BMS alpha CR User manual

Contents

Contents

1General information...........................................................................7

1.1 Operating instructions............................................................................................. 7

1.2 Address ..................................................................................................................... 7

1.3 Revision status ......................................................................................................... 7

1.4 Typographical conventions..................................................................................... 8

1.5 Explanation of symbols ........................................................................................... 9

1.6 Limitation of liability............................................................................................... 11

1.7 Copyright protection .............................................................................................. 11

1.8 Conformity............................................................................................................... 12

1.9 Customer service.................................................................................................... 12

1.10 Personnel conventions.......................................................................................... 13

1.11 Personnel requirements ........................................................................................ 14

2Safety................................................................................................16

2.1 General information................................................................................................ 16

2.2 Intended use............................................................................................................ 16

2.3 Improper use........................................................................................................... 16

2.4 Obligations of the machine operator.................................................................... 17

2.5 Responsibility of personnel .................................................................................. 18

2.6 Personal protective equipment............................................................................. 19

2.7 Residual hazards .................................................................................................... 20

2.7.1 Warning signs on the machine ................................................................................. 20

2.8 Security risks .......................................................................................................... 22

2.8.1 Risks from moving components ............................................................................... 22

2.8.2 Risks from thermal hazards...................................................................................... 22

2.8.3 Risks from noise ....................................................................................................... 22

2.8.4 Risks from electrical current ..................................................................................... 23

2.8.5 Risks due to hazardous substances......................................................................... 23

2.8.6 Risks from pressure vessels..................................................................................... 23

2.9 Safety and protective devices............................................................................... 24

2.9.1 Emergency stop button............................................................................................. 24

2.9.2 Safety switch............................................................................................................. 25

2.9.3 Breakaway cable ...................................................................................................... 26

2.9.4 Hose ......................................................................................................................... 26

2.10 Working safely ........................................................................................................ 27

2.11 Spare parts.............................................................................................................. 28

Contents

2.12 Structural changes ................................................................................................. 28

2.13 Disposal................................................................................................................... 28

3Technical data..................................................................................29

3.1 Chassis.................................................................................................................... 29

3.1.1 Standard ................................................................................................................... 29

3.1.2 Feeder ...................................................................................................................... 30

3.1.3 Feeder/scraper ......................................................................................................... 31

3.2 Machine ................................................................................................................... 32

3.3 Identification of the machine................................................................................. 33

3.3.1 Nameplate ................................................................................................................ 33

3.3.2 Machine equipment .................................................................................................. 34

4Layout and function ........................................................................35

4.1 Personnel ................................................................................................................ 35

4.2 Overview.................................................................................................................. 35

4.3 Chassis.................................................................................................................... 36

4.4 Machine ................................................................................................................... 44

4.4.1 Options ..................................................................................................................... 46

4.5 Functional sequence.............................................................................................. 47

4.6 Operating elements ................................................................................................ 48

4.6.1 Machine .................................................................................................................... 48

4.6.2 Multifunction display ................................................................................................. 52

4.6.3 Scraper radio system................................................................................................ 53

4.7 Menus ...................................................................................................................... 55

4.7.1 General display area................................................................................................. 56

4.7.2 Main menu................................................................................................................ 57

4.7.3 Submenu .................................................................................................................. 59

4.7.4 Diagnostic menu....................................................................................................... 60

4.7.5 Messages ................................................................................................................. 62

5Transport..........................................................................................63

5.1 Transport inspection.............................................................................................. 63

5.2 Transport restraints................................................................................................ 63

6Driving operation.............................................................................64

6.1 Personnel ................................................................................................................ 64

6.2 General instructions............................................................................................... 64

6.3 Checks before coupling......................................................................................... 65

6.4 Coupling .................................................................................................................. 66

6.5 Prepare driving operation...................................................................................... 72

Contents

6.6 Notes for driving operation ................................................................................... 74

6.7 Uncoupling and parking ........................................................................................ 75

7Work mode.......................................................................................80

7.1 Personnel ................................................................................................................ 80

7.2 Personal protective equipment............................................................................. 80

7.3 Safety instructions for work mode ....................................................................... 80

7.4 Connecting delivery hoses.................................................................................... 83

7.5 Prepare work operation ......................................................................................... 86

7.5.1 Preparing the feeder for filling .................................................................................. 92

7.6 Commissioning....................................................................................................... 93

7.7 Operation in working mode................................................................................... 95

7.7.1 Filling the mixing and delivery vessel....................................................................... 96

7.7.2 Closing the mixing and delivery vessel................................................................... 105

7.7.3 Switch on the mixing unit........................................................................................ 106

7.7.4 Delivery of the mix.................................................................................................. 107

7.7.5 Venting the mixing and delivery vessel .................................................................. 109

7.7.6 Open the mixing and delivery vessel...................................................................... 111

7.8 Interrupting the delivery of mix........................................................................... 111

7.9 Stopping the working operation ......................................................................... 112

7.10 Winter operation ................................................................................................... 116

8Cleaning..........................................................................................117

8.1 Personnel .............................................................................................................. 117

8.2 Personal protective equipment........................................................................... 117

8.3 Safety instructions for cleaning.......................................................................... 117

8.4 Air extraction connection .................................................................................... 118

8.4.1 Connection of an external device........................................................................... 119

8.5 Cleaning the machine........................................................................................... 120

8.5.1 Cleaning the vessel ventilation unit ........................................................................ 120

8.5.2 Cleaning the mixing and delivery vessel ................................................................ 121

8.5.3 Cleaning the upper and lower air............................................................................ 121

8.5.4 Cleaning the delivery hoses ................................................................................... 122

9Troubleshooting ............................................................................124

9.1 Personnel .............................................................................................................. 124

9.2 Personal protective equipment........................................................................... 124

9.3 Safety instructions for troubleshooting............................................................. 124

9.4 List of possible errors.......................................................................................... 125

9.5 Blockage in the conveyor machine .................................................................... 131

Contents

9.5.1 Cause for blockage................................................................................................. 131

9.5.2 Find a blockage ...................................................................................................... 132

9.5.3 Remove blockages................................................................................................. 133

9.5.4 Recommissioning after blockage removal.............................................................. 136

9.5.5 Avoiding blockage................................................................................................... 136

9.6 Battery empty........................................................................................................ 137

10 Maintenance...................................................................................138

10.1 Personnel .............................................................................................................. 138

10.2 Personal protective equipment........................................................................... 138

10.3 Safety instructions for maintenance and servicing.......................................... 138

10.4 General instructions............................................................................................. 141

10.5 Maintenance schedules ....................................................................................... 142

10.5.1 Maintenance schedule chassis............................................................................... 142

10.5.2 Maintenance schedule machine............................................................................. 145

10.5.3 Inspection after 500 operating hours...................................................................... 149

10.5.4 Inspection every 1000 operating hours .................................................................. 152

10.5.5 Inspection every 1500 operating hours .................................................................. 155

10.6 Lubrication schedule............................................................................................ 157

10.7 External inspections............................................................................................. 159

10.8 Maintenance and repair work.............................................................................. 160

10.8.1 Changing tyres........................................................................................................ 161

10.8.2 Checking the tyre pressure..................................................................................... 162

10.8.3 Oil change (compressor, motor and hydraulic oil).................................................. 163

10.8.4 Battery maintenance............................................................................................... 164

11 Storage ...........................................................................................165

11.1 Personnel .............................................................................................................. 165

11.2 Personal protective equipment........................................................................... 165

11.3 Storing the machine ............................................................................................. 165

11.4 Preserving the machine ....................................................................................... 167

11.5 Disposal................................................................................................................. 168

12 Optional versions ..........................................................................169

12.1 alpha E32 and alpha E63 .......................................................................................... 169

12.1.1 Interior view ............................................................................................................ 170

12.1.2 Control cabinet........................................................................................................ 171

12.1.3 Operating elements ................................................................................................ 172

12.1.4 Current connection ................................................................................................. 175

12.1.5 Notes on the delivery hoses ................................................................................... 176

13 Lists ................................................................................................177

Contents

13.1 List of figures........................................................................................................ 177

14 Appendix ........................................................................................179

14.1 Declaration of conformity .................................................................................... 180

14.2 Drawings................................................................................................................ 181

14.2.1 BMS alpha CR (standard) ........................................................................................ 181

14.2.2 BMS alpha CR B (feeder)......................................................................................... 182

14.2.3 BMS alpha CR B/S (feeder/scraper)........................................................................ 183

14.3 Circuit diagrams ................................................................................................... 184

14.3.1 Circuit diagrams alpha E32 and alpha E63................................................................. 184

Contents

General information

1

Operating instructions

1.1

7

1 General information

1.1 Operating instructions

These operating instructions are valid for the machine named on the cover

sheet.

The operating instructions convey important notes for the safe and efficient

handling of the machine. It is part of the machine and must be kept in legible

condition and accessible in the immediate vicinity of the machine for the

personnel working there at all times.

The prerequisite for safe working on and with the machine is the compliance

with all specified safety instructions and directives.

The operating instructions are the basis for all actions on the machine and

the basis for all training courses that take place on the machine. Personnel

must therefore have read the operating instructions carefully before starting

any work.

In addition, the national accident prevention regulations applicable at the

operating site of the machine and general safety regulations must be

observed.

1.2 Address

BMS Bau-Maschinen-Service AG

Daimlerstraße 10

33378 Rheda-Wiedenbrück, Germany

Tel.: +49(0)5242/9646-0

Fax: +49(0)5242/9646-29

Email: info@bmsbaumaschinen.de

1.3 Revision status

Date

Chapter

Reason

Responsible

19/05/2020

Operating instructions

Initial version

unique

1

General information

1.4

Typographical conventions

8

1.4 Typographical conventions

In order to be able to optimally work with the operating instructions, the

following clarifications on typographical conventions must be observed.

List

−First level bullet points.

−Second level bullet points.

Instruction

1. Step 1 of the instruction

2. Step 2 of the instruction

3. Step 3 of the instruction

The sequence of action steps must be adhered to.

Tips

➢Tips for situations that allow you to work efficiently.

General information

1

Explanation of symbols

1.5

9

1.5 Explanation of symbols

Explanatory symbols

Indicates a hotline.

Indicates maintenance work.

Indicates an inspection e.g. before starting work (as part of maintenance).

Indicates maintenance work that may be carried out only by service

personnel (see section 1.11) or by a specialist workshop authorized by BMS.

1

General information

1.5

Explanation of symbols

10

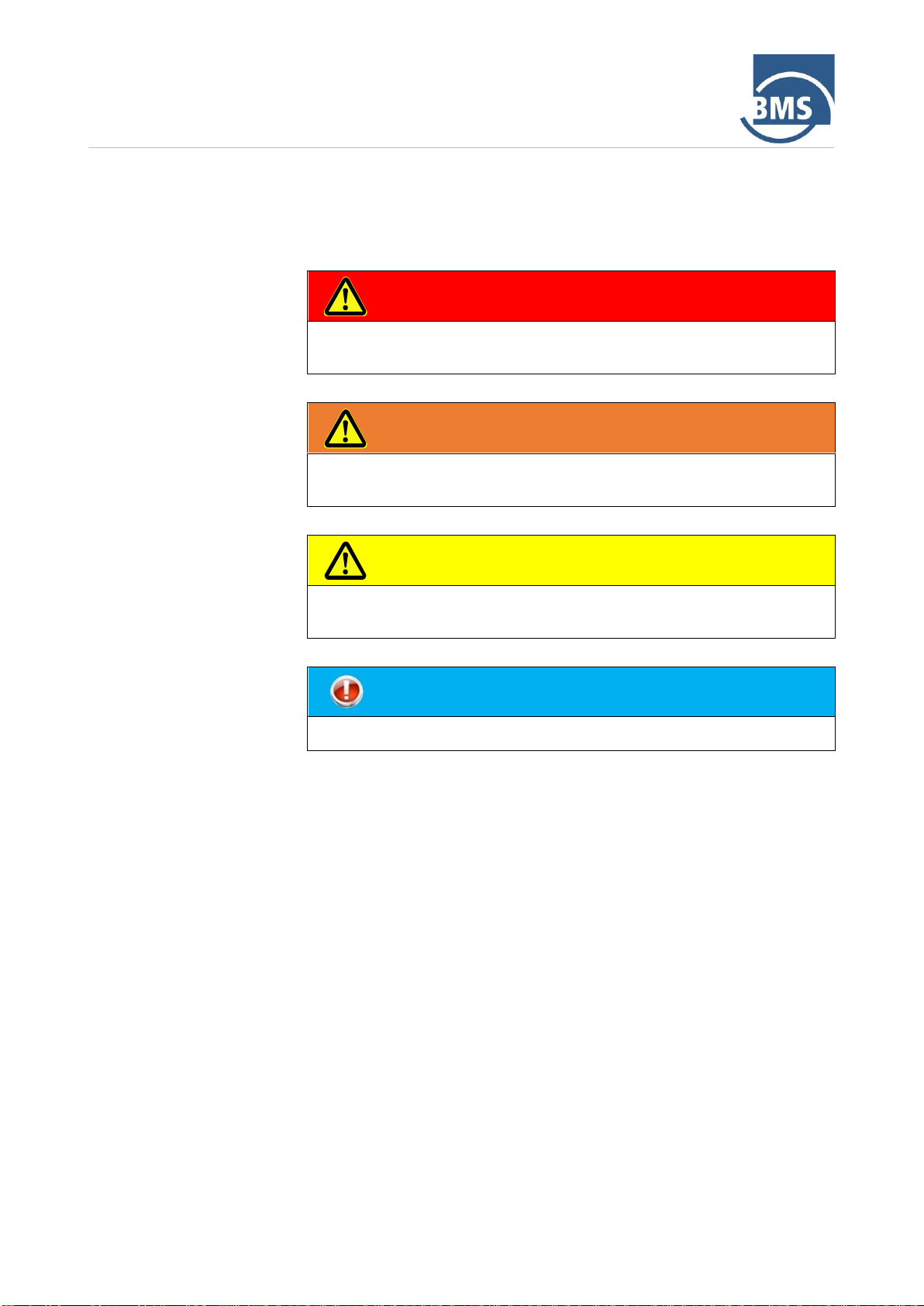

Warnings and safety instructions

The following symbols are used in these operating instructions to illustrate

hazards and notes:

DANGER

Designates a danger situation that results in severe physical injuries

or death.

WARNING

Designates a possible danger situation that can result in severe

physical injuries or death.

CAUTION

Designates a possible danger situation that can result in slight to

moderate injuries.

NOTE

Designates a situation that can result in material damage.

General information

1

Limitation of liability

1.6

11

1.6 Limitation of liability

All information and notes in these operating instructions were compiled

taking into consideration valid standards and regulations, the state of the art

as well as our long-standing insights and experiences.

The obligations as well as the general terms and conditions agreed in the

supply contract and the regulations valid at the time of contract conclusion

apply.

The manufacturer will not assume any liability for damage resulting from:

−failure to observe the operating instructions,

−use other than the intended one

−personnel that are not trained and not instructed,

−unauthorized/technical modifications and changes,

−improper assembly, commissioning, operation and maintenance of the

machine,

−Failure to observe the notes in the operating instructions regarding

transportation, storage, assembly, commissioning, operation,

maintenance. This applies in particular to the 1st inspection after 50

operating hours,

−use of not approved/incorrect spare parts that do not meet the

manufacturers specifications.

1.7 Copyright protection

These operating instructions are protected by copyright for BMS-Bau-

Maschinen-Service AG.

The operating instructions include regulations and drawings or sections of

drawings of a technical nature that may not be copied, distributed or used

without authorization for competition purposes or disclosed to third parties

either in part or in full.

The operator of the machine is permitted to make copies –even in excerpts

–expressly for internal use in connection with the operation of the machine.

BMS-Bau-Maschinen-Service AG reserves the right to grant permission for

the use for publications or for forwarding copies or information from these

operating instructions to third parties.

Any violations will result in a claim for compensation for the manufacturer.

Additional claims remain reserved.

1

General information

1.8

Conformity

12

1.8 Conformity

The declaration of conformity is based on the applicable guidelines (with

their associated amending directives) in the version at the time of

commissioning. Please refer to the declaration of conformity for information

on the individual guidelines.

The declaration of conformity is in the Appendix.

1.9 Customer service

Our customer service is available for technical information.

In addition, our employees are always interested in new information and

experiences that result from the application and which could be valuable for

the improvement of our add-on devices.

Tel.: +49(0)5242/9646-0

Fax: +49(0)5242/9646-29

Email: info@bmsbaumaschinen.de

If questions arise in practice, you can also contact BMS directly.

Service/workshop:

Telephone: +49(0)5242/9646-17

Email: werkstatt@bmsbaumaschinen.de

Spare parts warehouse:

Telephone: +49(0)5242/ 9646-15

Email: versand@bmsbaumaschinen.de

General information

1

Personnel conventions

1.10

13

1.10 Personnel conventions

Manufacturer

BMS-Bau-Maschinen-Service AG is the manufacturer of the machine and is

hereinafter referred to as “manufacturer”.

Personnel

Personnel are all persons who operate and work on the machine. The

different requirements for these persons are described in Section 1.11.

System operator

The operator is any natural or legal person who uses the machine or makes

it available to third parties for use. The operator is responsible for the safety

of the operator or third parties during use.

1

General information

1.11

Personnel requirements

14

1.11 Personnel requirements

Any activities on and with the machine must be performed only by persons

who can carry out their work properly and reliably and who meet the listed

requirements.

The responsibilities are assigned with specification of the symbols listed

below in the beginning of each chapter.

Target group

Symbol

Operating personnel

O

Specialist personnel

F

Specialist personnel for electrical equipment

E

Service personnel

S

Chapters "Safety" and "Technical data" are an exception. These chapters

are relevant for all target groups.

Operating personnel

Operating personnel are persons who were instructed thoroughly and

verifiably by the operator in their assigned tasks and possible hazards.

Operating personnel are responsible for operating the machine.

Tasks above and beyond that may be performed by operating personnel

only if these are specified in the operating instructions and if the operator

has expressly assigned them to the person.

General information

1

Personnel requirements

1.11

15

Specialist personnel

Specialist personnel are persons one who perform the assigned work

properly, detect possible hazards on their own and prevent personal or

material damage based on their professional training, knowledge and

experience as well as their knowledge of the pertinent regulations.

Their tasks include the identification, containment and elimination of errors

and malfunctions.

They are also responsible for the scheduled and standardized maintenance

to reduce and avoid incidents.

Specialist personnel for electrical equipment

Specialist personnel for electrical equipment (qualified electricians) are

persons who, based on their technical training, knowledge and experiences

as well as knowledge of the pertinent rules and regulations, are capable of

properly performing work on electrical systems, detecting possible hazards

independently and preventing personal and material damage from electrical

voltage.

All works on the electrical equipment must principally only be carried out by

a qualified electrician.

Service personnel

Authorised service personnel of BMS Bau-Maschinen-Service AG are

considered to be service personnel.

Their tasks include the identification, containment and elimination of errors

and malfunctions.

They are also responsible for the scheduled and standardized maintenance

to reduce and avoid incidents.

Unauthorized persons

Persons who were not instructed are unauthorised persons.

In case of doubt, talk to persons who might be unauthorised. Expel

unauthorised persons from the working area.

Any person other than those described in the section "Personnel

requirements" is considered to be unauthorized. The operator of the add-on

device will be solely responsible for any resulting damage.

2

Safety

2.1

General information

16

2 Safety

2.1 General information

This section provides an overview of important safety aspects for the

protection of the operator and personnel against possible hazards and the

safe and failure-free flow of operation.

Failure to observe the listed directives, warnings, and safety instructions can

result in considerable hazards.

2.2 Intended use

The BMS alpha CR is a screed machine used for the production and transport

of building materials. Only the materials listed below may be mixed and

transported with the machine:

−Screed up to a grain diameter of 16 mm.

−Other materials are permitted only in consultation with and with the

written approval of the manufacturer.

The machine must not be operated in closed rooms due to the exhaust

gases produced.

The compressed air connection may only be used to convey material to the

machine. Any other use is only permitted after consultation with and with the

written consent of the manufacturer.

2.3 Improper use

Any use of the add-on device other than the one described in “intended use”

is deemed to be inappropriate use. The operator is solely liable for any

resulting damage.

Safety

2

Obligations of the machine operator

2.4

17

2.4 Obligations of the machine operator

The machine is used in the industrial field. The machine operator is therefore

subject to the legal obligations of industrial safety.

Next to the warnings and safety instructions in these operating instructions,

safety, accident prevention and environmental guidelines valid for the

application area of the machine must be adhered to.

The operator must -

−obtain information on the valid industrial safety regulations.

−determine possible additional hazards resulting from the special

operating conditions at the operating site of the machine with a hazard

assessment.

−implement the necessary behavioural requirements for the operation of

the machine at the operating site in the operating instructions.

−check during the entire application period of the machine whether the

issued operating instructions comply with the current version of

regulations.

−adjust the operating instructions, insofar as necessary, to new

regulations, standards and operating conditions.

−clearly regulate and define the responsibilities for installation, operation,

maintenance and cleaning of the machine.

−ensure that all employees working on the machine have read and

understood the operating instructions. In addition, the operator must

verifiably train and inform personnel working on the machine about

possible hazards at regular intervals.

−provide the specified and recommended protective equipment for

personnel assigned to work on the machine.

The operator must ensure that:

−the machine is always in technically flawless condition.

−the vehicle with which the machine is towed is approved by the

Technical Control Board (TÜV) and is suitable for approval in

accordance with German traffic regulations (StVO).

−the machine is serviced according to the specified maintenance

intervals.

−all safety devices of the machine are checked regularly for

completeness and function.

−Replace damaged or illegible pictograms, marks, signs or labels

immediately.

2

Safety

2.5

Responsibility of personnel

18

2.5 Responsibility of personnel

Next to the warnings and safety instructions in these operating instructions,

safety, accident prevention and environmental guidelines valid for the

application area of the device must be adhered to.

In particular, personnel must:

−obtain information on the valid industrial safety regulations.

−adhere to the behavioural requirements in the operating instructions for

the operation of the machine at the operating site.

−properly exercise the assigned responsibilities for the operation,

maintenance, and cleaning of the machine.

−have read and understood the operating instructions before starting to

work for the first time,

−use the stipulated protective equipment. It must be checked regularly

and replaced if damaged. In particular, hearing protection must be worn

when operating the machine.

−avoid abnormal postures when working.

Furthermore, all employees working on the machine are within the scope of

their tasks responsible for

−ensuring that the machine is in perfect technical condition.

−that machine being serviced according to the specified maintenance

instructions.

−all safety devices being checked regularly for completeness and

function.

−order, cleanliness and sufficient workplace lighting being ensured.

In case of malfunction of the machine the personnel must

−notify the competent authority of the malfunction.

Safety

2

Personal protective equipment

2.6

19

2.6 Personal protective equipment

Working requires wearing personal protective equipment in order to

minimize health hazards. Therefore:

−Before starting any work, put on the respective specified protective

equipment properly and wear it during work.

−In addition, always observe the signs with pictograms for personal

protective equipment in the working area without fail.

Industrial safety clothing

Closely fitting work clothing with low tear strength, with narrow sleeves

and no protruding parts, predominantly as protection against getting

caught by moving machine parts.

Do not wear rings, necklaces or other jewellery.

Solid protective gloves

To protect hands against rubbing, abrasions, scratches, grazes, cuts,

punctures or similar superficial skin injuries.

Safety footwear

To protect feet against injuries from falling parts and against slipping and

falling on slippery surfaces.

Ear protection

To protect against hearing damage.

Safety goggles

To protect against injuries to the eyes from parts flying around, particles,

fluid splashing or escaping compressed air.

Mouthguard

To protect against lung damage.

Industrial safety helmet

To protect against head injuries, for example during maintenance work in

the machine.

2

Safety

2.7

Residual hazards

20

2.7 Residual hazards

The machine was subjected to a risk assessment. The hazards determined

in doing so were, in as much as possible, removed and detected risks

reduced. But the machine still harbours residual risks which are described in

the following section.

The warnings and safety instructions listed in here and in the action chapters

of these instructions must be observed without fail in order to prevent

possible damage to health and dangerous situations.

Danger zones which cannot be avoided due to the construction of the

machine are marked with warning signs.

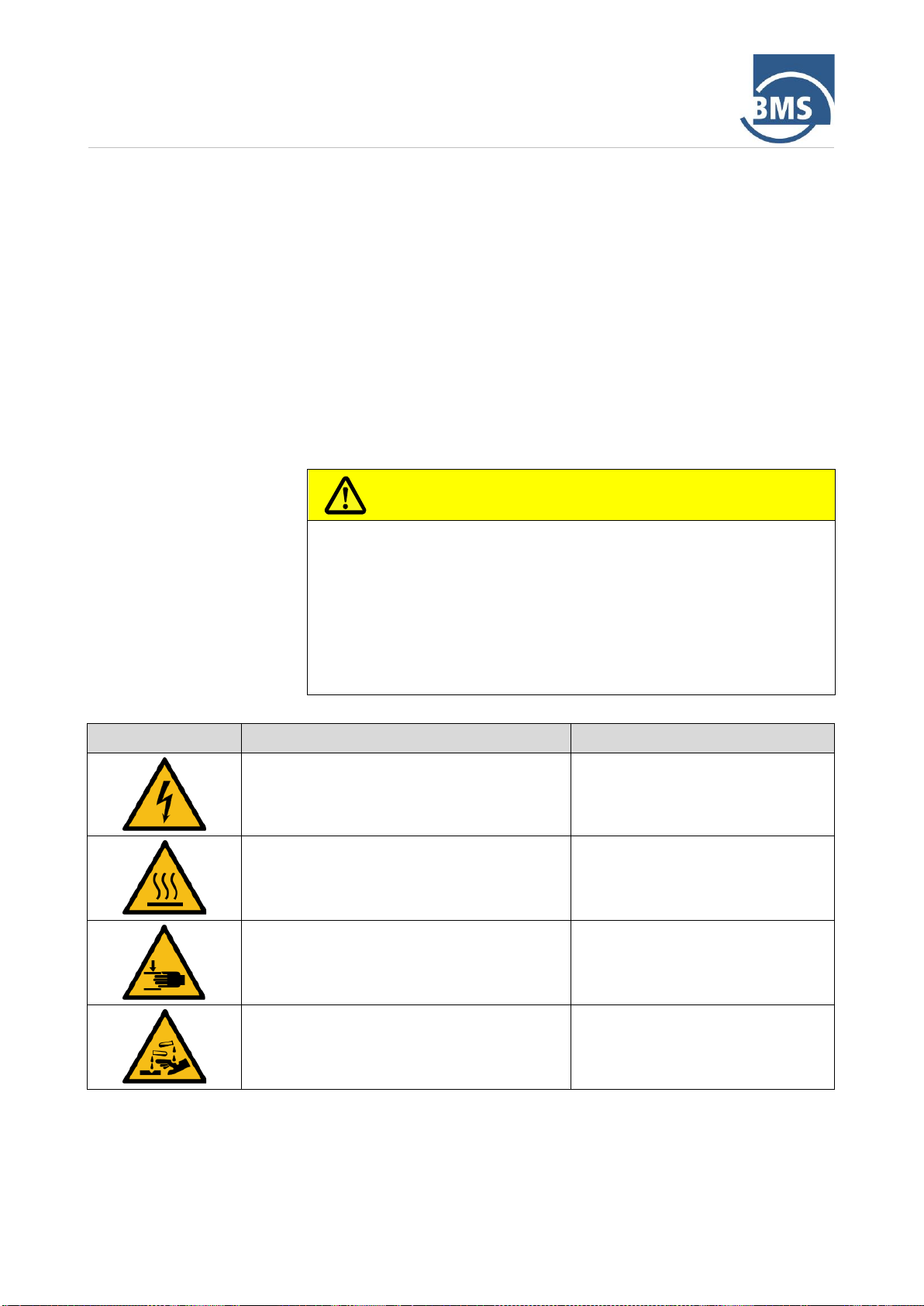

2.7.1 Warning signs on the machine

CAUTION

Risk of injury through illegible signs.

Labels and signs that have become blurred or illegible no longer

sufficiently mark danger points and cannot indicate possible risks of injury.

−Keep pictograms, safety, warning and operating instructions in

perfectly legible condition at all times.

−Replace damaged or illegible pictograms, marks, signs or labels

immediately.

Pictogram

Location

Explanation

On the battery,

On the generator

Dangerous electrical voltage

warning

On the motor

Hot surfaces warning

At the front

Hand injury warning

On the battery

Warning against burns

This manual suits for next models

2

Table of contents