elevator state

A-

Enter

Elevator State

H-Enter

Input Password

0000

General Para

Enter

Save Para

Enter

New Password

Enter

Group able set

Enter

S.X.N quotiety

K1:2 K2:2 K3:2

Mode select

Enter

Time Set

16-03-16

10:28

S Start Time

08:10

S Stop Time

09:00

X Start Time

16:55

X Stop Time

17:30

Esc

Esc

Esc

Enter

Enter

Esc

Esc

Esc

Esc

Esc

Esc

Esc

Esc

Esc

Esc

>

V

N: Stop Floor

Enter

N: Homing Floor

Enter

Esc

Esc

N: Passenger Set

13

IO GDCS Floor

Enter

Set Indication

Enter

7

Shenyang Bluelight Automatic Technology Co., Ltd.

BL2000-QKB-V3 Destination Group Control System User Manual

2.5 LCD Keypad Display Description

A, B, C, D, E, F, G and H are representing the eight elevator numbers within the group control; the

arrow beside each is indicating the elevator traveling direction; the number or alphabet below each

elevator number is indicating the current actual floor number; if an asterisk (*) is indicated under the

elevator number, it means there is communication error or abnormal with the group control, or

group control function of the elevator has been see to “NO”, or “Group able set” is set to “NO”.

2.6 Group Control Status and Communication

Balance mode : Hall calls are being divided into groups so as to serve the hall call registration as

soonest as possible.

On duty mode : Elevators are assigned to homing floor to serve up peak traffic during the pre-

set time.

Off duty mode : One elevator is assigned to serve up traffic, the rest of the elevator in the group

are assigned to serve down traffic.

Sys: ok : Group control communication is normal.

Sys: ET : Group control communication is abnormal.

2.7 Each Elevator Status and Description

Table 2.4 Elevator Status and Description

Elevator State

A-Enter

A00A01A02A03

A04A05A06A07

Enter

Esc

A08A09A10A11

A12A13A14A15

A16A17A18A19

A20A21A22A23

Elevator State

Enter

Enter

Esc

Elevator State

H-Enter

Balance mode

Sys: ok 000 000

AB C D E F G H

-1 2 3 4 2 * 19 *

Running direction

Elevator number

Current floor

number

Elevator Group

Comm. Error

8

Shenyang Bluelight Automatic Technology Co., Ltd.

BL2000-QKB-V3 Destination Group Control System User Manual

Item

Description

Item

Description

Item

Description

X00

Parking

X08

Over Load

X16

Load Weighing Fault

X01

Total Control

X09

Light Load

X17

Car Comm. Fault

X02

Inspection

X10

Full Load

X18

X03

Door Interlock

Contact

X11

Attendant Y/N

X19

Emergency Stop

X04

Speed Change

X12

Fault

X20

Door Zone

X05

Running

X13

Fireman

X21

Door Fault

X06

Down Direction

X14

VIP

X22

Door Open Fault

X07

Up Direction

X15

Buzzer

X23

Door Close Fault

Note: “X” is representing the elevator number from “A” to “H”.

2.8 Password Inputting

Password (User Level or Factory Level) must be correctly entered in order to enter into Parameter

Setting menu.

In the Input Password menu, use “Λ” key to increase the number, or “V” key to decrease the number,

use “>” key to scroll the desired password position. Press “Enter” key to enter the correct password,

hence, to enter the General Parameter setting menu. Or else it will display:

2.9 Save Parameter

Save Para

Enter

Save Para

Yes?

Enter

Esc

Save Para

Waiting………

Save Para

Success

Enter

Save Para

Failure

Esc

Esc

Password Error

Enter

Input Password

0000 Enter

9

Shenyang Bluelight Automatic Technology Co., Ltd.

BL2000-QKB-V3 Destination Group Control System User Manual

After entering “Save Para” menu, press “Enter” to select “Yes”, the system will automatically save

the amended parameter. “Success” will be displayed if the saving is succeeded, or else “Failure” is

shown. If the saving is failed, please contact factory for further assistance.

Note: Any changes in parameter setting will be effective immediately, however, if “Save Para” is

not performed, when system power is cut off, the changed parameter setting will be reverted to

before value.

2.10 Password Changing

It is for changing and setting new User Password.

2.11 General Parameter Settings

2.11.1 Group able set

Set “Yes” for each elevator in the group bank. If the elevator communication is normal and meeting

the group control condition, then the group control board can control the operation.

Group able set

Enter

Group able set

A: Yes/No

Enter

Esc

Group able set

B: Yes/No

Elevator number

Group able set

C: Yes/No

New Password

Enter

New Password

0 0 0 0

Enter

Esc

10

Shenyang Bluelight Automatic Technology Co., Ltd.

BL2000-QKB-V3 Destination Group Control System User Manual

2.11.2 S.X.N quotient

The value K1, K2 and K3 are for internal use, do not change the factory setting. (Note: “S” = Up Hall

Call, “X” = Down Hall Call and “N” = Car Call)

2.11.3 Mode Select

Mode 0 : Spare, not used.

Mode 1 : On Duty Mode; if “Yes”, during the pre-set “On Duty” time, the Group system will enter

the On Duty Mode.

Mode 2 : Off Duty Mode; if “Yes”, during the pre-set “Off Duty” time, the Group system will

enter the Off Duty Mode.

When “On Duty Mode” is set to “Yes”, during the prefix start working hours, the group control

system will enter On Duty mode; when “Off Duty Mode” is set to “Yes”, during the prefix finish

working hours, the group control system will enter Off Duty mode; if “On Duty Mode” is set to “No”,

the group control system will never enter On Duty mode; similarly, if “Off Duty Mode” is set to “No”,

the group control system will never enter Off Duty mode. If both “On Duty Mode” and “Off Duty

Mode” are set to “No”, then the group control system will be operated in averaging running mode.

Mode Select

Enter

Mode Select

Mode 0: Yes/No

Enter

Esc

Mode Select

Mode 1: Yes/No

Mode Select

Mode 2: Yes/No

S.X.N quotient

K1: 2 K2: 2 K3: 3

11

Shenyang Bluelight Automatic Technology Co., Ltd.

BL2000-QKB-V3 Destination Group Control System User Manual

2.11.4 Set System Time

This is to display and to set the system date & time; YY-MM-DD HH:MM

2.11.5 Set On Duty Time / Off Duty Time

When “On Duty Mode” is set to “Yes”, group control system will enter On Duty mode between the

start and stop On Duty mode times.

When “Off Duty Mode” is set to “Yes”, group control system will enter Off Duty mode between the

start and stop Off Duty mode times.

When “On Duty Mode” and “Off Duty Mode” have been set to “Yes”, if the system time is greater

than “S Start Time” and smaller than “S Stop Time”, the Group system will enter the “On Duty

Mode”; If the system time is greater than “X Start Time” and smaller than “X Stop Time”, the Group

system will enter the “Off Duty mode”.

Note: “S” stands for Up Peak On Duty; “X” is stands for Down Peak Off Duty.

S Start Time

08:20

S Stop Time

09:20

X Start Time

16:20

X Stop Time

17:20

Start time for On Duty Mode

Stop time for On Duty Mode

Start time for Off Duty Mode

Stop time for Off Duty Mode

Set Time

16-03-16 08:18

12

Shenyang Bluelight Automatic Technology Co., Ltd.

BL2000-QKB-V3 Destination Group Control System User Manual

2.11.6 Set Non-Stop Floor

If there are any non-stop floors setting required in the Group control system, the non-stop floor

setting in every main control board must be like the setting in Group control system.

Please be noted that the Main control board is using actual floor number(s) in the non-stop floor

setup, whereas, the Group control system is using absolute floor number(s) in the non-stop floor

setup (Refer to Chapter 2.12 for Group Control Elevator Bottom Floor Setting). If the setup of non-

stop floor is wrong (non-stop floor set in Main control board is not corresponding to the non-stop

floor set in Group control system), the group control system will not be able to distribute the

servicing elevators properly or unable to achieve destination control purposes.

A: Stop Floor

Enter

A: Stop Floor

01: ON / OFF

Enter

Esc

A: Stop Floor

02: ON / OFF

A: Stop Floor

03: ON / OFF

A: Stop Floor

64: ON / OFF

General Para

Enter

A: Stop Floor

Enter

Enter

Esc

B: Stop Floor

Enter

C: Stop Floor

Enter

H: Stop Floor

Enter

13

Shenyang Bluelight Automatic Technology Co., Ltd.

BL2000-QKB-V3 Destination Group Control System User Manual

2.11.7 Set Homing Floor

When the elevators in the group control are idle for 5 minutes (no car calls no hall calls), each

elevator will be dispatched to pre-set individual Homing Floor for waiting.

Remarks:

(1) During Group controlling, the Homing Floor setup of each elevator’s main control board will be

invalid, the Homing Floor of elevator controller will not be the Homing Floor of group control;

(2) The Group control system is using absolute floor number in the Homing Floor setup. (“1” = lowest

floor, so on and so forth) (Refer to Chapter 2.12 for Group Control Elevator Bottom Floor Setting)

A: Homing Floor

Enter

A: Homing Floor

01

Enter

Esc

General Para

Enter

A: Homing Floor

Enter

Enter

Esc

B: Homing Floor

Enter

C: Homing Floor

Enter

H: Homing Floor

Enter

14

Shenyang Bluelight Automatic Technology Co., Ltd.

BL2000-QKB-V3 Destination Group Control System User Manual

2.12 Group Control Elevator Bottom Floor Setting

The purpose of configuring the Bottom Floor of each elevator is to prevent staggered floor, if

elevators A, B, C and D are having the same Bottom Floor, then all settings shall be set to 1. If there

are elevators in a group having different basement floors, then the Bottom Floor shall be correctly

set, for example, elevator A floor numbers are B2, B1, G, 1, 2, 3, while elevator B floor numbers are

G, 1, 2, 3, then Elevator A has the lowest basement floor, the entire group destination control total

floor is 6 floors, therefore:

Elevator A’s lowest floor B2 is considered as 1of the group base floor number, and its Bottom Floor

shall be set to 1;

Elevator B’s lowest floor G is considered as 3of the group base floor number, and its Bottom Floor

shall be se to 3, and so on the other elevators’ Bottom Floor settings.

The following is an example of Bottom Floor setting for Group Destination Control:

There are two elevators, A and B; where, Elevator A has two basement floors, and Elevator B has no

basement floor.

A: Bottom Floor

Enter

A: Bottom Floor

01

Enter

Esc

General Para

Enter

A: Bottom Floor

Enter

Enter

Esc

B: Bottom Floor

Enter

C: Bottom Floor

Enter

H: Bottom Floor

Enter

15

Shenyang Bluelight Automatic Technology Co., Ltd.

BL2000-QKB-V3 Destination Group Control System User Manual

Table 2.5 Example of Bottom Floor setting for Group Destination Control

Absolute Floors of

Destination Control

1

2

3

4

5

6

7

8

…

Absolute Floors of

Elevator A Controller

1

2

3

4

5

6

7

Non-

stop

8

…

Floor Numbering of

Elevator A

B2

B1

G

1

2

3

4

Non-

stop

5

…

Absolute Floors of

Elevator B

X

X

1

2

3

4

Non-

stop

5

6

…

Floor Numbering of

Elevator B

X

X

G

1

2

3

Non-

stop

4

5

…

Note:

“Non-stop” stands for non-stopping floor

“X” stands for unavailable floor

The absolute floor numbers are used as the basic reference for destination control system.

The Bottom Floor settings for Elevator A shall be 1, and Elevator B shall be 3;

The Homing Floor setting for Elevator A shall be 3, and Elevator B shall be 3in case the Homing Floor

is required at G floor. The Homing Floor for each elevator can be set differently.

The Non-Stop Floor setting for Elevator A shall be 7, and Elevator B shall be 6.

The Floor Indication setting for group control shall be: 1: B2, 2: B1, 3: G, 4: 1, 5: 2, …

2.13 Group Control Elevator Passenger Full Setting

General Para

Enter

A: Passenger Set

13

Enter

Esc

B: Passenger Set

13

C: Passenger Set

13

H: Passenger Set

13

16

Shenyang Bluelight Automatic Technology Co., Ltd.

BL2000-QKB-V3 Destination Group Control System User Manual

This function is for setting the full load capacity (also known as the rated number of passenger) of

each elevator in the group destination control, this will enhance the handling of passenger, and to

optimize the distribution of the passengers entering the car according to the current operating range.

The default setting is 13 Persons, it must be set according to the actual rated capacity.

2.14 Regular Hall Operation Panel Configuration Option for Each Floor

This function configures whether to use regular hall operation panel for group control hall calling of

each individual floor (not using destination floor selector). For every floor that is using regular hall

operation panel for group control hall calling, please set the respect floor parameter to ON.

2.15 Setting Group Control Floor Numbering

The setup value of group floor numbering will be distributed to the destination control floor selector

after the saving of setting parameter, and it will refresh the floor numbering of every floor display. If

there is inconsistent of floor numbering setup, the destination control floor selector will show error

message.

General Para

Enter

IO GDCS Floor

01: OFF

Enter

Esc

IO GDCS Floor

02: OFF

IO GDCS Floor

03: OFF

IO GDCS Floor

64: OFF

Set Indication

Enter

Set Indication

01: 1

Enter

Esc

Set Indication

02: 2

Set Indication

03: 3

Set Indication

64: 64

17

Shenyang Bluelight Automatic Technology Co., Ltd.

BL2000-QKB-V3 Destination Group Control System User Manual

If the floor number of the lowest floor 01 is “1”, then set the Floor Indicator as “1”; if the floor

number of the lowest floor 01 is “B2”, then set the Floor Indicator as “B2”.

2.16 Setting Requirement for Group Control versus elevator numbers (A, B,

C, …)

On every elevator controller of the group control, the setting for fireman “Fire Floor” and

“Homing Floor” must be the same;

In Group control system (3-car group and above), if the bottom floors are not same (some

elevators are having basement floors), the most lowest floor elevator should be set to Elevator A,

the second most should be set to Elevator B and so on and so forth; If the bottom floors are

same whereas the top floors are not same, hence the highest floor elevator should be set to

Elevator A; If none of the above mentioned, elevator numbers can be randomly set.

2.17 Controller Parameter Settings Requirement for Group Control

F1-24 Parallel No. (Used to the elevator number of group-controlling as the group controlling is

enabled.) 0 to 7 is for the elevator number A to H.

F1-25 Twins Control. Set this parameter as 0 to disable the twins controlling.

F1-26 Group Control. Set this parameter as 1 to enable the group controlling.

Table of contents