English – 7

SAFETY INSTRUCTIONS

General safety precautions

Do not use the machine without first reading and

understanding the contents of this Operator’s Manual.

• Never use the machine if you are tired, if you have drunk

alcohol, or if you are taking medication that could affect

your vision, your judgement or your co-ordination.

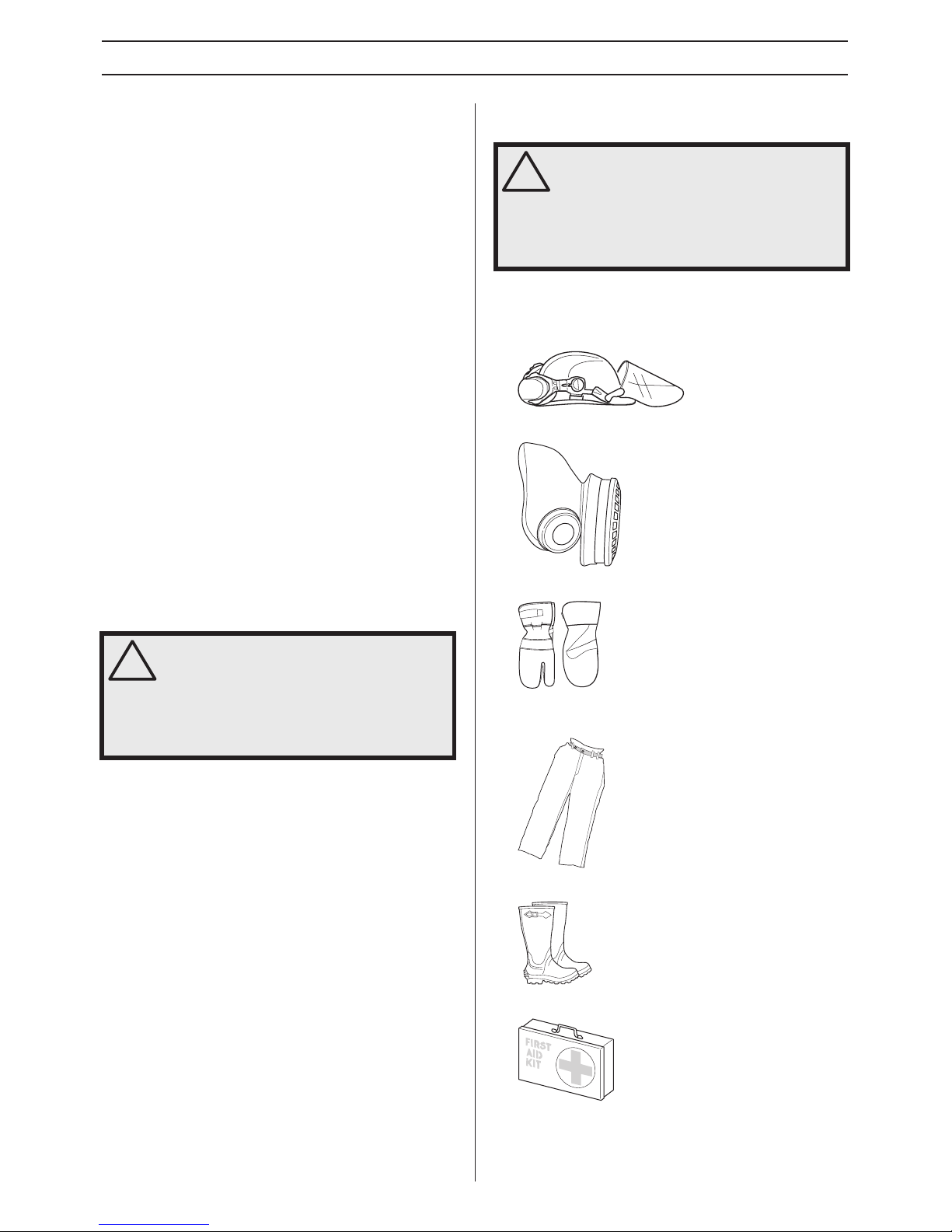

• Wear personal protective equipment. See instructions

under the heading Personal protective equipment.

• Never carry the machine by holding the cable and never

pull the plug by pulling the cable.

• Keep all cables away of water, oil and sharp edges. Make

sure the cable is not pinched in doors, fences or the like.

It can cause the object to become live.

• Check that the cables are intact and in good condition.

• Never use the machine if any cable is damaged, but hand

it in to an authorized service workshop for repair.

• The machine should be connected to an earthed outlet

socket.

• Check that the mains voltage corresponds with that stated

on the rating plate on the machine.

• Keep all parts in good working order and ensure that all

fixtures are properly tightened.

• Never use a machine that is faulty. Carry out the checks,

maintenance and service instructions described in this

manual. Some maintenance and service measures must

be carried out by trained and qualified specialists. See

instructions under the heading Maintenance.

• Do not modify safety equipment. Check regularly that they

function as they should.The machine must not be run with

defective or disassembled safety equipment.

• Never allow anyone else to use the machine without first

ensuring that they have understood the contents of the

operator’s manual.

• People and animals can distract you causing you to lose

control of the machine. For this reason, always remain

concentrated and focused on the task.

• Be careful as clothing, long hair, and jewellery can get

caught in moving parts.

• Observe care when lifting. You are handling heavy parts,

which implies the risk of pinch injuries or other injuries.

Transport and storage

• Always switch of the power unit and pull out the electric

cable before moving the equipment.

• Store the equipment in a lockable area so that it is out of

reach of children and unauthorised persons.

• If there is a risk of freezing, the machine must be drained

of any remaining water coolant.

• Use the cases provided to store the equipment.

General working instructions

• All operators shall be trained in the use of the machine.

The owner is responsible for ensuring that the operators

receive training.

• Check that all couplings, connections and cables are

intact and free from dirt.

• Check that all cables and the water supply are correctly

connected to the machine before starting it.

• Never pull out the power cable without first switching off

the power unit and waiting for the engine to come to a

complete halt.

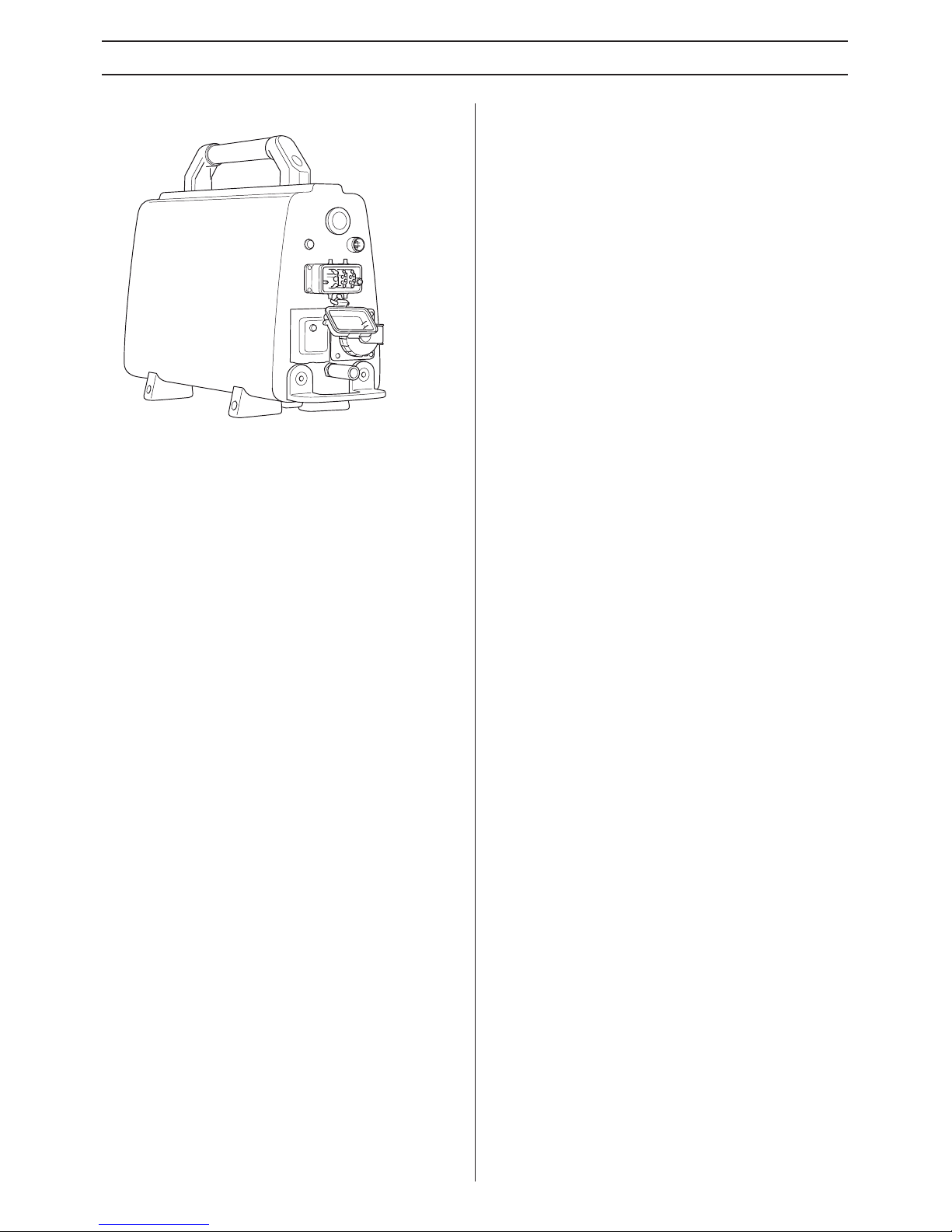

• If an emergency situation should arise anyway, push the

red emergency stop button on the power unit or the stop

button on the remote control.

• Always check and mark out where gas pipes are routed.

Cutting close to gas pipes always entails danger. Make

sure that sparks are not caused when cutting in view of

the risk of explosion. Remain concentrated and focused

on the task. Carelessness can result in serious personal

injury or death.

• Make sure that no pipes or electrical cables are routed in

the area to be cut.

• Check that electrical cables within the working area are

not live.

• Never leave the machine unsupervised with the engine

running.

• Always saw in a manner that permits easy access to the

emergency stop.

• Make sure that there is always another person close at

hand when you use the machines, so that you can call for

help if an accident should occur.

• Do not use the machine in bad weather, such as dense

fog, rain, strong wind, intense cold, etc. Working in bad

weather is tiring and can lead to dangerous conditions,

e.g. slippery surfaces.

• Ensure that the working area is sufficiently illuminated to

create a safe working environment.

• Always ensure you have a safe and stable working

position.

• Observe care when lifting. You are handling heavy parts,

which implies the risk of pinch injuries or other injuries.

!

WARNING! There is always a risk of shocks

from electrically powered machines. Avoid

unfavourable weather conditions and body

contact with lightning conductors and metal

objects. Always follow the instructions in the

Operator’s manual to avoid damage.

!

WARNING! This section describes basic

safety directions for using the machine.This

information is never a substitute for

professional skills and experience. If you get

into a situation where you feel unsafe, stop

and seek expert advice. Contact your dealer,

service agent or an experienced power

cutter user. Do not attempt any task that you

feel unsure of!