1

MANUAL for:

UNIVERSAL SPRING COMPRESSOR 91XL (SC91XL)

Read this manual before you start to work

with the SC91XL.

SC91XL designed and made by:

LEURS PRECISION

Nijverheidsweg 11

2821 AT Stolwijk

Holland

Tel.: +31 ‒ (0)182 342 342

info@leursprecision.nl

https://www.springcompressor.nl

2

INTRODUCTION

The Universal Spring Compressor 91 XL (SC91XL) is intended as a tool for the changing of main springs of

air rifles.

By using the SC91XL changing of these springs can be done safer, with much less physical force and without

damaging the rifle.

The SC91XL is suitable for almost all types of air rifles.

SAFETY

1. Read this manual carefully, before using your SC91XL.

2. Check in a safe way and in safe direction if the air rifle, of which you want to change the spring, is not

loaded and is not cocked. (See the manual of the air rifle)

3. Wear safety goggles when using the SC91XL.

4. Use no "violence" when using the SC91XL. Due to the many different air rifle constructions, you

sometimes have to try how the air rifle can fit the SC91XL. If so, do this safe.

PREPARING WORK

1. Put the SC91XL with the middle of the frame in a vice, or with a clamp on a workbench. Take care not

to damage the SC91XL, do not "compress" the SC91XL.

2. Read the air rifle manual for how to prepare the air rifle for changing the spring of the air rifle.

3. Air rifles with the end plug screwed in the cylinder (as example Weihrauch HW77 or HW85), screw out

the end plug a few turns.

USING the SC91XL

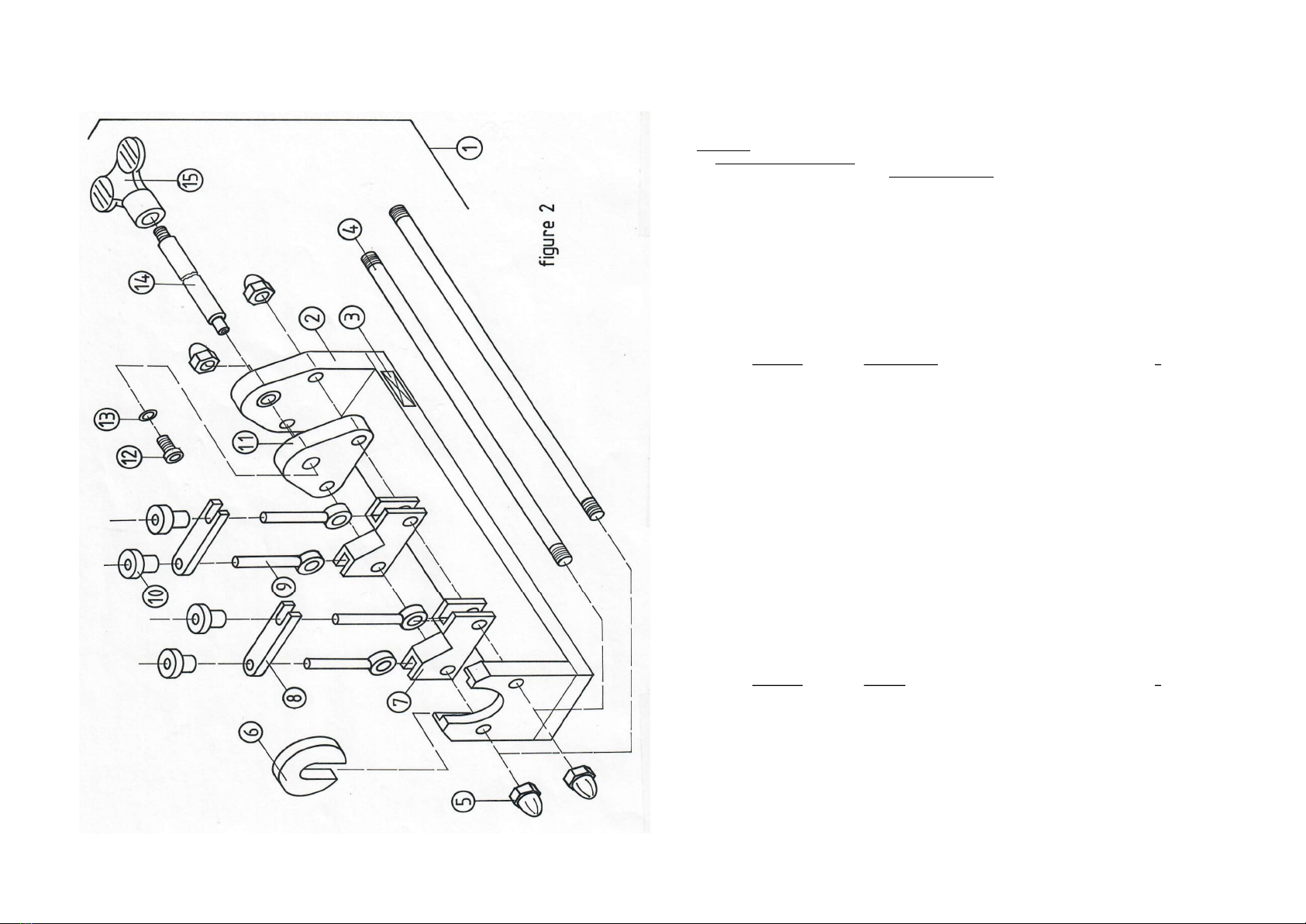

1. Place the air rifle as follows in the SC91XL (see figure 1):

- move clamp blocks (“V-blocks”) so that the SC91XL fits the rifle.

- if necessary turn the air rifle around until it fits the SC91XL.

- place stop disc (1) over the barrel, in the recess of the frame. (otherwise the rifle will shift out

of the SC91XL)

There are 3 different stop discs supplied , one with a slot of 16.5mm, one with a slot of 21mm,

and one without a slot

The stop disc without a slot can be, if necessary, adapted to an air rifle.

Pay especially attention if the adapted stop disc is still strong enough and can be

used safely as intended.

2. Clamp the air rifle in the SC91XL by putting the two clamp covers (2) over the air rifle cylinder. Tighten

the clamp covers with the four knurled nuts (3).

3. Air rifles were a safety knob protrudes out of the end of the end plug (for example Webley Eclipse)

should, for preventing damage to this knob, be put a wooden or plastic piece between the end plug

and the push block (4).