Bluerock Tools CG-211Y Quick start guide

OPERATIONAL MANUAL

MODEL: CG-211YPIPE TORCH/BURNER MACHINE

by BLUEROCK ® Tools

Volume

1.1

MWS-CG-211Y TORCH BURNER MACHINE

UNPACKING THE ITEM

Caution: This machine is packed together with items that may be sharp, oily and overly heavy objects.

Remove the machine from the packaging in a safe manner. Check to ensure all accessories are included with

the item while unpacking. If any parts are found to be missing, contact the retailer as soon as possible. Do

not throw away the packaging until the item is out of the guarantee period. Dispose of the packaging in an

environmentally responsible manner. Recycle if possible. Keep all plastic bags away from children due to

risk of suffocation.

©THE NEWMAN TRADING COMPANY LLC DBA BLUEROCK® TOOLS 2016

1100 SW 16th St • Suite D

Renton, WA 98057

Phone 206.604.8363 • Fax 425.572.5167

www.bluerocktools.com

CG-211Y TORCH BURNER MACHINE

Table&of&Contents&

SAFETY' 1!

PRE-OPERATIONAL SAFETY CHECKS! 1!

OPERATIONAL SAFETY CHECKS! 1!

SPECIFICATIONS' 3!

INCLUDED'ACCESSORIES' 3!

ADDITIONAL ACCESSORIES FOR THIS MACHINE CAN BE FOUND IN BLUEROCK ®TOOLS ONLINE SHOP AT

WWW.BLUEROCKTOOLS.COM OR FROM YOUR LOCAL RETAILER.! 3!

CUTTING'TIP'SPECIFICATIONS' 4!

OPERATIONS' 5!

PURPOSE! 5!

OPERATIONAL PRINCIPLES! 5!

MACHINE COMPONENTS! 5!

SETTING UP THE MACHINE! 6!

TRANSPORTING THE MACHINE! 7!

RUNNING THE MACHINE! 8!

PROPER LIGHTING OF GAS TORCH!10!

TROUBLESHOOTING'12!

GENERAL'MAINTENANCE'13!

CG-211Y TORCH BURNER MACHINE

1

Safety

DO NOT USE THIS MACHINE UNLESS YOU HAVE READ THE

OPERATING INSTRUCTIONS!

Welding safety glasses must be worn at

all times in work areas.

Long and loose hair must be

contained.

Appropriate steel toe footwear must be

worn.

Close fitting/protective leather

clothing must be worn.

Leather safety gloves should be worn at

all times and jewelry must not be worn.

Hearing protection should be

worn when using this machine.

Hard-hat must be worn while using

machine.

Dust/fume mask must be worn

while using this machine.

Read operational manual prior to use.

PRE-OPERATIONAL SAFETY CHECKS

ØExamine the body of the machine and inspect for damage or defects.

ØExamine the body and hoses of the cutting assembly.

ØExamine the cutting torch tips and torch barrel inside and out for damage and/or defect.

OPERATIONAL SAFETY CHECKS

ØONLY to be operated by qualified personal who have read instructions.

oNOTE: Failure to read and follow instructions could result in fire, property damage

and/or serious injury!

ØDO ensure all non-essential people are clear of the immediate work area.

ØDO keep body parts, clothing & power cords clear of turning/cutting pieces.Stay alert and

use common since when using this tool.

Chapter

1

CG-211Y TORCH BURNER MACHINE

2

ØDO shut off gas while changing cutting tips so as not to accidentally cause gas related

injuries.

ØDO ensure all tightening points, brackets, wing-nuts, and lever-bolts are tight and stable prior

to turning the machine on and/or starting the gas flame.

ØDO use a dust/fumes extraction system for cutting all materials. The operator should also

wear a protective respiratory device in accordance with welding safety standards.

ØDO NOT make adjustments to machine while the machine is running.

ØDO NOT remove or modify grounding plug. Only to be used on a properly grounded circuit.

ØDO NOT leave the flame running when not in use.

ØDO NOT hold the work piece by hand or using body. Always mechanically clamp or secure.

ØDO NOT allow flame too close to the machine body. This can cause machine components to

fail.

ØDO NOT allow flame to come in contact with power cords.

ØDO NOT operate machine outside of machine specifications.

ØDO NOT touch moving parts or cutting flame while the machine is running as death or

dismemberment could occur.

ØDO NOT stand under machine while running. The machine can fall and cause damage or

harm to the user.

ØDO NOT allow children or untrained personal to operate machine.

ØDO NOT use this machine in the rain or a wet environment. If using outdoors, make sure the

adhering surface is clean and dry.

ØDO NOT cut into steel that may contain a live electrical wire/circuit.

CG-211Y TORCH BURNER MACHINE

3

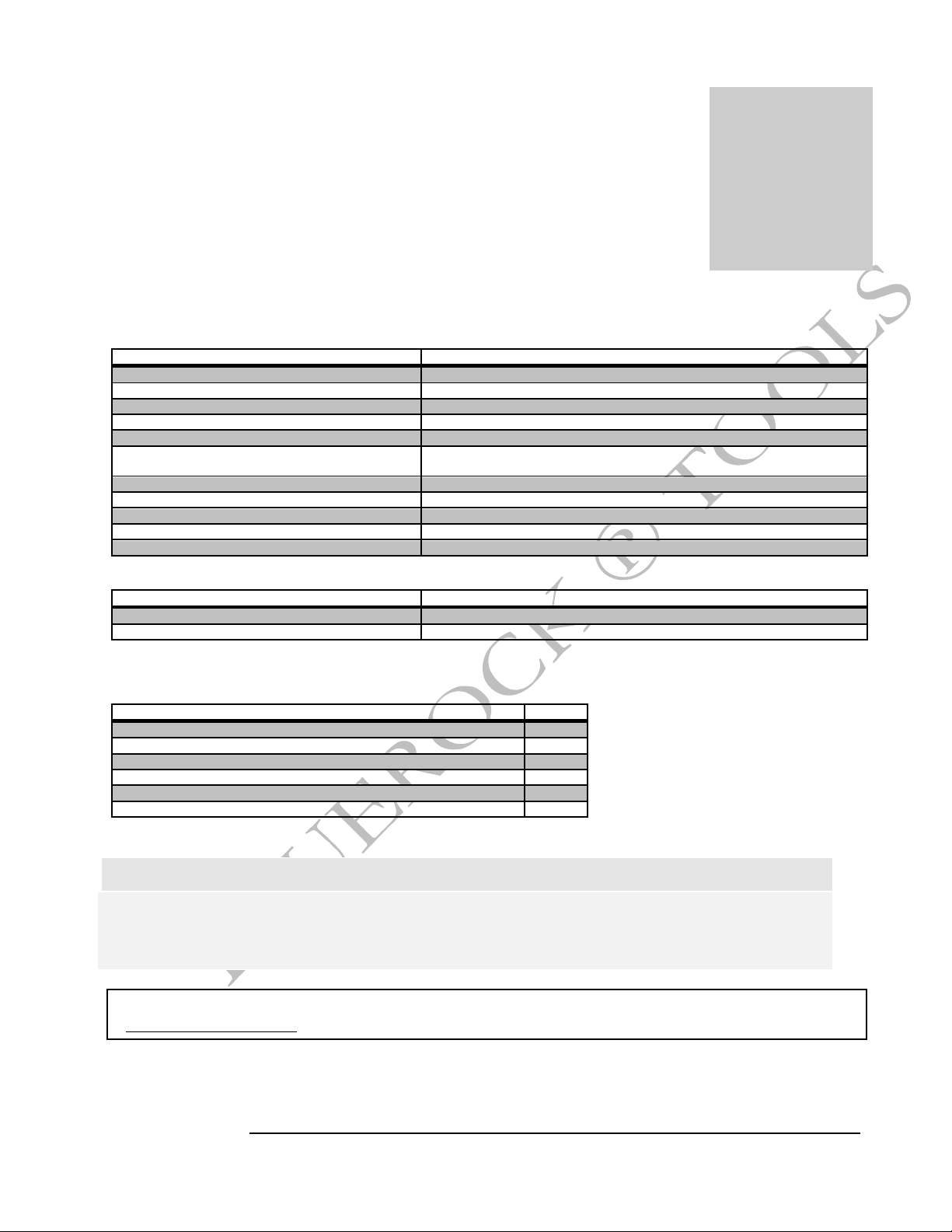

Specifications

MECHANICAL DATA

Forward or Reverse

Yes

Movement Type

Manual Hand Power

Wormwheel

Yes

Electricity Used

No

Cutting Tip Types

G02, G03 (similar to Airco Brand)

Minimum Pipe Cutting Diameter

4” (100mm) to 24” (600mm) with Chain Provided

With additional chain there is no maximum pipe size.

Cutting Depth

Up to 2” Thick (5mm min to 50mm max)

Cutting Speed

Manual – Depends on user

Cutting Movement Precision

0.039” per 40” (1mm/1000mm)

Bevel Angle

0-45 Degrees

Machine Main Structure Material

Alloy-aluminum (Zl101)

SHIPPING DATA

Shipping Weight

1) 32 lbs

Shipping Package Size

1) 13” x 13” x 17”

Included Accessories

DESCRIPTION

QTY

Instruction Manual

1

87” of Chain

1

Large Wheel (for smaller pipe)

2

Troch Bracket Assembly

1

G02 Oxy-Acetylene Cutting Tips

3

G03 Oxy-Propane Cutting Tips

3

Note

UPON RECEIPT, CHECK CAREFULLY TO ENSURE THAT THE MACHINE IS IN GOOD

CONDITION AND HAS ALL ACCESSORIES LISTED ABOVE.

Additional accessories for this machine can be found in BLUEROCK ® Tools online shop at

www.bluerocktools.com or from your local retailer.

Chapter

2

CG-211Y TORCH BURNER MACHINE

4

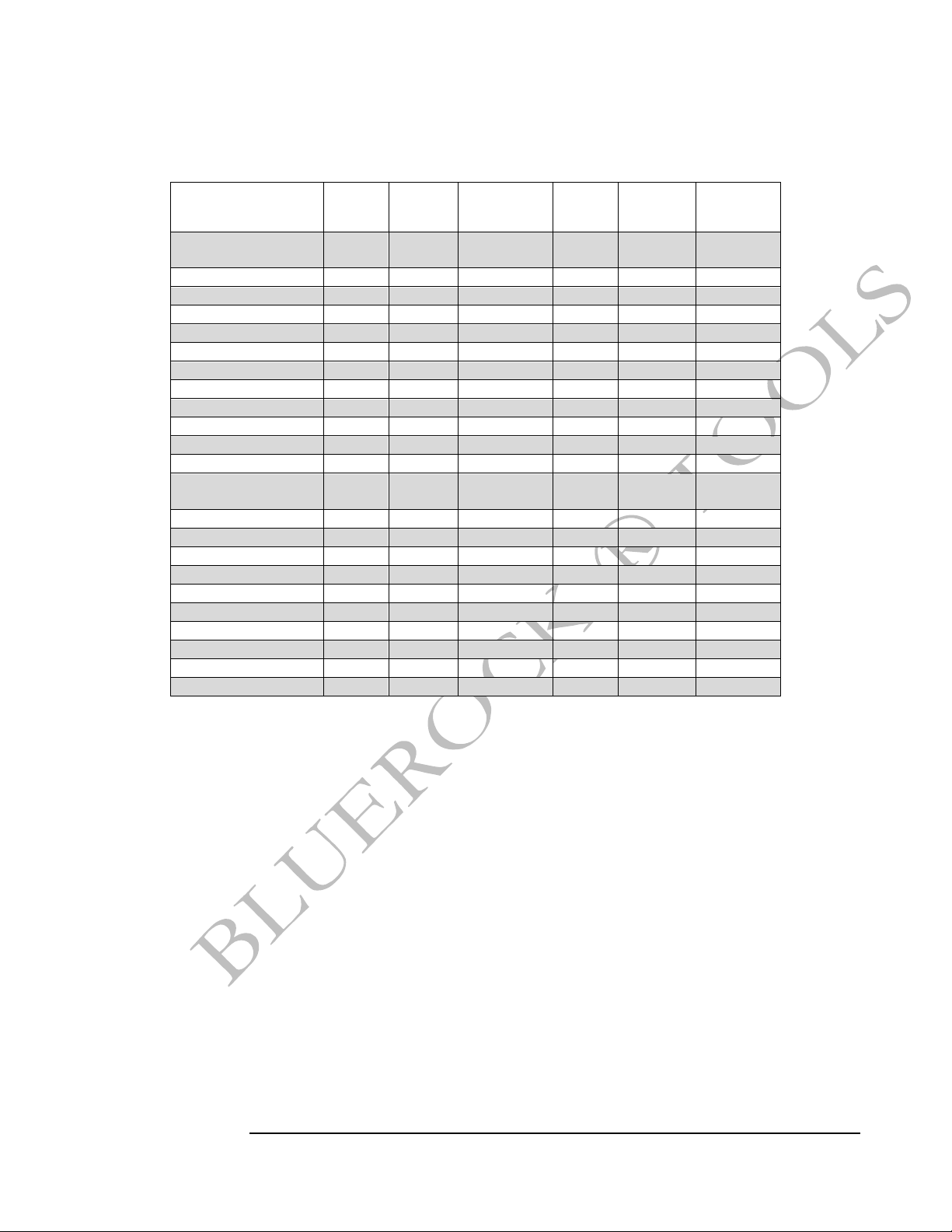

Cutting Tip Specifications

Type

Model

Cutting

Diameter

(mm)

Cutting

Thickness

(mm)

Cutting

Speed

(mm)

Oxygen

Pressure

(Mpa)

Acetylene

Pressure

(Mpa)

GO2Acetylene

Cutting tip

#00

0.8

5-10

600-450

0.2-0.3

>0.03

#0

1

10-20

480-380

0.2-0.3

0.03

#1

1.2

20-30

400-320

0.25-0.35

0.03

#2

1.4

30-50

350-280

0.25-0.35

0.03

#3

1.6

50-70

300-240

0.3-0.4

0.04

#4

1.8

70-90

260-200

0.3-0.4

0.04

#5

2

90-120

210-170

0.4-0.6

0.04

#6

2.4

120-160

180-140

0.5-0.8

0.05

#7

2.8

160-200

150-110

0.6-0.9

0.05

#8

3.2

200-280

90-60

0.6-1.0

0.05

#9

3.6

270-350

90-60

0.7-1.1

0.05

#10

4

350-400

70-50

0.7-1.2

0.06

G03Propane

Cutting tip

#0

0.7

5-10

800-450

0.2-0.3

>0.03

#1

0.9

10-20

480-300

0.2-0.3

0.03

#2

1.2

20-35

400-320

0.3-0.4

0.03

#3

1.5

35-60

350-280

0.3-0.4

0.03

#4

1.8

60-90

300-240

0.4-0.6

0.04

#5

2.1

90-130

260-200

0.4-0.6

0.04

#6

2.5

130-180

220-180

0.4-0.6

0.04

#7

2.7

180-250

200-160

0.5-0.7

0.05

#8

3.1

250-330

180-140

0.5-0.7

0.05

#9

3.5

330-380

130-90

0.6-0.8

0.05

#10

4

380-450

90-50

0.6-0.8

0.05

CG-211Y TORCH BURNER MACHINE

5

Operations

WARNING

DO NOT attempt to use this machine unless you are trained in its proper use as

well as trained in the proper use of gas cutting equipment. THOROUGHLY READ

THROUGH THE ENTIRE MANUAL BEFORE OPERATING THIS MACHINE!

PURPOSE

ØThe purpose of the CG-211Y is to cut steel pipe using oxy-acetylene or propane gas flame

cutting. The machine is designed to cut straight and bevel cuts. This machine is used for

seamless steel pipe cutting and beveling. It’s suitable for work in outside areas where there is

no electricity available.

OPERATIONAL PRINCIPLES

ØWhen placed on pipe, the main machine wheels rotate in a forward or reverse direction. When

engaged, the flame cuts into the steel. The machine speed can be increased or decreased using

human power. Using the adjusting knobs on the machine, the user can raise or lower the torch

holder.

oWARNING: Be careful not leave the machine cutting unattended as it may fall from the

end of the elevated work piece.

MACHINE COMPONENTS

ØThe main components of the CG-211Y are the clutch carriage, torch holder assembly, machine

body, wheels and chain

ØThis machine has two primary adjusting knobs to position the torch holder.

oThese knobs are both located on the torch bracket assembly and main spreader bar (see

figure below).

oThe spreader bar adjuster knob will adjust the torch holder left to right.

oThe side torch height knob will adjust the torch holder up or down.

Chapter

3

CG-211Y TORCH BURNER MACHINE

6

SETTING UP THE MACHINE

ØInstall the main spreader bar and the torch holder assembly.

oTighten the appropriate wing-nuts.

ØInstall the torch holder into the torch holder assembly.

oMake certain the inside if the torch holder is clean and does not have any burrs. Also

make certain any tips you use are free or burrs or defect. It is important the seats are

tight.

§See section below on “proper lighting of gas torch”

oFor straight cuts, ensure the torch holder is square (see figure below).

CG-211Y TORCH BURNER MACHINE

7

ØTighten the valve assembly side onto the top of the flat steel bar left of the main chain tightener

wing nut (see figure above). Ensure it is secured tightly.

ØInstall the large wheels if you are going to be cutting smaller pipe (see figure below).

oNote: You do not want the middle of the machine to high center on smaller pipe, hence

the need for the large wheels.

TRANSPORTING THE MACHINE

ØWhen transporting the machine, always carry under the machine wheels.

ØEnsure the torch tip is in a raised position so it will not get damaged when lifting up the machine

or putting down the machine on pipe.

ØIf transporting inside a vehicle, it is recommended to transport it on its side so as to avoid the

item falling over. It is also recommended to protect the wheels from damage by placing on non-

abrasive surface.

ØDO NOT carry the machine by the hoses.

CG-211Y TORCH BURNER MACHINE

8

RUNNING THE MACHINE

ØDo all pre-operational and operational safety checks from Chapter 1.

ØConsider your security and stability as well as the orientation of the machine in the work area.

oConsider the work surface material, condition, strength, density and rigidity. These

factors directly affect the tools use.

oWARNING: Ensure the piece being cut will be stable after the cut has been made.

ØEnsure the work surface and machine are free of debris, oil, etc.

oNOTE: The machine will deviate from the cut if the material is not clean (bare) and

seamless.

ØCarefully place machine at the start of the cut ensuring the wheels gently make contact with the

cutting surface. If cutting pipe, it is generally easiest to start at the top of the pipe.

ØAdjust the main chain tightening wing-nut so that the clutch carriage assembly is in a low

position.

ØLoop the chain through the top of the clutch sprocket and around the pipe.

ØInterlock the chain as in the illustration below.

oTake out the appropriate number of chain lengths so the chain is moderately tight.

oA quick way to figure out the specific number of chain lengths to use can be found using

the following equation:

§D=d+12

•D= The number of sections

•d= The diameter of pipe.

CG-211Y TORCH BURNER MACHINE

9

•12= Constant

•Example: d=299mm=29.9cm=30 sections of chain.

oD=30+12=42 Sections of Chain Total, So you would use 42

sections of chain for a pipe 299mm in diameter.

ØTighten up the main chain tightening wing-nut until the machine is adequately tight.

oDo not over-tighten wing-nut.

oEnsure the chain is at a straight 90 degree to the pipe.

ØEngage the clutch handle on the clutch carriage assembly. This should engage the worm-wheel

and allow for activated movement when the handle is turned.

oTurn the handle to ensure movement

ØSelect appropriate size torch tips for the application. Install tip.

ØSelect cutting angle.

ØConnect applicable gas lines.

oMake certain they are properly secured and there are no leaks. It is highly recommended

that leak testing be performed on the system prior to using the machine.

oEnsure the lines are long enough to complete the cut you are planning.

oALWAYS use gas tank cylinders with properly outfitted regulators/flowmeters.

ØEnsure the torch holder is not too close to the side of the machine body.

ØAdjust the side knobs to raise the torch tip to a suitable level for lighting.

ØLight the torch flame (see section below on proper lighting of torch flame).

ØAdjust the side knobs a suitable level for cutting though the material.

ØCut material by rotating the worm-wheel handle.

oCAUTION: Make certain the user is clear of the flame when manually rotating the handle.

ØWhen the cut is complete, stop the machine rotation.

ØShut off the torch flame.

CG-211Y TORCH BURNER MACHINE

10

PROPER LIGHTING OF GAS TORCH

ØBefore attempting to light the torch tip follow this check list:

oVerify the regulator pressure adjustment screws are backed out.

oVerify the torch valves are in the closed position.

oPosition yourself away from the front side of the regulator.

oSlowly open the oxygen valve and acetylene valve at the cylinder.

oAdjust regulator pressure adjustment screws to the tip pressure.

oOpen and close the torch valves at the machine separately and tune the regulator

pressure settings on the regulator.

ØLighting the torch:

oOpen gas valve ½turn.

oImmediately ignite flame with striker.

§CAUTION: Light flame immediately so gas does not enter machine body or

general atmosphere around the machine.

§Ensure proper ventilation around the work area.

oIncrease gas flow until flame leaves end of tip and smoke is not present.

oDecrease until flame goes back to tip.

oOpen pre-heating oxygen valve and adjust until neutral flame is achieved.

oWhen the temperature of the steel is suitable temperature for the steel plate, open the

cutting oxygen valve.

oAfter adjustment of the flames efficiency, turn on the machine rotation.

ØAfter cutting is complete, close oxygen cutting valve.

ØNext close pre-heating oxygen valve.

ØLastly, close the gas-cutting valve.

CG-211Y TORCH BURNER MACHINE

11

ØIf done using the machine, close oxygen and gas valves on the main cylinder regulators.

oPurge oxygen and gas lines.

CG-211Y TORCH BURNER MACHINE

12

Troubleshooting

Note

SERVICING SHOULD ONLY BE DONE BY A QUALIFIED TECHNICIAN.

No

Problem

Cause

Solution

1

Leak gas

and/or flame in

the joint of

torch and

torch cutting

tip.

1. The torch holder inlet is damaged.

2. There is copper burr or materials on the

surface of the torch tip.

1. Softly grind the torch cone with small sand paper to clean

out the burr.

2. Clean the material on the cutting tip. Softly grind the

surface with small sand paper. Change the cutting tip if it is

badly damaged.

2

The flame

goes out as

soon as the

oxygen valve

is opened

The cutting oxygen leaked into the preheating

oxygen area.

1. Copper stain or useless materials on the inner

part of torch

2. The smaller cone of torch cutting mouth was

stuck with some with material or was damaged.

1. Softly grind the most inner part of torch holder with sand

paper to clean out the debris or damage.

2. Softly grind the smaller surface of the cutting mouth.

Change the cutting mouth if it is serious damaged.

3

The steel can’t

be cut through

1. The torch cutting-tip is too small.

2. The flame frequency is not strong enough

3. Low pressure for cutting oxygen

4. The hole channel of cutting mouth may be

jammed

5. The cutting oxygen is not pure.

6. The cutting oxygen was leaked into the

preheating oxygen hole channel.

1. Choose the cutting tip spec according to the cutting

thickness.

2. Increase flame frequency properly.

3. Properly increase the cutting oxygen to ensure the enough

flow speed of cutting oxygen.

4. Clean the useless materials in the torch cutting mouth with

cutting pin.

5. Use oxygen with more than 95% purity.

6. Clean the useless materials on the cutting mouth and

torch, repair the damaged surface and change cutting mouth

if needed.

4

The cutting is

not straight

enough.

1. The steel pipe was deformed.

2. The flame line was not straight.

3. Uneven pipe surface

4. The torch was poorly fixed and can be moved.

5. The chain is not straight

1. Use round steel and calibrate it before cutting.

2. The torch should have a 90o angle with the steel and tightly

fixed. Clean the useless materials in the torch cutting mouth

with cutting pin.

3. Fix surface irregularities.

4. Tighten all connections.

5. Straighten the chain.

5

The clutch will

not engage.

1. The clutch carriage is damaged

2. The clutch is dirty

1. Repair or replace the carriage

2. Lubricate the clutch and ensure it moves freely

Chapter

4

CG-211Y TORCH BURNER MACHINE

13

General Maintenance

ØInspect valve assembly connections.

ØLubricate all moving parts in the clutch assembly.

ØKeep machine clean and free of debris.

oMake sure to frequently clean metal scraps from the roll wheels.

ØCheck for misalignment, binding and breakage of all moving parts. If damaged, repair tool before use.

ØCheck to ensure the torch holder is clean and free of debris.

oInspect the inside of the holder as well.

ØInspect all torch tips and ensure they are not damaged and the small cutting holes are clean.

ØInspect cutting hoses to ensure they are not damaged.

ØDO NOT oil and connection points used in the gas/oxy system!

Chapter

5

Table of contents

Popular Welding System manuals by other brands

Yeswelder

Yeswelder YWM-200 Operator's manual

Lincoln Electric

Lincoln Electric Ranger 305 G Technical specifications

Lincoln Electric

Lincoln Electric BIG RED 500 Service manual

Husqvarna

Husqvarna PP 440 HF Operator's manual

EWM

EWM Tetrix DC Smart 2.0 T4.05 operating instructions

SWS

SWS ALUMMIG 230 operating manual