BLUEROCK GCD4 Quick start guide

OPERATIONAL MANUAL

MODEL: GCD4 CORE DRILL MACHINE PORTABLE

GAS DRILL USED BY HAND

by BLUEROCK ® Tools

Volume

1.0

MWS-

GDC4 CORE DRILL

UNPACKING THE ITEM

CAUTION: This machine is packed together with items that may be sharp, oily and overly

heavy objects. Remove the machine from the packaging in a safe manner. Check to ensure

all accessories are included with the item while unpacking. If any parts are found to be

missing, contact the retailer as soon as possible. Do not throw away the packaging until the

item is out of the guarantee period. Dispose of the packaging in an environmentally

responsible manner. Recycle if possible. Keep all plastic bags away from children due to risk

of suffocation.

WEEE - Waste Electrical & Electronic Equipment. Note that parts of this machine should be disposed of as electrical &

electronic waste.

SLURRY DISPOSAL

NOTE: It is recommended to dispose of the drilling slurry (the muddy/dusty water material) in

an environmentally responsible manner. The disposal of slurry directly into sewage

systems, sewers, lakes, rivers, or direct earth without treatment can be environmentally

harmful and possibly illegal. Ask your local public authorities about current regulations in

your area.

ãTHE NEWMAN TRADING COMPANY LLC DBA BLUEROCK® TOOLS 2020

1033 Andover Park East

Tukwila, WA 98188

Phone 206.604.8363 • Fax 425.572.5167

www.bluerocktools.com

GDC4 CORE DRILL

Table of Contents

SAFETY' 1!

PRE-OPERATIONAL SAFETY CHECKS! 1!

OPERATIONAL SAFETY CHECKS! 2!

HEALTH WARNINGS! 3!

SPECIFICATIONS' 4!

INCLUDED'ACCESSORIES' 4!

ADDITIONAL'AVAILABLE'ACCESSORIES' 5!

ADDITIONAL ACCESSORIES FOR THIS MACHINE CAN BE FOUND IN BLUEROCK ® TOOLS ONLINE SHOP AT

WWW.BLUEROCKTOOLS.COM OR FROM YOUR LOCAL RETAILER.! 5!

OPERATIONS' 6!

PURPOSE! 6!

OPERATIONAL PRINCIPLES! 6!

MACHINE COMPONENTS! 6!

TRANSPORTING AND STORAGE OF THE MACHINE! 7!

RUNNING THE MACHINE USING THE HANDHELD DRILLING METHOD! 7!

INSTALLING CORING BITS! 9!

TROUBLESHOOTING'10!

GENERAL'MAINTENANCE'11!

OCCASIONAL'MAINTENANCE'11!

PARTS'LIST'12!

BREAKDOWN'VIEW'-'OVERVIEW'13!

GDC4 CORE DRILL

1

Safety

DO NOT USE THIS MACHINE UNLESS YOU HAVE READ THE OPERATING

INSTRUCTIONS!

Safety glasses must be worn at all

times in work areas.

Long and loose hair must be

contained.

Appropriate footwear must be worn.

Close fitting/protective

clothing must be worn.

Safety gloves should be worn at all

times and jewelry must not be worn.

Hearing protection should be

worn when using this

machine.

Hard-hat must be worn while using

machine.

Dust mask must be worn

while using this machine.

Read operational manual prior to use.

PRE-OPERATIONAL SAFETY CHECKS

Ø Examine the body of the machine and inspect for damage or defects.

Ø Inspect your core bit for damage, correct/tight connection to machine and no debris inside.

Ø Inspect the machine’s watering system to ensure it will deliver a smooth flow of water.

Ø Check to ensure the air filter is clean.

Ø Check the engine oil before starting the machine. Fill if needed with SAE 10W-30.

o NOTE: Always switch OFF the engine before checking the oil or

adding oil. Do not overfill with oil.

Chapter

1

GDC4 CORE DRILL

2

Ø Check to ensure the machine has fuel before starting.

o NOTE: This machine takes unleaded fuel with octane 86 or above.

o NOTE: Always switch OFF the engine before checking the fuel or

re-fueling. DO NOT overfill with fuel.

OPERATIONAL SAFETY CHECKS

Ø ONLY to be operated by qualified personal who have read instructions.

o NOTE: Failure to read and follow instructions could result in electrical shock, fire,

property damage and/or serious injury!

Ø DO ensure all non-essential people are clear of the immediate work area.

Ø DO be attentive at all times. Keep your eye on the work piece. Always be in a sensible state

of mind and do not use the machine if you cannot fully concentrate.

Ø DO keep body parts, clothing & power cords clear of turning/cutting pieces. Stay alert and

use common since when using this tool.

Ø DO allow machine to reach operating speed before starting a hole.

Ø DO shut down machine while changing or adjusting cutting bits so as not to accidentally turn

machine on.

Ø DO remove adjusting wrenches prior to turning the machine on.

Ø DO be mindful that power tools can expose an operator to vibrations transmitted trough

contact with the machine. Prolonged exposure can lead to medical issues which should be

discussed with a medical professional.

Ø DO use a dust extraction system for cutting materials that create dust. The operator should

also wear a protective respiratory device.

Ø DO keep the engine at least 3 feet away from buildings or flammable objects during operation

as the engines exhaust can become very hot during operation.

Ø DO NOT make adjustments to machine while the machine is running.

Ø DO NOT switch off the machine when it is under load, except in an emergency.

Ø DO NOT leave the machine running when not in use.

Ø NO NOT touch the motor or motor parts while hot as burns may occur.

Ø DO NOT hold the work piece by hand or using body. Always mechanically clamp or secure

work piece.

Ø DO NOT allow liquids to enter the machine’s ventilation system.

Ø DO NOT operate machine outside of machine specifications.

GDC4 CORE DRILL

3

Ø DO NOT touch moving parts while the machine is running as death or dismemberment could

occur.

Ø DO NOT operate machine overhead (Inverted) when drilling “wet” type cores.

Ø DO NOT allow children or untrained personal to operate machine.

Ø DO NOT use this machine in the rain or a wet environment.

Ø DO NOT operate in the presence of explosive materials as power tools create sparks which

may ignite dust or fumes.

Ø DO NOT place anything on the motor while running.

Ø DO NOT drill into an area that may contain a live electrical wire/circuit.

Ø DO NOT use full water pressure when drilling with “wet” type bits! You need minimal water to

drill with these machines. Extreme water pressure can damage machine and cutting bits.

Ø DO NOT depress throttle engaging clutch when starting the motor as you do not want the core

bit to spin quickly while not held securely.

Ø DO NOT use this gas machine indoors.

Ø DO NOT smoke or allow flames around this gas machine.

HEALTH WARNINGS

Ø Certain dust created by drilling contains chemicals known to cause cancer, birth defects or

other reproductive harm. The examples of these chemicals are below:

o Lead from lead based paint.

o Crystalline silica from bricks, cement and assorted masonry products.

§ TO REDUCE RISK OF EXPOSURE TO THESE CHEMICALS, WORK IN A WELL

VENTILATED AREA WITH VACUUM SYSTEMS, RESPIRATORS AND WITH

ALL SUITABLE SAFETY EQUIPMENT.

Ø This machine’s exhaust contains poisonous carbon monoxide. Breathing in carbon

monoxide can lead to unconsciousness, injury or death.

o DO NOT run the engine without adequate ventilation and never run indoors.

GDC4 CORE DRILL

4

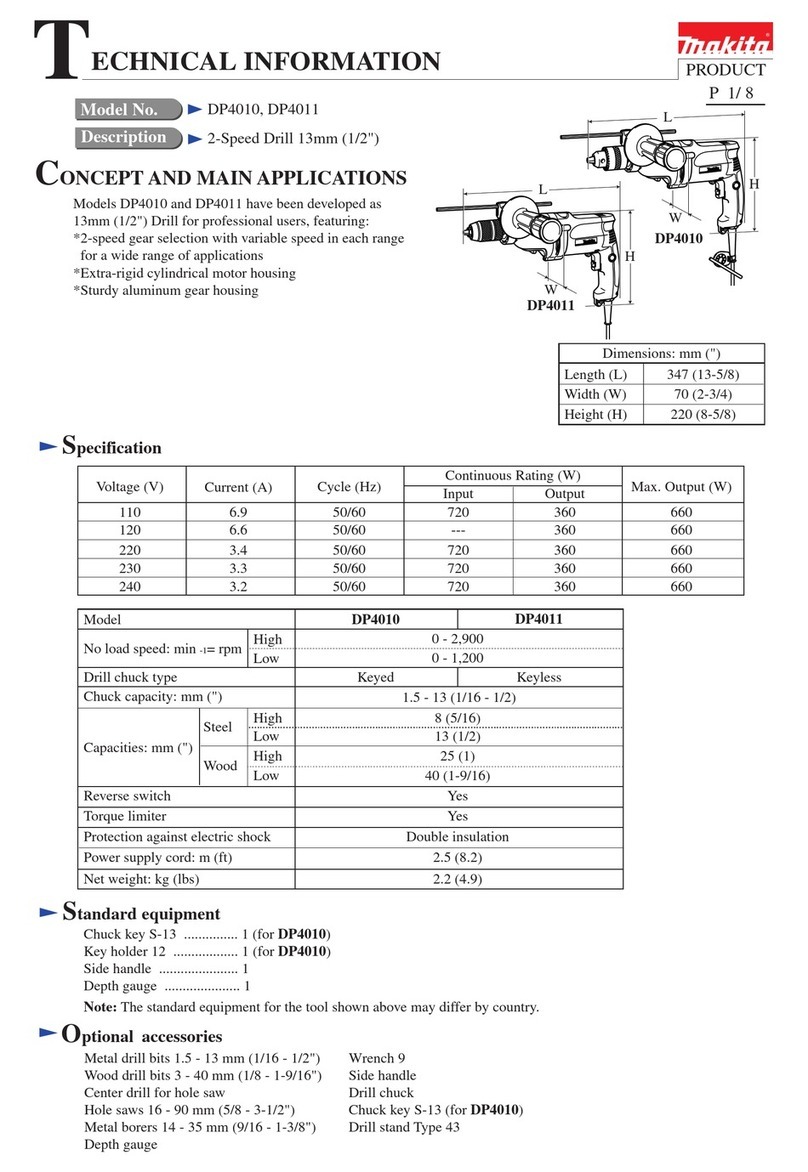

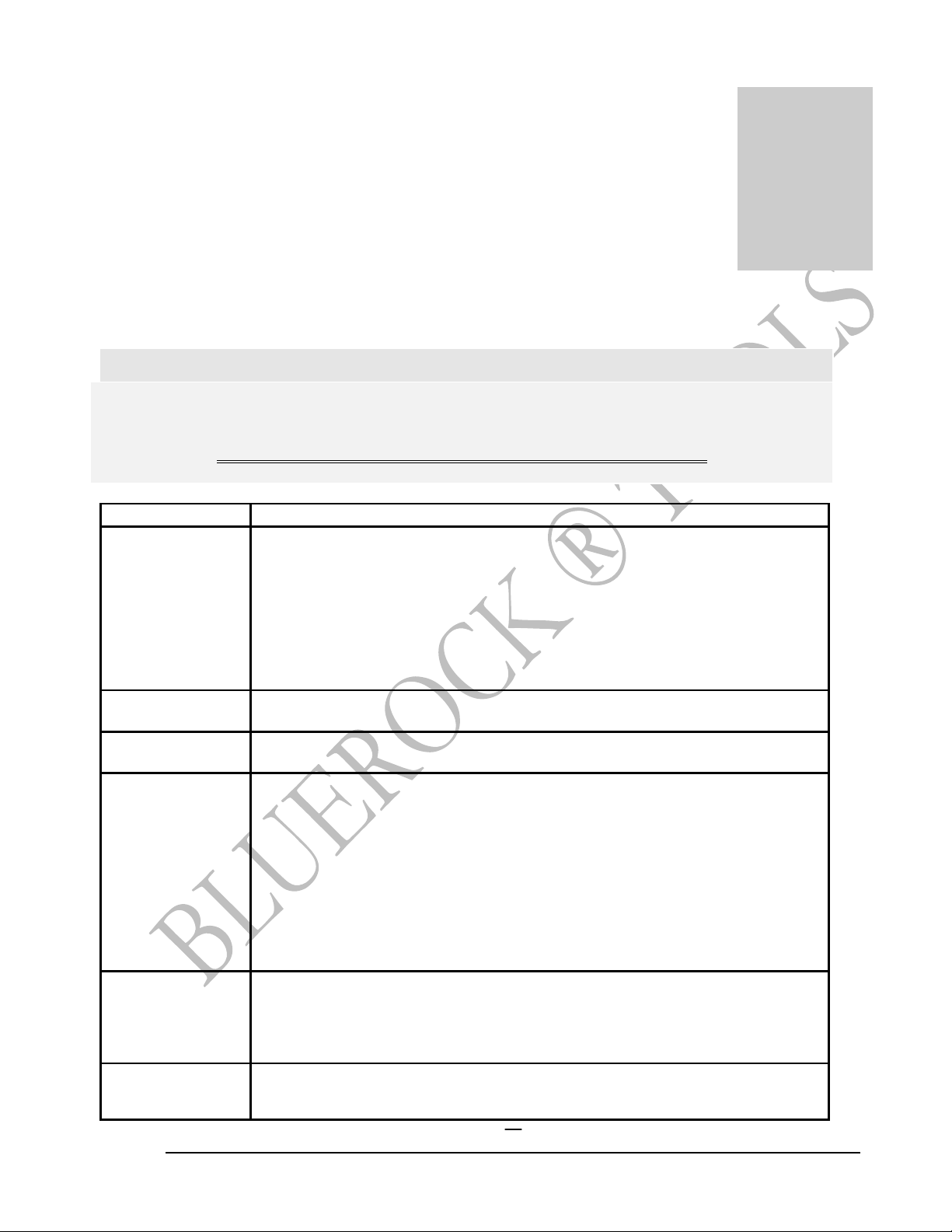

Specifications

MOTOR DATA

Motor Type

4 Stroke Gas Driven (Unleaded Fuel)

Motor Model

Honda GX35 EPA Certified

Motor Oil Type

10W-30

Maximum Power

1.5KW/350RPM

Maximum Torque

40N/m

Cooling System

Forced Air Cooling

Spark Plug

CMR5H (NGK)

MECHANICAL DATA

Cutter Range

1” to 4” Max Diameter by Hand

Cutting Speed of Core Bits

700 RPM

Tool Holder

Direct Arbor 1-1/4” 7 UNC Spindle

Clutch

Yes, Clutch Drum Type Assembly

Water hose and Valve

Yes

Hand held capable

Yes

Item Weight

22 Lbs

Included Accessories

DESCRIPTION

QTY

Instruction Manual

1

Water Hose and Valve

1

Note

UPON RECEIPT, CHECK CAREFULLY TO ENSURE THAT THE

MACHINE IS IN GOOD CONDITION AND HAS ALL ACCESSORIES

LISTED ABOVE.

Chapter

2

GDC4 CORE DRILL

5

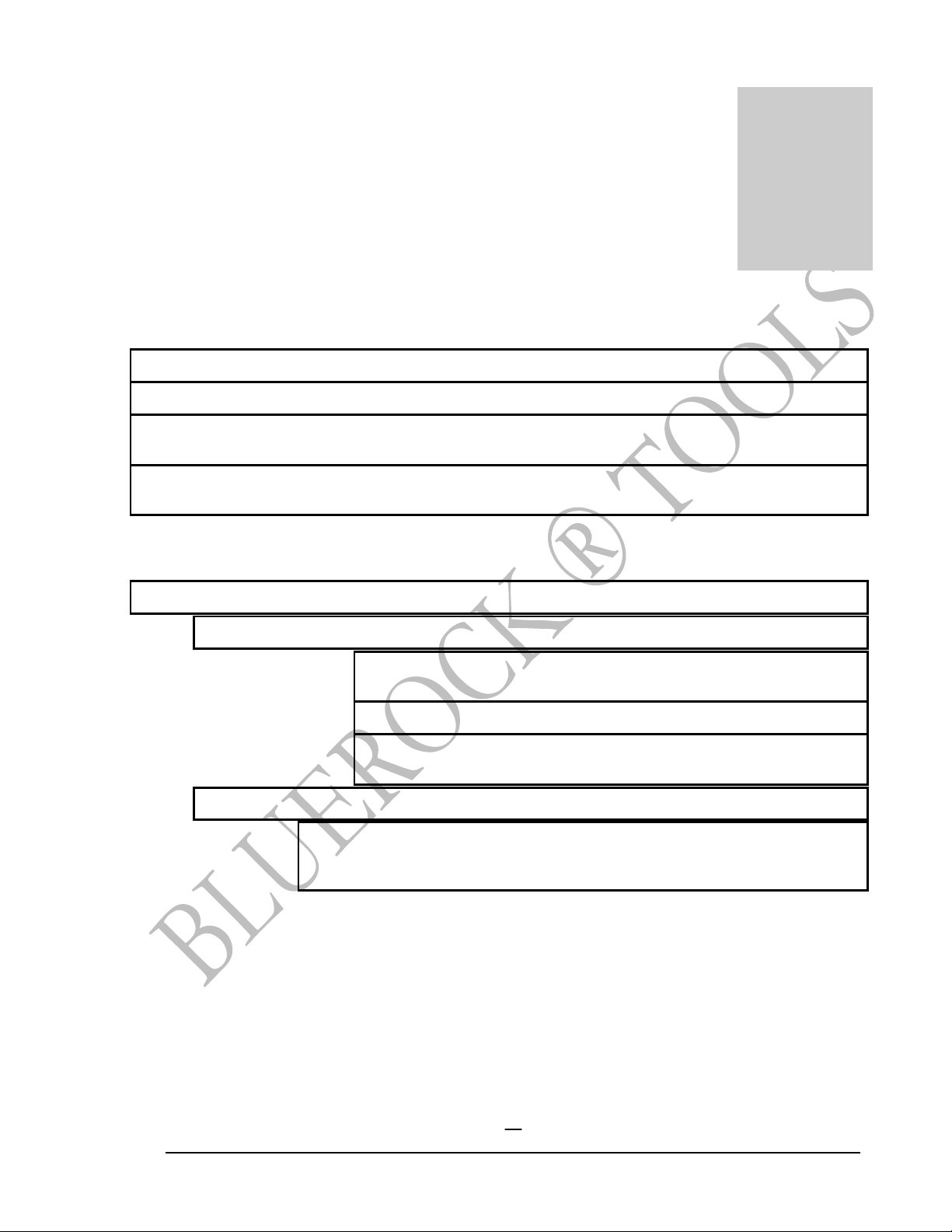

Additional Available Accessories

Additional accessories for this machine can be found in BLUEROCK ® Tools

online shop at www.bluerocktools.com or from your local retailer.

DESCRIPTION

1” Wet Coring Bit

1.25” Wet Coring Bit

1.5” Wet Coring Bit

1.75” Wet Coring Bit

2” Wet Coring Bit

2.5” Wet Coring Bit

3” Wet Coring Bit

3.5” Wet Coring Bit

4” Wet Coring Bit

1” Dry Coring Bit

1.25” Dry Coring Bit

1.5” Dry Coring Bit

1.75” Dry Coring Bit

2” Dry Coring Bit

2.5” Dry Coring Bit

2.75” Dry Coring Bit

3” Dry Coring Bit

3.5” Dry Coring Bit

4” Dry Coring Bit

1-1/4” 7 UNC to 5/8” 11 UNC Core Bit Adapter

10” Extension Rod

12” Extension Rod

18” Extension Rod

GDC4 CORE DRILL

6

Operations

Note

THOROUGHLY READ THROUGH THE ENTIRE MANUAL BEFORE

OPERATING THIS MACHINE!

PURPOSE

Ø The purpose of the GCD4 core drill is to drill through masonry, concrete or other

mineral rock types using annular coring bits.

Ø These drills are designed to be used by hand.

Ø These machines can be used vertically, horizontally or overhead (inverted) provided

an acceptable work environment.

o CAUTION: If drilling overhead you are only permitted to use dry type core bits

with a vacuum system. “Wet” type holes overhead would allow water into the

motor and create an extremely dangerous situation.

OPERATIONAL PRINCIPLES

Ø The main drilling shaft rotates in a forward clockwise direction. The main drilling

motor connects to the tool spindle to make contact with a surface and slowly bore a

hole.

Ø These drills are ONLY to be used with diamond impregnated coring bits.

o When drilling with “wet” type bits, the bit ends pulverizes the material and the

water brings the material out of the cut.

o When drilling with “dry” type bits, the bit end pulverizes the material and dust

brings the material out of the cut.

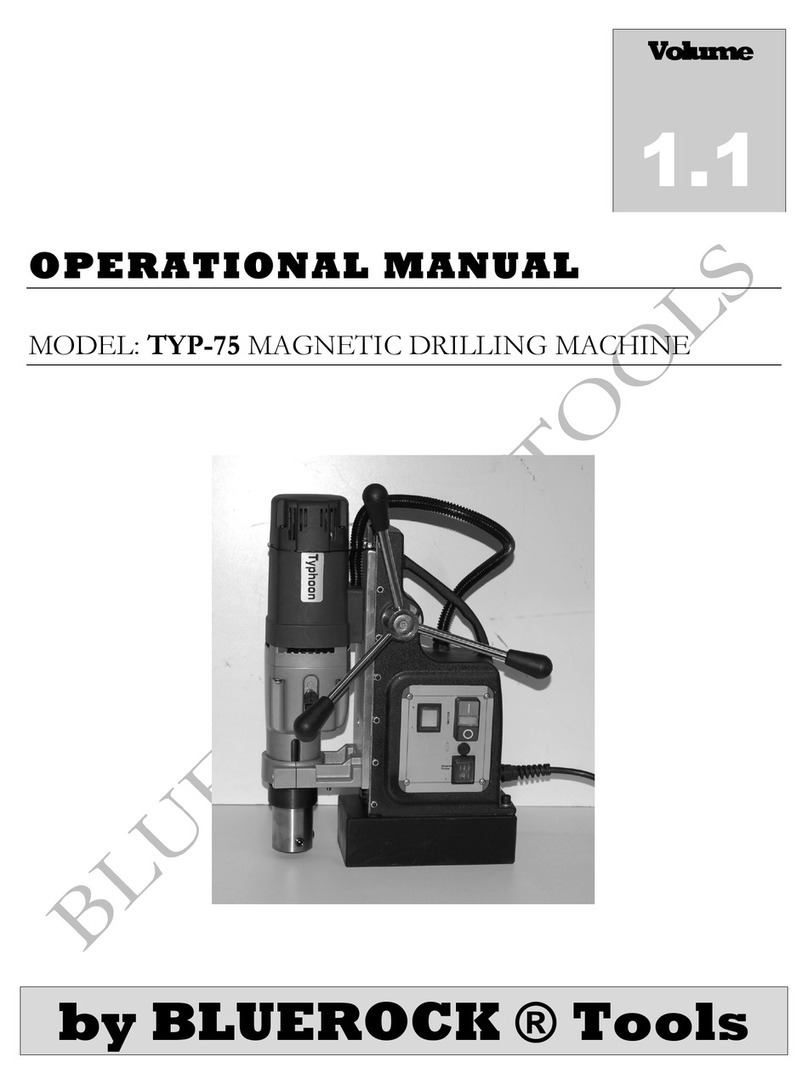

MACHINE COMPONENTS

Ø The main components of the GDC4 are the spindle, gearbox and motor. The spindle

is driven by the transfer case and the motor. There is a centrifugal clutch that

engages and drives the spindle once the motor begins to turn.

Chapter

3

GDC4 CORE DRILL

7

TRANSPORTING AND STORAGE OF THE MACHINE

Ø CAUTION: GAS FUMES ARE HIGLY FLAMABLE! GAS FUMES CAN CAUSE

DIZZINESS, VOMITING, AND A COMBUSTIBLE ENVIRONEMENT THAT CAN CAUSE

INJURY OR DEATH!

Ø When transporting the machine, always use two hands.

Ø DO NOT transport the machine with bits attached.

Ø As this is machine has a gas storage tank attached to the motor, it is NOT

recommended that this machine be transported inside of a vehicle. It is only

recommended to transport in a clean, dry, ventilated environment. ALWAYS secure

the machine when transporting with any vehicle so it does not move or bounce.

Ø The machine should be stored in a clean, dry, ventilated environment.

Ø “Winterizing” - It is recommended to run the machine dry (no gas in the fuel tank or in

the carburetor) if storing for more than 2 months as fuel can decay.

RUNNING THE MACHINE USING THE HANDHELD DRILLING METHOD

Ø Do all pre-operational and operational safety checks from Chapter 1.

Ø Consider your security and stability as well as the orientation of the machine in the

work area.

o DO NOT use this item in an unstable position (such as on a ladder, leaning

outside of center of gravity, etc). When using by hand, these drills could bind

up and personal injury could occur if not taking into account a very stable

body position.

o Consider the work surface material, condition, strength, density and rigidity.

These factors directly affect the tool’s efficiency.

Ø Ensure the work surface is free of debris, oil, etc.

Ø If using “wet” type bits, set up your drilling templates or other professional methods

for starting your hole.

Ø Select and set up fluid delivery method or dust collection system.

Ø If using the machine with the water system, connect hose to the side of the machine

using the connector.

o This connector takes standard ¾” US garden hose or quick disconnect

hookup depending on the model.

o Make sure the water valve is in the off position.

§ This is generally at a 90 degree angle from the valve hose.

o Partially turn the water spigot on (usually half a turn).

§ CAUTION: DO NOT turn the hose on fully! You need sufficient water

when using wet type bits. Using too much water pressure can cause

the bits to not cut properly as well as water entering the gearbox.

GDC4 CORE DRILL

8

Ø Select appropriate size cutting bit and install by screwing the bit onto the spindle.

See section below for details on securing bit.

Ø Open the water valve to allow water to come out to the work surface.

Ø If the engine is cold, shift the choke lever to the CLOSED position.

Ø If restarting a warm engine, the choke lever should be set the OPEN position.

Ø Press the priming bulb several times until there is fuel in the fuel-return tube.

Ø Turn the on/off switch into the “on” position.

Ø Adjust the throttle valve to the appropriate start position.

Ø Adjust the machine location to ensure the core bit do not contact any object in the

event it may accidentally rotate during the starting procedure.

Ø Pull starter handle lightly until resistance is felt once. Then pull the starter handle all

the way until the engine starts.

Ø Adjust the throttle valve to enable the engine to idle.

Ø As the engine temperature increases, gradually adjust the choke lever to the OPEN

position.

Ø Adjust the throttle valve to enable the engine to reach desired operating speed.

Ø ATTENTION: BE AWARE THESE MACHINES ARE EXTREMELY POWERFUL. THEY

HAVE A TREMENDOUS AMOUNT OF TORQUE WHICH MIGHT NOT BE SUITABLE

FOR ALL POTENTIAL USERS. ESPECIALLY WITH LARGER BITS. DESPITE THE

SAFETY CLUTCH, THESE DRILLS CAN STILL INJURE THE USER. IF IN DOUBT,

CONTACT A PROFESSIONAL FOR ADVICE.

Ø Very slowly engage the cutting bit with the material surface by lightly engaging the

bit with the material.

o NOTE: During the initial stages of contact the bit may wander.

o NOTE: If drilling and not using a guide, a common way to start the hole uses a

30 degree angle to slightly cut into the material. Once the bit has bored

slightly into the material, the user will slowly level the machine out straightly.

If unsure, it is recommended to contact a coring professional.

Ø After about 1/8” of cutting has been achieved in the work surface, slightly more force

can be applied. This will be the normal amount of force the rest of the hole.

o NOTE: Do not force the hole. Let the machine do most of the work.

Excessive physical effort should be avoided as it can cause damage to the

machine or cause injury to the user.

o If the unit jams in a hole, stop the drill immediately by quickly disengaging the

throttle switch to prevent injury. Loosen the cutter by turning drill spindle

counterclockwise. Never attempt to free a stuck bit by starting motor!

§ After an interruption in drilling, make sure the drill bit is free and turns

before restarting the hole. Be very careful at this point to make certain

the drill does not bind when restarting.

Ø Make sure to keep the cutting material lubricated when “wet” drilling.

Ø Ease up on pressure as the cutter starts breaking through the backside of the

material (if cutting completely through the material)

o Be certain all is clear on the output side of this core to prevent injury to

persons or property.

GDC4 CORE DRILL

9

o If drilling completely through the material, stop drilling after breaking through

the bottom, stop bit rotation and slowly pull out the bit and the core.

Ø If drilling to a specified depth (and not breaking all the way through the material)

leave the drill bit rotating until you reach your desired depth. Continue to leave the

drill bit rotating as you pull the bit completely out of the material.

Ø Once the drill is safely back to the non-drilling position, adjust the throttle valve to

enable the engine back to the idle state.

Ø Switch engine to “off” position.

Ø Turn water valve off. Turn off main water supply as well.

INSTALLING CORING BITS

Ø WARNING: Core bits can be sharp and should only be handled with gloves so as not

to cut the user during installation or removal.

Ø Check that the bits are not damaged.

o NOTE: Coring bits that are damaged should not be used.

Ø Make certain the machine is turned off.

Ø Apply grease to the spindle thread to prevent corrosion and allow easier core bit

removal.

Ø Insert the coring bit and screw it onto the drill spindle.

Ø Tighten the bit until fully tightened.

o Use wrenches that fit the spindle and coring bit to fully tighten.

GDC4 CORE DRILL

10

Troubleshooting

Note

SERVICING SHOULD ONLY BE DONE BY A QUALIFIED TECHNICIAN.

DON’T FORGET TO POWER DOWN UNIT PRIOR TO SERVICE!

PROBLEM

SOLUTION

Motor does not

turn on.

1) Check fuel level.

2) Fuel Filter is clogged. Replace filter.

3) Check oil level.

4) Check air filter is clean.

5) Motor carburetor needs cleaning.

6) Loose internal wire. Check and secure if necessary.

7) Spark plug issue. Inspect/replace if necessary.

8) Check to ensure the motor on/off switch is operable. Replace if

necessary.

Hole is not

cutting.

1) Cutting bit is dull. Replace bit.

2) Work area material is not appropriate for bit type.

Bit is jammed

while coring.

1) Debris is lodged between core hole and bit. Rotate bit in both

directions to and inspect bit for debris.

Coring speed has

reduced.

1) Bit has hit rebar. Adjust feed pressure to prevent motor overload while

cutting through rebar.

2) Diamonds on bit have glazed over. Deglaze bit or dress diamond rim on

bit and check water flow rate.

3) Diamonds on bit have worn away. Replace core bit.

4) New core bit. Core at slow rate with new bits for 2-3 coring cycles.

5) The safety clutch is slipping. Inspect and assess clutch condition.

6) DRY type drilling progress is prevented by an accumulation of dust.

Use suitable vacuum cleaner.

7) Water flow rate is too low. Increase water flow.

8) Core is stuck in the core bit. Remove core.

Core bit appears

to wobble.

1) Spindle is damaged. Replace spindle and check bearings.

2) Bit is bent or damaged. Replace bit.

3) The core bit is not screwed securely onto the spindle.

4) Coring material is attaching to the bit. Inspect bit and increase water

flow rate.

Water escapes at

the water swivel

or gear housing.

1) The water pressure is too high. Turn down water flow.

2) The shaft seal is defective. Replace seal

3) The water hose is damaged. Replace hose.

Chapter

4

GDC4 CORE DRILL

11

General Maintenance

Ø Inspect machine and machine body connections.

Ø Keep machine clean and free of debris. Do not forget to grease the drill spindle.

Ø Check for misalignment, binding and breakage of all moving parts. If damaged, repair tool

before use.

Ø Keep cutting tools sharp and clean. Sharp bits are less likely to bind and are easier to

control.

Occasional Maintenance

Ø Have the tool serviced by a qualified service technician using identical replacement parts.

o Inspect/Change Spark Plug:

o After 100hrs of use, inspect and remove the carbon build up

on the spark plugs.

o Check and adjust the spark plug gap to 0.6mm.

o Replace spark plug if necessary. Ensure the 0.6mm gap is

correct for a new plug.

o Change Gear Oil:

1) Change engine oil after 10 hours for a new machine (for engine break

in). After initial break in period, change oil at the 50 hour service

mark.

Chapter

5

GDC4 CORE DRILL

12

Parts List

NO.

Description

Item No.

Qty

1

Engine

Honda GX35

1

2

Handle

BKQYJ2018090101

2

3

Switch block

1

4

Inner hexagon screw

M6x20

2

5

Support plate

BKQYJ2018090102

2

6

Inner hexagon screw

M8x40

4

7

Mounting sleeve for handle

BKQYJ2018090103

2

8

Connecting plate

BKQYJ2018090104

1

9

Inner hexagon screw

M6x20

4

10

Inner hexagon screw

M6x20

2

11

Gearbox

BKQYJ2018090105

1

12

Baffle hexagon screw

BKQYJ2018090106

1

13

Inner hexagon screw

M6x15

2

14

O ring

16x3.1

1

15

1/4 Quick coupling

BKQYJ2018090108

1

16

1/4 valve

1

17

1/4 water tube connector

1

18

Water collecting ring

BKQYJ2018090109

1

19

TC Framework oil seal

35x50x8

2

20

Connection axle

BKQYJ2018090110

1

21

Cylindrical pin

8x35

1

22

Inner hexagon screw

M6x55

4

23

Handle cover

BKQYJ2018090111

1

Chapter

6

GDC4 CORE DRILL

13

Breakdown View - Overview

Table of contents

Other BLUEROCK Drill manuals