3

3. Remove the inlet tting or air strainer and discard

the gasket (2).

4. Remove the inlet and outlet water lines after draining

the radiator.

5. Remove and retain the four hex head cap screws

from the head. Tap the head with a mallet to break

the gasket seal and remove the head. Remove and

discard the head gasket (14).

6. Remove the unloader stop assembly (3) and discard.

7. Remove the unloader piston assembly (4) and discard.

8. Insert a spanner-type wrench into the holes of the inlet

valve stop (5). Remove and discard.

9. Remove and discard the inlet valve spring (6), inlet

valve (7), inlet valve seat (8), unloader gasket (9), and

unloader spring (10).

10. Using a 9/16" Allen®wrench, remove and discard the

discharge valve seat (11).

11. Remove and discard the discharge valve (12) and the

discharge valve spring (13).

12. Remove and discard the cylinder head gasket (14).

CLEANING

Remove all carbon deposits, rust, and scale from all cavities

in the cylinder head. Use shop air to clear any loose

particles from these recesses. Scrape the body surfaces

of the head and the crankcase taking care not to allow

foreign material to fall into the cylinder.

INSPECTION

1. Inspect the inlet bushing and discharge valve stop for

excessive wear, nicks, and scratches. These surfaces

can be "dressed" with a lapping stone to improve their

condition.

2. If it is apparent that these parts are not salvageable,

obtain replacement parts through a local Bendix®outlet.

For instructions on the installation of parts not contained

in maintenance kits, refer to SD-01-331.

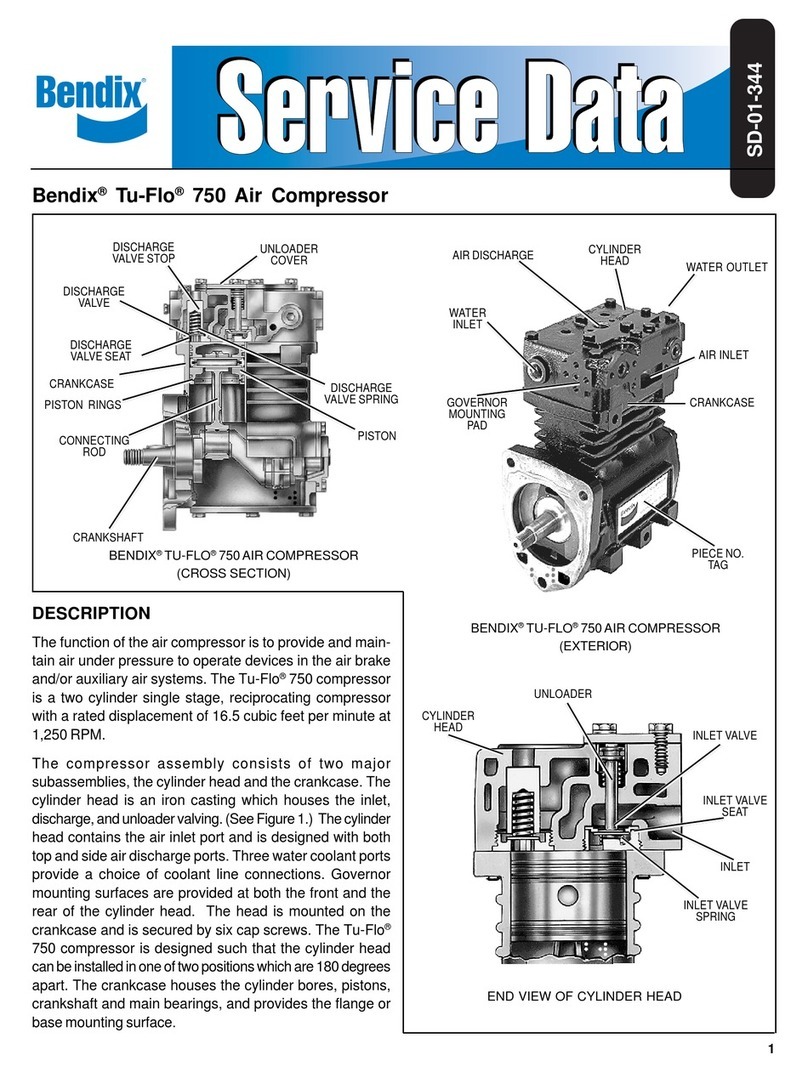

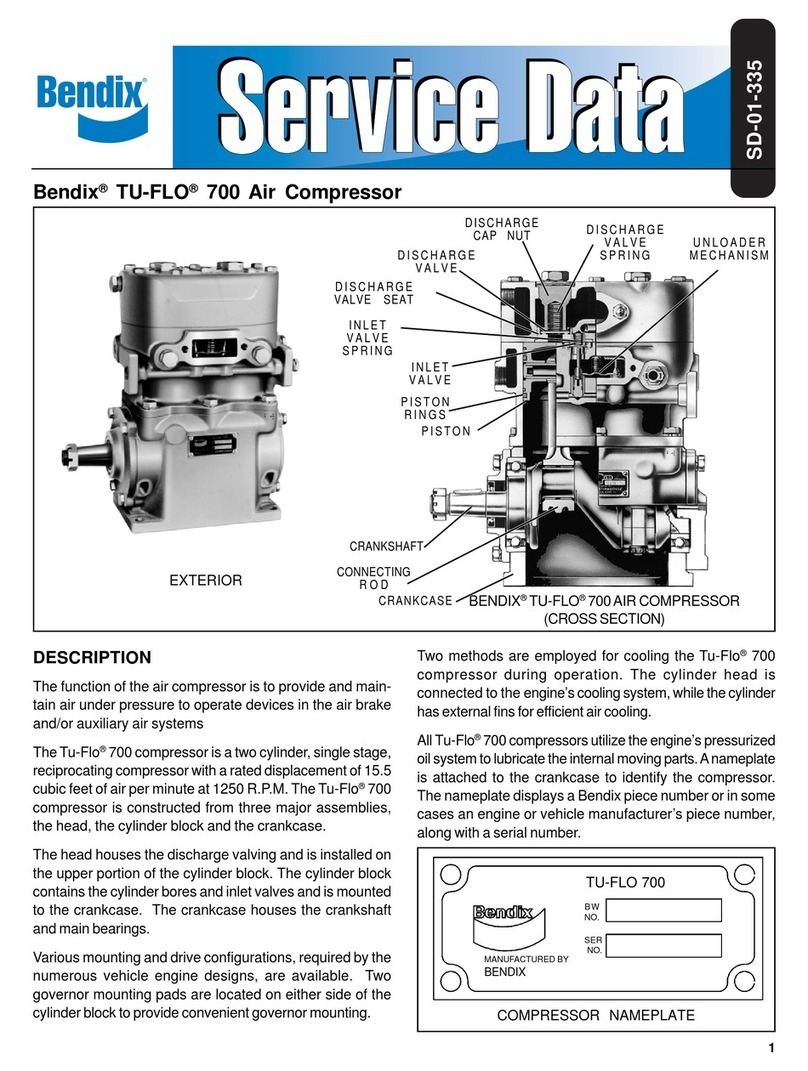

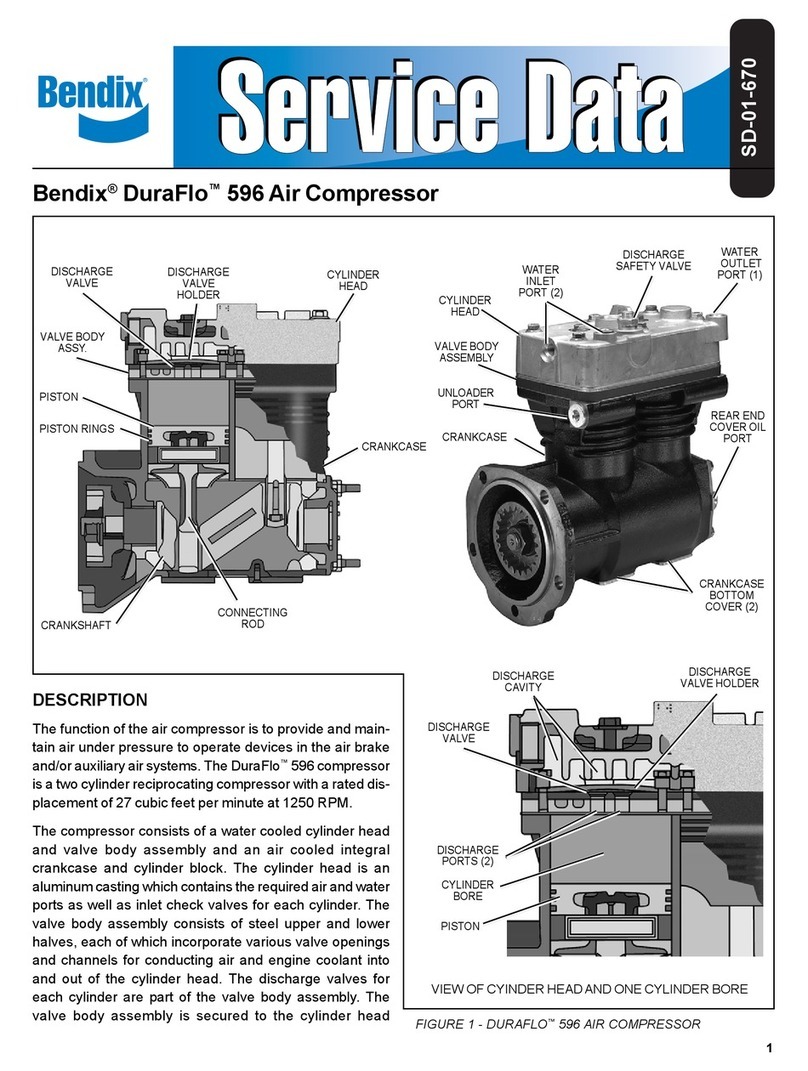

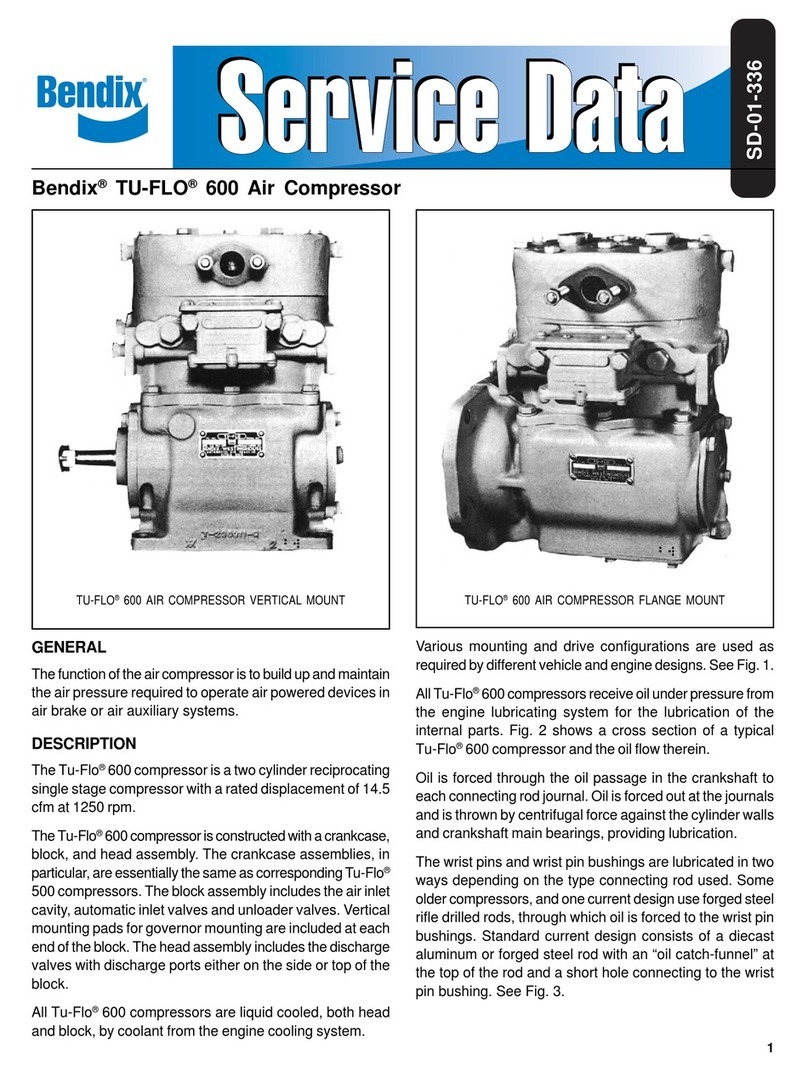

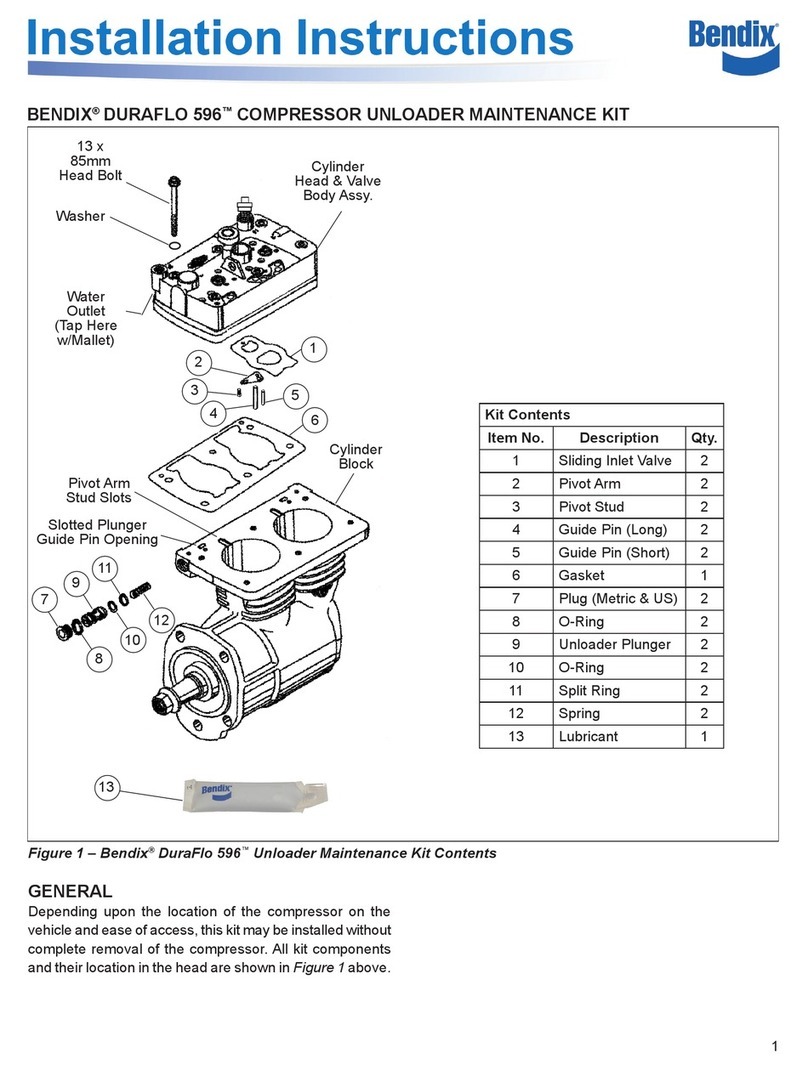

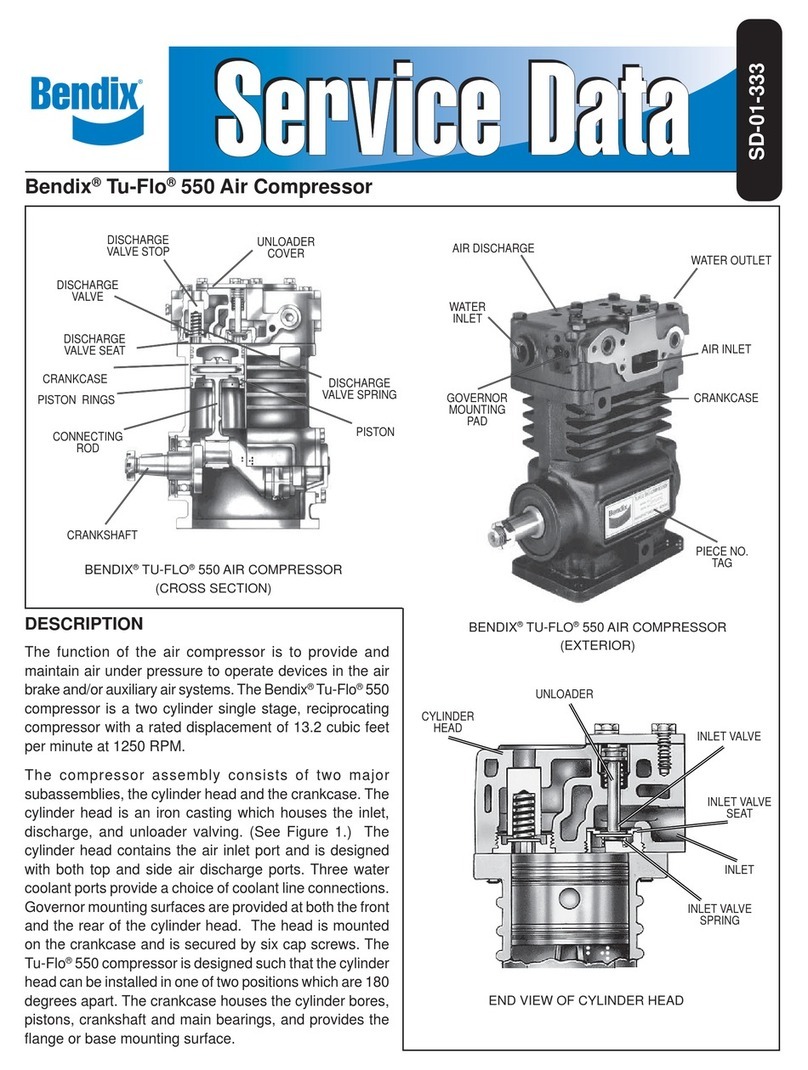

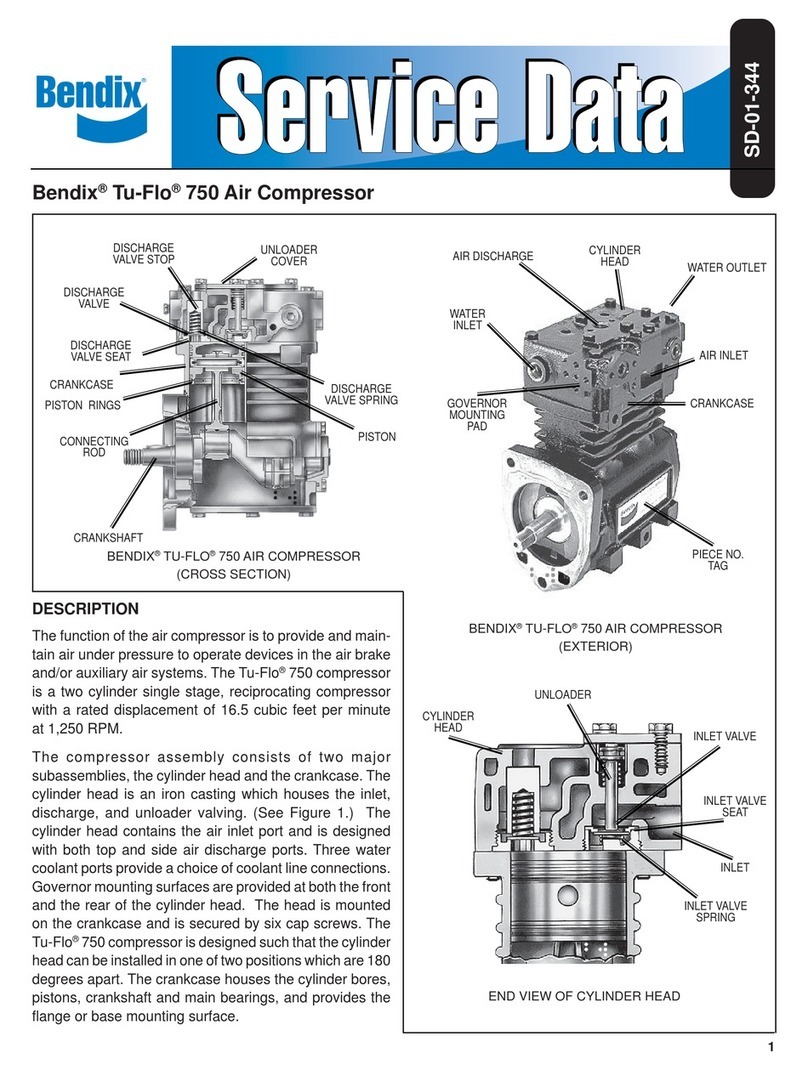

ASSEMBLY (Refer to Figure 1)

1. Install the unloader stop assembly (3) into the threaded

port on the top of the head above the air inlet cavity.

Torque to 175-225 in-lbs.

2. Turn the head over and install the unloader piston

assembly (4) into the unloader cavity (short stem rst).

Install unloader spring (10) (small end rst) onto the

long stem of the unloader piston assembly (4). Install

the unloader gasket (9) over the unloader spring and

rest it on the shoulder of the hole in the unloader cavity.

Install the valve seat (8) on top of the unloader gasket

(bevel side of valve seat up). Install the inlet valve (7)

on the valve seat. Install the inlet valve spring (6) on the

inlet valve. Retain with the inlet valve stop (5). Using a

spanner-type wrench, torque to 840-1080 in-lbs.

3. Install the discharge valve spring (13) into the cavity of

the discharge valve stop. Install the discharge valve (12) on

top of the discharge spring and retain with the discharge

valve seat (11). Using a 9/16" Allen wrench, torque to

840-1080 in-lbs.

4. Test the head for air leakage prior to installing the head

onto the compressor. Refer to the Air Leakage Tests

section.

5. Make sure the mating surfaces of the head and the

crankcase have been properly prepared. (Refer

to cleaning instructions.) Install the cylinder head

gasket (14) onto the crankcase. Place the head in the

proper position onto the crankcase and retain with the

four 5/16" cap screws. Snug all four cap screws prior to

torquing in a cross pattern to 175-225 in-lbs.

6. Install the inlet tting or air strainer onto the compressor.

Install the strainer gasket (2) between either component

and the compressor.

7. Replace the governor or air line from the governor onto

the compressor. If the governor is direct mounted onto

the mounting pad of the compressor, install the governor

gasket (1) between the mounting pad and the governor.

8. Connect the discharge air line to the discharge port on

the top of the head.

9. Connect the inlet and outlet water lines to the head and

rell the radiator.

COMPRESSOR TESTING

Vehicles manufactured after the effective date of FMVSS

121, with the minimum required reservoir volume, must

have a compressor capable of raising air system pressure

from 85-100 psi in 25 seconds or less. This test is performed

with the engine operating at maximum recommended

governed speed. The vehicle manufacturer must certify this

performance on new vehicles with appropriate allowances

for air systems with greater than the minimum required

reservoir volume.

AIR LEAKAGE TESTS

Leakage past the discharge valves can be detected as

follows: Remove the discharge line and cylinder head

from the compressor and apply shop air back through

the discharge port. Coat the discharge valve seat with

soapsuds. Bubble leakage is permitted.

The unloader piston can be checked for leakage as follows:

Build up the air system to governor cut-out and shut off

the engine. (If the head is removed from the compressor,

apply shop air to the governor unloader port.) Listen for

escaping air at the compressor inlet cavity. To pinpoint the

leakage, apply a small amount of oil around the unloader

piston. No leakage is permitted.