BMI Schiedel RITE-VENT ICID PLUS User manual

100 - 200mm Internal Diameter

Twin Wall Insulated Chimney System for gas, oil, wood and

multi-fuel applications (including condensing applications)

ICID PLUS

INSTALLATION INSTRUCTIONS

Part of BMI Group

SAP Version 3 940002165 November 2017

CONTENTS

2

APPROVALS

ICID Plus is CE Certied to EN1856-1 TÜV 0036 CPR 9195 010 with designations:

ICID Plus is CE Certied to EN1856-2 TÜV 0036 CPR 9195 042 with designations:

* For full information please see p.8 - Distance to Combustibles Section

• Manufactured under a Quality Management Scheme approved to BS EN ISO 9001

• 4 Hour Fire Rating to BS476 Part 20

• Certied for corrosion resistance on gas, oil and solid fuel by Gastec, MPA and TÜV

• HETAS listed for use on solid fuel applications.

APPROVALS

DESIGN GUIDE

- Mandatory Requirements

PRIOR TO INSTALLATION

- Ventilation

- Carbon Monoxide Alarms

- Painting

- Handling

- Delivery to Site and Storage

CONNECTING FLUE PIPE

- Appliance/Chimney Connection

- Provision for Condensate Disposal

- Connection to Draught Diverter

- Connecting Flue Pipe Diameter

- Distance to Combustibles

- Connecting Flue Pipe Route

- Inspection

BS EN 15287-1

ACCEPTABLE ALTERNATIVE

METHODS OF CONNECTION

SYSTEM CHIMNEY

- Chimney Diameter

- Chimney Route

- Connection to Draught Diverter

- Direct Connection Appliance

to System Chimney

- Distance to Combustibles

- Enclosures/Shafts

- Support Components

- Chimney Termination

- Terminals

Page 2

Page 3

Page 4

Page 5

Page 7

Page 8

Page 9

System Chimney EN1856-1

Connecting Flue Pipe EN1856-2

T450 N1 D V2 L50050 G100 M

T450 N1 W V2 L50050 G60

T450 N1 D V3 L50050 G60

60mm Distance to combustibles

in a combustible shaft*

T450 N1 W V2 L50050 G50

T450 N1 D V3 L50050 G50

50mm Distance to combustibles

in a non combustible shaft or in free air*

T200 P1 W V2 L50050 O00

Zero distance to combustibles*

INSTALLATION

INSTRUCTIONS

- Jointing System

- Standard Chimney Sections

- Gasket Kits

- Individual Components

OFFSET DIMENSIONS

FIRESTOP COMPONENTS

OUTLET SITING

TYPICAL EXTERNAL

INSTALLATIONS

LOAD BEARING DATA

COMPONENT WEIGHTS

AFTER INSTALLATION

- Testing and Commissioning prior to rst use

- Appliance Operation

- Multi-Fuel Applications

- Maintenance

- Fuel Storage and Usage

NOTICE PLATE

PRODUCT GUARANTEE

- Product Registration

- QR for Installation Assistant

App download

- QR link for Online

Guarantee Registration

Page 10

Page 18

Page 19

Page 31

Page 32

Page 33

Page 34

Page 35

DESIGN GUIDE

PRIOR TO INSTALLATION

3

Mandatory Requirements

Connection to an appliance which is not connected to the fuel supply, should be carried out by a competent person. We

recommend the use of HETAS approved installers for solid fuel applications. If installation is carried out by a non HETAS

registered installer, the installation must be certied by a local Building Control inspector. Connection to an appliance that is

connected to the fuel supply must be carried out by a Gas Safe (Gas) or OFTEC (Oil) registered installer.

The design guide must be read in conjunction with the detailed component installation instructions. For full design and

installation details the key referral documents are:

•BSEN1856-1: Chimneys - System Chimney Products

•BSEN1856-2: Connecting Flue Pipes

•BSEN1859: Metal Chimneys - Testing Methods

•BSEN1443: Chimneys - General Requirements

•BSEN15287-1: Chimneys. Design, installation and commissioning of chimneys. Chimneys for non-room sealed heating appliances.

•BS5440-1: Fluing and ventilation for gas appliances of rated input not exceeding 70kW net (1st, 2nd and 3rd family gases).

Specication for installation of gas appliances to chimneys and for maintenance of chimneys.

•ApprovedDocumentJ: - Combustion appliances and fuel storage systems (England & Wales)

•DFPTechnicalBookletL: - Combustion appliances and fuel storage systems (NI)

•TechnicalHandbook(Domestic&NonDomestic),Section3 - Environment (Scotland)

•ApplianceInstallationInstructions and related standards. Other standards covering specic applications will also

be relevant and must be adhered to.

Planning permission may be required, and reference should be made to the local Building Control Department.

Ensure all chimney components are available and check them to ensure there has been no damage. Do not use damaged

components. Build the chimney up through the previous designed route which should be as straight as possible.

Ventilation

It is very important that sufcient air for combustion and ventilation is provided to the room containing the appliance, to enable

correct and efcient working of the appliance and chimney system. Reference should be made to the appliance manufacturer’s

instructions and recommendations are also given in the Building Regulations Document J, CIBSE guidance notes and BS 5440.

CarbonMonoxideAlarms

The carbon monoxide alarms should comply with BS EN 50291

Where a new or replacement xed solid fuel appliance is installed in a dwelling, a carbon monoxide alarm must be provided

in the room where the appliance is located.

Please follow manufacturers instructions with regards to siting and xing or alternatively :-

a) On the ceiling at least 300mm from any wall or if it is located on a wall, as high up as possible (above any doors and

windows), but not within 150mm of the ceiling and

b) between 1m and 3m horizontally from the appliance.

N.B Provision of a carbon monoxide alarm should not be regarded as a substitute for correct installation and regular servicing.

Painting

If painting of any external sections is required, it is important to de-grease, dry and prime the exterior surface prior to the

application of appropriate heat resistant paint. Schiedel Chimney Systems can provide to special order, chimney sections and

accessories painted to an extensive range of British Standard RAL colours – details on application.

Handling

It is advised that suitable PPE should be used when handling the products.

DeliverytoSiteandStorage

Components should be carefully transported and off loaded. They should be inspected to ensure they have not been damaged,

and should be stored off the ground and under cover so that they are protected from accidental damage and the adverse

effects of weather.

Appliance/Chimney Connection

Connection to the appliance can be made using Prima Smooth, Prima Plus or alternative approved single wall connecting

ue pipes, or ICID Plus.

This must be done by using the appropriate appliance connector. When a single wall connecting ue pipe is used to

connect an appliance to the chimney, the lower end of the chimney section must extend a minimum of 425mm below

the ceiling. When connecting the appliance to the ue pipe all joints between the ue pipe/appliance outlet must be

securely caulked and sealed with non asbestos rope (or suitable alternative) and re cement on solid fuel appliances.

Any ue pipe connection to the chimney MUST be made in the same room as the appliance.

ProvisionforCondensateDisposal(subjecttoappliancemanufacturers’recommendations)

Condensing appliances need provision for drainage. Choose the appropriate ue drainage components normally tted

at the base of the vertical stack and/or close to the appliance outlet. Any ‘horizontal’ runs must allow for a minimum 3°

slope and therefore, where required, 87° bends and 93° tees must be used rather than 90° bends and tees.

ConnectiontoDraughtDiverter

Where the appliance features a draught diverter the connection should rise vertically from it for at least 600mm before

any change of direction (unless otherwise specied by the appliance manufacturer). This is in accordance with the

recommendations contained in BS 5440 Part 1 section 6.1.4

Connecting Flue Pipe Diameter

Connecting Flue Pipe Diameter size should be as recommended by the appliance manufacturer. Under all circumstances

the operational requirements of the appliance and the conguration of the ue must satisfy the ue sizing requirements

of EN13384-1.

DistancetoCombustibles

In accordance with building regulations, it is essential that the correct distance to combustible material is maintained

on connecting ue pipes. On solid fuel applications, where there is a risk of soot re, on unmeasured (NM) designated

single wall product, this distance is 3 x ØInt of the pipe, e.g. for Ø125mm the distance is 375mm and for Ø150mm the

distance is 450mm to combustibles on both painted and non painted variants. On measured (M) single wall or double wall

products this distance will be as declared by the chimney manufacturer. On ICID Plus this distance has been measured and

is set at 100mm.

Connecting Flue Pipe Route

Single wall connecting ue pipes should only be used to connect appliances to a Chimney. They should not pass through

any roof space, partition, internal wall or oor, except to pass directly into a chimney through a wall of the chimney.

Connecting ue pipes should be located as to avoid igniting combustible material.

On solid fuel appliances the maximum length of a connecting ue pipe is 2m. This distance is reduced to 1.5m if any of

the acceptable alternative methods of connection are adopted as per BS EN15287-1. (See p.5-6 for full details.)

On appliances with a top outlet, it is recommended that a vertical run of at least 600mm should be allowed immediately

above the appliance prior to any change of direction.

On appliances with a rear outlet, it is recommended that there is maximum of 150mm in the horizontal run however

under certain conditions, as described in alternative methods in BS EN 15287-1, this may be increased to 450mm. (See

p.5-6 for full details.)

Within a system (Chimney + Connecting Flue Pipe) there should be no more than 4 changes of direction of maximum 45˚.

90˚ Factory made bends or tees within the system may be treated as being equal to two 45˚ bends (as per Document

J of the Building Regulations issued October 2010).

Inspection

On solid fuel applications to conform to Building Regulations, provisions should be made to enable a chimney to be

inspected and cleaned.

An inspection pipe, inspection elbow or a 90° or 135° Tee with tee cap can form a suitable inspection point (unless

cleaning/inspection can be done through the appliance). To aid cleaning, sufcient distance should be left between changes

of direction to permit the safe passage of cleaning brushes within the system. This is particularly important on solid fuel

applications. It is recommended that chimneys serving solid fuel appliances be swept as frequently as necessary, but at

least twice a year.

4

CONNECTING FLUE PIPE

5

BS EN 15287-1

ACCEPTABLE ALTERNATIVE

METHODS OF CONNECTION

Where a horizontal connecting ue of more than 150mm is required to connect a solid fuel red appliance to a chimney,

an installation method as per the examples below may be used provided the following criteria is met:-

a)Themaximumlengthofhorizontalconnectinguepipedoesnotexceed450mm;

b)ADefraexemptapplianceoranappliance,whichislimitedtoburningauthorisedsmokelessfuelonly,isinstalled;

c)AcalculationaccordingtoBSEN13384-1hasindicatedsafeoperationoftheproposedconguration,andtheresults

ofthecalculationareleftwiththehouseholderalongwiththeapplianceinstallationinstructions;

d)Theappliancemanufactureragreesinwritingtotheproposedconguration;

e)Thechimneymanufactureragreesinwritingtotheproposedconguration;

f) Thetotallengthofsinglewallconnectinguepipeisnotmorethan1.5m;

g)Theappropriatedistancestocombustiblematerialsfromboththeapplianceandtheconnectinguepipearemaintained.

Top Outlet Single Wall Connecting

Flue Pipe through Solid Wall into

Twin Wall System Chimney

NB Where the connecting ue pipe from

the appliance passes through any wall other

than the existing chimney wall, the connecting

ue pipe must be a System Chimney of twin

wall insulated design.

Top Outlet Twin Wall Connecting

Flue Pipe through Solid Wall into

Twin Wall System Chimney

For minimum distance for

this configuration check

manufacturers distance

to combustibles

Measured from back

of appliance to outside

surface of chimney

Measured from back

of appliance to liner

of masonry chimney

Twin Wall

Chimney System

300

Wall Support

Tee Cap for

Debris Collection/

Cleaning Access

Wall Sleeve

Trim Collar

Cavity Wall Wall Band

450mm MAX 300

450mm MAX

External Masonry

Chimney System

Inspection/

Cleanout Door

Cavity Wall

Wall Sleeve

Trim Collar

Debris

Collector

Wall Sleeve

Trim Collar

100100

225 square

(9” x 9”)

Flexible Twin Wall

Chimney Liner

Chimney Wall

Support Bracket

Swept Elbow

Sweep access

Tee Piece

Single Wall to

Flex Connector

450mm

MAX

Measured from

back of appliance

to flue liner

Wall Support

Measured from back

of connecting flue

pipe to outside

surface of chimney

Tee Cap for

Debris Collection/

Cleaning Access

Twin Wall

Chimney System

Solid Wall

Inspection Bend

Wall Sleeve

Trim Collar

600 min

225

For minimum distance for

this configuration check

manufacturers distance

to combustibles

No further

bends allowed

on this

configuration

Wall Band

450mm MAX

Measured from back

of connecting flue

pipe to outside

surface of chimney

Tee Cap for

Debris Collection/

Cleaning Access

Twin Wall

Chimney System

Solid Wall

Inspection Bend

Wall Sleeve

Trim Collar

225

Wall Support

Wall Band

450mm MAX

600 min

For minimum distance for

this configuration check

manufacturers distance

to combustibles

No further

bends allowed

on this

configuration

Flexible Twin Wall

Chimney Liner

Inspection/

Cleanout Door

Inspection Bend

Wall Sleeve

Trim Collar

Chimney Wall

Support Bracket

Tee Piece

Tee Cap for

Debris Collection/

Cleaning Access

Single Wall to

Flex Connector

225 square

(9” x 9”)

450mm

MAX

For minimum distance for

this configuration check

manufacturers distance

to combustibles

For minimum distance for

this configuration check

manufacturers distance

to combustibles

For minimum distance for

this configuration check

manufacturers distance

to combustibles

Measured from back

of connecting flue pipe

to flue liner

No further

bends allowed

on this

configuration 600 min

100100

6

Top Outlet Twin Wall Connecting

Flue Pipe into Re-lined Masonry

Chimney

Rear Outlet Twin Wall Connecting

FluePipeThroughCavityWall

into Twin Wall System Chimney

Rear Outlet Twin Wall Connecting

Flue Pipe into Re-lined Masonry

Chimney

Rear Outlet Twin Wall Connecting

FluePipeintoExternalMasonry

ChimneythroughaCavityWall

For minimum distance for

this configuration check

manufacturers distance

to combustibles

Measured from back

of appliance to outside

surface of chimney

Measured from back

of appliance to liner

of masonry chimney

Twin Wall

Chimney System

300

Wall Support

Tee Cap for

Debris Collection/

Cleaning Access

Wall Sleeve

Trim Collar

Cavity Wall Wall Band

450mm MAX 300

450mm MAX

External Masonry

Chimney System

Inspection/

Cleanout Door

Cavity Wall

Wall Sleeve

Trim Collar

Debris

Collector

Wall Sleeve

Trim Collar

100100

225 square

(9” x 9”)

Flexible Twin Wall

Chimney Liner

Chimney Wall

Support Bracket

Swept Elbow

Sweep access

Tee Piece

Single Wall to

Flex Connector

450mm

MAX

Measured from

back of appliance

to flue liner

Wall Support

Measured from back

of connecting flue

pipe to outside

surface of chimney

Tee Cap for

Debris Collection/

Cleaning Access

Twin Wall

Chimney System

Solid Wall

Inspection Bend

Wall Sleeve

Trim Collar

600 min

225

For minimum distance for

this configuration check

manufacturers distance

to combustibles

No further

bends allowed

on this

configuration

Wall Band

450mm MAX

Measured from back

of connecting flue

pipe to outside

surface of chimney

Tee Cap for

Debris Collection/

Cleaning Access

Twin Wall

Chimney System

Solid Wall

Inspection Bend

Wall Sleeve

Trim Collar

225

Wall Support

Wall Band

450mm MAX

600 min

For minimum distance for

this configuration check

manufacturers distance

to combustibles

No further

bends allowed

on this

configuration

Flexible Twin Wall

Chimney Liner

Inspection/

Cleanout Door

Inspection Bend

Wall Sleeve

Trim Collar

Chimney Wall

Support Bracket

Tee Piece

Tee Cap for

Debris Collection/

Cleaning Access

Single Wall to

Flex Connector

225 square

(9” x 9”)

450mm

MAX

For minimum distance for

this configuration check

manufacturers distance

to combustibles

For minimum distance for

this configuration check

manufacturers distance

to combustibles

For minimum distance for

this configuration check

manufacturers distance

to combustibles

Measured from back

of connecting flue pipe

to flue liner

No further

bends allowed

on this

configuration 600 min

100100

For minimum distance for

this configuration check

manufacturers distance

to combustibles

Measured from back

of appliance to outside

surface of chimney

Measured from back

of appliance to liner

of masonry chimney

Twin Wall

Chimney System

300

Wall Support

Tee Cap for

Debris Collection/

Cleaning Access

Wall Sleeve

Trim Collar

Cavity Wall Wall Band

450mm MAX 300

450mm MAX

External Masonry

Chimney System

Inspection/

Cleanout Door

Cavity Wall

Wall Sleeve

Trim Collar

Debris

Collector

Wall Sleeve

Trim Collar

100100

225 square

(9” x 9”)

Flexible Twin Wall

Chimney Liner

Chimney Wall

Support Bracket

Swept Elbow

Sweep access

Tee Piece

Single Wall to

Flex Connector

450mm

MAX

Measured from

back of appliance

to flue liner

Wall Support

Measured from back

of connecting flue

pipe to outside

surface of chimney

Tee Cap for

Debris Collection/

Cleaning Access

Twin Wall

Chimney System

Solid Wall

Inspection Bend

Wall Sleeve

Trim Collar

600 min

225

For minimum distance for

this configuration check

manufacturers distance

to combustibles

No further

bends allowed

on this

configuration

Wall Band

450mm MAX

Measured from back

of connecting flue

pipe to outside

surface of chimney

Tee Cap for

Debris Collection/

Cleaning Access

Twin Wall

Chimney System

Solid Wall

Inspection Bend

Wall Sleeve

Trim Collar

225

Wall Support

Wall Band

450mm MAX

600 min

For minimum distance for

this configuration check

manufacturers distance

to combustibles

No further

bends allowed

on this

configuration

Flexible Twin Wall

Chimney Liner

Inspection/

Cleanout Door

Inspection Bend

Wall Sleeve

Trim Collar

Chimney Wall

Support Bracket

Tee Piece

Tee Cap for

Debris Collection/

Cleaning Access

Single Wall to

Flex Connector

225 square

(9” x 9”)

450mm

MAX

For minimum distance for

this configuration check

manufacturers distance

to combustibles

For minimum distance for

this configuration check

manufacturers distance

to combustibles

For minimum distance for

this configuration check

manufacturers distance

to combustibles

Measured from back

of connecting flue pipe

to flue liner

No further

bends allowed

on this

configuration 600 min

100100

7

SYSTEM CHIMNEY

Chimney Diameter

The chimney size should be as recommended by the appliance manufacturer. Where there is a requirement for a ue

diameter smaller than the appliance spigot, then the operational requirements of the appliance and the conguration of

the ue must satisfy the ue sizing requirements of EN13384-1 for single appliances, and EN13384-2 for multi appliances.

Chimney Route

The chimney should remain as straight as possible through its vertical run to assist ow. Should it be necessary to offset

a chimney run then the following guidelines should be adhered to:

It is recommended that a vertical run of at least 600mm should be allowed immediately above the appliance prior to

any change of direction. Within a system, on all fuels, there should be no more than 4 changes of direction of maximum

45°. Factory made 90° bends or tees within the system may be treated as being equal to two 45° bends (as per

Document J of the Building Regulations issued October 2010).

ConnectiontoDraughtDiverter

Where the appliance features a draught diverter the connection should rise vertically from it for at least 600mm

before any change of direction (unless otherwise specied by the appliance manufacturer). This is in accordance with

the recommendations contained in BS 5440 Part 1 section 6.1.4

Direct Connection Appliance to System Chimney

When connecting from the appliance directly to a system chimney, the appropriate appliance connector must be used

and the joint between the appliance spigot and the appliance connector must be securely caulked and sealed with non

asbestos rope (or suitable alternative) and re cement on solid fuel appliances.

ICID Plus direct connection

fromappliance.

8

DistancetoCombustibles

In accordance with building regulations, it is essential that the correct distance to combustible material is maintained.

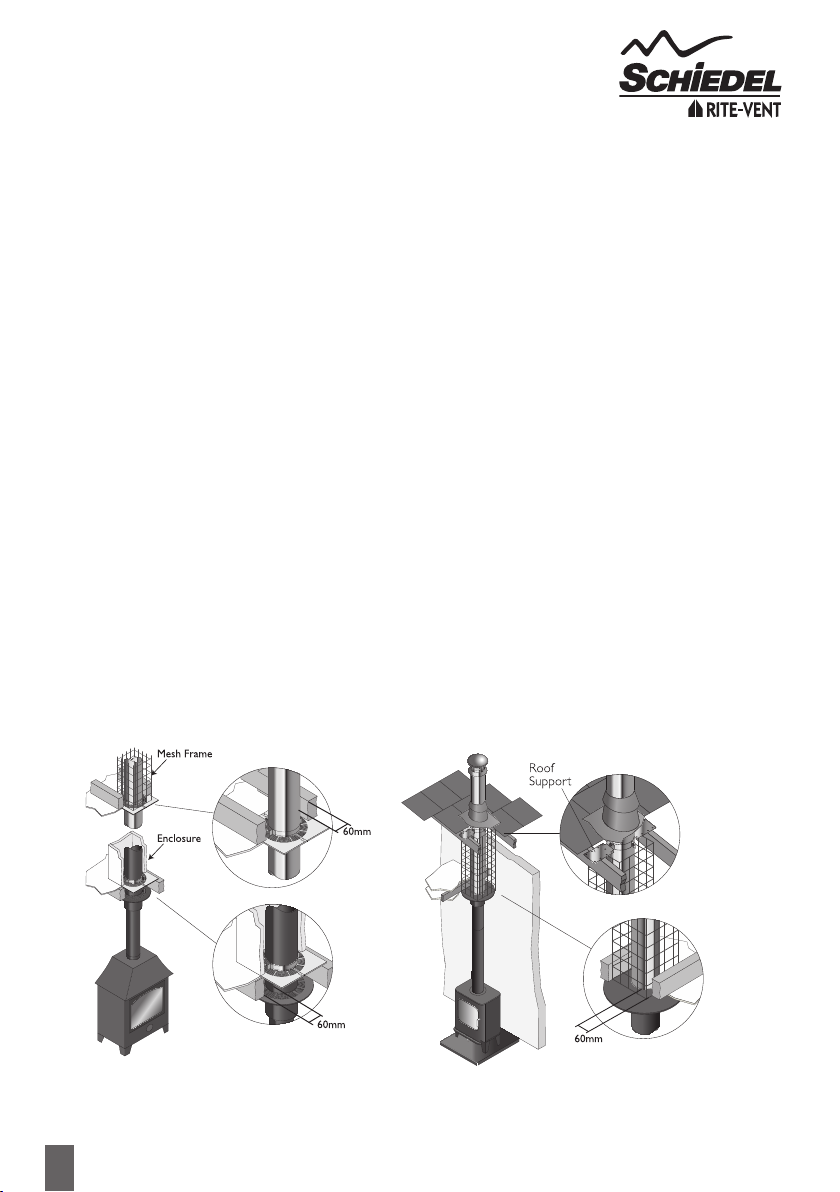

On solidfuel applications, where there is a risk of soot re, a distance of 60mmtocombustibles must be

maintained within a combustibleoor and within a combustibleshaft (see Fig.1 below).There is no need to

line the area within the oor cavity with plasterboard; however the ventilatedrestopplate andventilated

support plate must be used.

On gas and oil applications, a distance of 50mmtocombustibles must be maintained within a combustible

oor and within a combustibleshaft. The ventilatedrestopplate and ventilatedsupportplate

must be used.

Where the chimney penetrates a non combustible oor and where a non combustible shaft is used, a

distance of 50mmtotheshaft is sufcient. In this case, nonventilatedrestopplatesandsupport

plates may be used with a ventilatedrestop being used where the chimney penetrates into the roofspace.

On bungalow applications where the chimney runs through either a combustible or non-combustible ceiling, an

unventilated bungalow re stop plate kit can be used. Please note that an unventilated support plate can not be

used above the ceiling in this case. The weight of the chimney should be supported using the roof support (see p.19).

Distance to combustibles must be respected within the ceiling space (see Fig. 2 below) and mesh frame should be used

within the loft space, which must be ventilated (see Fig. 2 below).

Enclosure/Shafts

With the exception of the room containing the appliance, where the chimney passes through any part of the

building, where there is a risk of accidental human contact, i.e a bedroom etc., or where there is a risk of contact with

combustible materials stored in a cupboard or in the roof-space, the chimney must be enclosed in an appropriate way

to meet Building Regulations. This can be achieved by boxing in the chimney in habitable rooms, or by the use of a

protective wire mesh frame in roof spaces etc. In all cases the minimum distance to any combustible material, including

loft insulation, must be respected according to the table on p.1, and any enclosure should be ventilated using the

appropriate ventilated re stops (see p.13).

Fig.1 Fig.2

Internal House

Combustible Floors

InternalBungalow(VentilatedLoftSpace)

Combustible and Non-Combustible Floors

9

Support Components

The weight of a chimney system is considerable and requires independent support. Minimal weight should be borne

by the appliance. The weight of the chimney can be supported from oor level by using a base support plate, or oor

support; from the wall by using wall support top plates together with side plates or cantilever brackets; or from rst

oor level by using a support plate and clamp xed to the oor/ceiling joists.

Wall brackets are non load bearing and provide lateral support only. Refer to the load bearing tables on page 33 for

full details of maximum loadings.

Where the ue is freestanding above the roof and its height exceeds 1.5m above the last support or above the roof, a

height of up to 3m can be achieved unsupported using the extended locking bands at the joint immediately below the

last support and on each pipe joint above the last support.

Alternatively guy wire brackets can be used at the 1.5m level and every 1.5m thereafter in conjunction with guy wires,

or rigid stays (provided by others).

Chimney Termination

For full information regarding to chimney termination, please refer to Annex M of BS EN 15287-1. As a guide please

refer to page 31 of these installation instructions.

Terminals

All terminals must be secured with the use of a locking band. On solid fuel appliances, an open termination is normally

recommended. However in certain conditions, rain caps or anti-downdraught terminals may be used.

Rain caps and anti-downdraught terminals are available in three versions, with anti-bird mesh, with spark guard, or

without mesh. Where a terminal with mesh is used, there is a risk of soot build up, and therefore regular cleaning is

required to avoid blockage, particularly when using oil or solid fuel.

10

INSTALLATION INSTRUCTIONS

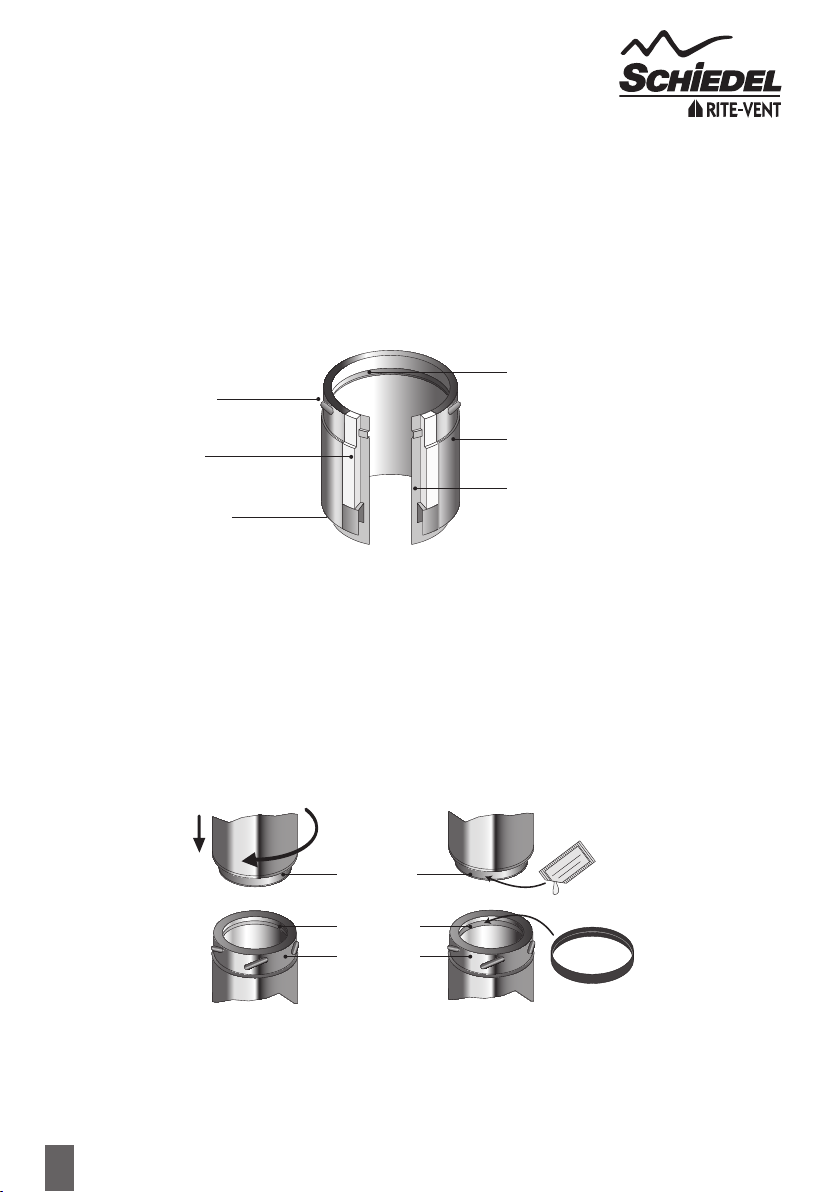

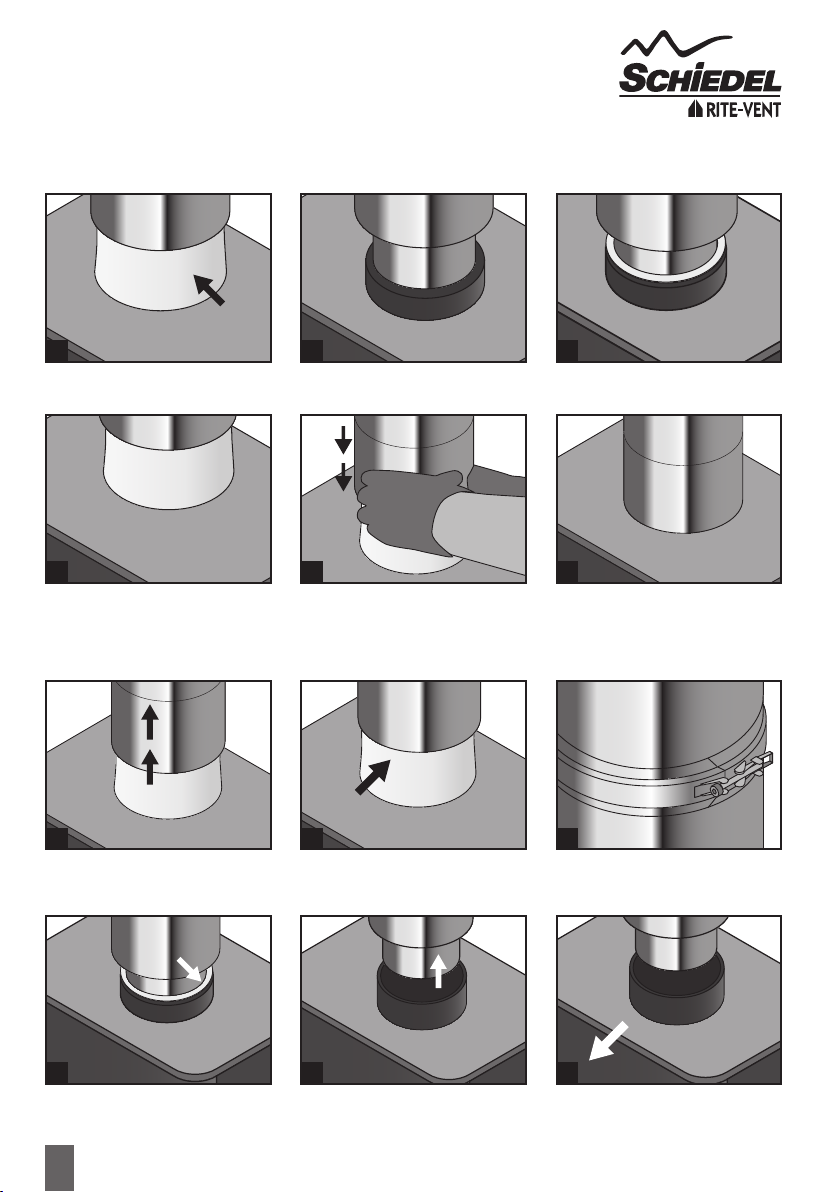

JointingSystem

All joints in the ICID Plus chimney range, which require a locking band, are made by means of a simple twist lock

jointing method. This is achieved by pushing together the male and female collars on each end of the main chimney

components and twisting the components through 1/6 of a turn to lock the collars into place.

It should be noted that the female collars on elbows and tees are not barbed in order to allow for these items to be

positioned according to requirements on site. In all cases the joints should be held securely in place using the locking

band, which is supplied with all components with a female collar.

StandardChimneySections(Pipes,TeesandElbows)

Before assembling chimney sections, loosen the locking band by lifting the clip. Push the interlocking collars together and

twist into position (see Fig.1). Position the locking band so that it grips both collars then fasten using the clip.

Note:-joints must NOT occur within oor or ceiling spaces.

All ue gas carrying components must be installed with the direction arrow on the product label pointing to termination

with the external male collar uppermost.

LockingBand(supplied with each component with a female collar)

A locking band must be tted to every joint in the system. The band is of stainless steel construction and is tted with

a quick release clip.

Fig.1

Without Lip Seal

ICID Plus for N rated

Negative Pressure

Applications

(i.e Stoves)

Fig.2

With Lip Seal

ICID Plus for P rated

Positive Pressure

Applications

(i.e Condensing Boilers)

Stainless Steel Outer Case

Male Collar

Stainless Steel Inner Liner

Insulation

Inward Bead

Female Collar

Male Collar

Lubricant

Female Lip Seal

Inward Bead

YELLOW PARAFFINWAX

DO NOT SWALLOW

Male Spigot

11

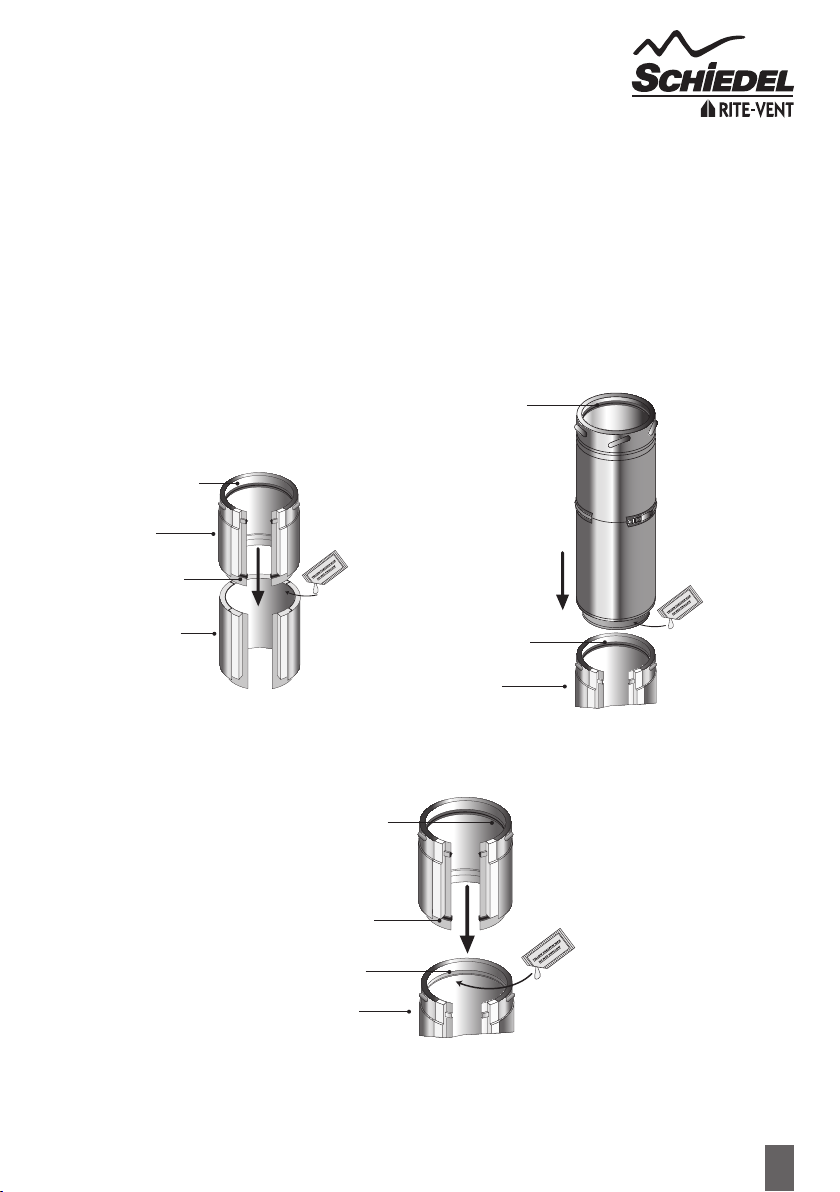

GasketKits

The standard single female lip seal kit is used to convert standard xed components with a male collar for use in

condensing applications. The female lip seal must be tted into the inward bead on the liner just below the male collar.

Lubricant should be applied to the outside of the protruding liner of the next component to be tted (see Fig.2)

A separate gasket kit with 2 gaskets (1 female and 1 male) and a sachet of lubricant is required for adjustable pipes.

The female lip seal, with the lip on the inside is tted, as per a standard component, into the inward bead as shown in

Fig.2. The second male lip seal with the lip on the outside of the ring is tted into the inward bead, which is situated in

the top half of the 2-piece adjustable pipe (see Fig.3) and at the bottom of the 1-piece adjustable pipe.

N.B Where a 1-piece adjustable pipe is used, then no female lip seal is required in the groove below the male collar

of the preceeding pipe.

Fig.3

2-PieceAdjustablePipe

1-PieceAdjustablePipe

On 2-Piece Adjustable Pipe a female lip seal is required on the preceeding standard pipe to ensure leakage performance

of the system. All lip seals to be added by installer.

On 1-Piece Adjustable Pipe no lip seal is required on preceeding standard pipe, as a male lip seal (once added) will ensure

leakage performance. All lip seals to be added by installer.

Female Lip Seal

(lip on inside)

Male Lip Seal

(lip on outside)

Lubricant

Top Half

Bottom Half

Female Lip Seal

(lip on inside)

Female Lip Seal

(lip on inside)

Lubricant

Preceeding

Standard Pipe

Lubricant

Female Lip Seal

(lip on inside)

Male Lip Seal

(lip on outside)

No Lip Seal

is required

Preceeding

Standard Pipe

12

AdaptorsfromPrimaPlus&PrimaSmoothtoICIDPlus

These components are used to convert from a single wall connecting ue pipe to the ICID Plus system chimney. The

protruding liner should be pushed down inside the female socket of the connecting ue pipe, with the male collar

pointing upwards.

AdaptortoFlex/TecnoFlexPlus

This component is used to convert from ICID Plus to Flex/TecnoFlex Plus.The Flex/TecnoFlex Plus is pushed down

inside the upstand on the adaptor, secured using self tapping screws and sealed with re cement and re rope to

provide a gas tight joint.

AdaptorfromICIDPlustoPrimaPlus

This component is manufactured with an ICID Plus female collar and a Prima Plus female socket, and is used where

there is a requirement to convert from ICID Plus to Prima Plus.The ICID Plus female collar should be attached to

the previous ICID Plus component and the joint secured using the locking band provided.

AdaptorfromICIDPlustoPrimaSmooth

This component is manufactured with an ICID Plus female collar and a Prima Smooth female socket, and is used where

there is a requirement to convert from ICID Plus to Prima Smooth. The ICID Plus female collar should be attached to

the previous ICID Plus component and the joint secured using the locking band provided.

StructuralLockingBand

The structural locking band, which is purchased separately, is used instead of a standard locking band in a situation

where extra structural support is required, for instance where the chimney height is >1.5m above the last support or

above the roof. It is also used to provide extra support in long horizontal runs. A maximum of 3m unsupported height

can be achieved by tting the structural locking band on the joint immediately below and on every joint above the last

support. Please see diagram on page 32.

StructuralLockingBandforBends

The structural locking band for Bend, which is purchased separately, is used instead of a standard locking band in a

situation where extra structural support is needed in an offset.

Appliance Connector

Male

Collar

Protuding

Liner

Appliance Connector

1.

2.

The protruding liner of these components should be pushed into the appliance

spigot with the male collar pointing upwards. The liner can be trimmed to suit

the depth of the appliance spigot.

On solid fuel appliances the appliance connector should be sealed to the

appliance with re rope and re cement or high temperature sealant to provide

a gas tight joint.

13

SW-DWStovePipeStarterSection

This component is used to connect from a vitreous enamel or stainless steel single

wall connecting ue pipe to ICID Plus. The protruding liner should be pushed

down inside the female socket of the connecting ue pipe and the joint sealed with

re cement or high temperature sealant to provide a gas tight joint.

Please note that when a single wall connecting ue pipe is used to connect to the

starter section, the joint between these two components must be a minimum of

425mm below the ceiling in accordance with BS EN 15287-1. This component

MUST only be tted to stove pipe and NOT directly to appliance.

SW-DWAdjustableStarterSection

The protruding male spigot of the adaptor slides down inside the female socket of the Prima Smooth pipe and the

socket of the Prima Smooth pipe slides within the conical section of the starter adaptor, to a maximum length of 75mm

into the cone with a minimum of 15mm to ensure a secure connection.

This maximum length of 75mm will leave sufcient space within the adaptor to allow for thermal expansion of the

single wall pipe and also to allow for the connecting ue pipe to be removed without cutting, if the appliance has to

be moved for servicing.

This component MUST only be tted to stove pipe and NOT directly to appliance.

SW-DW

StovePipe

Starter Section

100

15 min 75 max

Prima Smooth

SW-DW

Adjustable

Starter Section

14

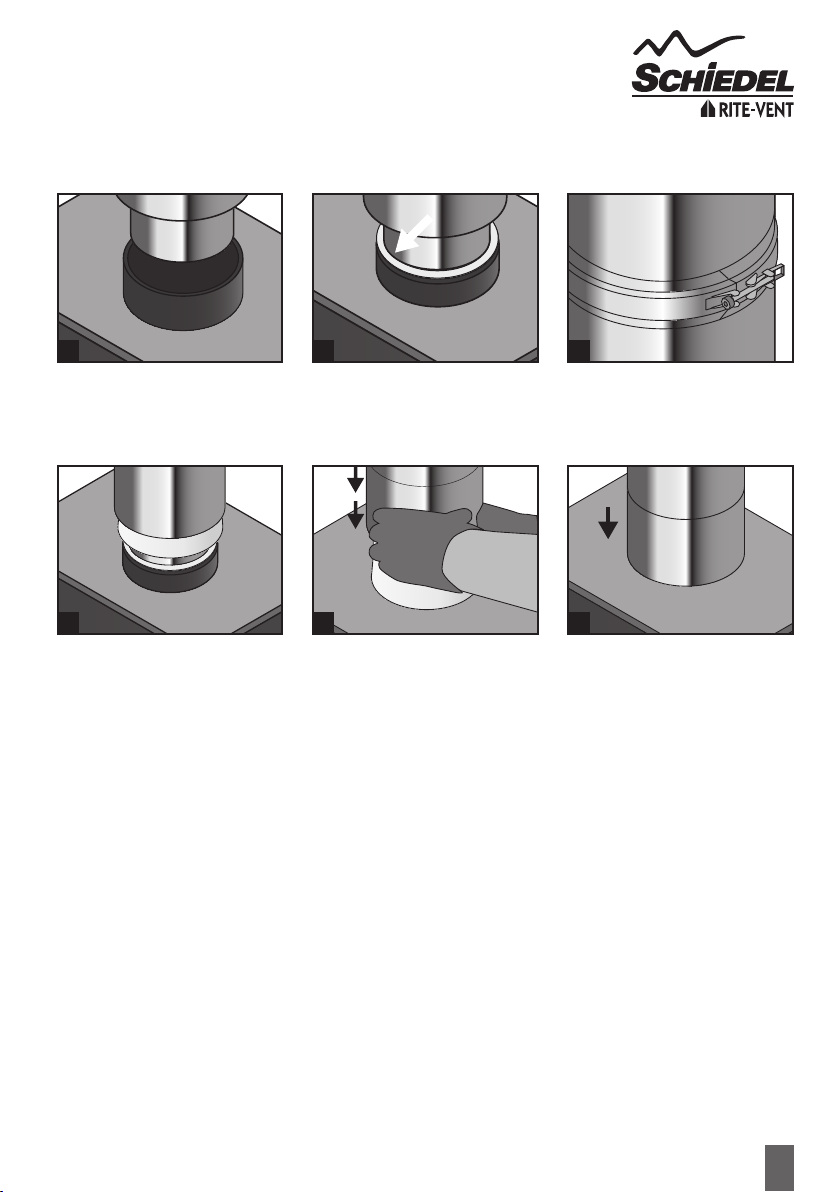

DoubleWallAdjustableStarterSection

Initial installation

Removal of stove for servicing

Remove loose strip of insulation and

keep to one side.

Slide adjustable case up inside the

outer wall of the chimney.

4.

1.

1.

2.

2.

3.

3.

Insulate liner using strip of insulation

with joint to rear. Width of insulation

can be trimmed to suit.

Insert male spigot of liner into the

appliance spigot.

Remove two loose insulation strips

and keep to one side.

Slide adjustable case down over the

insulation to cover the appliance spigot.

Finished installation.

Seal using the rope gasket, re

cement or similar.

Loosen the locking band on the liner

using the quick release clip (retain the

locking band to one side).

Break the re cement seal between

the appliance spigot and chimney liner.

4. 5. 6.

Slide the liner spigot up inside the

chimney until clear of appliance spigot.

Remove the appliance.

5. 6.

15

Re-installation of stove after servicing

Position stove spigot immediately

beneath liner spigot of chimney.

Position narrower strip of insulation

around the locking band with joint

to the rear.

1.

4.

2.

5. 6.

Slide liner spigot down inside the

appliance spigot and seal using the

re cement, rope gasket or similar.

Slide adjustable cover down 5mm

past insulation. Position nal insulation

around spigot with joint to the rear.

Slide locking band into place around

the joint on the liner. Now tighten the

bolt on the locking band around the

joint of the liner.

Slide adjustable case down over the

insulation to cover the appliance spigot.

3.

16

Anchor Plate

When commencing an installation with a re chest, or when extending an existing

brick or masonry chimney stack, an anchor plate must be used. The liner of the

Anchor Plate should be pushed into the opening of the re chest with the plate

resting on a bed of re cement. The plate should then be xed onto the concrete

slab by masonry screws tted through the pre-drilled holes in the plate. In the case

of a chimney extension, the liner of the anchor plate ts down inside the existing

chimney stack, or if TecnoFlex Plus liner has been used, inside the chimney as a liner,

use the anchor plate with screw type connections. Refer Flexible Liners installation

instructions for more details. The plate should then be then be xed to the top of

the existing chimney and sealed using re cement.

Inspection Pipe with Test Point

The inspection length is a component providing the facility for ue inspection

and cleaning, including a test point. It is installed as per a standard pipe section.

Two versions available for Dry and Wet systems. The removable inspection door

must be parallel with the front of the stove, or at least 3 x the internal diameter

from any combustible material (125mm I/D door must be at least 450mm from

combustible material).

AdjustablePipe/TelescopicPipes

They are used with standard components to achieve an exact length on site and

avoid on-site cutting of components.

1. Calculate the length required.

2. Remove insulation as required to achieve the correct length.

3. Fix the adjusted section to standard components using the locking band provided.

Please note that the adjustable pipe is non load bearing.

When used in a condensing or a positive pressure application, the relevant gasket

kits must be applied by the installer (gaskets purchased separately). Follow Page 11

for instructions on Gasket Kits.

Adjustable

Pipe

(50-230mm)

Telescopic

Pipe

a)215-310mm

b)350-570mm

Anchor Plate

Inspection Length

(DrySystems)

Effective

Length

302mm

Increaser

This component is used to increase from one diameter to the next diameter (e.g.) 125mm to 150mm. The component

is tted in the same way as a standard pipe length and should be secured with the locking band provided.

90˚Tee

Int Ø

Ext Ø

A

B

C

Int Ø

Ext Ø

90˚

90°TeeincludingDrainCap

This component may be used to connect from a connecting ue pipe to the

vertical system chimney at 90° or the branch may be used to locate a draft

stabiliser. It is installed as per a standard pipe section. Please note that there are

no barbs on the female collar in order to allow for the tee to be positioned at the

correct angle. It is supplied complete with a locking plug.

Int Ø

Ext Ø

A (mm)

B (mm)

C (mm)

100

150

282

150

120

200

256

394

195

170

125

180

301

154

133

150

200

329

162

142

180

235

354

176

160

17

Elbowsand90°InspectionElbows

For offset information on standard elbows, please refer to p.18

Please note that 90° Inspection bends may be incorporated into a connecting ue pipe arrangement on all fuels, please

refer to National Annex of BS EN 15387-1 for specic guidance re use on solid fuel applications.

In cases of top mounted stoves, a minimum vertical height of 600mm from the appliance is recommended prior to any

change of direction in the ue pipe.

On condensing appliances 87° bends must be used rather than 90° bends where required in order to ensure correct

run off of condensates.

93˚Tee including Drain Cap

This component must be used in place of a 90° tee to connect from a connecting

ue pipe to the vertical System Chimney on condensing systems to ensure that

condensate can drain down through the system to a drain point. This component

is installed as per a standard pipe section.

135°Tee including Drain Cap

There are 2 versions of the 135˚ tee available. The condensing version has a fully

welded liner, so please ensure, prior to installation on a condensing appliance, that

you have the fully welded version to hand.

This component may be used in combination with a 45° elbow to connect from a

connecting ue pipe to the vertical system chimney. It is installed as per a standard

pipe section and provides the least resistance to the ow of the ue gases. Please

note that there are no barbs on the female collar in order to allow for the tee to

be positioned at the correct angle. It is supplied complete with a drain plug.

135˚Tee

Int Ø

Ext Ø

A

B

C

Int Ø

Ext Ø

135˚

A

93˚Tee

Int Ø

Ext Ø

B

C

Int Ø

Ext Ø

93˚

Int Ø

Ext Ø

A (mm)

B (mm)

C (mm)

100

150

285

155

121

200

256

396

201

177

125

180

297

158

136

150

200

322

166

147

180

235

356

180

167

Int Ø

Ext Ø

A (mm)

B (mm)

C (mm)

100

150

325

254

254

200

256

444

351

351

125

180

336

259

259

150

200

365

283

283

180

235

414

326

326

18

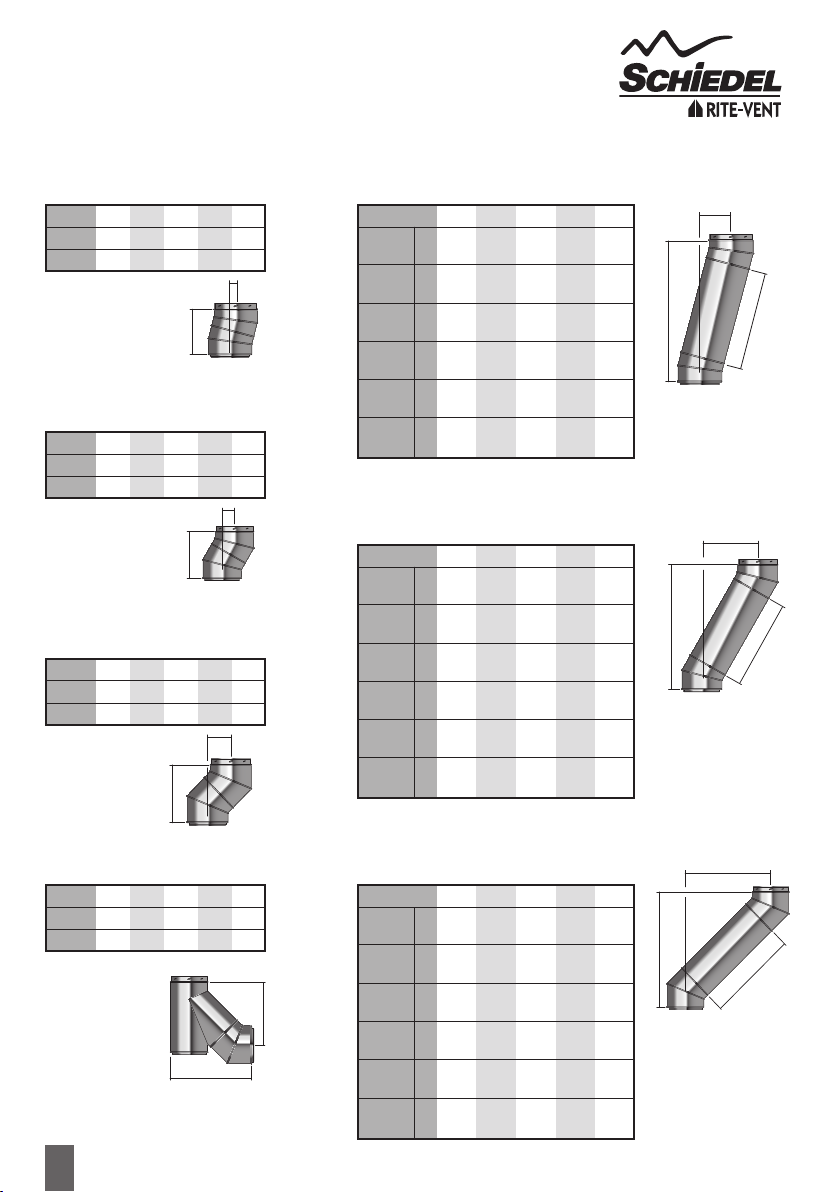

OFFSET DIMENSIONS

(made by assembling 2 bends)

Int Ø

A (mm)

B (mm)

125

232

31

100

228

30

150

234

31

180

234

31

200

238

31

Offsetsfor

15˚Bend

Int Ø

A (mm)

B (mm)

125

230

62

100

228

61

150

244

66

180

256

69

200

271

73

Offsetsfor

30˚Bend

Int Ø

A (mm)

B (mm)

125

254

105

100

256

106

150

268

111

180

295

122

200

309

128

Offsetsfor

45˚Bend

Int Ø

A (mm)

B (mm)

125

402

310

100

383

303

150

435

334

180

497

376

200

532

402

Offsetsfor

135˚Teeand45˚Bend

A

B

A

B

B

A

B

Effective Pipe

A

B

A

Effective Pipe

B

A

Effective Pipe

Offsetsfor15˚Bend

with Standard Pipe Length

Int Ø (mm)

1460 Eff A

Pipe B

960 Eff A

Pipe B

750 Eff A

Pipe B

460 Eff A

Pipe B

293 Eff A

Pipe B

160 Eff A

Pipe B

125

1642

408

1159

279

956

225

676

150

515

106

387

72

100

-

-

1155

278

952

224

672

149

511

106

383

71

150

1644

409

1161

279

958

225

678

150

517

107

388

72

180

1644

409

1161

279

958

225

678

150

517

107

388

72

200

1648

409

1165

280

962

225

682

150

521

107

392

73

Offsetsfor30˚Bend

with Standard Pipe Length

Int Ø (mm)

1460 Eff A

Pipe B

960 Eff A

Pipe B

750 Eff A

Pipe B

460 Eff A

Pipe B

293 Eff A

Pipe B

160 Eff A

Pipe B

125

1494

792

1061

542

879

437

628

292

483

208

368

142

100

-

-

1059

541

877

436

626

291

481

208

366

141

150

1509

796

1076

546

894

441

643

296

498

212

383

146

180

1520

799

1087

549

905

444

654

299

509

215

394

149

200

1535

803

1102

553

920

448

669

303

524

219

409

153

Offsetsfor45˚Bend

with Standard Pipe Length

Int Ø (mm)

1460 Eff A

Pipe B

960 Eff A

Pipe B

750 Eff A

Pipe B

460 Eff A

Pipe B

293 Eff A

Pipe B

160 Eff A

Pipe B

125

1287

1138

933

784

785

636

580

431

462

313

367

218

100

-

-

935

785

786

636

581

431

463

313

369

219

150

1300

1143

947

790

798

641

593

436

475

318

381

224

180

1328

1151

974

801

826

653

621

448

503

330

408

235

200

1341

1160

988

807

839

658

634

453

516

335

422

241

A

B

19

1.

2.

3.

4.

5.

Frame a four sided level square opening within the joists using timber stringers where necessary to allow for the

correct distance to combustibles from the outer wall of the chimney. This distance must be a minimum of 50mm on

Gas and Oil applications and 60mm for solid fuel applications (see Fig. 3 below).

Lower the chimney section through the opening in the oor, and secure to the next section of pipe.

Locate the two halves of the support plates around the chimney section, and secure to the joists using screws or bolts.

Remove the self-drilling screws which are fastened to the clamp band.Then fasten clamp band around the chimney

section and position on top of the plate. Tighten using the nuts and bolts provided.

Using the holes in the clamp band as a guide, fasten the three self-drilling screws to the outer case of the ICID Plus system.

Note:JointsmustNOToccurwithintheoororceilingjoists.

Ventilated Support Plate (Galvanised plate with S/S Band)

The support plate is used where the chimney passes through a combustible oor, and the weight

of the chimney has to be taken at oor level. The support plate must be rmly xed by using bolts

or screws. For load bearing Data refer to tables 1 and 2 on page 33.

Ventilated

Firestop Plate

Ventilated

Support Plate

FIRESTOP COMPONENTS

Fig.1 Fig.2 Fig.3

Ventilated Firestop Plate (1 & 2-Piece Round and 2-Piece Rectangular)

The ventilated re stop plates are used in combination with standard ICID Plus pipes where the

chimney passes through a combustible oor or ceiling.The outermost circle of ventilation slots gives

a distance to combustibles of 60mm. This measures the required distance for solid fuel applications.

For gas and oil applications a minimum of 50mm is required, which should be measured on site.The

re stop plate should be positioned around the chimney and fastened to the pre-cut plasterboard

or to the timber frame with nails or screws using the location holes provided (see Fig. 2 above).

MagneticFirestopCover(Optional)

Can be used in combination with 1-piece Ventilated Firestop Plate)

Non-Ventilated Bungalow Firestop

Installed as per a ventilated restop using the xing holes provided (see Fig.4 above). Distance to combustibles

must be respected - see p.8 for further info.

Support Plate with S/S Clamp Band (Non Combustible Floor)

The support plate is used where the chimney passes through a non combustible oor, and the weight of the chimney

has to be taken at oor level. The support plate must be rmly xed to the oor using bolts or screws provided by

others. For Load Bearing Data refer to table on page 33.

Fire stop Plate (Non Combustible Floor)

This re stop plate is used exclusively where the chimney passes through a non combustible oor.The two halves of

the plate are located around the chimney section and fastened to the oor using bolts or screws provided by others.

Non-Ventilated

Bungalow Firestop

Kit Installation In Situ

20

RetrotWallBand

AdjustableBackBracket(60-300mm)

Internal and External Application

The adjustable wall bracket is supplied in three parts, a ‘U’ shaped stainless steel

adjustable section, two bolts for xing the wall band to the back bracket and a

strengthening cross bracket.

WallBand(60mm)

Internal and External Application

The wall band is supplied in three parts, two stainless steel split bands which t

tightly around the outside of the chimney and a stainless steel back bracket.The

parts are joined together by means of the nuts and bolts provided.The use of the

item maintains a xed distance of 60mm from the outer casing of the chimney to

the wall or xing point.

Once the position of the support has been determined, secure the back bracket

to the wall with a method of xing to ensure adequate attachment and support.

The stainless steel split band is then positioned around the chimney section and

secured with the nuts and bolts provided to the back bracket.

The wall bracket provides lateral stability only, it is NOT load bearing and is to

be positioned at 3 metre centres.

1.

2.

3.

Once the position of the support has been determined, secure the U shaped

bracket to the wall with a method of xing to ensure adequate attachment

and support.

Determine the amount of extension required and secure the back bracket of

the wall band in place onto the adjustable section.

Fasten the strengthening cross bracket in place using the bolts provided.

With the back bracket in place, locate the rear portion of the band onto the

back bracket, the outer part of the band is then positioned around the chimney

section and secure with the nuts and bolts provided.

The adjustable wall band provides lateral stability only, it is NOT load bearing

and is to be positioned at 3 metre centres.

1.

2.

3.

4.

5.

Wall Band

(60mm)

Retrot

Wall Band

AdjustableBack

Bracket

(60-300mm)

Wall Band and

AdjustableBack

BracketAssembly

A

B

C

B

Int Ø

Ext Ø

A (mm)

B (mm)

C (mm)

125

180

131

112

25

100

150

131

83

25

150

200

148

132

25

180

235

185

162

25

200

256

202

186

25

Slide bracket down of chimney to the required position.

Once the position of the support has been determined, secure the back bracket

to the wall with a method of xing to ensure adequate attachment and support.

The wall bracket provides lateral stability only, it is NOT load bearing and is to

be positioned at 3 metre centres.

1.

2.

3.

60mm

60mm

Step 1 Step 2 In situ

Table of contents

Popular Fan manuals by other brands

Ebmpapst

Ebmpapst R2D250-AF10-12 operating instructions

System air

System air Sense SNX Installation,operation and maintenance instruction

Delta

Delta breez Smart SMT150-200 Installation and operating instructions

Ebmpapst

Ebmpapst S1G300-CA23-02 operating instructions

Holmes

Holmes Heater Fan owner's guide

Sulion

Sulion ALAN MOVE manual