BM KAPTOR MINI User manual

KAPTOR MINI

User Manual

Firmware Revision: Flow-V1.3.4 / Standard-V1.0.0

App Revision: Easysetup 1.5.1

Manual Revision: V0.1 dtd 30/03/2020

KAPTOR MINI –User Manual –V0.1 - pg.2

Documents revision

REV.

Type of Revision

Approval

Date

01

First Version in English

30/03/2020

KAPTOR MINI –User Manual –V0.1 - pg.3

1Summary

1 Summary 3

2 Introduction 6

2.1 Manual feasability 7

3 General information 8

3.1 Main sensors 9

3.2 Main applications 9

3.3 Technical, functional, electrical and mechanical features 10

3.4 Functional features 11

4 Dimensions and fixing system 14

4.1 Mouting bracket 15

4.2 Quick release wall mounting support 15

4.3 Combined mounting bracket 16

5 Case opening and closure 17

6 Power supply 19

6.1 Primary internal battery (not rechargeable) –3,6V 19

6.1.1 Internal battery replacement 19

6.2 Exernal rechargeable battery 20

6.2.1 Battery charging 21

6.3 External primary battery (not rechargeable) –14,4V 22

6.4 External power supply 22

6.5 Battery selector 22

7 Wiring and connections 24

7.1 Wiring ID colours 25

8 SIM card 27

9 Working modes 29

9.1 Continuous mode 29

9.2 Discontinuous/Low power Mode 29

9.3 Data transmission 30

9.4 Freezing 30

10 Status led 31

11 App EasySetup 32

KAPTOR MINI –User Manual –V0.1 - pg.4

11.1 Device features for App EasySetup Installation 32

11.2 Installation and update 33

11.3 Authorizations 33

11.4 How does EasySetup works? 34

11.4.1 App working mode (live and off-line) 34

11.4.2 Status bar 35

11.4.3 App Settings 36

11.4.4 Codes and Passwords 37

11.5 Wi-Fi Connection to the device 37

11.6 Profiles management 38

11.6.1 Duplication and association of profiles 39

11.7 “Save” and “Save and upload” buttons 40

12 Configuration 41

12.1 Sensors connected to RS485 port 41

12.1.1 RS485 standard 41

12.1.2 RS485 flow 44

12.2 Built-in pressure sensor 54

12.3 Analog inputs 54

12.4 Digital inputs 55

12.5 Auto cleaning 56

12.6 Warm up time 57

12.7 Variables log 57

12.8 Data 58

12.8.1 Real time data 58

12.8.2 Historical Data 58

12.9 Communication 60

12.9.1 Connection parameters 61

12.9.2 Data Transmission 62

12.9.3 SIM 64

12.9.4 Functional test 65

12.10 Alarms and events 66

12.10.1 Thresholds 66

KAPTOR MINI –User Manual –V0.1 - pg.5

12.10.2 Users 67

12.10.3 Digital events 67

12.10.4 Download events 68

12.10.5 Reset alarms 68

12.10.6 Diagnostics 68

12.11 Service Function 69

12.11.1 Reboot 69

12.11.2 Firmware Update 69

12.11.3 Wi-Fi password 69

12.11.4 Set modem profile 70

12.11.5 Battery calibration 70

12.11.6 Factory settings 71

13 Conformity standards 72

14 Conformity certificates of manufacturer 73

15 Maintenance 75

16 Service 75

17 Warranty 75

18 Disposal 75

19 Ordering Code 76

KAPTOR MINI –User Manual –V0.1 - pg.6

2Introduction

Please read this part carefully before starting using the device.

Dear Customer,

congratulations for choosing a product manufactured by B.M. Tecnologie Industriali.

This manual is the main source of information for the right use of KAPTOR MINI.

This manual includes important information, advices and warnings for the right use of the device and its

potentials.

Please read this manual carefully and before starting any installation procedure. Pay attention to the

notes referring to Warnings and Safety.

Keep the manual in a safe place and ready to use in any moment.

If you have problems or cannot understand the information included, please contact the manufacturer or

its local Distributors.

The manufacturer, B.M. Tecnologie Industriali srl, is not responsible for any damages to

people or things caused by the misuse of the device.

The manual states the right way to use it.

This manual describes all the functions of KAPTOR MINI, referring to any specific version of

hardware and/or software. Optional contents, dedicated functions or peculiar versions are

NOT tagged specifically. You just need to consider only the information referring to the device

you have. Contents implemented during the device working period are precisely identified.

B.M. Tecnologie Industriali is constantly improving its devices, though it has the right to

change the device’s features for commercial/technical purposes. For further information,

please contact the sales team of B.M. Tecnologie Industriali.

KAPTOR MINI –User Manual –V0.1 - pg.7

2.1 Manual feasability

This manual describes features, functions, and instructions for using KAPTOR MINI. For installation and

start-up of the sensors, please refer to their specific manuals.

KAPTOR MINI –User Manual –V0.1 - pg.8

3General information

KAPTOR MINI is the evolution of KAPTOR MULTI, successfully used in thousands of applications.

This device was developped and realized by B.M. Tecnologie Industriali as a central element of a system

managing measures, data acquisitions and transmissions. Its unique features make it a milestone in the

whole panorama of similar devices.

It has its main use in all the fuctions regarding water cycle, such as: flow rate and pressure measurement

in full pipes or open channels, parameters analysis on drinking and waste water, spillways and overflows

activations, submerged and not contact level measurement, events acquisition (on/off), etc. etc.

KAPTOR MINI can be supplied by an internal primary or rechargeable battery to manage itself the sensors

connected to analog and digital inputs, but it could also be supplied by an external battery, connected to

a dedicated input, to manage sensors with higher power consumption.

External high capacity battery can be easily removed and replaced.

KAPTOR MINI is suitable for medium and long term monitoring campaigns. Its built-in memory can record

over 800.000 records.

Its built-in modem allows transmission of saved data and diagnostics to a remote server in order to

monitor the device’s status and the data reading. The device could be equipped with a built-in high

efficiency antenna for data transmission even if the signal is low, or with an external antenna.

KAPTOR MINI can manage alerts on every variable through the event recording, transmitting to a remote

server, sending SMS to a list of users.

IP68 protection of the datalogger unit and its modules complete the excellent performances of this device.

EasySetup App for AndroidTM, connecting via Wi-Fi, thanks to its simple interface, similar to smartphones,

allows the user to setup the device and read data.

KAPTOR MINI –User Manual –V0.1 - pg.9

3.1 Main sensors

✓Area velocity doppler sensor for flow measurement on part filled pipes and open channels.

✓Transit Time module for flow measurement on full pipes.

✓Pressure sensor for pressure measurement of full pipes.

✓Ultrasonic sensor for level/flow measurement on open channels.

✓Overflow sensor for overflow detection.

✓Analytical sensors for the analysis of water quality and chemical-physical parameters.

✓Digital pulse inputs for volumetric flow meters reading.

✓Digital event inputs for monitoring on/off status (activation)

✓Connection of standard 4..20mA or 0..10V sensors for standard signal recording.

3.2 Main applications

✓Water Losses: DMAs and measurement of inflows.

✓Monitoring Campaigns for the calibration of mathematical models.

✓Measurement in the sewage networks for overflow activation and volumes.

✓Water losses in water networks.

✓Search for extraneous waters in sewage networks.

✓DMAs –District Metered Areas.

✓Overflow check.

✓Fire systems check.

✓Calibration of numerical models.

✓Long and short term measurement campaigns in aqueducts and sewers.

✓Water balances.

✓Pumping stations.

✓Water treatment plants.

✓Hydroelectric plants.

✓Industrial processes monitoring.

KAPTOR MINI –User Manual –V0.1 - pg.10

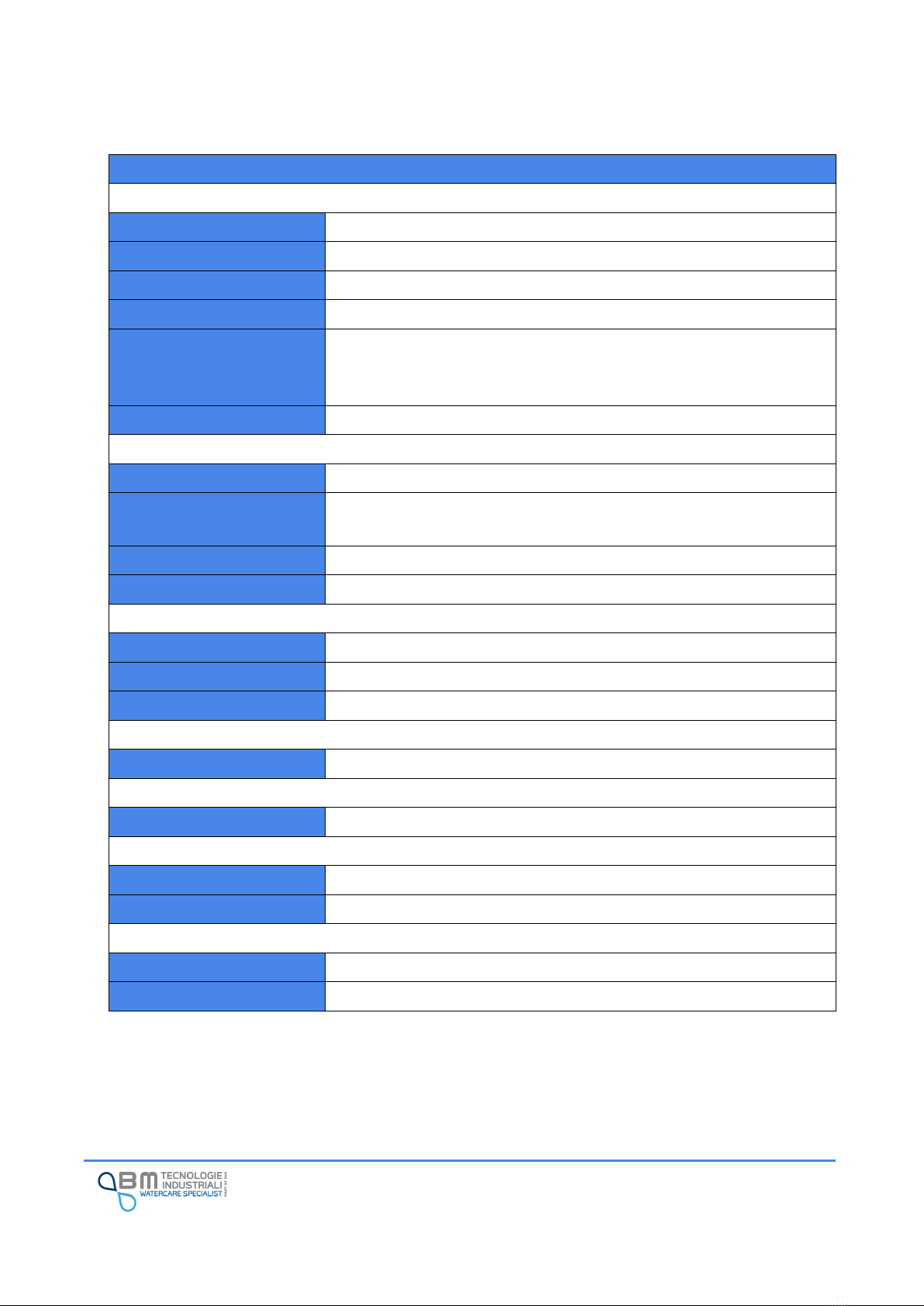

3.3 Technical, functional, electrical and mechanical features

HARDWARE FEATURES DATALOGGER KAPTORMINI

I/O

2 Analog Inputs

4 wires –4..20mA and 0..10V –Active 42mA@24V –Resolution: 16 bit

4 Digital inputs (active)

Digital inputs (clean contact) –Max frequency: 60 Hz

RS485 (supplied)

RS485 interface powered from Standard voltage power supply

4 Digital inputs (events)

ON/OFF event (clean contact)

2 Relays

Configuration SPST-NO - Contact nominal current: 500mA –Contact

nominal tension: 200 Vac/Vdc.

Relay 1: cleaning function. Relay 2: alarm function.

Built-in pressure sensor

Range to be selected in order. Connection ¼”GAS M

DIAGNOSTICS

4 Logic inputs

Check case closure

Internal case relative

humidity

Accuracy +/-2% –Resolution: 14 bit

Internal case temperature

Accuracy +/-0,2% –Resolution: 14 bit

Battery tension reading

Resolution: 10 bit

POWER SUPPLY

Low voltage

Tension 3,6V

Standard voltage

8..24VDC

Power consumption

Max.: 200mA @ 12V - Min.: 0,08mA @ 12V

DATA ACQUISITION MEMORY

Internal Flash

800.000 records –Cycle buffer

REAL TIME CLOCK

Real Time Clock

Internal with back-up battery

CONNECTIVITY

Modem

2G and 3G (SIM holder included for standard SIM card)

Wi-Fi

Suitable for AndroidTM systems, for setup and data display

ANTENNA

Built-in

Standard or high efficiency for transmissions in case of low signal.

External

Linear Up Polarization with 1.5 mt cable

KAPTOR MINI –User Manual –V0.1 - pg.11

INTERFACE

4 Leds

Green: App connection, Red: active alarm, Yellow: diagnostics, Blue: data

transmission modem status

Activation

By Magnet

ENVIRONMENTAL

Temperature

-10°C … +50°C (14°F … 104°F)

IP68 Protection degree

Immersion up to 1 year @ 1 mt

MECHANICAL

Case material

POM-C. Clamp closure.

Weights and Dimensions

H242 mm X D166 mm –1,8 Kg (mounting system NOT included)

Connectors

Water proof, military type

COMPLIANCE

Electrical safety

Directive 2014/35/EU "low Tension”

Eelectromagnetic

compatibility

Directive 2014/30/EU "Radio Machinery"

Telecommunications

Directive 2014/53/EU "Telecommunication Terminals"

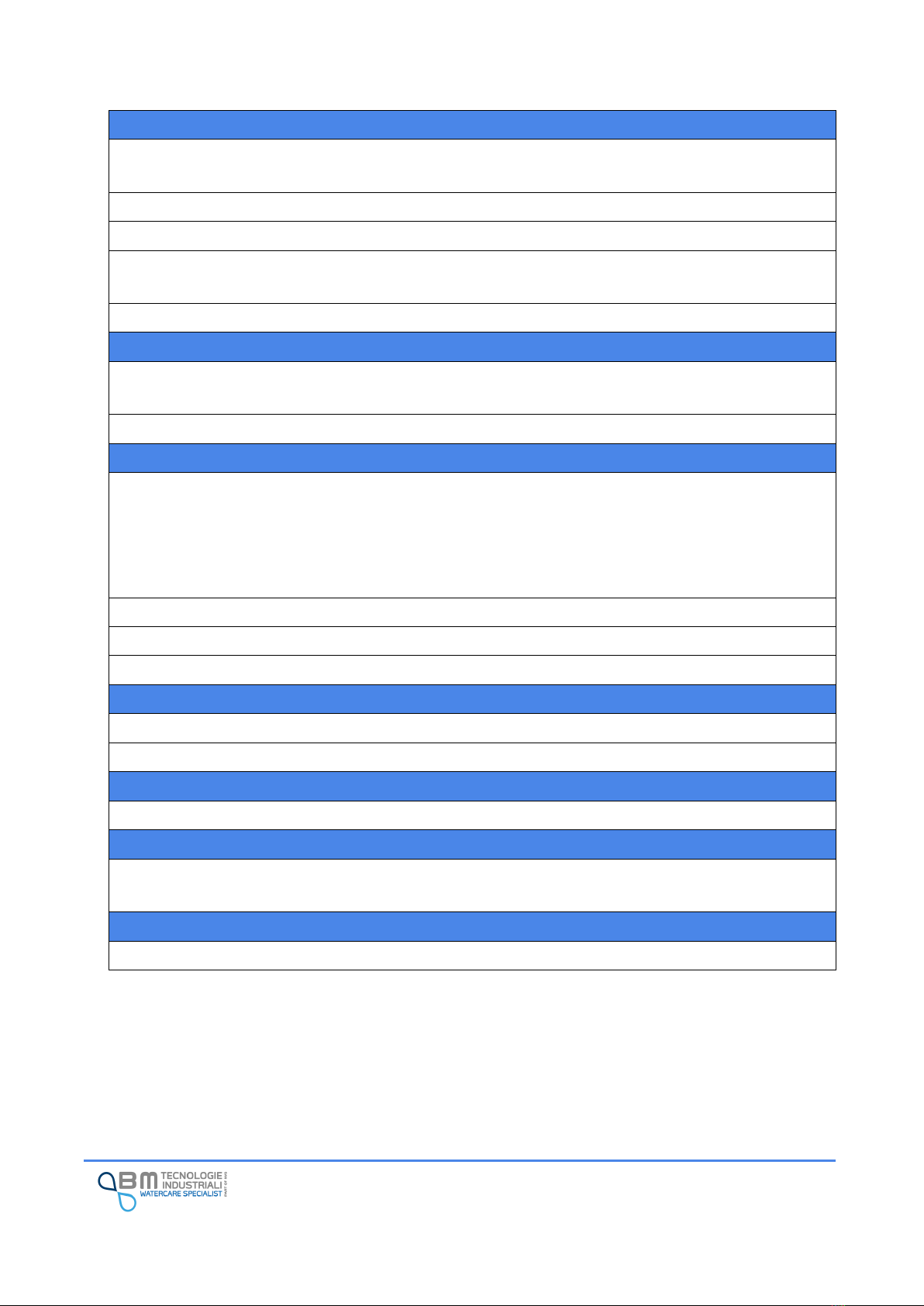

3.4 Functional features

FUNCTIONAL FEATURES of KAPTORMINI

CONFIGURATION

Through a free of charge AndroidTM app, the user can setup the device with a simple and intuitive

interface typical of modern apps. In, the user can download data and events, monitor the values read,

diagnose the device. Kaptor mini is connected to the user's device (tablet, smartphone) via a secure Wi-

Fi connection.

The downloaded files are in CSV format, easily processed in Excel.

Via Remote system (under development)

DIAGNOSTICS

Through signal leds

By checking the case’s mechanical and environmental conditions

By sending through modem the closing and covering GPRS conditions

DATA ACQUISITION

Data of every I/O are saved in the circular memory buffer. Time interval is set by the user: from 1 to 60

minutes.

Variable reading data are saved on a cyclic buffer of 255 events.

Sensors warm-up times are user set for every I/O.

KAPTOR MINI –User Manual –V0.1 - pg.12

I/O CONFIGURATION

Analog inputs: measuring range, entering a linearization curve on 16 points, entering offset. Calibration

on low and full range. Current or voltage input selection.

Digital counter inputs: pulse weight, counter increase, calculation of average pulses in the unit of time

Event digital inputs: check on/off status (activation), log status, sampling rate change on event.

RS485 port: complete configuration of the connected sensor, reading of variables, flow calculation (with

sensors for flow measurements).

Relay: configuration for alarm signaling and cleaning function (cleaning system not included).

EVENT MANAGEMENT

Alarm events on each of the variables read by the device. Each event is associated with an alarm message

which is recorded in memory and can be sent via SMS or GPRS.

Diagnostic events: case closure, GPRS network, internal board status.

CONNECTIVITY TO A REMOTE SERVER

Proprietary communication protocol: data sending to a remote server using a proprietary

communication protocol with http service via GET. The protocol can be provided to the user for the

development of the driver for receiving data on his server.

FTP: the data is sent by transferring a CSV file, with FTP protocol, to a folder of an accessible remote

device.

Ability to select 2G or 3G network depending on coverage.

Automatic search for the best operator (with multi-operator SIM).

Possibility to identify the IMEI of the modem and IMEI of the SIM.

DATA TRANSMISSION

Saved data from the oldest to the last one.

Data transmission frequency from 1 to 24 hours.

ALARMS

Alarms transmission to a remote server. Historical data transmission when alarm occurs.

DIAGNOSTICS

Diagnostics transmission to a remote server: all diagnostics parameters referring to the device’s status

are sent to the remote server.

CONFIGURATION TRANSMISSION

Configuration parameters are sent to check the configuration/setup remotely.

KAPTOR MINI –User Manual –V0.1 - pg.13

SMS

Alarm events can be sent via SMS to 3 users max. If the transmission fails, the device could be setup to

retry sending SMS to selected intervals.

DATE/TIME SYNCHRONIZATION

If enabled, the device can synchronize the date and time of its internal clock with that of the server to

ensure that multiple instruments can have the same time.

If enabled, time can be synchronized to a remote NTP server.

CLEANING CYCLES

Cleaning cycles for the sensors connected to the device can be programmed. The cleaning cycle consists

of activating a relay output for a set time, waiting for a post-cleaning time and logging the sensor

variables. This function can be particularly useful if sensors need cleaning before to be read.

KAPTOR MINI –User Manual –V0.1 - pg.14

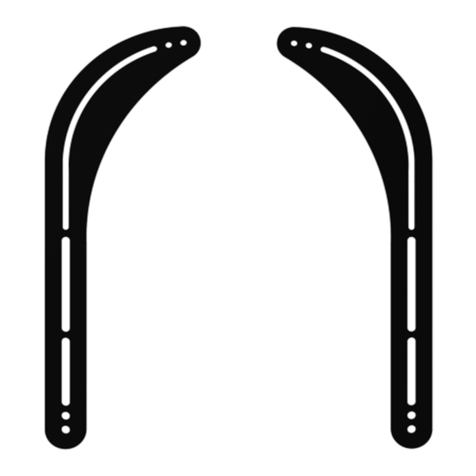

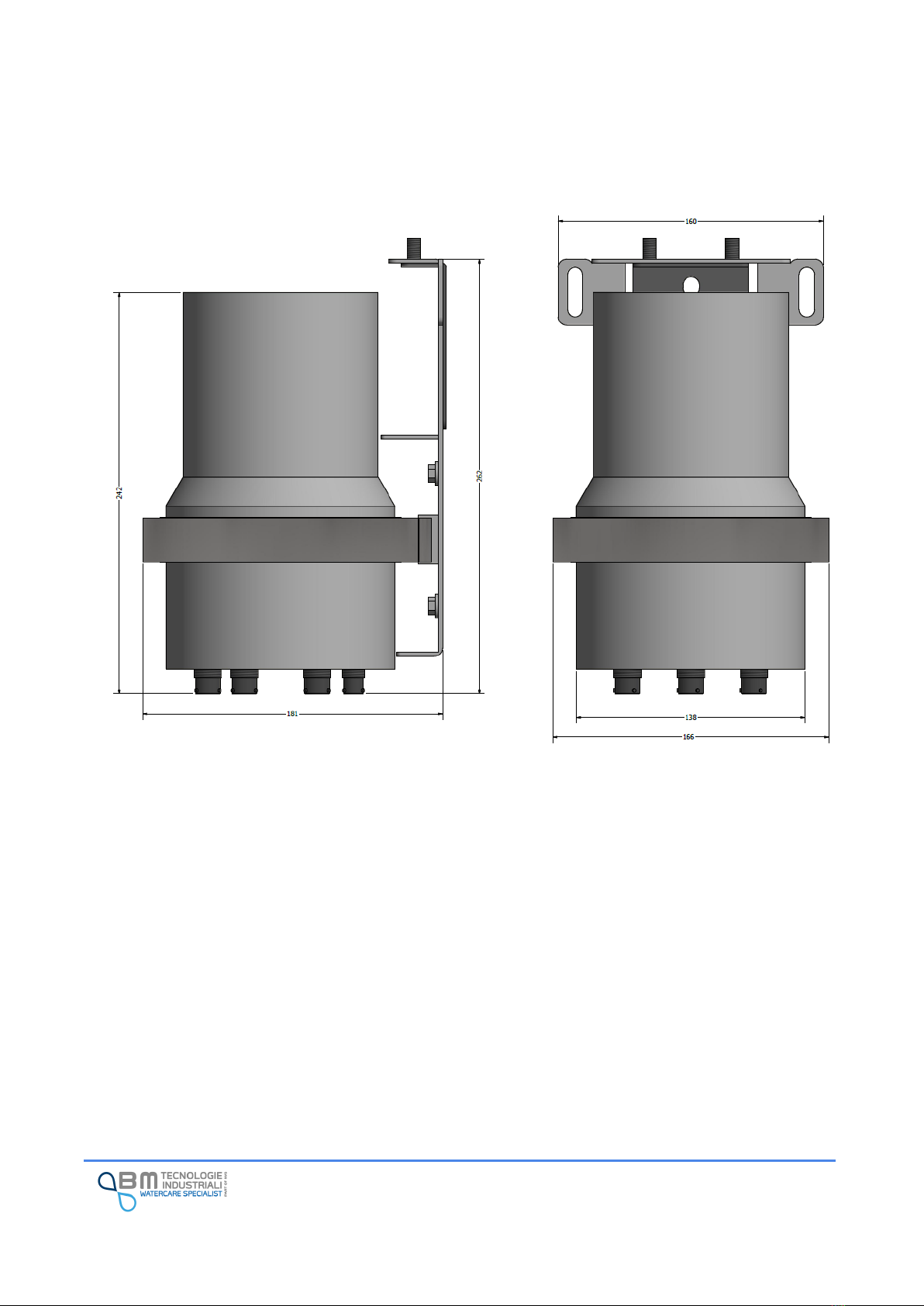

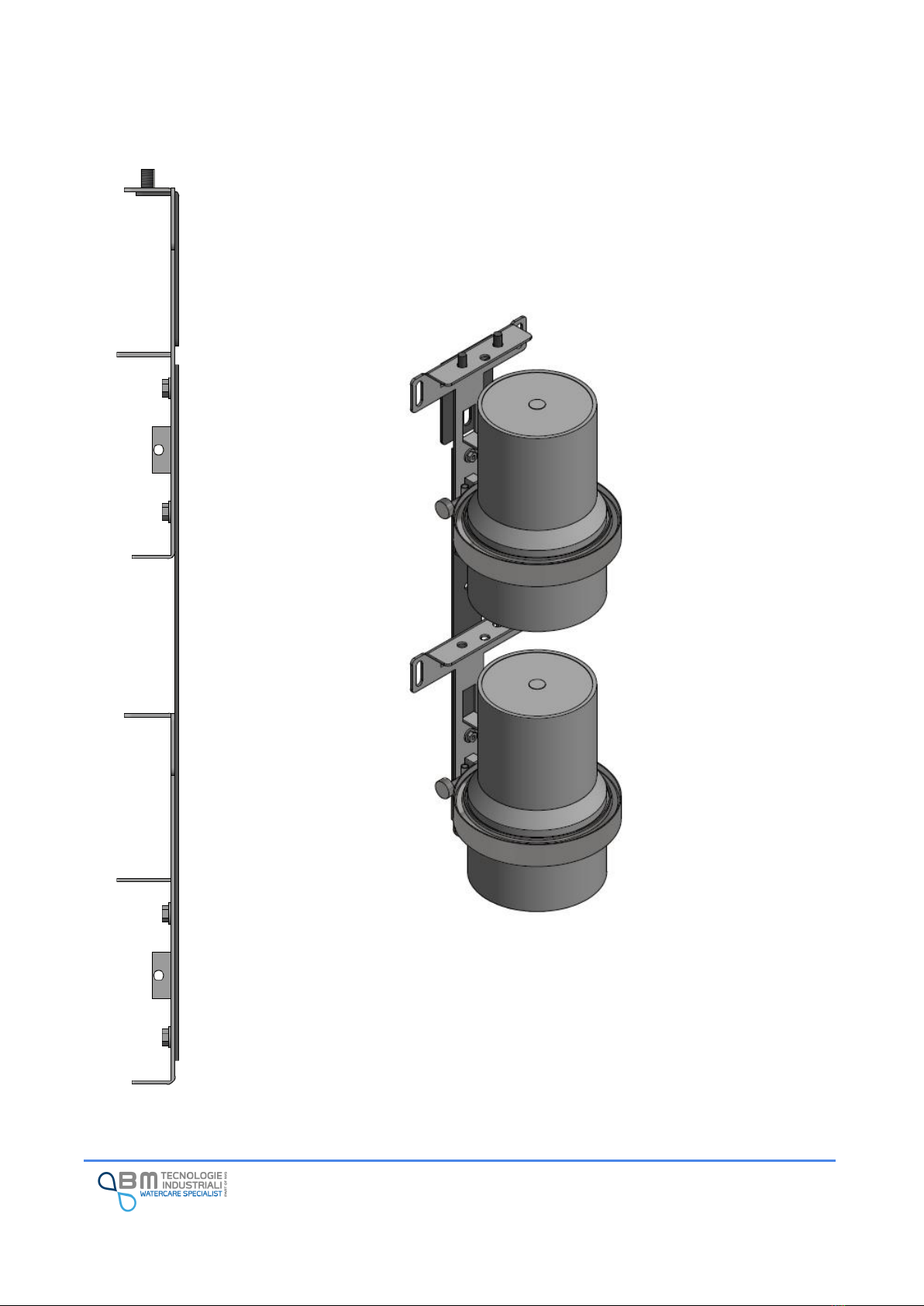

4Dimensions and fixing system

KAPTOR MINI was designed to be wall mounted with a bracket made of stainless steel. The bracket keeps

the device in vertical position in order to reach external connectors easily.

KAPTOR MINI –User Manual –V0.1 - pg.15

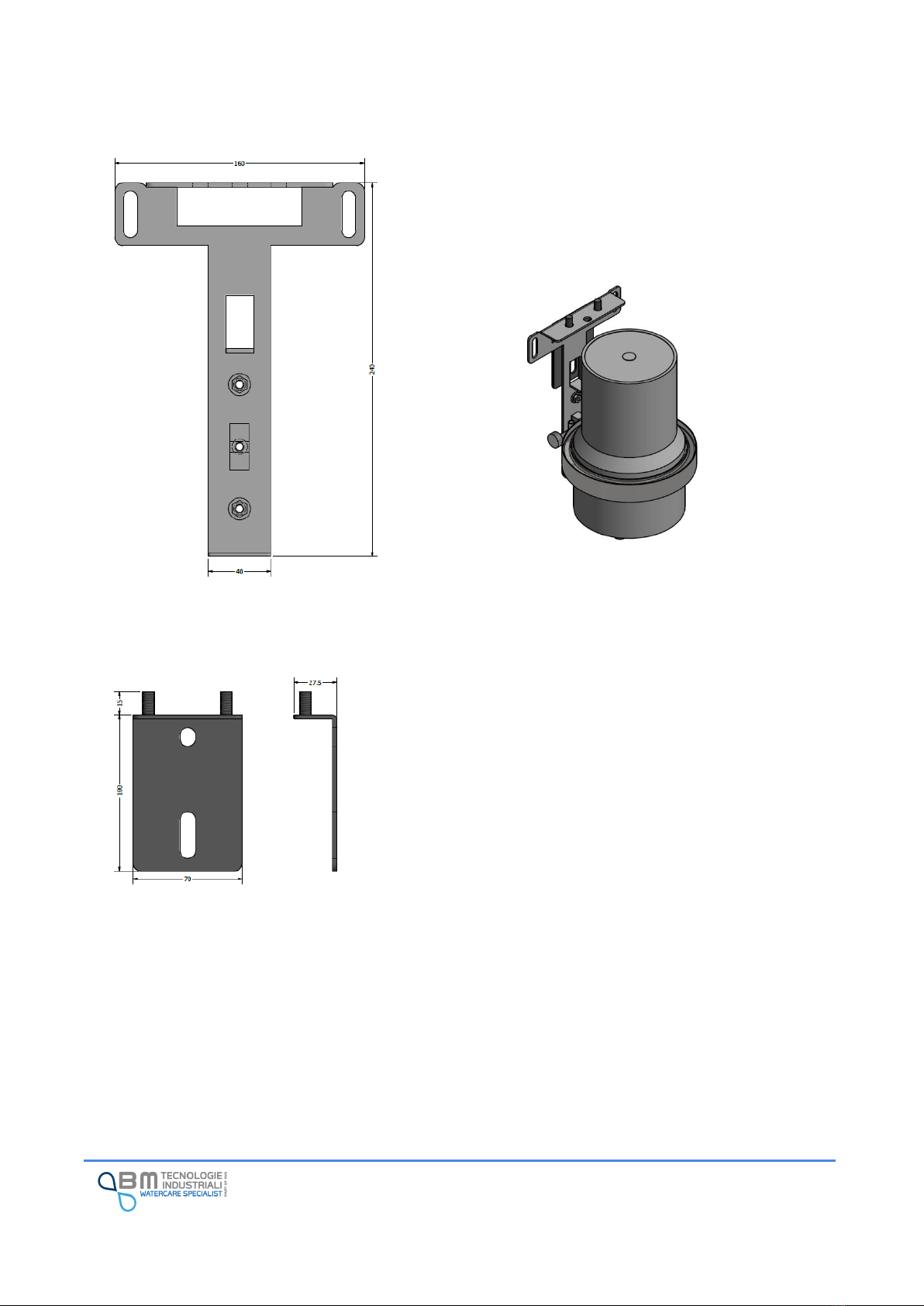

4.1 Mouting bracket

This bracket is used to hook up the device through the closing

clamp.

The bracket can be wall mounted by using two plugs (hole

diameter in the bracket is 10mm).

4.2 Quick release wall mounting support

If you plan to replace the device frequently, it is possible to use a

wall support that allows the quick release of the mounting

bracket.

Once fixed to the wall with two dowels, the bracket simply hooks

from above by inserting the two holes in the threaded stubs at the

top and screwing the two nuts.

This support is also particularly suitable when using external

batteries, in order to simplify their replacement.

KAPTOR MINI –User Manual –V0.1 - pg.16

4.3 Combined mounting bracket

If your device has an external battery, or in other peculiar cases including two devices, a

combined mounting system is foreseen. It consists of two brackets with a coupler.

The coupler allows two mounting brackets to be hold together, in order to reduce installation

space and use a single quick-release system.

KAPTOR MINI –User Manual –V0.1 - pg.17

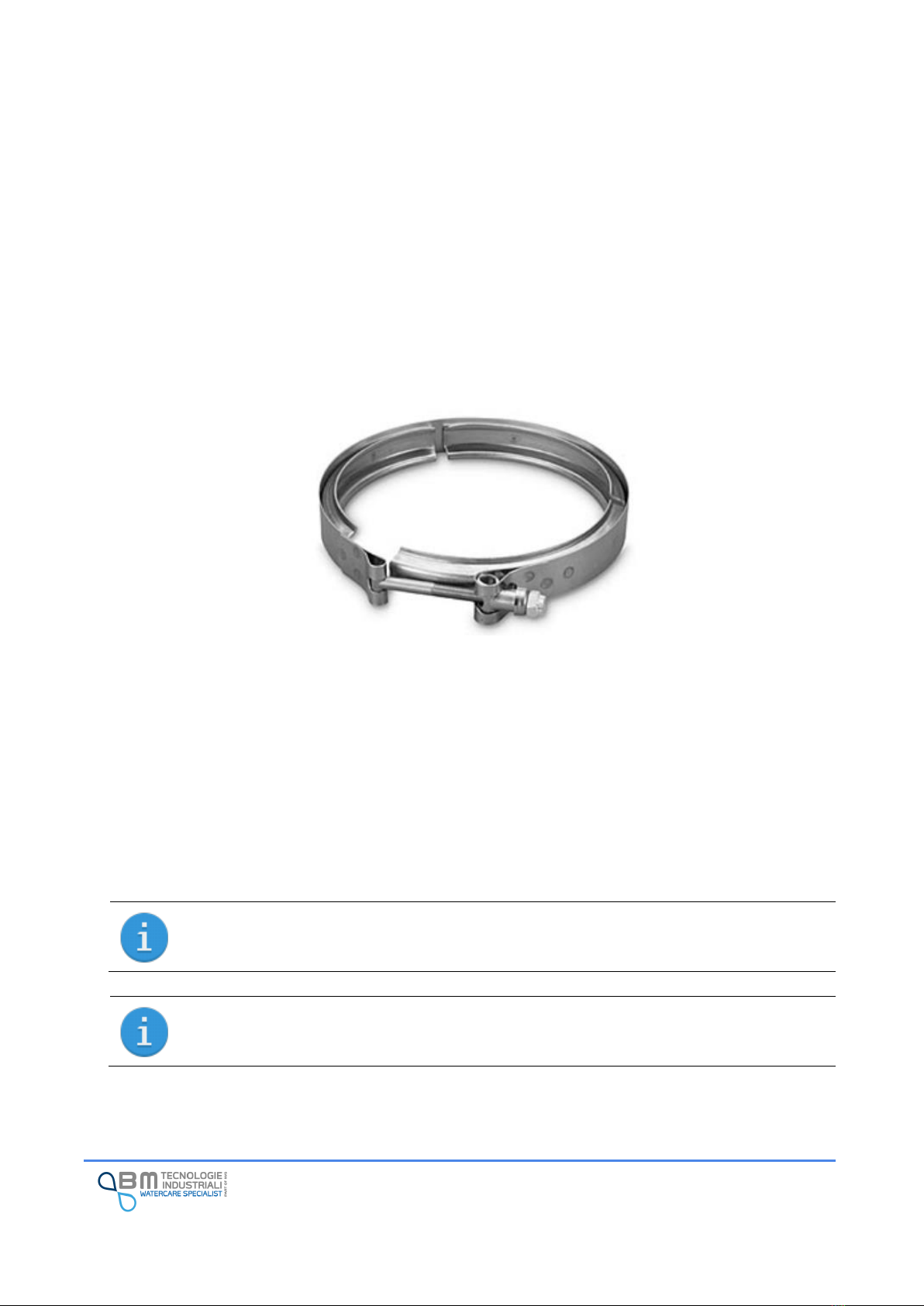

5Case opening and closure

In standard operating conditions, it is not necessary to open or close the KAPTOR MINI case.

But it could be in these cases:

✓Primary battery replacement

✓SIM card Installation/replacement/removal

✓Data transmission Antenna replacement

If necessary, unscrew the collar external clamp nut and use the quick-release system to remove the

device.

Once the clamp is removed, separate the two parts of the case. The O-rings guarantee the degree of

protection IP68 so it is completely normal to find resistance in this phase. If so, you can help yourself by

levering with two flat screwdrivers.

To close bring the two parts of the case closer so that they fit together. Pay attention to any wires: do not

press them between the parts of the case itself or of the internal components. Install the locking collar

and tighten the nut.

The correct tightening is done by applying a force of 9Nm and, in any case, when the two parts of the case

come into contact.

Before closing the case you have to check if all connections (internal battery, antenna…) are

ok.

A torque wrench can be supplied by B.M. Tecnologie Industriali on request.

KAPTOR MINI –User Manual –V0.1 - pg.18

The IP68 protection degree of the case is guaranteed by two O-rings: before closing, check

that they are present, correctly positioned, lubricated and not damaged. Cracks, cuts and

deformations can seriously affect the IP68 seal of the case.

Long periods of closure, exposure to high or low temperatures are natural conditions of

deterioration of the O-rings

In the event of damage, it is necessary to replace them by requesting them from the assistance

service.

A drying bag is necessary to remove any residual moisture, place it inside the case before

closing. It is possible to request a desiccant kit from the assistance service.

O-rings and drying bags must be replaced every time the case is opened.

B.M. Tecnologie Industriali is not liable for any damage caused by failure to keep the case due

to non-compliance with the indicated requirements.

KAPTOR MINI –User Manual –V0.1 - pg.19

6Power supply

KAPTOR MINI can be powered via 2 inputs. One with 3.6Vdc voltage and one with 8..24Vdc. The power

sources can be battery (rechargeable or primary) or a power supply on site with working voltage in the

declared range. The batteries can be connected externally through a special connector or placed inside

the case in the appropriate battery holder.

B.M. Tecnologie Industriali supplies different external and internal battery technologies to cover the

different fields of application of the device. External batteries is connected with a dedicated cable to

facilitate the user for quick replacement without opening the device.

The range of batteries used and supplied by B.M. Tecnologie is wide and not limited to those

listed below, to guarantee compatibility with the most different installations. Please refer to

any additional documentation attached regarding the supplied battery.

Disassembling the battery pack, replacing cells, attempting to recharge non-rechargeable

batteries or using unsuitable chargers can cause serious damage to the battery, things and

people.

B.M. Tecnologie Industriali is not liable for any damage caused by incorrect installation and/or

use.

6.1 Primary internal battery (not rechargeable) –3,6V

Chamical

component

Lithium

Tension

3,6V

Capacity

38AH or higher

Sensors

Power supply of digital/analog inputs and built-in pressure sensor. It cannot supply

sensors connected to RS485.

Main

Application

Long time monitoring activities (i.e. 4 years) with low power sensors connected to

analog/digital inputs.

6.1.1 Internal battery replacement

Kaptor Mini can be equipped with an Internal Battery of 3,6V.

Follow these steps for battery replacement:

1. Open the case by using the external collar;

2. Pay attention to the cable to the antenna (if the device has a built-in antenna);

Table of contents