Epcom EPIG7K User manual

Table of Contents

1General Information ........................................................................................................1

1.1 Safety Messages......................................................................................................1

1.2 Validity.......................................................................................................................2

1.3 Safety Precautions ...................................................................................................2

2 Product Overview............................................................................................................5

2.1 Components of PV Grid-Connected System..........................................................5

2.2 Schematic Diagram..................................................................................................6

2.3Appearance of Inverter.............................................................................................6

2.4Weights and Dimensions of Inverter........................................................................7

2.5 Specifications............................................................................................................8

3 Unpacking and Storage.................................................................................................11

3.1 Unpacking Inspection.............................................................................................11

3.2 Storage....................................................................................................................11

4Installation......................................................................................................................12

4.1 Mounting Location..................................................................................................12

4.2 Mounting the Inverter.............................................................................................13

4.2.1Clearance......................................................................................................13

4.2.2 Installation Procedure...................................................................................13

5 Electrical Connection....................................................................................................15

5.1 Safety Precautions .................................................................................................15

5.2 Electrical Connection Diagram ..............................................................................16

5.3 Cable Requirements...............................................................................................17

5.4 DC Connection........................................................................................................18

5.5AC Connection........................................................................................................20

5.6 Second Protective EarthConnection....................................................................21

5.7 Connection of Anti-Backflow Meter (Optional)......................................................

22

6 Installing the Communication Module..........................................................................24

7 Operation.......................................................................................................................26

7.1 Switching On...........................................................................................................26

7.2 Switching Off...........................................................................................................26

7.3 LED Indicator Lights...............................................................................................27

8 Monitoring......................................................................................................................28

8.1 Professional EditionApp........................................................................................28

8.1.1 Software Installation......................................................................................28

8.1.2Registration& Login......................................................................................28

8.1.3Create Plant...................................................................................................30

8.2 Home EditionApp...................................................................................................33

8.2.1 Software Installation......................................................................................33

8.2.2Registration& Login......................................................................................33

8.2.3Create Plant...................................................................................................34

9 Troubleshooting for Fault Messages Displayed onAPP.............................................36

1 General Information

1.1 Safety Messages

Read the manual carefully to become familiarwith the equipment before trying to install,

operate, service or maintain it. The following safety messages may appear throughout

this manual oron the equipment to warnof potential hazards.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result

in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION

CAUTION indicates a potentially hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE

NOTICE is used to address practices not related to physical injury, butto

property damage.

NOTE

NOTE is additional information in the manual, which is emphasis and

supplement to the contents and provides prompts that are valuable for the

optimal installation and operation.

This manual and device mayalso use the following electrical symbols and identification,

shown as follows:

Symbol Description Symbol Description

DC — Voltage negative pole

AC + Voltage positive pole

Earth (Ground)

Off (Power supply)

Protective earth On (Power supply)

Frame or chassis terminal

Refer to the manual

description

~ 1 ~

Caution, risk of electric

shock Warning of danger

Caution, hot surface

Danger alert of electric

shock. Energy storage

timed discharge

(time to be indicated

adjacent to the symbol)

1.2 Validity

This manual is valid for the following residential single phase on-grid PV inverters

(hereinafter referred to as inverter):

2 kW / 2.5 kW / 3 kW / 3 kW – D / 3.68 kW / 4 kW / 4.6 kW / 5 kW / 6 kW / 7kW

1.3 Safety Precautions

Follow the precautions and special safety instructions provided in the manual when

operating the products. Our company will not be liable for any consequences that are

caused due to violations regarding general safety regulations and equipment design,

production,and usage safetystandards.

Disclaimer

Our company shall not be liable for any consequence caused by any of the following

events:

Damage caused by transportation

Storage conditions that do not meet the requirementsspecified in this document

Incorrect storage, installation, or use

Installation or use by unqualified personnel

Failure to comply with the operation instructions and safety precautions in this

document

Operation in extreme environments which are not specified in this document

Operation beyond specified ranges

Unauthorized modifications to the productor software code or removal of the

product

Device damage due to force majeure (such as lightning, earthquakes, fire,and

storms)

Warranty expiration without extension of the warranty service

Installation or use in environments which are not specified in related international

standards

~ 2 ~

DANGER!High voltage mayresult in death or serious burns!

● Operations on the inverter must be performed by qualified

personnel.

● PV arrays exposed to light may generate dangerous voltage.

● Do not touch the electriferous modules in the PV system while the

inverter is running.

● Carefully read the safetyprecautions in this manual.

DANGER!Do not touch the contacts or terminals connected to

the gridor the equipment, or it mayresult in electric shock to

death or outbreak of a fire!

●Do not touch the terminals or conductors connected to the grid

circuit.

● Read and understand all instructions and safety precautions for

grid connection.

● Followall the safetyprecautions forlowvoltage powergrid.

DANGER! The damaged device or system fault may result in

electric shock or outbreak of a fire!

●Check if there is damage or otherdangerous conditions for the

device beforeoperation.

●Check if the external device and circuit connection are in a safe

state.

●Make sure the device is ina safe state for operating.

WARNING!

●The inverter can be connected to the grid only if it gets permission

from the local electric power department.

●All electrical installations must be made in accordance with national

and local standards and regulations.

WARNING! Operation by non-

professional may result in death o

r

severe burns.

●Only trained electrically qualified persons are permitted to do

electrical operation onthis product.

●During maintenance, it is necessary to ensure that at least two staff

members work inthe field; the breakers of AC terminal and DC

terminal must be fully disconnected for at least 10 minutes for

internal energy storage components discharging completely, which

should be confirmed witha voltmeter.

~ 3 ~

NOTICE!Contact or improper operation on printed circuit board

or

other electrostatic sensitive components may result in

damage to the components.

●Avoid unnecessary contacts with circuit boards.

●Comply with electrostatic protection standards, wear an antistatic

wrist strap.

When installing PV arrays during the day, opaque material should be used tocover

the solar battery arrays, otherwise, the solar array will generate high voltage under

sunlight.

The input DC voltage must not exceed 600 V, and the excessive voltage mayresult

indamage to the device.

The inverter must be properlytransported, stored, assembled, installed, operated

and maintained.

All operations and wiring must be made by qualified personnel only to ensure that

all electrical installations meet the electrical installation standards. In order to

ensure safe operation, the device should be grounded properly and provided with

necessary short circuit protection.

Ensure that DC side and AC side have no electric charge before maintaining or

checking the inverter.

The capacitorinthe inverter maypresent a shock hazard even all connections of

the inverterare disconnected.Therefore, the device should be maintained and

operated after turning off the inverter for at least 10 minutes.

Follow all the instructions in this manual.

The inverter will generate heat during operating, do not touch the radiator and other

hot components of the inverter during operating to avoid burns.

~ 4 ~

2 Product Overview

2.1 Components of PV Grid-Connected System

PV grid-connected system consists of PV modules, PV grid-connected inverters,

metering device and power distribution system. The solar energy is converted into DC

via PV modules, and then the DC is converted into sinusoidal AC which has the same

frequency and phase as the utility grid and fed into the utility grid via inverters.

Components Description

A PV modules Monocrystalline silicon, polycrystalline silicon, and thin-film

batteries with Ⅱlevel protectionand no need to be grounded

B Inverter

2 kW / 2.5 kW / 3 kW / 3 kW-D / 3.68 kW / 4 kW / 4.6 kW / 5

kW / 6 kW / 7 kW

C Electric meter Standard measuring tools for inverter output power

D Utility grid TT, TN-C, TN-S, TN-C-S

~ 5 ~

2.2 Schematic Diagram

PV1

+

-

PV2

+

-

DC Switch MPPT1

(DC/DC)

MPPT2

(DC/DC)

DC BUS Inverter

(DC/AC) LCL Filter

Relay GFCI

L

N

PE

GND

PV

Insulation

Detection

Dual DSP/MCU

LED

RS485/GPRS/WiFi

Note: The above figure is the schematic diagram of 3 kW-D / 3.68 kW / 4 kW / 4.6

kW / 5 kW / 6 kW / 7kW inverters. A single input is applied to 2 kW / 2.5 kW / 3 kW

inverters.

The inverter topology consists of boost and inversion. PV input feeds into the public

power grid via DC filtering, boosting, DC bus decoupling, inverter and AC filtering.

It adopts DSP and MCU dual-chip redundancy technology to realize fault detection

and protection of the inverter. The interior of the inverter has two groups of relays

connected between the inverter circuit output and power grid port, and the groups of

relays have self-test function that can ensure reliable disconnecting of the

connection between the inverter circuit and the utility grid in the event of afailure.

It realizes the remote monitoring of the PV power generation system via the

communication methods of RS485, GPRS and Wi-Fi.

2.3 Appearance of Inverter

~ 6 ~

No.

Description

Explanation

①LED display panel To display the inverter running state /

communication status

②DC input terminals To connect inverter to PV modules

③DC switch To directly control DC input On / Off

④Communication terminals

ToconnectWi-Fi or other communication

module

⑤

Meter communication and

digital input

Input interface for electric meter communication

and external digital input

⑥DRMcommunication

Interface of demand response modesfor

Australia grid dispatching

⑦Ventilation valve

To prevent from condensing and fogging, and

balance differential pressure betweeninside

and outside the cabinet

⑧AC output terminals

Tofeed the inverteroutput energy into the grid

⑨Mounting bracket

Tofixthe inverteron the wall mounting bracket

2.4 Weights and Dimensions of Inverter

Inverters

Weight

Dimensions (W×D×H)

2 kW / 2.5 kW / 3 kW

< 9 kg

308 mm ×116.5 mm × 353 mm

3 kW-D / 3.68 kW / 4 kW / 4.6 kW / 5

kW / 6 kW / 7kW

< 11.5 kg

370 mm ×126.5 mm × 420 mm

Dimensions of 2 kW / 2.5 kW / 3 kW inverter:

~ 7 ~

Dimensions of 3 kW-D / 3.68 kW / 4 kW / 4.6 kW / 5 kW / 6 kW / 7kW inverter:

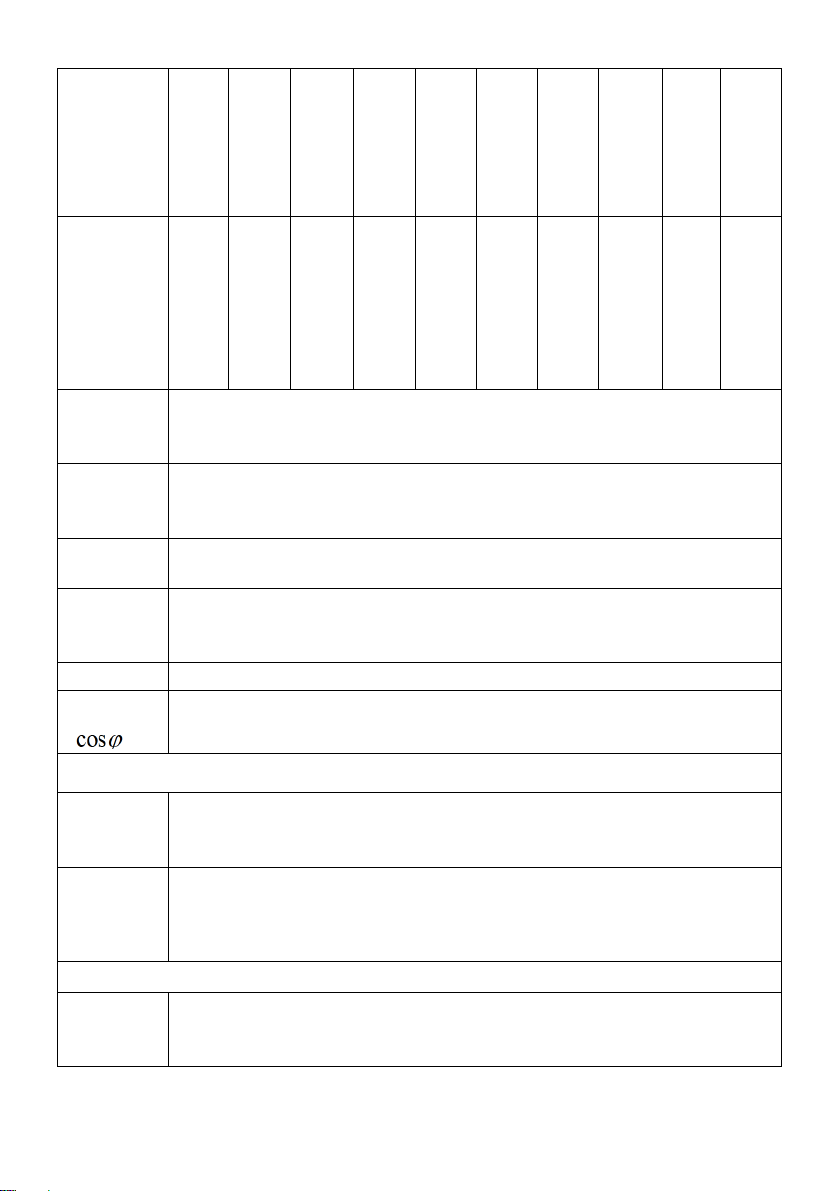

2.5 Specifications

Model 2

kW 2.5

kW 3

kW

3

kW -

D

3.68

kW 4

kW 4.6

kW 5

kW 6

kW 7

kW

Input (DC)

Max. input

power (W)

260

0

3250

3900 390

0

480

0

520

0

600

0

650

0

780

0

780

0

Max. input

voltage

600 V

Start-up

voltage

120 V

Rated

voltage

360 V

MPPT

voltage

range

90 – 550 V

MPPT

voltage

range at

full load

200

–

480

V

250

–

480

V

300

–

480

V

150

–

480

V

200

–

480

V

200

–

480

V

230

–

480

V

250

–

480

V

300

–

480

V

350

–

480

V

Max. input

current

11 A 11 A × 2

Number of

MPPTs

1 2

Output (AC)

~ 8 ~

Rated

output

power (W)

200

0 2500 3000 300

0 368

0 400

0 460

0

4900

(AU

S)

5000

(EU

R)

600

0 700

0

Max.

output

current

8.7

A 10.9

A 13A 13 A 16A 17.4

A 20

A

21.3

A

(AUS)

21.8

A

(EUR)

26.1

A 30.5

A

Rated

output

voltage

230 Vac

On-grid

voltage

range

180 – 280 Vac

Rated

frequency

50/60 Hz

On-grid

frequency

range

45 – 55 Hz /55 – 65 Hz

THD

< 3% (rated output power)

Power

factor

( )

> 0.99

Efficiency

Max.

conversion

efficiency

97.8%

European

efficiency 97.3%

Others

Protection

s

DC reverse polarity protection - DC input impedance monitoring - Leakage

current protection - Output short-circuit protection - Islanding protection –

Output DC component detection

~ 9 ~

Communic

ation

RS485*2,Wi-Fi / Ethernet

Dimension

s (W×D×H)

(mm)

308 × 116.5 × 353

370 × 126.5 ×420

Weight < 9 kg < 11.5 kg

Operating

temperatur

e

- 25℃~ + 60℃(> 45℃downgrading)

Relative

humidity

0% ~ 100%

Altitude 4000 m (> 2000 mdowngrading)

IP rating IP 65

Cooling

Natural cooling

Display

LED indicators

Self-consu

mption at

night

< 0.5W

Noise < 40 dB

Installation

method

Wall-mounted

Note: The above specifications are for reference only, please prevail inkind in the

event of any inconsistency.

~ 10 ~

3 Unpacking and Storage

3.1 Unpacking Inspection

Although the product has been rigorously tested and inspected before delivery, damage

may still occur during transport. Check that the delivery is complete,check the packaging

and the inverter for externally visible damage, and inspect the package contents upon

receipt. Notify the carrier and dealer If any damage is found or any component is

missing.

Scope of delivery:

No.

Designation

Quantity

1 Grid-Connected PV inverter 1 pcs

2

User manual

1 pcs

3 Quick guide 1 pcs

4

PV input terminal

1 set

5 AC output terminal 1 set

6 Communication module (Wi-Fi) 1 set

7

Expansion screws

4 sets

8 Hexagon socket head cap screws 2 pcs

9

Outer hex-cross screw withspring and plain washer

1 pcs

10 Wall mounting bracket 1 pcs

11 Waterproof terminal 1 set

3.2 Storage

If the inverter is not immediately put into operation, it needs to be stored in a specific

environment:

The inverter needs to be repackaged with the originalpackaging and the desiccant

is retained. The packaging box needs tobesealed with tape.

The inverter should be stored in a clean and dry place that free from dust and water

vapor erosion.

The temperature of the storage place should be kept at -30°C - +85°C and the

relative humidityshould be maintained between0 and 100% withoutcondensation.

If the inverter should be stacked, it is recommended that the maximum number of

layers can be accumulated no more than 5 layers.

The inverter mustavoid the corrosive chemicals, otherwise it maybe corroded.

It needs regular inspection during the storage, and the packaging materials should

be replaced timely in the case of damage by rats and vermin.

Do not tilt orinvert the packaging box.

After long-term storage, the inverter can’t be put into operation until the

comprehensive inspection and testing is made by qualifiedpersonnel.

~ 11 ~

4 Installation

4.1 Mounting Location

DANGER! Danger to life due to fire or explosion!

● Do not mount the inverter on flammable construction materials.

●Do not install the inverter in areas where highly flammable

materials are stored.

● Do not install the inverter in areas with a risk of explosion.

In order to ensure that the inverteroperatesproperly, the installationenvironmentand

requirements are as follows:

The inverter is intended for outdoor use withIP 65 rating. The installation location

should be cool and ingood ventilation.Do not expose the inverterin the direct

sunlight, otherwise, itmay result inexcessive temperature rise inside the inverter,

downgrading operationof protectioncircuitand evenshutdown due to

over-temperature fault.

Rain and snow do impactontheservice life of the inverter,do not installthe inverter

inthe rain and snowor do some appropriate shelter.

The inverter adopts natural cooling, the ventilation and cooling are veryimportant.

Do not install the inverter in a closed enclosure,otherwise the invertershould be

too hot to operate oreven damaged.

The inverter should be installed inthe reinforced concrete wall or metal wall that

canbear the weight of the inverter. The inverter mustbe installed vertically.Ensure

that the installation place does not shaking.

The inverter operationwill generate some noise (< 40 dB),it should be installed

away from the residential areas. Ensure that the installation location is convenient

for viewing LED lights and LCDdisplay screen. Sufficient clearances around the

inverter must be reserved for ventilation, cooling, installation, maintenance and safe

access.

Do not install the inverter outdoors insaltareas because it will be corroded there

and may cause fire. A salt area refers to the region within 500 meters from the

coastor prone toseabreeze. The regions prone to seabreeze varydepending on

weather conditions (such as typhoons and monsoons) or terrains (such as dams

and hills).

CAUTION

Ambient temperature range shallbe -25°C to +60°C. It will affect the

inverter output power when the temperature exceeds the limit.

Environmental relative humiditymust be in the range of 0% ~ 100%.

~ 12 ~

4.2 Mounting the Inverter

4.2.1 Clearance

Note: Only install the inverter vertically or tilted backwards no more than 15 degrees. Do

nottiltor installthe inverter horizontally. The wiring terminal should be downwards.

In order to maintain sufficient ventilation, when installing the inverter a minimum

clearance of 30 cm at the sides and top must be maintained. Operation and reading are

made easier by installing the inverter with its display at eye level and by keeping a

distance of 30 cm from the front. All cables are routed to the outside through the

underside of the enclosure, therefore a minimum clearance of 50 cm must be observed

here.

4.2.2 Installation Procedure

1. Place the wall mounting bracket against a suitable wall for mounting and align using

alevel.Mark the positionof the drill holes using the wallmounting bracket.

2. Drill holes onthe markings forthem.

3. Secure the wall mounting bracket to the wall using expansion screws. Tighten the

screws with a minimum torque of 30Nm, and M6 x 50 expansion bolts are

recommendedfor use.

~ 13 ~

4. Attach the inverter to the wall mounting bracket. Screw the inverter to the wall

mounting bracket on both sides using the M5 screws provided. Tighten the screws

and make sure that they are securely in place.

5. The Wall mounting bracket reserved a padlock hole to prevent the inverter from

beingstolen. The anti-theft lockneeds to be prepared bythe user himself.

~ 14 ~

5 Electrical Connection

5.1 Safety Precautions

DANGER!

Improper wiring may result in fatal injury to operator or unrecoverable

damage to the inverter. Only qualified personnel can perform th

e

wiring operation. The breakers on the AC/DC sides of the inverter

must be disconnected and the warning marks must be set before

wiring.

WARNING!

The voltage and current parameters of the inverter must be

considered when designing the PV system (see 2.5).

WARNING!

Ensure that the electrical connection design is in compliance with the

local national and local standards.

CAUTION

The IP rating of this inverter is IP 65, please use the wiring terminal

provided, otherwise the IP rating of the invertermay be reduced.

CAUTION

All cables must be connected firmly and reliably, properly insulated

and avoid to be damaged easily.

CAUTION

The inverter can only be connected to the utilitygrid after getting the

approval from the local electric power department.

~ 15 ~

5.2 Electrical Connection Diagram

Electrical connection of the inverter includes connection on the DC side, connectionon

the AC side, communication modules connection, second protective earth connection

and connection of anti-backflow meter.

No.

Item

Description

APV arrays

2 kW / 2.5 kW / 3 kW inverters are featured withsingle

MPPT and single string input. 3kW-D / 3.68 kW / 4 kW /

4.6 kW / 5 kW / 6 kW / 7 kW

inverters are double MPPT

and two strings input. The maximum allowable

open-circuit voltage of each PV string is 600V, and the

maximum allowable working current of the each string

input terminal is 11 A.

B

DC switch

Users can directly control DC input On / Off.

CCommunication

modules

It is used to connect Wi-Fior other communication

module.

DAC circuit breaker

It is used as aprotective deviceduring electrical

connection. PE protection cable must be reliably

grounded. It is recommended that 2 kW / 2.5 kW / 3 kW /

3kW-D inverters use AC circuit breakers of 25 A, 3.68

kW / 4 kW / 4.6 kW / 5 kW / 6 kW / 7 kW inverters use

AC circuit breakers of 32 A. Each inverter requires a

separate circuit breaker, and multiple inverters cannot

share the same circuit breaker.

E

Utility grid

The rated voltage of the power grid is 230 V.

~ 16 ~

5.3 Cable Requirements

Only waterproof terminals are included in scope of delivery. The user should select

appropriate cables according to the following recommended cable size.

2 kW / 2.5 kW / 3 kW /

3 kW-D inverters

AC OutputTerminals

PV InputTerminals

L N PE Input + Input -

Recommended

Cross-sectional Area

4 mm24 mm24 mm24 mm24 mm2

3.68kW / 4 kW / 4.6 kW

/ 5 kW / 6 kW / 7 kW

inverters

AC OutputTerminals

PV Input Terminals

L N PE Input + Input -

Recommended

Cross-sectional Area

6 mm26 mm26 mm24 mm24 mm2

2 kW / 2.5 kW / 3 kW inverters are featured with one DC input, which can be connected

with one PV string. 3kW-D / 3.68 kW / 4 kW / 4.6 kW / 5 kW /6 kW / 7 kW inverters are

featured with two DC input terminals, which can be connected with two PV strings. The

output terminals on the AC side are marked with L, N, PE for easy installation. It is

recommended that users use4 mm2(2 kW / 2.5 kW / 3 kW / 3kW-D inverters) and 6 mm2

(3.68 kW / 4 kW / 4.6 kW / 5 kW / 6 kW / 7 kW inverters) copper cables to perform

connection.

CAUTION

Multiple inverters can be connected to a grid-

connected grid, but it

should not exceed 10 units. Otherwise, the inverter may not operate

normally.

CAUTION

It is forbidden to connect the load between the inverter and the circuit

breaker.

~ 17 ~

5.4 DC Connection

DANGER !

Before electrical connection, cover the PV battery modules with

light-proof material and disconnect the circuit breaker on the DC side.

WARNING !

This product is a non-isolated inverter, the positive and negative

electrodes of the PV module

cannot be grounded, otherwise it will

emit PV ISO Fault. The inverter cannot operate normally even be

damaged.

CAUTION

When designing PV arrays, the open-circuit voltage of each PV string

less than 600 V must be considered, and the maximum allowable

short-circuit current for each PV string is no more than 12 A.

NOTE

2 kW / 2.5 kW / 3 kW inverters are featured with a single MPPT input

and a group of input terminals, and a group of PV strings can be

connected to the DC side. 3kW-D /

3.68 kW / 4 kW / 4.6 kW / 5 kW / 6

kW /7 kW inverters are featured with two MPPT inputs and two groups

of input terminals, and two groups of PV strings can be connected to

the DC side.

DC connection terminals are included in scope of delivery. Please connect the DC cables

selectedbased on the above requirements to the connectorbyfollowing the steps below.

(Note:During connecting, use the same colorfor the positive cables withamark and use

another same color for negative cables with a mark. For example, generally red cables

are used for the positive terminal and black cables are used forthe negative .)

Negative (-)

Positive (+)

~ 18 ~

Positive (+) Input Terminal and Die Negative (-) Input Terminal and Die

Wiring on theDC side

1. Strip the DCcable insulationabout8 mm to expose the copperwire.Insertthe cable

copper wire into the metal core of the connector and tighten it with a crimper (As

shown inthe figure below).

2. Loosen the terminalcover and pass the cable through the terminal cover. Insert the

die into the wiring slot till you hear a sound indicating that the connection is in place.

Tightenthe terminal cover (As shown inthe figure below).

3. Check whether the PV array cable connection polarity is correct with a voltmeter

whose DC voltage measurement range is over 1000 V, and verify that the

open-circuit voltage does not exceed the specification. When the ambient

temperature is above 10°C,the open-circuit voltage of PV arrays can’t exceed 90%

of the maximum DC voltage of the inverter. Otherwise, at the low temperatures, the

voltage of PV arrays may exceed the maximum input voltage of the inverter and

cause damage to the inverter.

4. Disconnect the circuit breaker on the DC side and connect the PV input cable to the

inverter separately.

~ 19 ~

Table of contents

Other Epcom Inverter manuals