ESAB ARC300i User manual

Other ESAB Welding System manuals

ESAB

ESAB Caddy Tig 1500i User manual

ESAB

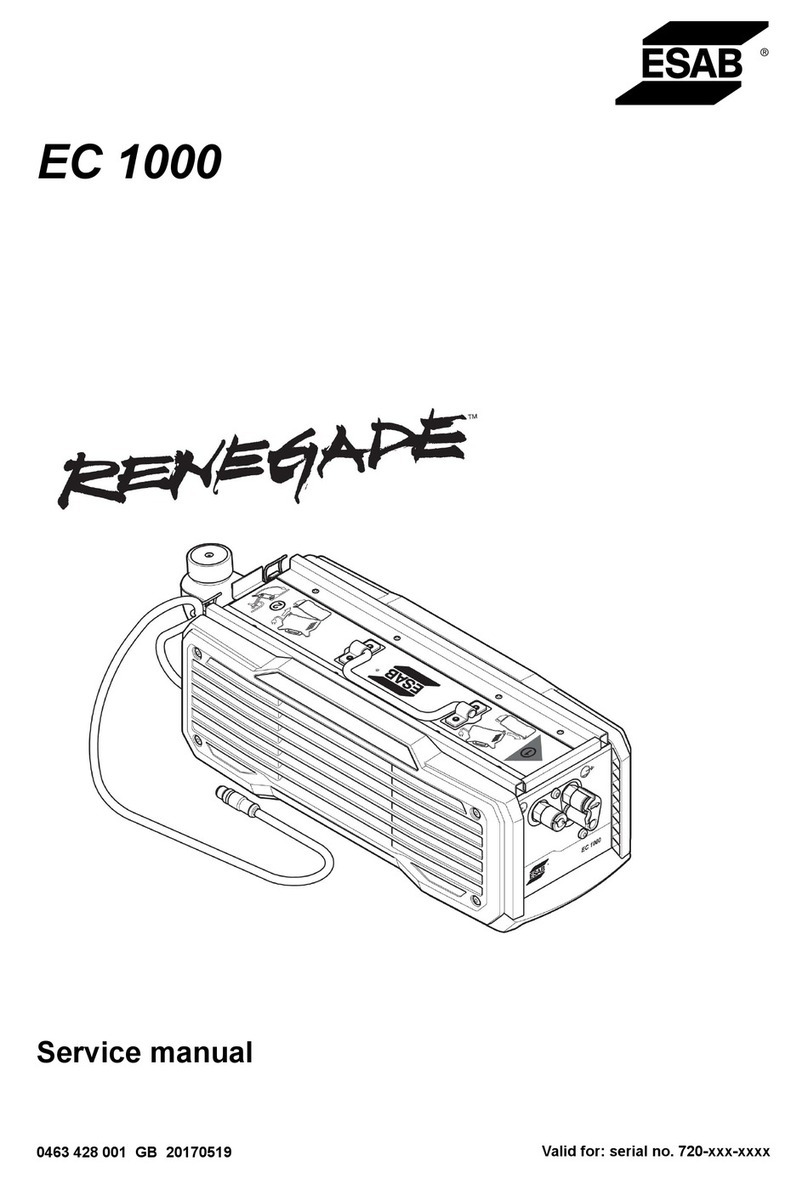

ESAB Renegade EC 1000 User manual

ESAB

ESAB Origo Mig 3001i User manual

ESAB

ESAB Aristo Mig U4000iw User manual

ESAB

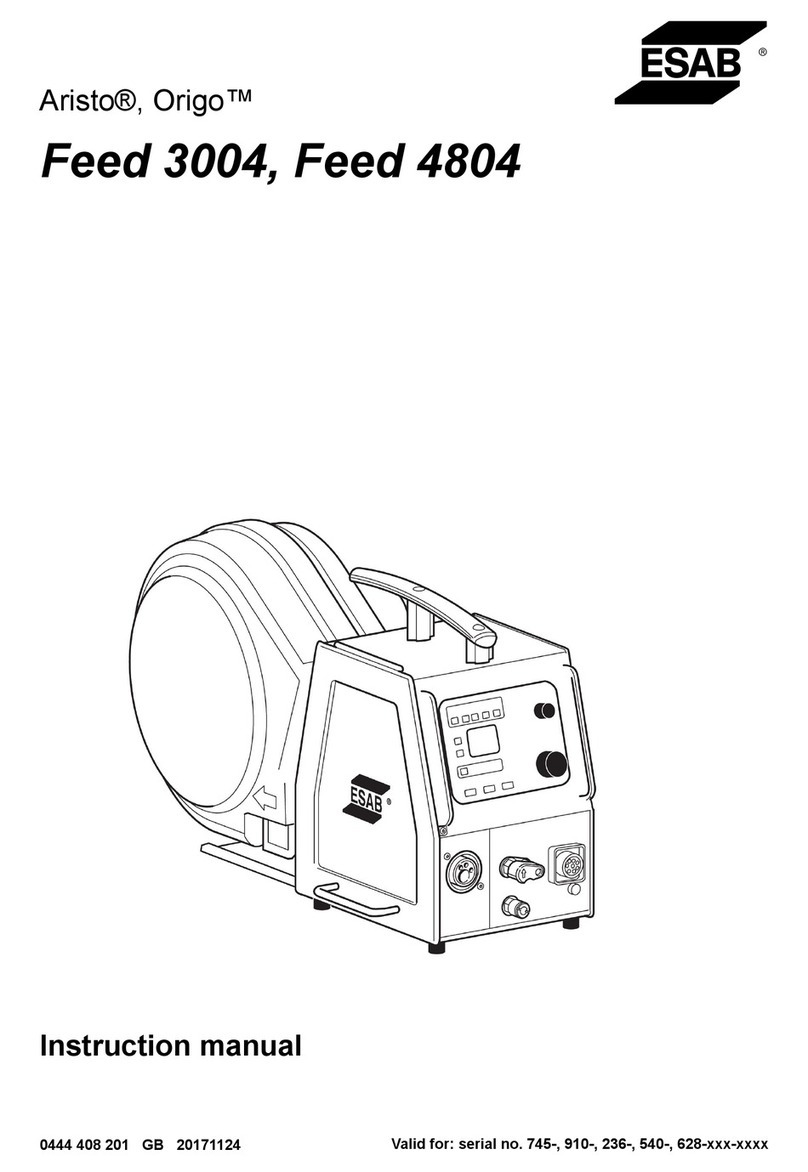

ESAB Aristo Origo Feed 4804 User manual

ESAB

ESAB m3 G2 User guide

ESAB

ESAB DTG 405 User manual

ESAB

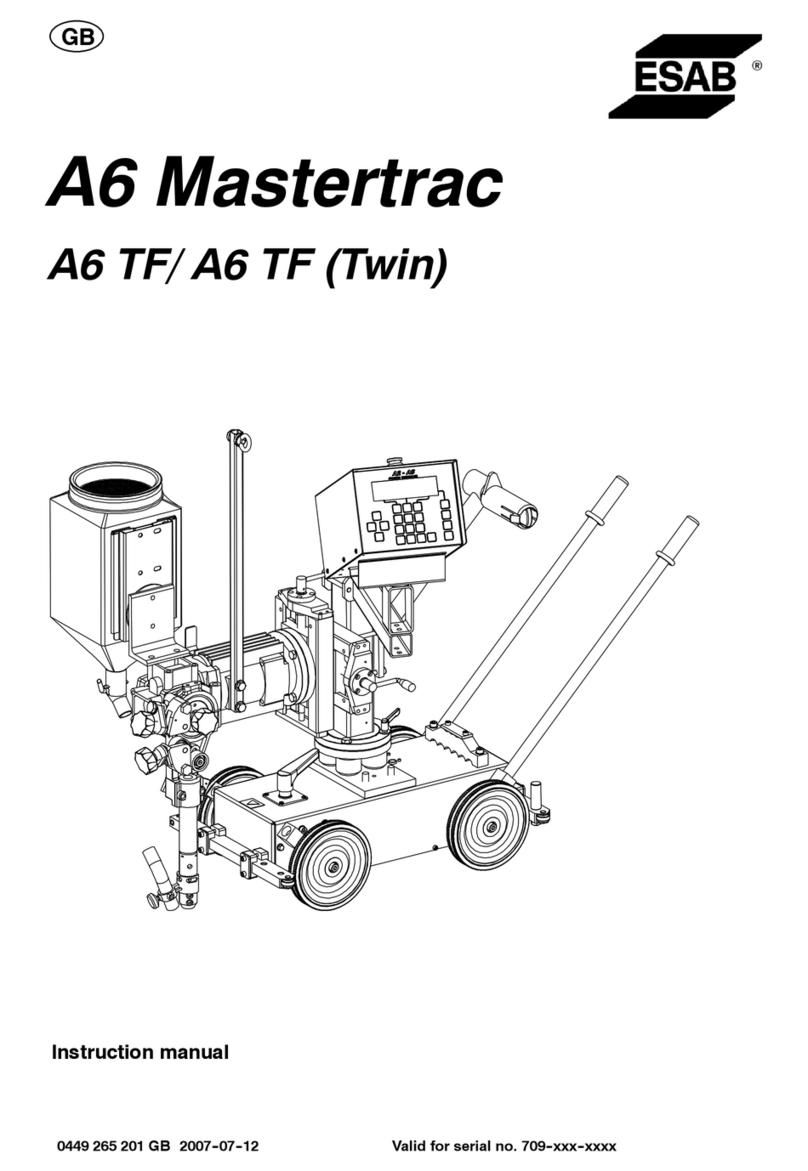

ESAB Miggytrac B501 User manual

ESAB

ESAB ARC250i User manual

ESAB

ESAB ESABMig 405 User manual

ESAB

ESAB OrigoArc 200 User manual

ESAB

ESAB EMP 210 User manual

ESAB

ESAB Aristo 300 User manual

ESAB

ESAB LKB 265 User manual

ESAB

ESAB Origo Mig 320 User manual

ESAB

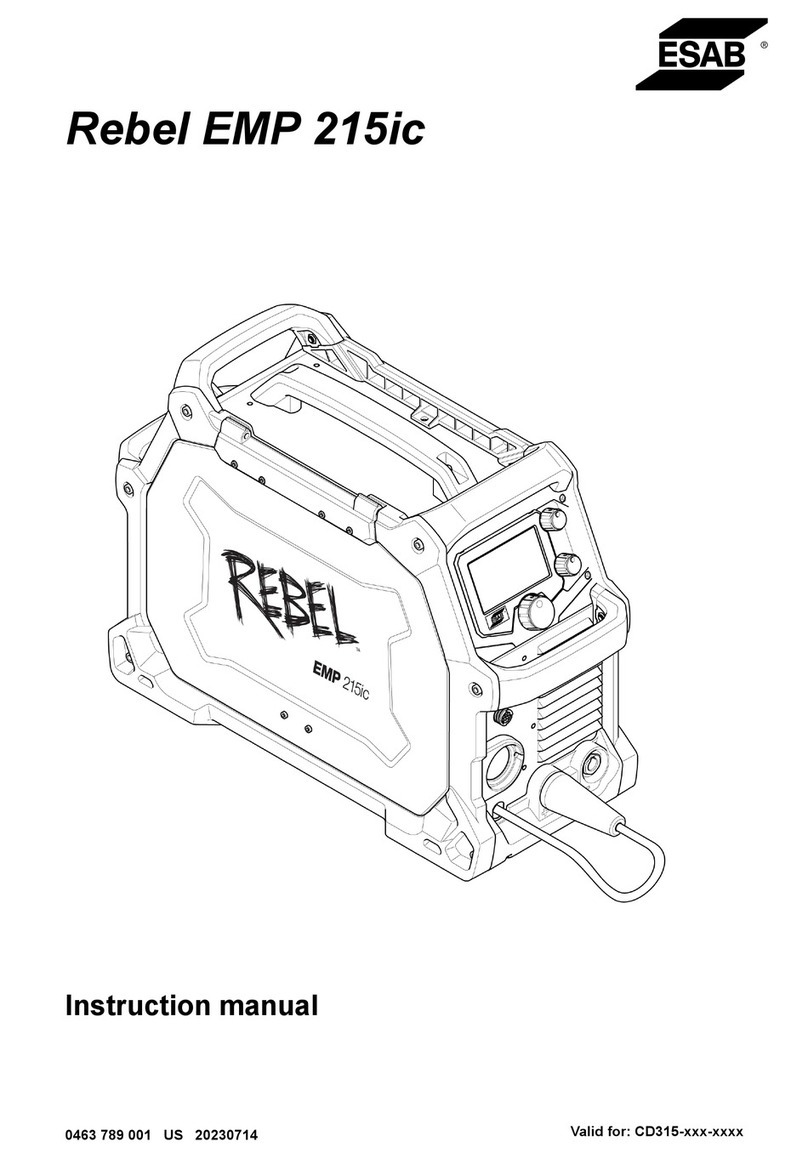

ESAB EMS 215ic User manual

ESAB

ESAB POWERCUT-1500 User manual

ESAB

ESAB OXWELD C-62 User manual

ESAB

ESAB Caddy Arc 201i User manual

ESAB

ESAB Powercut 650 User manual

Popular Welding System manuals by other brands

TAFA

TAFA 30*8B35 owner's manual

Lincoln Electric

Lincoln Electric INVERTEC V350-PRO CE Technical specifications

CIGWELD

CIGWELD 636804 use instructions

Red-D-Arc

Red-D-Arc DC-400 Operator's manual

Hobart Welding Products

Hobart Welding Products Spool Gun DP 3035-10 owner's manual

Elettro

Elettro HI-MIG 3000 SYNERGIC instruction manual