Blueworks BLSC User manual

BLSC

1

Table of Contents

IMPORTANT SAFETY INSTRUCTIONS:.................................... 2

INTRODUCTION:......................................................................... 3

SYSTEM OVERVIEW:................................................................. 4

WATER CHEMISTRY: ................................................................. 5

ADDING SALT/SALT LEVEL:...................................................... 6

INSTALL CELL:............................................................................ 9

INSTALL CONTROL:..................................................................11

WIRING...................................................................................... 12

INSTALLATION CHECKLIST:.................................................... 16

INITIAL START UP:.................................................................... 16

OPERATION:............................................................................. 17

GENERAL MAINTENANCE:...................................................... 21

WINTERIZING: .......................................................................... 23

HELPFUL NOTES:..................................................................... 24

TROUBLESHOOTING............................................................... 25

WARRANTY............................................................................... 28

BLSC LABEL.............................................................................. 30

BLSC CELL REPLACEMENT LABEL ....................................... 31

2

BLUEWORKS BLSC

GENERATOR GENERATOR

Installation and Operation Manual

For BLSC

IMPORTANT SAFETY INSTRUCTIONS

When using electrical equipment, basic safety precautions should

always be exercised, including the following:

READ AND FOLLOW ALL INSTRUCTIONS

Disconnect all AC power during installation.

Do not permit children to use this product.

Agreen colored screw is located inside the wiring compartment,

against the back panel. To reduce the risk of electric shock, this

terminal must be connected to the grounding means provided in

the electric supply service panel with a continuous copper wire

equivalent in size to the circuit conductors supplying the

equipment.

One bonding lug for US models (two for Canadian models) is

provided on the external surface. To reduce the risk of electric

shock, connect the local common bonding grid in the area of

the swimming pool, spa, or hot tub to these terminals with an

3

insulated or bare copper conductor not smaller than 8 AWG

US/6AWG Canada.

All field-installed metal components such as rails, ladders,

drains, or other similar hardware located within 10 feet (3

meters) of the pool, spa or hot tub shall be bonded to the

equipment grounding bus with copper conductors not smaller

than 8 AWG US/ 6 AWG Canada.

Introduction:

The BLSC chlorine generator, by electrolysis, creates chlorine to

sanitize your pool from the salt molecules (NaCL) in your water. A

small electric charge is applied across a set of titanium plates inside

the Electrolytic Cell. This produces Sodium Hypochlorite (NaOCl). In

water, Sodium Hypochlorite dissociates into sodium (NA+) and

hypochlorite (OCl-) ions. It is the hypochlorite ions that form with the

hydrogen (H+) ions (from the water) to form hypochlorous acid

(HOCl), which is the active agent that destroys bacteria and algae,

and oxidizes organic matter. This form of chlorine works quickly in

the pipe, leaving only a mild residual in the pool. In addition, the

Electrolytic Cell continuously“shocks”the incoming water- burning

off any oils, organic matter, or other particles that need to be

oxidized.

Best of all, the process continuously recycles the salt: after cleaning

the pool, the original molecules reform and the whole process

begins again. The salt doesn't get used up!

4

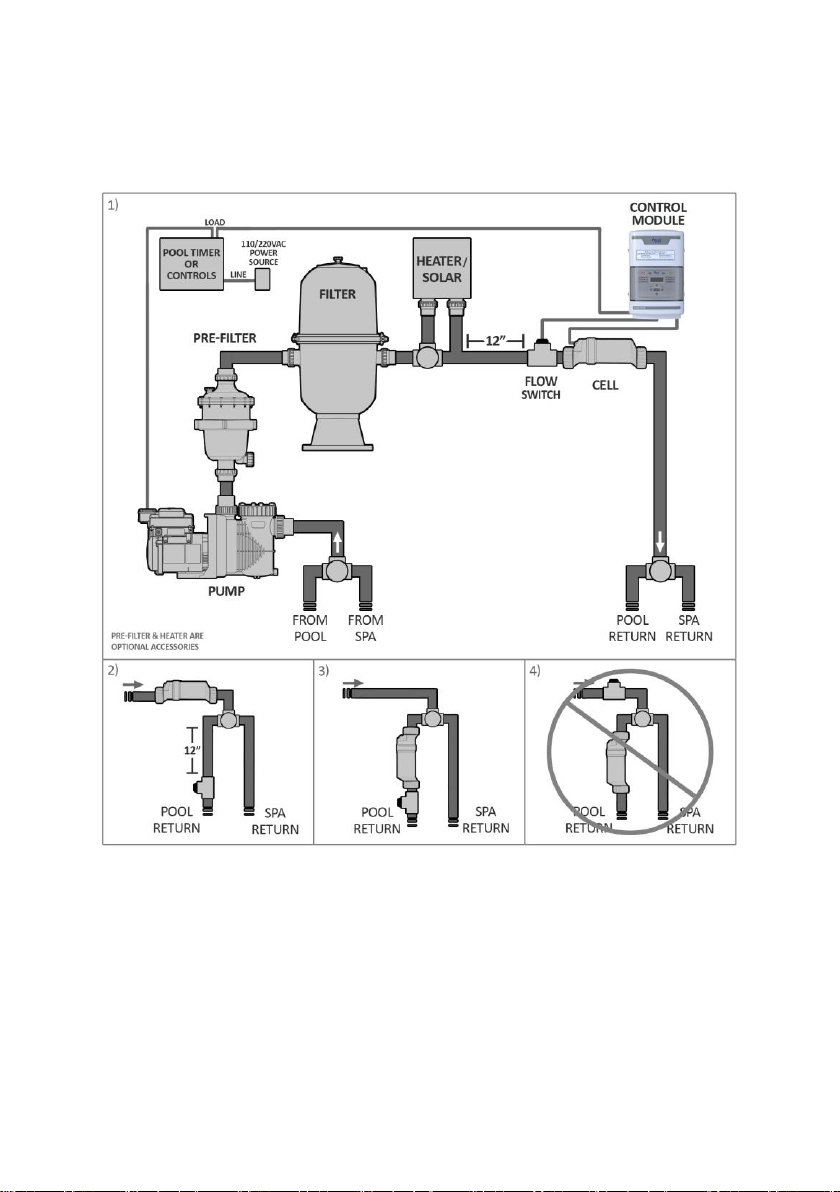

System Overview :

There are three main Parts to BLSC system: the Control Unit, the Electrolytic Cell, and

the Flow Switch.

Control Unit: Supplies power to the cell and allows you customize the system's operation,

in order to meet your pool's unique needs.

5

Electrolytic Cell: Creates chlorine as the water inside passes through and returns to the

pool. The Electrolytic Cell ("Cell") contains a number of titanium plates that use a lowlevel

of electrical power to generate chlorine from salt in the water. The Cell comes with Unions

to connect to the plumbing; each Union has a Threaded Collar that secures the Cell to the

Unions, and enables the Cell to be easily removed for cleaning and inspection purposes.

Flow Switch: This component detect the water flow in pipe and protect the system.

WATER CHEMISTRY:

As with any pool, it is important that you maintain proper water chemistry of the pool water,

including pH, alkaline content, and calcium levels. The only special requirement for BLSC

is to maintain proper levels of salt and stabilizer. It is important to maintain these levels in

order to prevent corrosion or scaling and to ensure maximum enjoyment of the pool. Test

your water periodically. It is recommended that pool water be professionally tested a

minimum of twice per season. Your local pool store can provide you with the chemicals

and procedures to adjust the water chemistry. Be sure to tell the pool store that you are

using a salt chlorine generator.

IDEAL CHEMICAL LEVELS

Swimming Pools

Spas

Free chlorine

1.0 to 3.0 ppm

3.0 to 5.0 ppm

Salinity

3000 to 4000 ppm

3000 to 4000 ppm

pH

7.2 to 7.8

7.2 to 7.8

Cyanuric Acid (Stabilizer)

60 to 80 ppm

60 to 80 ppm

Total Alkalinity

80 to 120 ppm

80 to 120 ppm

Calcium Hardness

200 to 400 ppm

150 to 450 ppm

Saturation Index

-0.2 to 0.2

-0.2 to 0.2

6

Adding Salt:

IMPORTANT: Before adding salt, ALWAYS perform an independent water test to measure

pre-existing salt levels.

Use only evaporated, granulated, non-iodized salt (Sodium Chloride). The purer the salt

(at least 99%), the better the life and performance of the Electrolytic Cell.

DO NOT add chemicals or salt directly to the skimmer. This may damage the cell. If the

Electrolytic Cell has already been installed, it should not be turned on before adding salt.

For pools, it is best to empty the required salt into the shallow end of the pool and run the

filter and pump simultaneously in order to circulate the water and dissolve the salt (the is

to remain off during this time period). Do not throw the salt bag into the water as

chemicals and inks on the bag can interfere with water balance. Salt may take 24 - 48

hours to dissolve in summer, and longer in winter. Finer granules of salt will dissolve

faster than compressed pellets.

Water Softener salt (also known as Water Conditioning pellets) is an economical way to

buy large quantities of salt. However, only salt that is at least 99% pure NaCl can be used.

Pellets are compressed forms of evaporated salt that may take longer to dissolve. Avoid

using salt with anti- caking agents (Sodium Ferrocyanide, also known as YPS or Yellow

Prussiate of Soda) that could cause discoloration of fittings and surface finishes in pool.

Do not use Calcium Chloride as a source of salt. Do not use Rock Salt; insoluble

impurities mixed with the rock salt can shorten the life of the unit.

7

Salt Levels:

The system can work within a broad salinity range, from a minimum of 3000 ppm (parts

per million), up to 4000 ppm. However, the ideal level for operation is about 3400 ppm. To

achieve this level of salinity, add approximately 30 lbs of salt for every 1000 gallons of

water (or 3.4 Kilograms of salt for every 1000 Liters). If you are unsure of the number of

gallons in your pool, double-check with the following equations.

Notice: When adding large quantities of salt, start with an independent test of the existing

salinity level and add in portions, retesting at each stage.

Calculating Gallons (Measurements in Feet)

Rectangular -Length x Width x Average Depth x 7.5

Round -Diameter x Diameter x Average Depth x

5.9

Oval -Length x Width x Average Depth x 6.7

Before adding salt, check your water for any existing salt content and add according to

the chart below. If too little salt is added, the result will be reduced efficiency and a low

level of chlorine production. In addition, operation at low salt levels will reduce the

longevity of the cell. The salt in your pool is constantly recycled, and the loss of salt

throughout the swimming season should be small. This loss is due primarily to the

addition of extra water to replace water lost from splashing, backwashing, and draining.

Salt is not lost due to evaporation.

8

POUNDS and (Kg) OF SALT NEEDED FOR 3400 PPM Gallons and (Liters) of

Pool/Spa water

Current

salt level

ppm

6,000 8,000 10,000 12,000 14,000 16,000 18,000

(22,500) (30,000) (37,500) (45,000) (52,500) (60,000) (67,500)

0

180

(82)

239

(109)

301

(136)

360

(163)

419

(190)

481

(218)

540

(245)

200

170

(78)

226

(103)

284

(129)

340

(154)

396

(180)

454

(206)

510

(232)

400

160

(73)

213

(97)

267

(121)

320

(145)

373

(170)

427

(194)

480

(218)

600

150

(69)

200

(91)

250

(114)

300

(136)

350

(159)

400

(182)

450

(205)

800

140

(64)

187

(85)

233

(106)

280

(127)

327

(148)

373

(170)

420

(191)

1000

130

(59)

173

(79)

217

(98)

260

(118)

303

(138)

347

(158)

390

(177)

1200

120

(55)

160

(73)

200

(91)

240

(109)

280

(127)

320

(145)

360

(164)

1400

110

(51)

147

(67)

183

(83)

220

(100)

257

(117)

293

(133)

330

(150)

1600

100

(46)

133

(61)

167

(76)

200

(91)

233

(106)

267

(121)

300

(136)

1800

90

(41)

120

(55)

150

(68)

180

(82)

210

(95)

240

(109)

270

(123)

2000

80

(36)

107

(48)

133

(61)

160

(73)

187

(85)

213

(97)

240

(109)

2200

70

(32)

93

(42)

117

(53)

140

(64)

163

(74)

187

(85)

210

(95)

2400

60

(27)

80

(36)

100

(45)

120

(55)

140

(64)

160

(73)

180

(82)

2600

50

(23)

67

(30)

83

(38)

100

(45)

117

(53)

133

(61)

150

(68)

2800

40

(18)

53

(24)

67

(30)

80

(36)

93

(42)

107

(48)

120

(55)

3000

OK

OK

OK

OK

OK

OK

OK

3200

OK

OK

OK

OK

OK

OK

OK

3400

Ideal

Ideal

Ideal

Ideal

Ideal

Ideal

Ideal

3600

OK

OK

OK

OK

OK

OK

OK

3800

OK

OK

OK

OK

OK

OK

OK

4000

OK

OK

OK

OK

OK

OK

OK

4200

High

High

High

High

High

High

High

4400

Dilute

Dilute

Dilute

Dilute

Dilute

Dilute

Dilute

9

Install cell:

Install using the unions provided. Tighten by HAND for a watertight seal. For pool/spa

combination systems with spillover, refer to the above Overview to allow chlorination for

both the pool and spa during spillover but preventing over chlorination when operating the

spa only. For proper plumbing, refer to the overview diagram on page 4. NOTE: The

following are basic plumbing instructions for the typical installation, which entail

positioning the Flow Switch and Cell adjacent to each other on 2" plumbing. Your

installation may vary depending on space available and your specific arrangement of

equipment. IMPORTANT: Ensure that the pool pump and all AC power is turned off before

installation.

Flow switch:

IMPORTANT: To insure proper operation, verify that the arrow on the flow switch (located

on the side) points in the same direction of water flow.

The Flow Switch and Cell are to be fitted into the return line as the last pieces of

equipment the water passes through before returning to the pool: always after the pump,

filter, heater (if applicable), etc. If a heater is present, all equipment must be a minimum

distance away, per heater manufacturer recommendations.

Lay out your equipment to ensure there is enough pipe space available.

When positioning the Flow Switch, ensure at least 6 to 12”(30cm) of straight pipe

before the Flow Switch. If installed after the Electrolytic Cell, the Cell provides this

space. The raised arrow on the black plastic cap must be pointed with the direction

of water flow as it returns to the pool. If installed horizontally, ensure that the

wire-side faces upwards. The Flow Switch is approximately 4" in length; the typical

gap required is 1 ¼".

When positioning the Cell, you can consider the side of the cell with the cord the

10

"inlet" side. If installed horizontally, ensure that the wire- side faces upwards. From

end to end, the Cell with both Unions is approximately 15 ¾" in length; the typical

gap required is 13 ¼".

Refer to the overview diagram on page 4 for alternate configurations. For combined pool

and spa systems with a spillover, allow chlorination for both the pool and spa during

spillover but preventing possible over-chlorination when operating the spa only. Vertical

Installation Kits are also available to minimize plumbing space required and increase

ease of installation.

TIP: Double-check that all Cell and Flow Switch cables can reach the Control Panel.

Note: For installations with 1 ½" plumbing, use 2" to 1 ½" reducer bushings with flow

switch, and use alternate 1 ½" Cell Unions; be sure to note any new or additional

measurements before cutting pipe.

After determining the section of plumbing to install the Flow Switch and Cell, measure out

and mark the selected area.

1. To install the Flow Switch, cut out a section of pipe at the desired installation

location. Use PVC Primer to clean and prepare the pipe ends and interior of Flow

Switch. Using plumbing Solvent Cement, glue the Flow Switch to the pipe ends.

Ensure excess glue does not become affixed to movable parts within Flow Switch.

IMPORTANT: To insure proper operation, verify that the arrow on the flow switch

(located on the black plastic) points in the direction of water flow; the water flow

must depress the hinged activator inside of the Flow Switch. This portion is

threaded and may be turned during service; additional thread seal tape may be

added if necessary.

11

2. To install the Cell Unions, cut out a section of pipe at the desired installation location.

Clean parts and plumbing with PVC Primer to prepare the pipe ends and interior of

Unions. Place the Threaded Collars over the pipe ends. Using plumbing Solvent

Cement, glue one Union to the pipe end.

3. Hold the Cell and second Union up to the first, to gauge the correct distance before

gluing the second Union to the remaining pipe end. Allow sufficient time for glue to

dry.

Ensure that the O-rings are fitted to the Unions. Place the Electrolytic Cell between the

Unions and tighten the Collars onto the Cell. For a watertight seal, do not over-tighten the

Collars, and only tighten them by hand.

When using a Variable-Speed or Multi-Speed pump on a low speed setting, the cell

should be inverted in order to ensure adequate flow & efficient chlorine production.

Install Control Unit:

The BLSC control must be mounted a minimum of 5 ft. (2 meters) horizontal distance (or

more if local codes require) from the pool/spa. The control is designed to mount vertically

on a flat surface facing downward. Because back of enclosure also acts as a heat sink

(disperses heat from inside the box), it is important not to block the back sides of the

control.

Overview: Using screws, secure the Control unit mounting at a comfortable level on a

wall or vertical support, at least 3 feet above ground level. Minimize direct exposure to

rain, sunlight, water runoff, and lawn sprinkler systems. As with most electronics, avoid

placing the controls in tightly enclosed spaces to avoid a build-up of excess heat. For

12

operation, the Control Unit may be wired in to the pump's power source so that both turn

on and off together, or energized continuously for use with variable speed pumps (Flow

switch will control Cell power but lights will remain on).

Notice: Do not operate unit until all salt is dissolved in pool water

Wiring:

Power must be shut off at the circuit breaker before performing any wiring. Be sure to

follow local and NEC/CEC electrical codes. The system has been designed to easily wire

into typical in- ground pool systems. To provide safe operation, the unit must be properly

grounded and bonded.

Bonding:

A lug used for bonding is attached to the bottom of the Control Unit. The Control Unit

must be bonded with an 8AWG copper wire to the pool bonding system.

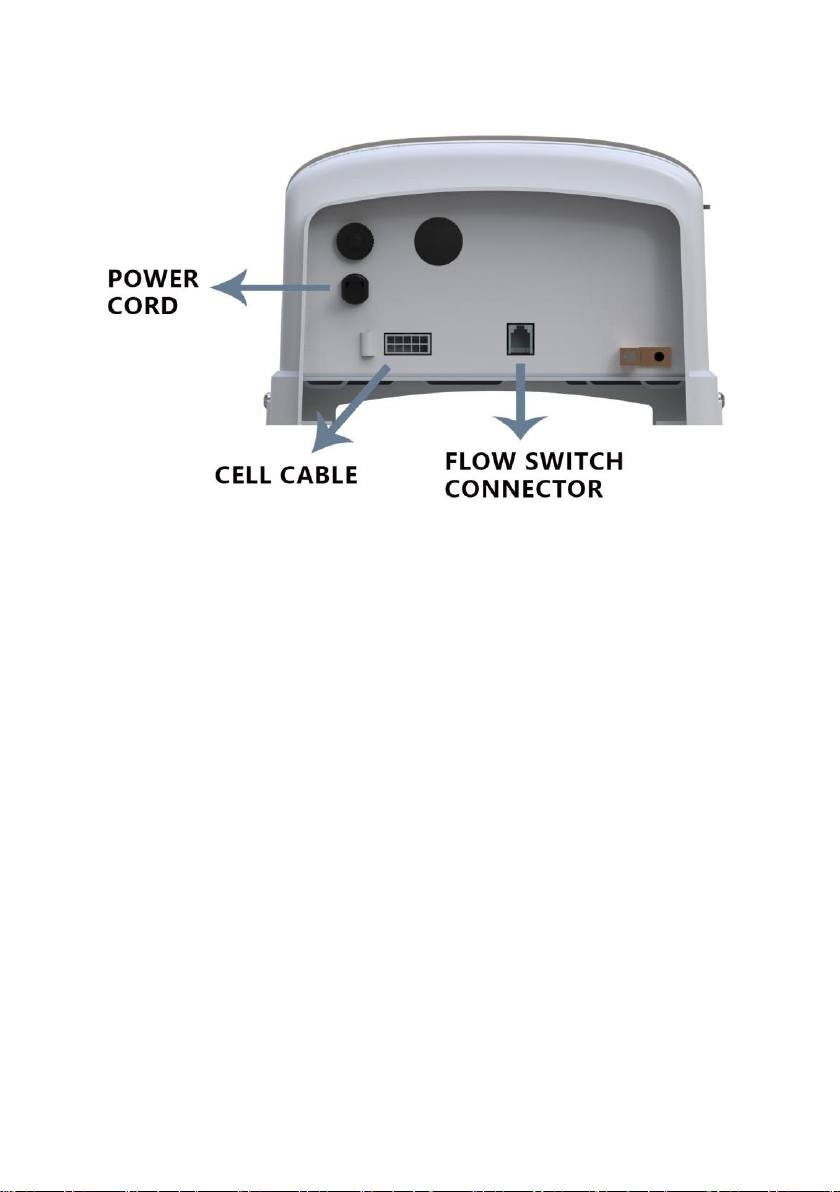

Electrolytic Cell and Flow Switch Connections:

The Cell and Flow Switch cables have easy plug-in connectors, which attach easily to

the Control Unit. Refer to the diagram below for the location of these connections.

13

Wiring to Power Source:

The Control Unit comes with an un-terminated Power Cord (AC Input) which is typically

connected to an external timer, which will turn the pump and Control Unit on and off

together. Have the Control Unit wired to the load side of the timer by a qualified person.

See the following diagram for typical wiring. See voltage warning on page 15.

The is shipped from the factory with a 240 VAC configuration. If 120 VAC is needed, move

the internal jumpers as shown on page 15. If unsure, seek professional advice.

When used with variable-speed or other electronically controlled pumps, you may wish to

wire the Control Unit directly to your power source. This will allow the pump to determine

when the Cell is energized or dormant by activation of the Flow Switch.

Always double-check the voltage of your power source. Connection to improper voltage

can: a) cause severe damage/harm, or b) cause lights and screen to power on without

system function.

14

In some parts of the United States and Canada, the Control Unit must be connected to a

circuit protected by a Class A ground fault interrupter (GFI). Check local codes before

connecting.

At this point, this installation of your equipment is complete. If the water has not yet been

prepared, then you are ready to begin adding salt and balancing your water chemistry.

Turn to Control Unit to the Power Off mode until enough salt has been added to the water.

The following information will give you more information about the process of adding salt.

Be sure to familiarize yourself with your pool's ideal chemistry levels, which play a critical

role in the operation and longevity of your pool and pool equipment.

VOLTAGE CONVERSION:

Always double-check the voltage of your power source. Connection to improper voltage

can: a) cause severe damage/harm, or b) cause lights and screen to power on without

15

system function.

All service should only be attempted by a person with appropriate electrical skills, with all

equipment disconnected from power.

The is shipped from the factory with a 240 VAC configuration. If 120VAC is needed, move

the internal jumpers as shown below. If unsure, seek professional advice.

This set of terminal screws can be located inside of the Control Unit, and accessed by

removing the four screws from the Control Unit's aluminum base. The factory voltage

setting is the 240V configuration, with a jumper clip inserted between the second and third

terminals. The Control Unit can be made to accept 110V by reconfiguring the jumper clips

as shown above left, with two jumper clips instead connecting the first and second

terminals, and the third and fourth terminals.

16

INSTALLATION CHECKLIST:

□Cell Unions installed and glued into pipe work.

□Threaded Collars on either side of the Cell are hand tight.

□Flow Switch is installed and oriented properly.

□Control Unit is affixed to wall and wired correctly.

□Cell Cable and Flow Switch are connected to Control Unit.

□You have checked and confirmed that Control Unit switches ON and OFF concurrently

with filter pump, or is energized continuously for use with variable speed pump.

□You have checked all connections and joints for leaks.

□Sufficient salt has been added and fully dissolved and circulated throughout pool water.

□Pool has properly balanced water chemistry.

Initial Start Up:

Once installation is complete, ensure that the added salt has been fully dissolved in the

pool, and that the pool is clean and chemically balanced.

Apply power to the pool pump switch (or timer controls). This should activate the system,

and within moments the green LED lights for "Power" and "Generating" should be

illuminated. During this time, you may also see the "No-Flow" light flash for up to 60

seconds as your pump begins its operation.

To find the optimum Chlorine Output setting, start at a setting of 70% and adjust as

needed over the initial start up period. Measure your available chlorine in the pool after

two to three days, and adjust the Chlorine Output level accordingly. If the available

chlorine is too high, lower the Output level; if the available chlorine is too low, raise the

Output level. It will take a few adjustments to find the ideal setting for your pool. Once

determined, it should only take minor adjustments throughout the season.

17

Operation:

By familiarizing yourself with the operation of the BLSC, you can achieve the maximum

performance for your pool. There are typically three factors that you can control which

directly contribute to the amount of chlorine the will generate:

1) The chosen percentage of Chlorine Output, 2) Hours of pump run- time each day, 3)

Water chemistry balance, including the amount of salt in the pool, and chemicals that

minimize chlorine demand, such as stabilizer level in the water. See "Ideal Chemistry

Levels" for more important information.

After making the initial adjustments to your chosen Chlorine Output level, additional

adjustments are typically only necessary due to changing seasonal temperatures, or

changes in pool use and bather load. Ensure that your pump runs long enough each day

to move at least two times the amount of water in your pool through the filter daily. This is

typically more than a sufficient amount of time for chlorination of the pool, but if

the pool has high chlorine demand, running the pool pump longer allows for more

chlorination. Measure your water chemistry and chlorine level on a regular basis.

18

Control Keypad

CONTROL BUTTONS:

1)Power: Use this button to manually power the system on or off.

2)Salinity: Displays the average measurement of the most recent salinity levels in the pool

water. The average is constantly being updated by real-time salinity readings.

Notice: When first installed, this reading may display the last salinity readings taken at the

factory. This average will begin to update with your pool's operation over the first 24

hours.

3)Super CL: Temporarily boosts Chlorine Output to Maximum Power for 24 hours, or until

power is removed from the system.

19

4)Winter Mode: Reduces the chosen Chlorine Output setting by half, for periods of low

chlorine demand during cool weather.

5)Chlorine Output: Use the left/right arrow buttons to raise/lower the system's power

setting (the rate of chlorine production), in order to customize operation for your pool's

needs.

6)Select: While in the Menu, the left/right arrows change options for Pool Temperature,

Instant Salinity, and Cell Version.

7)Menu: Press sequentially to cycle through the following information:

1. Pool Temperature (xx degrees Fahrenheit or Celsius)

2. Cell Voltage (in many cases 21.0 to 27.0 volts when chlorine is

being generated, otherwise 16-31V)

3. Cell Current (in many cases 2.50 to 7.80 amps when chlorine is

being generated, otherwise 0 amps during normal rest cycles.)

4. Real-Time Salinity reading ( xxxx ppm or x.x grams/Liter.)

5. System ID

6. Software revision level

7. Cell Version.

LED INDICATOR LIGHTS:

•Power: Located on the Power Button, this LED indicates that the Control Unit is

receiving input power when illuminated.

•Generate: This LED is illuminated during normal operation, and indicates that the

system is able to generate chlorine. When flashing, the pool water is either too hot

Table of contents

Popular Inverter manuals by other brands

Black & Decker

Black & Decker PI800BB instruction manual

Rotex

Rotex E-Solar Unit ESU 509 Installation and maintenance instructions

HP

HP 8114A Service guide

Mitsubishi Electric

Mitsubishi Electric FR-E720-0.1KNC instruction manual

Siemens

Siemens Simovert P 6SE21 Series operating instructions

Eversol

Eversol TL1500AS operating instructions

SMA

SMA WINDY BOY 3300 installation manual

Carrier

Carrier ASPAS1CCA012 Parts, adjustment and maintenance manual

Mitsubishi Electric

Mitsubishi Electric FR-F820-00046 instruction manual

Leroy-Somer

Leroy-Somer POWERDRIVE MD2CS Installation and Maintenance

Sole Diesel

Sole Diesel 35 GTC Operator's manual

HP

HP 70301A Installation and verification manual