BlueSens YeastForce User manual

Rev 220301 003

Operating manual

Betriebsanleitung

Rev 220301 003

2

OPERATING MANUAL

EN

Content

1ABOUT THIS DOCUMENT ..............................................................................................3

Purpose.................................................................................................................................... 3

Target group............................................................................................................................. 3

Symbols in use......................................................................................................................... 3

2FOR YOUR SAFETY........................................................................................................4

In general ................................................................................................................................. 4

Authorized personnel ............................................................................................................... 4

Proper and intended usage...................................................................................................... 4

Warning against misuse........................................................................................................... 5

General safety instructions....................................................................................................... 5

CE conformity........................................................................................................................... 5

3PRODUCT DESCRIPTION ..............................................................................................6

The sensor ............................................................................................................................... 6

Converting to a standardized gas ............................................................................................ 6

Accessories.............................................................................................................................. 7

Required laboratory materials.................................................................................................. 8

4INSTALLATION................................................................................................................9

General instructions ................................................................................................................. 9

Attaching the filter adapter ....................................................................................................... 9

5ELECTRICAL CONNECTION ........................................................................................10

In general ............................................................................................................................... 10

USB - RS232 cable wrap-around........................................................................................... 10

RS232 connection to the PC.................................................................................................. 10

6YEASTFORCE MONITOR .............................................................................................12

Installing the software............................................................................................................. 12

Connecting the sensors ......................................................................................................... 14

Search for heads:................................................................................................................... 14

CO2sensor: single-point calibration....................................................................................... 16

Volume inspection.................................................................................................................. 19

Preparing a measurement...................................................................................................... 22

Starting a measurement......................................................................................................... 26

7APPENDIX.....................................................................................................................28

Technical data........................................................................................................................ 28

Warranty................................................................................................................................. 28

Service and Support............................................................................................................... 28

Proper disposal ...................................................................................................................... 29

Imprint .................................................................................................................................... 29

8CE-CONFORMITY.........................................................................................................30

9FCC-CONFORMITY.......................................................................................................31

Rev 220301 003

3

OPERATING MANUAL

EN

1 About this document

Purpose

This operating manual provides you with all the information you need to

quickly commission and safely operate the YeastForce. Please read this op-

erating manual before you start the initial commissioning. Keep this operating

manual in a safe place for future reference.

Target group

This operating manual is intended for trained specialist personnel. The con-

tents of this manual must be provided to and implemented by the trained

personnel.

Symbols in use

Danger!

This symbol indicates a possibly dangerous situation. Failure to

comply with these safety instructions may result in personal in-

jury.

Caution!

This symbol indicates a situation, which could result in damage

to equipment or other property.

Note!

This symbol indicates additional helpful information.

1 Sequence of actions

Sequential numbering indicates successive steps.

Rev 220301 003

4

OPERATING MANUAL

EN

2 For your safety

In general

The YeastForce was inspected before it left the factory and was in an oper-

ationally ready condition.

Please read this operating manual carefully before installing and commis-

sioning the device. The operating manual contains safety instructions that

must be followed to ensure safe operation.

The contents of this manual correspond to the status as of November 2020;

they may be changed without prior notice. We reserve the right to make tech-

nical changes in the course of further developments.

The accuracy of the information in this manual has been carefully checked.

Nevertheless, the BlueSens gas sensor GmbH assumes no liability for con-

sequences arising from any errors in the description and illustrations. The

General Terms and Conditions of BlueSens Gas Sensor GmbH apply.

This device must never be operated under conditions that do not conform to

its specifications and information specified on the ratings plate.

Maintenance and repair may only be carried out by properly trained, compe-

tent personnel who are familiar with the associated risks and warranty provi-

sions.

Authorized personnel

The operations described in this operating manual may only be carried out

by trained specialist personnel who have been authorized by the facility op-

erator. For safety and warranty reasons, any further intervention or repairs

to this device may only be carried out by personnel from BlueSens gas sen-

sor GmbH.

Proper and intended usage

The YeastForce, as described in the Technical Specifications, is a device

for measuring volumetric flows in the specified flow range and under the

specified conditions. It is used to monitor metabolic procedures within bio-

logical processes. The YeastForce measuring device may only be used in

well-ventilated rooms.

Rev 220301 003

5

OPERATING MANUAL

EN

Danger!

This measuring device has no ATEX approval and may only be used

in well-ventilated rooms.

Warning against misuse

The YeastForce may not be used as a safety component for monitoring in

facilities; it must not be used in explosive zones.

General safety instructions

This device may pose application-specific hazards if it is used improperly.

Danger!

Incorrect installation or configuration may result in an explosion.

Check all connections for leaks after the installation is finished.

CE conformity

The YeastForce complies with the EMC Directive (2014/30/EU) using the

harmonized standards EN 55011, EN 61326-1.

The Low Voltage Directive (2014/35/EU) does not apply because no voltage

higher than 24 V is used.

See the last pages of this manual for the CE and the FCC certificate.

Rev 220301 003

6

OPERATING MANUAL

EN

3 Product description

The sensor

The YeastForce consists of a sensor top section [A]

(with sensors for pressure, CO2concentration and

temperature) and a lower section consisting of a jar

[B] with one bracket [C].

There are two connectors on the top of the

YeastForce. One connection is used for the power

supply and communications [D]. The other connec-

tion is used for the gas discharge [E]. A filter is in-

cluded for the gas discharge.

Figure 1

During operations, the filter must be mounted at the gas discharge outlet.

Otherwise, the pressure cannot be released from the sensor.

This would prevent the sensor from functioning correctly; dangerous over-

pressure could then occur.

To achieve the best measurement result, the

YeastForce should be operated in a bath of water at

a constant temperature while measuring. The water

level must not be higher than the glass jar.

Converting to a standardized gas

The YeastForce has sensors for pressure and tem-

perature. With the help of these measured values,

the internally calculated volume is normalized to the

standard conditions of 1013.25 mbar and 273.15 K

(0°C).

The calculation can be converted back to any labor-

atory conditions by using the general gas equation.

Since the number of particles in a closed system is

constant, the following formula applies:

𝑝 ∗ 𝑉

𝑇= 𝑐𝑜𝑛𝑠𝑡𝑎𝑛𝑡

where 𝑝 = 𝑃𝑟𝑒𝑠𝑠𝑢𝑟𝑒 [𝑚𝑏𝑎𝑟]

𝑉 = 𝑉𝑜𝑙𝑢𝑚𝑒 [𝑚𝑙]

𝑇 = 𝑇𝑒𝑚𝑝𝑒𝑟𝑎𝑡𝑢𝑟𝑒 [𝐾]

In the template settings of the YeastForce Monitor,

you can set the standard conditions for the tempera-

ture to easily compare it with other measuring meth-

ods according to user requirements.

Rev 220301 003

7

OPERATING MANUAL

EN

Accessories

The following accessories are required for the ini-

tial commissioning of the YeastForce:

3.3.1 USB RS232 serial port adapter with

power supply connection

(Z-KA-00014)

With wrap-around (refer to chapter 5.2)

Figure 2. Connection from the PC (USB) to the

YeastForce (M12 / 8-pin)

3.3.2 12 V DC power supply

(Z-NT-00010)

Figure 3. 12 V DC power supply

3.3.3 Glass jar for the YeastForce

Standard empty volume of 562.5 ml (± 2

ml)

(Z-GF-00019)

Figure 4 Glass jar for the YeastForce

3.3.4 Bracket for the YeastForce

(Z-XX-00166)

Figure 5 Bracket

3.3.5 Filter adapter for the YeastForce gas

discharge

(Z-XX-00133)

Figure 6 Filter adapter

Rev 220301 003

8

OPERATING MANUAL

EN

3.3.6 Piston pump for volume inspection (20

ml)

(Z-XX-00134)

Figure 7 Piston pump

3.3.7 Active USB hub

Optional

(K-00006)

Figure 8 Active USB hub

3.3.8 Seal ring

(Z-XX-00200)

Figure 9 Seal Ring

Required laboratory materials

3.4.1 Sodium hydroxide NaOH

For removing residual CO2during the single-point

calibration of the CO2sensor

Available from chemical specialty stores

3.4.2 Water bath

The sensor is calibrated to a temperature range of

15-40°C. Therefore the water bath may have a tem-

perature range of 25-40°C.

Water height: 5 –9 cm (maximum height of glass

jar)

The YeastForce must not be completely im-

mersed because it has a protection class of IP64!

Rev 220301 003

9

OPERATING MANUAL

EN

4 Installation

General instructions

During delivery, the YeastForce has been shipped in

protective packaging. This packaging protects

against normal transport loads. Nevertheless, please

check before installation whether the device has

been damaged by improper transport or improper

storage. Safe operation is not possible if the device

is damaged. The device may not be installed or put

into operation if damage is detected.

Make sure that the specified operating conditions are

maintained at all times.

Installation should only be carried out under expert

guidance and in accordance with the relevant recog-

nized occupational safety regulations.

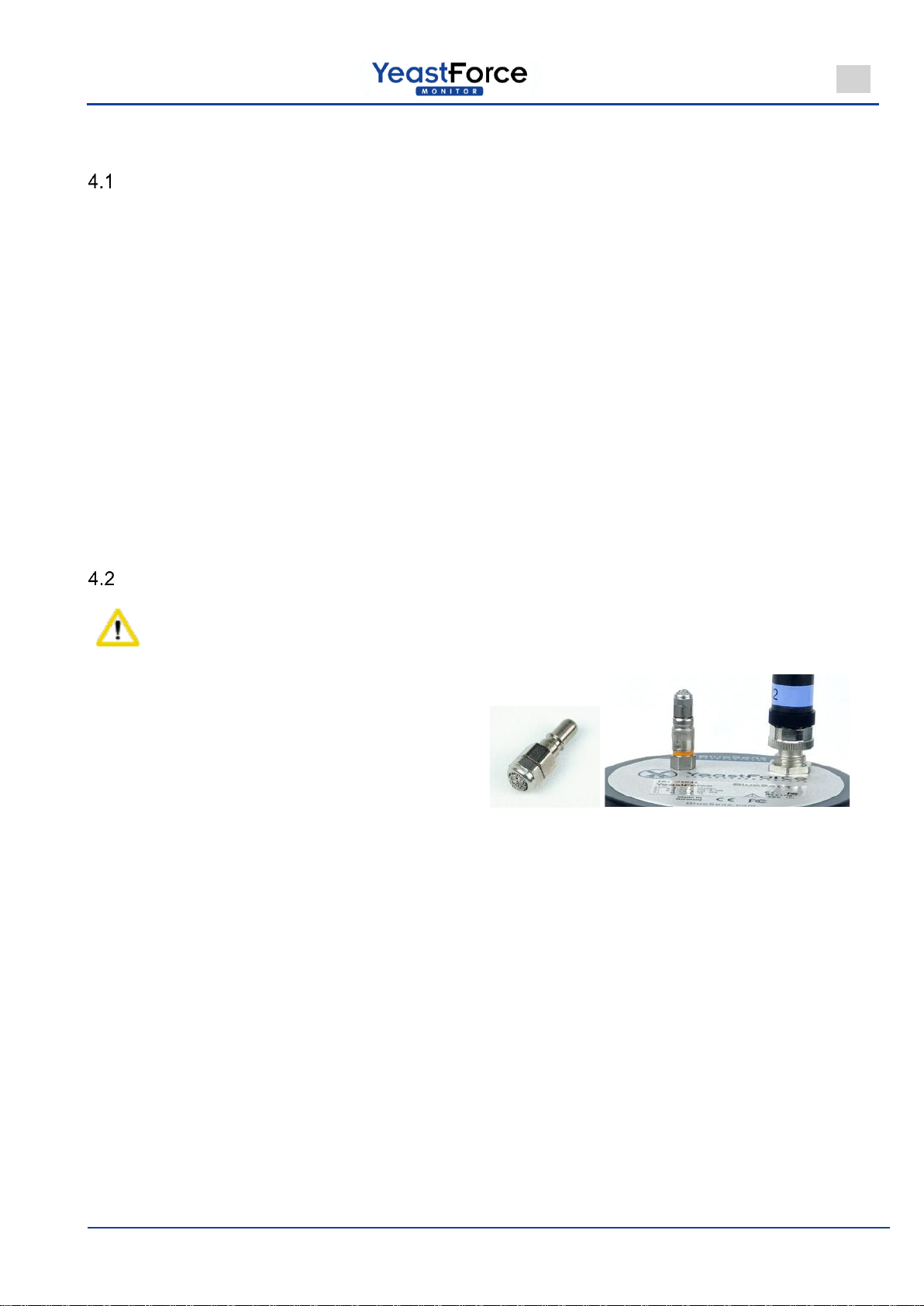

Attaching the filter adapter

Important!

If the sensor is supplied without a filter adapter on

the gas discharge, the filter adapter must be at-

tached to the gas discharge after unpacking the

YeastForce sensors.

Figure 10 Attaching the filter adapter

Rev 220301 003

10

OPERATING MANUAL

EN

5 Electrical connection

In general

Caution!

Read the installation instructions carefully to

avoid damaging this device.

Proceed step by step.

Use only the original plugs, cables and power

supplies.

Never connect or disconnect the plug when

the device is connected to the power supply.

This device has no on/off switch. It starts op-

erating immediately after it is connected to the

power supply.

Incorrect operations may damage the device.

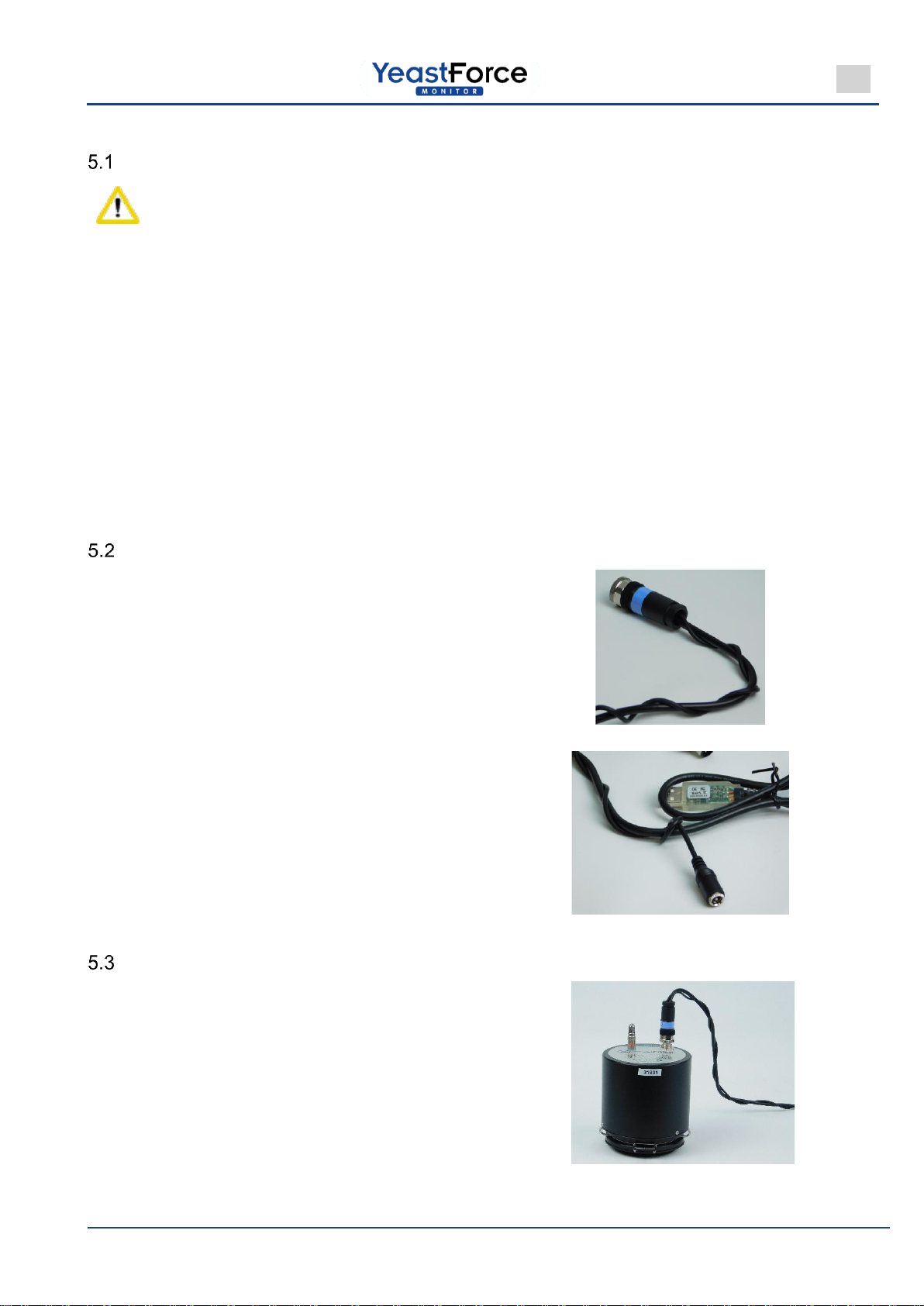

USB - RS232 cable wrap-around

To minimize the risk that the YeastForce cable

tangles with any other cables, the power supply

cable should be wrapped around the data cable. A

simple method is to wrap the power supply cable

around the data cable.

First, wrap the data cable around the M12 8-pin

connector. Continue until the power supply cable

is completely wrapped around the data cable.

Figure 11 Wrapping the cables

At the end, make a small loop and form the cable

into a knot. This prevents the power cable from un-

winding.

Figure 12 Knot the cables at the end

RS232 connection to the PC

The USB-to-RS232 cable (with power supply) is

first attached to the YeastForce using the M12 8-

pin adapter.

The plug of the power supply unit is then connected

to the power connection of the data cable and se-

cured so that it cannot slip out.

Figure 13

Rev 220301 003

11

OPERATING MANUAL

EN

The power supply unit may now be plugged into a

power outlet. Now, the sensor starts working.

The cable's USB plug should now be connected to

a computer (in an active hub if necessary).

Figure 14

The sensor needs about one hour un-

til it is ready for operations. No meas-

urement may be made before this.

The YeastForce Monitor program shows a flash-

ing icon during this warm-up period:

[Wait while sensor heats up]

Figure 15

Rev 220301 003

12

OPERATING MANUAL

EN

6 YeastForce Monitor

You can download the latest software at the following link:

https://www.bluesens.com/fileadmin/user_upload/downloads/YeastForceMonitorSetup_1_4_20.msi

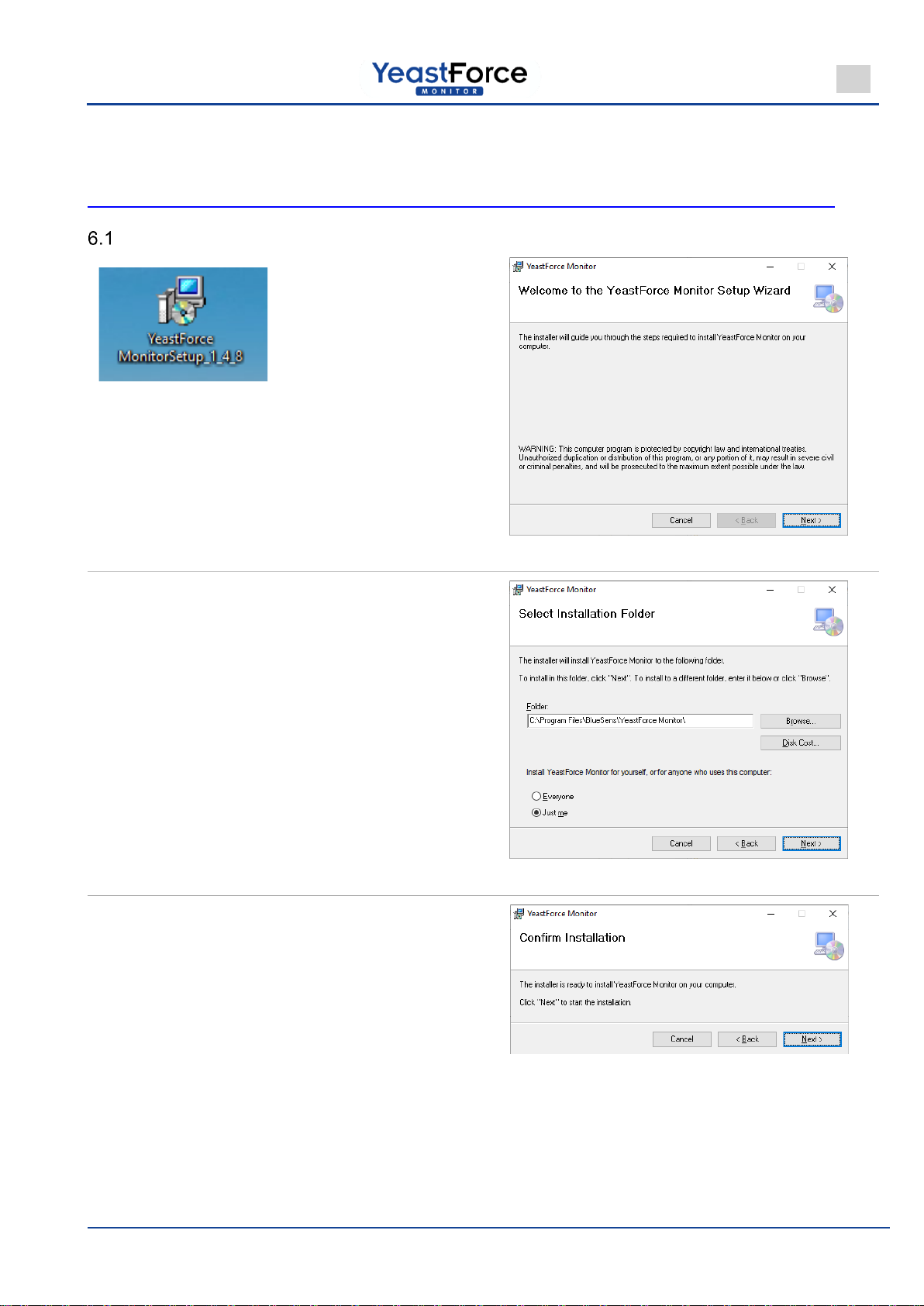

Installing the software

Double-click on the .msi file to start the installa-

tion. Since the program is installed in the Program

Files folder, admin rights are required during in-

stallation.

The Welcome page appears.

Click on [Next]

Figure 16

Select the installation path and user settings.

Click on [Next]

Figure 17

Confirm and start the installation:

Click on [Next]

Figure 18

Rev 220301 003

13

OPERATING MANUAL

EN

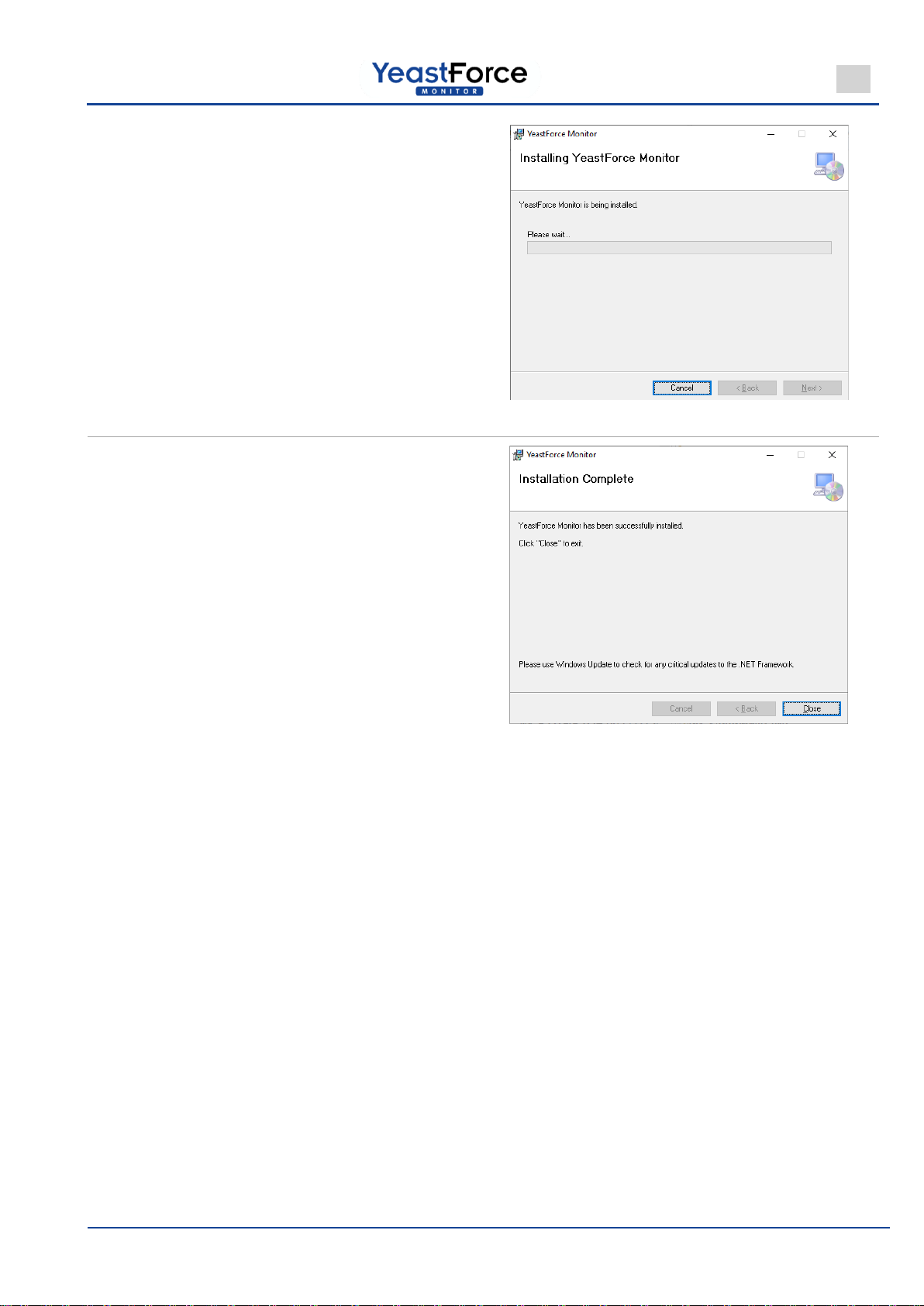

The program is installed:

Please wait:

A progress bar shows the

installation progress.

Figure 19

The final dialogue box appears after a successful

installation:

Click on [Close]

Figure 20

Rev 220301 003

14

OPERATING MANUAL

EN

Connecting the sensors

If the drivers are not found automatically, you can

download the latest FTDI-VCP driver from the follow-

ing page:

https://www.ftdichip.com/Drivers/VCP.htm

Search for heads:

Figure 21 YeastForce Monitor, after the program start

When the program is started, all available COM

ports in the computer are scanned for connected

sensors. These are then loaded into the program.

If not all sensors are found, the program can

search for more sensors again via the

[HeadsSearch Heads] option.

Figure 22

If a found sensor is then disconnected and recon-

nected to the computer, it can be reactivated with

the [Reconnect] option.

Figure 23

Rev 220301 003

15

OPERATING MANUAL

EN

6.3.1 Configuring a sensor head

To configure the YeastForce sensor, the

Configuration window can be invoked from

the [Heads] menu or the [HeadInfo] right-

click context menu.

Figure 24

Use the [Custom Head Color] drop-down

list to change the display colour of the sen-

sor.

The [Show Always] option causes the sen-

sor to always be displayed on the user in-

terface. If the sensor is not found, this is

displayed immediately. You can reactivate

the sensor in the program's context menu

via [Reconnect].

Figure 25

If the [Show Export Options / Calibration]

option is selected, additional information

about the sensor is displayed.

This calibration information relates to the

data about the operating status saved in

the sensor or the program. If the single-

point calibration or volume inspection was

performed more than one month ago, it

must be carried out again. The previous

dates (of last execution) are displayed in

this window.

Figure 26

Rev 220301 003

16

OPERATING MANUAL

EN

CO2sensor: single-point calibration

CO2absorber NaOH

Danger!

NaOH may only be used in accord-

ance with the applicable safety pre-

cautions!

Serious injury to skin

or eyes

Wear protective gloves

Wear safety goggles

Gather the materials together:

- YeastForce sensor

- Glass jar for the YeastForce

- NaOH solution (e.g. 3 M ~= 10 %)

- Small vessel for at least 20 ml NaOH (e.g.

100 ml beaker),

which will fit into the glass jar

Figure 27

Pour 20 to 100 ml NaOH into a suitable vessel and

place it in the glass jar.

Figure 28

Attach the YeastForce to the jar using the bracket

on the glass jar.

Figure 29

Rev 220301 003

17

OPERATING MANUAL

EN

Startthe single-pointcalibrationinthe YeastForce

Monitor (via the right-click context menu for the

sensor and confirm the information about the ad-

dition of NaOH by clicking on OK).

Figure 30

The concentration is then recorded for 5 minutes

and the slope of the graph is displayed. The upper

graph shows the progress over the entire time of

the measurement. The lower graph always shows

only the last five minutes. The slope of the graph

is also calculated during these five minutes.

Figure 31

The CO2concentration now decreases until there

are hardly any CO2molecules left in the vessel. If

the slope drops below 2 ppm/min, the button for

the single-point is enabled.

Figure 32

After the single-point calibration is finished, the

new concentration for the sensor is displayed. If

this is more than 0.01% by volume, the single-

point calibration should be performed again.

Figure 33

Rev 220301 003

18

OPERATING MANUAL

EN

Click on the Restart button: the instrument waits

again for 5 minutes until a new single-point cali-

bration is possible.

Also here, the slope must be less than 2 ppm/min.

Figure 34

You can click on the [Return to YeastForce Moni-

tor] button to return to the main program.

Figure 35

Rev 220301 003

19

OPERATING MANUAL

EN

Volume inspection

Connect the sensor to the power supply. Connect

the USB cable to the computer.

(Refer to chapter 5)

Mount the YeastForce on a glass jar. Place them

together in a water bath with a water height be-

tween 5 and 9 cm.

The temperature in the water bath should be be-

tween 25 and 40 °C, and higher than room tem-

perature.

Keep the water bath and sensor at a constant

temperature for at least 30 minutes.

Figure 36

Start the YeastForce Monitor software program

and search for the connected YeastForce head.

(Refer to chapter 6.3 Search for heads)

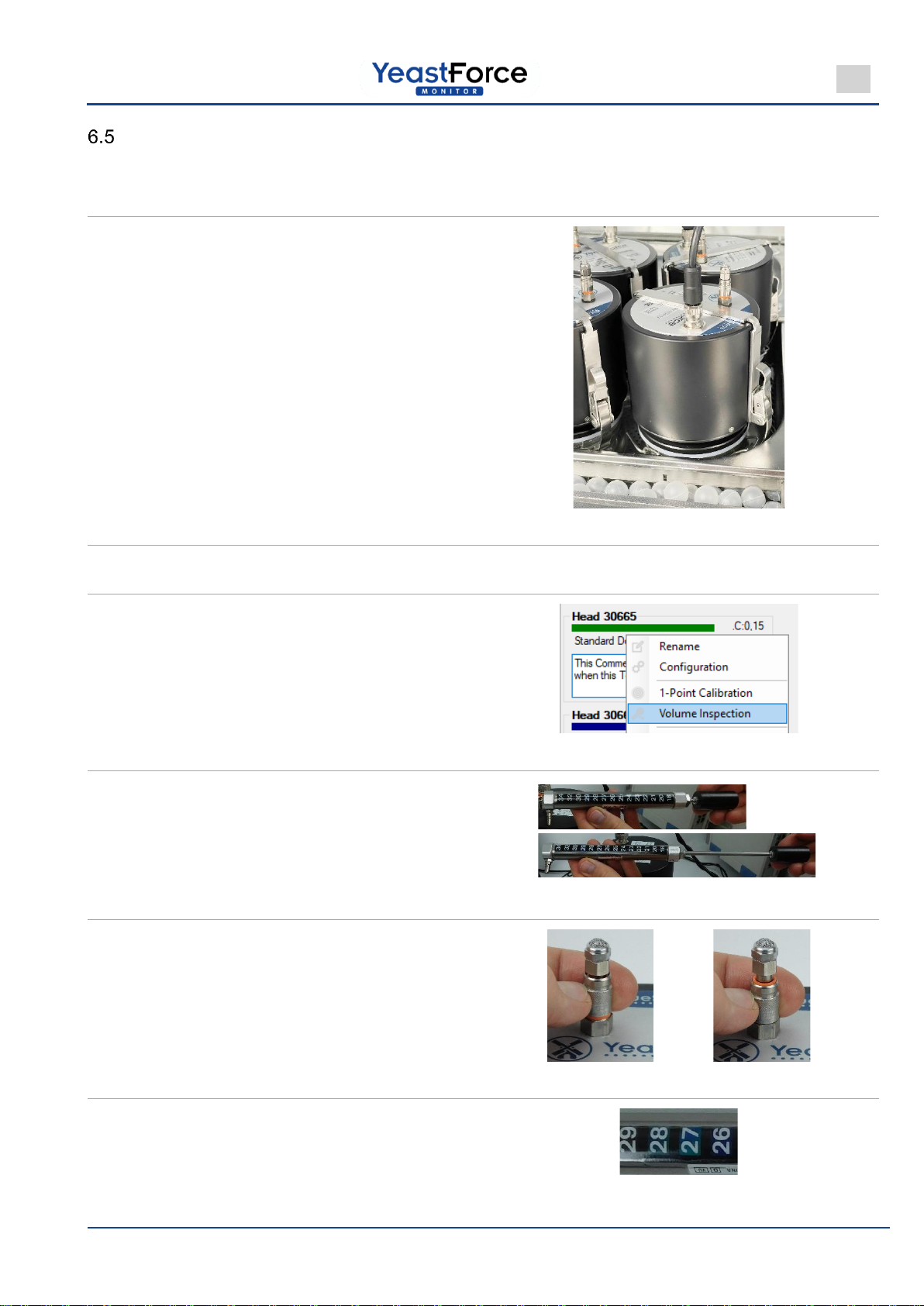

Start a volume inspection from the right-click con-

text menu.

Figure 37

Pull out the piston pump.

Figure 38

Remove the YeastForce's protective filter by

pushing the fluted ring down towards the orange

band.

Figure 39

Enter the temperature of the piston in the pro-

gram. (here: 27.5°C)

If it is too cold, heat the piston to 20°C with your

hands.

Figure 40

Rev 220301 003

20

OPERATING MANUAL

EN

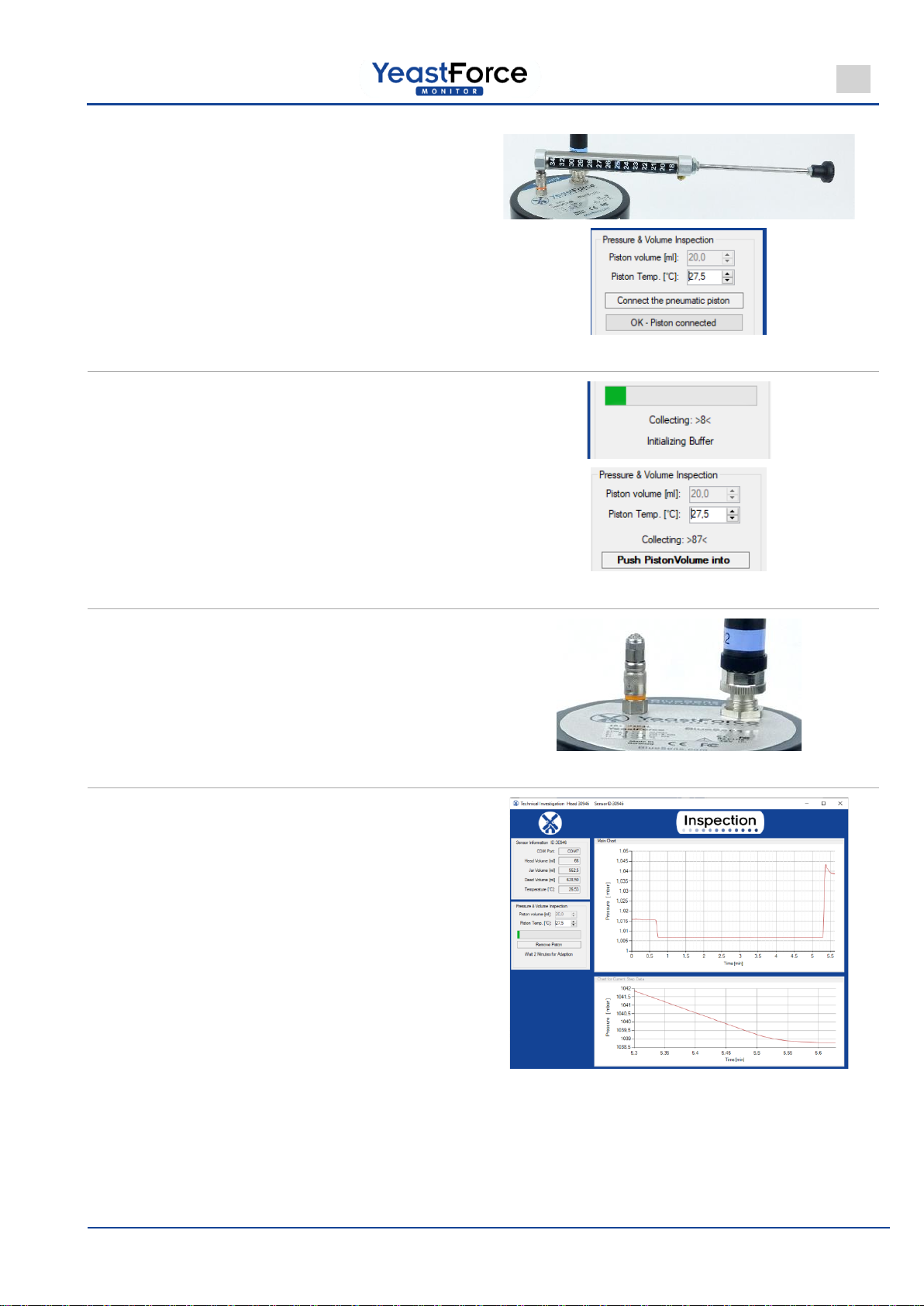

Place the piston pump on the YeastForce until

the piston clicks into place.

Then, confirm this in the program:

[OK –Piston connected]

Figure 41

Wait about 10 seconds.

If the pressure is constant and the program

prompts you to do so, press the piston rod into the

piston slowly and consistently.

Figure 42

After the valve closes (audible soft click and the

message [Remove Piston]), the piston can be re-

moved and the filter can be put on.

Figure 43

The pressure rises in the YeastForce.

The program records the pressure and calculates

the tightness and volume of the system.

The lower graph shows a partial section of the up-

per graph.

This automatically displays the relevant part of the

measurement with more details.

Figure 44

Table of contents

Languages: