01

Thank you for purchasing a BlueSpot product, you can find further information on our

range at www.BlueSpot.uk.com. Please ensure that you are using the product correct-

ly and that all guidance and cautions are followed in accordance with the instructions.

Please retain these instructions for future reference.

General Information

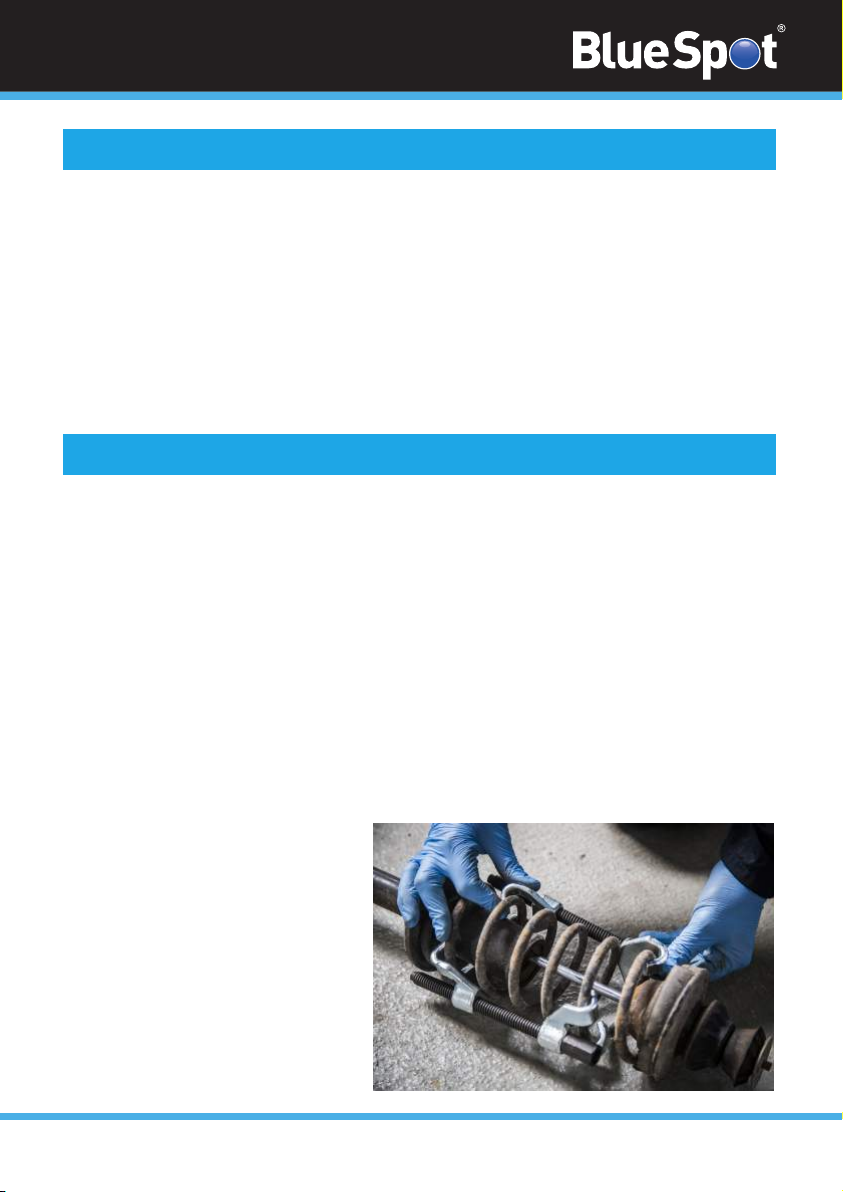

Please make sure that you read these instructions carefully in order to avoid injury when using

the coil spring compressor. Follow all health and safety rules and regulations. If in doubt and

available please contact a more knowledgeable source.

It is inadvisable to leave a coil spring under tension due to the stored energy. Immediately replace

the coil spring onto the shock absorber in order to reduce time that spring is under tension away

from the vehicle and potentially a danger to you or anyone in your workshop.

DO NOT use if damaged.

• Maintain tool in good and clean condition for best and safest performance.

• Keep the work area clean, uncluttered and ensure there is adequate lighting.

• Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip

shoes.

• Keep children and unauthorised persons away from the work area.

• If the spring compressors are damaged do not use.

• ALWAYS dress appropriately – clothing should be close fitted and long hair tied back.

Jewellery should be removed and shoes should be worn with a non-slip sole.

• ALWAYS wear the correct eye or face protection when operating the spring

compressors.

• ALWAYS wear approved respiratory protection if needed.

• ALWAYS ensure you work in a well ventilated room.

• ALWAYS check and ensure the hooks are connected securely on the spring before

commencing compression.

• DO NOT allow for the spring to become coil bound.

• DO NOT leave a compressed spring unattended.

• NEVER use air tools to compress a spring.

• NEVER operate the tool if you are under the influence of drugs or alcohol as this

is dangerous.

• NEVER make modifications to the tool.

• NEVER use the spring compressor for a task that it was not designed for.

• DO NOT operate the spring compressors if you are tired as this could be dangerous.

• ALWAYS stop using the tool straight away if you start to experience discomfort or pain.

Consult with a qualified health professional if needed.

Safe use