BMS Truck-Coder II User manual

Installation and Operations Manual

7GHz Truck Coder II

System

DOC# 6051419100X3 July 2006

Broadcast Microwave Services, Inc.

12367 Crosthwaite Circle

Poway, CA 92064

800-669-9667, 858-391-3050

858-391-3049 FAX

This Page Intentionally Left Blank

INTRODUCTION

The BMS Truck-Coder II (TCII) is an ENG transmitter that operates in both digital (COFDM) and legacy

analog (FM) transmission modes. It features a DVB-T compliant (COFDM) modulator MPEG2 video

encoder. The system is designed to support both 12 MHz and 17 MHz BAS channel plans (in both Digital

and FM transmission modes). The two-unit system consists of an Indoor rack-mounted exciter Unit (IDU)

and an Outdoor mast-mounted RF Transmitter Unit (ODU). An optional second RF unit can be added to

support dual band operation. The system integrates support for mast mounted antenna relay, feed controls

and other accessories. The indoor unit provides support for multiple analog and video signal formats and

provides an industry standard 70MHz IF output.

The Truck-Coder II is designed to meet the rugged environmental needs of ENG news vehicles. It blends

our field proven technology with a rich feature set and the simple operation needed for ENG/OB

operations.

Applications:

•ENG News Vehicles

•Law Enforcement Command Posts

Key Features:

•Digital (COFDM) and Analog (FM) Transmission

•Ease of installation – a single coax cable interconnects the IDU and ODU

•Simple Set-up and Operation – menu driven user interface

•Up to 999 easily configurable user Presets (each capable of storing all system parameters)

•Front panel Ethernet Port simplifies firmware upgrades and supports web based management

•Fully configurable FM, COFDM and MPEG parameters (including PID’s) ensure product

compatibility

•Optional Dual Band Capability

This document provides instructions for the installation, operation and maintenance of the Truck Coder II

system.

Broadcast Microwave Services (BMS) is a leader in wireless digital microwave technology providing

innovative products for the television broadcast, video, telemetry and surveillance industries. A wholly

owned subsidiary of Cohu, Inc., BMS designs and manufactures a comprehensive line of microwave

communications equipment for broadcasting sports venues, law enforcement and military applications.

BMS also builds and integrates command and control centers to provide fully functioning, complex, end to

end digital systems.

For the latest product and system information please visit www.bms-inc.com.

Broadcast Microwave Services, Inc.

12367 Crosthwaite Circle

Poway, CA 92064

Tel: +1 (858) 391-3050

Toll free (US): 800-669-9667

Fax: +1 (858) 391-3049

Email:[email protected]

Web: www.bms-inc.com

ii

This Page Intentionally Left Blank

iii

Table of Contents

INTRODUCTION........................................................................................................................................... i

SYSTEM DESCRIPTION ............................................................................................................................. 1

Overview.................................................................................................................................................... 1

Indoor Unit................................................................................................................................................. 2

Outdoor Unit .............................................................................................................................................. 4

Technical Specifications ............................................................................................................................ 5

UNPACKING ................................................................................................................................................ 9

Parts List .................................................................................................................................................... 9

Manuals ................................................................................................................................................. 9

Components ........................................................................................................................................... 9

Cables .................................................................................................................................................... 9

INSTALLATION......................................................................................................................................... 11

Equipment Installation ............................................................................................................................. 11

Installing the Indoor Unit (IDU).......................................................................................................... 15

Indoor Unit (IDU) Connections........................................................................................................... 17

Installing the Outdoor Unit (ODU)...................................................................................................... 18

OPERATION ............................................................................................................................................... 22

Initialization ............................................................................................................................................. 22

WARRANTY............................................................................................................................................... 25

Customer Service Information ................................................................................................................. 25

TROUBLE SHOOTING .............................................................................................................................. 27

Diagnostics............................................................................................................................................... 28

PIN OUTS................................................................................................................................................ 30

IDU ...................................................................................................................................................... 30

ODU .................................................................................................................................................... 32

US Broadcast Frequency Assignments......................................................................................................... 34

Coded Orthogonal Frequency Division Multiplex (COFDM) Modulation .................................................. 36

Glossary........................................................................................................................................................ 40

List of Figures

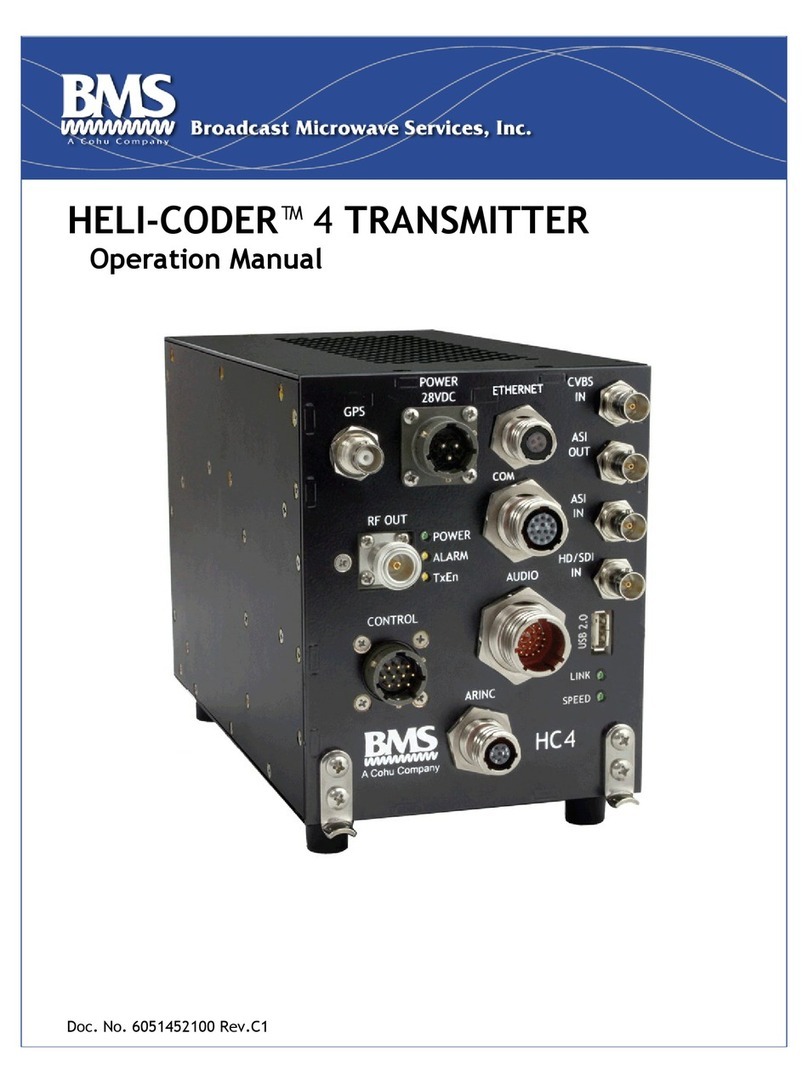

Figure 1 TCII System Overview .................................................................................................................... 1

Figure 2 TCII IDU (Indoor Unit) Block Diagram .......................................................................................... 2

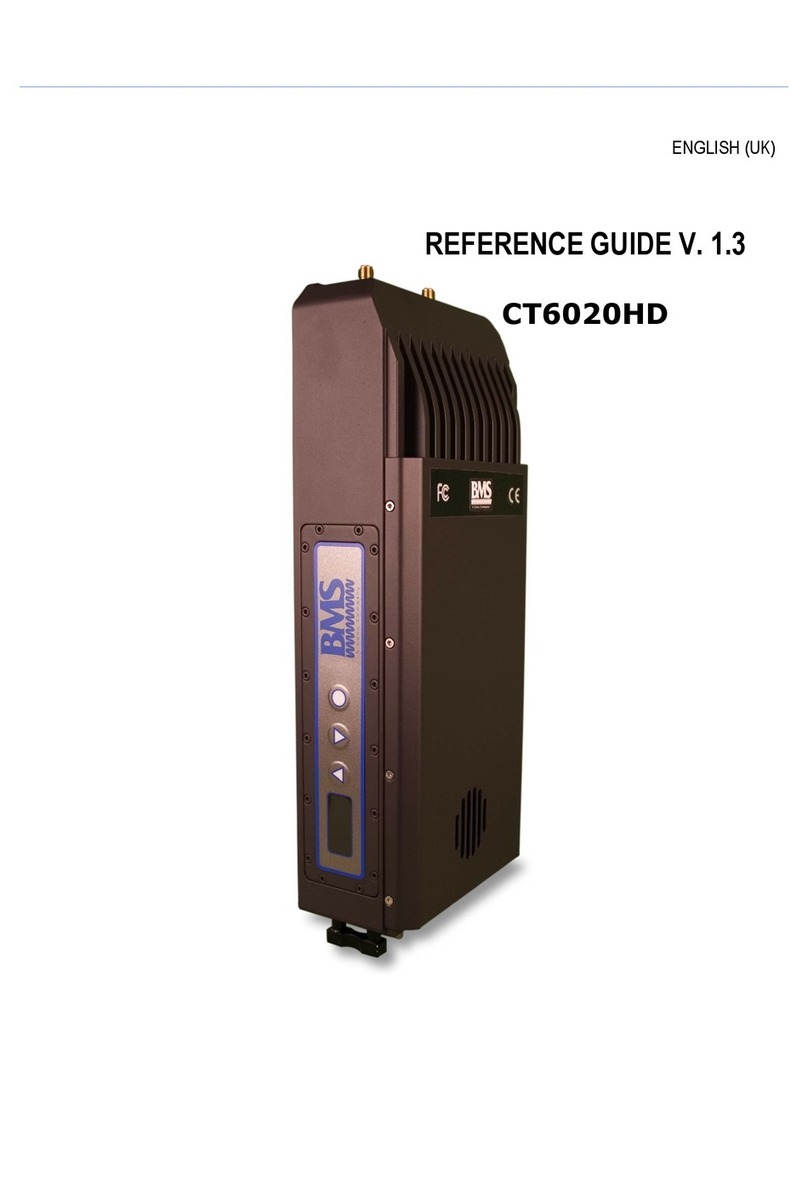

Figure 3 TCII Outdoor Unit (ODU) Block Diagram...................................................................................... 4

iv

Figure 4 IDU Footprint................................................................................................................................. 13

Figure 5 ODU Footprint ............................................................................................................................... 14

Figure 6 TCII Indoor Unit ............................................................................................................................ 15

Figure 7 TCII Indoor Unit Rear Panel Connections ..................................................................................... 17

Figure 8 TCII Outdoor Unit.......................................................................................................................... 18

Figure 9 ODU Mounting Footprint .............................................................................................................. 19

Figure 10 ODU Mounting Orientation ......................................................................................................... 20

Figure 11 ODU Connections ........................................................................................................................ 21

Figure 34 The HOME Menu ........................................................................................................................ 22

Figure 36 Product Label ............................................................................................................................... 25

Figure 37 IDU REAR PANEL CONNECTORS.......................................................................................... 30

Figure 38 ODU CONNECTORS ................................................................................................................. 32

List of Tables

Table 1 General Specifications....................................................................................................................... 5

Table 2 Analog (FM)...................................................................................................................................... 6

Table 3 Digital (COFDM) .............................................................................................................................. 6

Table 4 TCII Input/Output.............................................................................................................................. 7

Table 5 Component Mounting Requirement Reference ............................................................................... 11

Table 6 ODU Connections ........................................................................................................................... 21

Table 7 AUXILIARY INPUT PINOUTS .................................................................................................... 30

Table 8 SUMMARY ALARM PINOUTS ...................................................................................................30

Table 9 AUDIO 1 IN PINOUTS .................................................................................................................. 31

Table 10 AUDIO 2 IN PINOUTS ................................................................................................................ 31

Table 11 J1 EXTERNAL DATA IN ............................................................................................................ 32

Table 12 J2 EXTERNAL DC IN PIN OUTS (Optional) ............................................................................. 32

Table 13 J4 ANTENNA CONTROL PIN OUTS......................................................................................... 33

Table 14 ODU J5 EXTERNAL CONTROL PIN OUT................................................................................ 33

v

WARNING!

RF RADIATION EXPOSURE HAZARD

This warning is provided by Broadcast Microwave Services (BMS) Inc. for safety purpose. The

following information help to reduce the risk of RF exposure hazard.

FCC Limit of RF Exposure

According to Federal Communication Commission (FCC), the Maximum Permissible Exposure (MPE) for

FR radiation has been set to 1.0 mW/cm2for the 7GHz Truck-Coder II equipment (OET Bulletin 65).

The 7GHz Truck-Coder II is a non-broadcast transmitter and without an antenna it will not create RF

exposure (power density) exceeding the 1.0 W/cm2FCC limit.

However a high-gain antenna such as a parabolic dish will greatly enhance the Field-Coder II output power

density beyond the MPE limit of 1.0 mW/cm2.

In this situation a minimum distance from the antenna needs to be calculated in order to keep the MPE

always below the safety limit. The calculation has been done for Field-Coder II based on the formula

mentioned in OET Bulletin 56.

The calculations have been done for different commonly used antenna in Electronic New Gathering (ENG)

systems.

Transmission

Figure 1 shows the plot of the minimum exposure distance for 0dBi, 5dBi, 16dBi, and 30dBi antennas. The

7GHz Truck-Coder II transmits the maximum power of 4 Watts. The minimum exposure distances are

found from the cross points of the exposure graphs (for various antennas) with the line of maximum

permissible exposure (i.e. 1 W/cm2). Notice that the numbers in Figure 1 predict the worse case scenario,

which is straight in front of the antenna (exposing to the antenna main-lobe). Obviously the side-lobe

exposures are well below these numbers as the radiation intensity dramatically reduces on the side lobes.

The antenna used for this transmitter must not be co-located or operating in conjunction with any other

antenna or transmitter.

Antenna Specifications

The antenna for Truck-Coder II is customer's furnished equipment. The customer has a choice of using, for

instance, a 0dBi Omni antenna or a 30dBi dish antenna. The plots of Figure 1 provide the exposure distance

for 0dBi and 5dBi Omni antennas as well as 16dBi and 30dBi dish antennas.

vi

Estimated RF Exposure for 7 GHz Truck-Coder II

0.0

1.0

2.0

3.0

4.0

5.0

0 100 200 300 400 500 600 700

Distance , cm

Power Density, mW/cm^2

Max Permissible

Exposure: 1mW/cm2

30 dBi Antenna

Max Exposure at 560 cm

0 dBi Antenna

Max Exposure at 20 cm

16 dBi Antenna

Max Exposure at 112 cm

5 dBi Antenna

Max Exposure at 35 cm

Figure 1

Summary

In order the keep the RF exposure within the FCC limit, it is necessary to maintain the safe distance from

the antenna. The results shown in Figures 1 can be summarized in the following table:

Minimum permissible distance from antenna (cm)

Antenna Gain

(dBi)

0 20

5 35

16 112

30 560

Notice the above table indicates worst-case situation (straight in front of the antenna).

1

SYSTEM DESCRIPTION

Overview

The Truck-Coder II (TCII) is an ENG transmitter that will operate in both Digital (COFDM) and Analog

(FM) modes. The system comprises of an indoor unit (Exciter) and a mast mounted outdoor unit (RF

transmitter).

Figure 1 TCII System Overview

The indoor unit is designed to be rack mounted within an ENG van. It is housed in a 2RU 19-inch rack

mount enclosure and powered from a conventional 120V AC source. The indoor unit contains full featured

DVB-T compliant Digital (COFDM) and Analog (FM) exciters and associated power supplies. The IDU

provides the necessary DC voltage to power the ODU.

2

To simplify installation, only a single coaxial cable is required to interconnect the IDU to the ODU; DC

power, 70MHz IF and telemetry signals are all multiplexed onto this single cable. The system also supports

legacy cable systems that feed DC power on separate conductors.

The indoor unit features a menu driven front panel display (vacuum fluorescent) that is used to configure

the equipment and monitor its performance. The system is also designed to support remote control by 3rd

party equipment using either web based or simple RS232 protocol.

The outdoor RF unit (ODU) is designed to be mounted outdoors adjacent to the antenna. The ODU

translates the 70MHz IF signal from the IDU (exciter) to the desired operating frequency and amplifies the

signal to the desired level. The RF unit employs automatic level control circuits that keep the system

operating optimally and eliminate the need for any user adjustments.

The ODU uses a common signal path for both Analog (FM) and digital (COFDM) operation. Performance

is automatically optimized for both methods. BMS transmitters feature superior COFDM performance that

is adequate to support split channel operation in a 12MHz channel (see BMS white paper).

The ODU provides signals to control an antenna relay and feed polarity. Additional contact closures are

also provided for user specific applications.

A more detailed description follows:

Indoor Unit

A simplified block diagram of the IDU is shown below:

Figure 2 TCII IDU (Indoor Unit) Block Diagram

3

The FM modulator is designed to accept analog audio and video inputs. Support for 2 audio channels is

provided via frequency programmable sub carriers that ride above the video signal The frequency deviation

is user configurable to support operation in either a 17 MHz or 12 MHz channel allowing Analog operation

to continue after the channel plan transition is complete. Analog transmission offers a more graceful

degradation in performance and might be preferred under certain conditions.

The Digital (COFDM) modulator also supports 2 analog audio and one analog video input but also supports

advanced digital interfaces (ASI, SDI) as well. The digital modulator includes an MPEG2 encoder and a

DVB-T compliant COFDM modulator. Both MPEG and COFDM parameters are fully configurable by the

system controller in support of optimum performance and compatibility with other vendors equipment. For

those users less familiar with detailed COFDM and MPEG settings, the equipment provides 3 preset

robustness settings (low, mid and high) that each optimize video performance at the expense of modulation

complexity. High robustness provides the lowest quality video but is able to operate in severely

compromised locations. Low robustness provides the best quality video but may require a clear line of sight

shot.

An integrated SMPTE color bar generator with programmable text overlay is included. The indoor unit

features a menu driven VFD front panel display. Two levels of user access are supported; Operator and

Engineer. Operator is designed for non-technical users and assumes that the equipment has been

preconfigured by a station engineer. Engineer has full access to all menus and the ability to set up the

equipment for a less qualified operator.

The system accommodates up to 999 user programmable presets. These can be uniquely named and

configured; each preset records all of the configurable variables within the system. Presets 1 thru 6 are

conveniently displayed on their own screen for quick and easy recall. All presets can be uniquely named

via the front panel menu system to simplify identification and can be recalled quickly to put the equipment

in a known state. Presets are an ideal mechanism for the station engineer to pre-configure the equipment for

simplified operation by a less skilled operator.

The system also features a front and rear panel ethernet interface that can be conveniently used to upload

new operating firmware into the unit. This interface supports high data transfer rates and simplifies the

firmware upgrade process. This equipment makes extensive use of FPGA (field programmable gate array)

and microprocessor controlled hardware. Ease of firmware upgrade helps ensure that the equipment is

always kept up to date.

The TCII also includes embedded web based management that can be accessed with any PC using a web

browser and connected to the front or rear panel Ethernet port. This interface supports all the front panel

programmable features as well as others such as the ability to configure channel plans, and download

preconfigured presets (duplicate equipment setups). The system can be controlled remotely via an RS232

control port as well; consult BMS for the protocol specification for this port.

4

Outdoor Unit

A simplified block diagram of the ODU is shown below:

Figure 3 TCII Outdoor Unit (ODU) Block Diagram

The ODU is mounted outdoors and connected to the IDU by a single coaxial cable.

The ODU is in constant communication with the IDU via a telemetry channel that is frequency multiplexed

onto the single cable interface between the IDU and ODU. This channel is used to configure the ODU

(select frequency, power level etc) and also to monitor performance (PLL lock, temperature etc). A

microcontroller within the ODU handles this communication and controls the respective parts of the ODU.

The 70MHz input is first up-converted to the UHF band and then up-converted again to the desired

operating frequency. The signal is then amplified and fed to the antenna. A power detector at the

transmitter output helps ensure that the transmitter always operates most efficiently which is particularly

important when transmitting digital COFDM.

The ODU provides connector interfaces to support remote (mast mounted) antenna selection and antenna

feed polarity selection. Four additional contact closures are also provided for user specific applications.

These are controlled by corresponding inputs at the IDU.

A temperature sensor is included in the ODU and can be monitored on the IDU front panel. If the

equipment is operated in extremely hot temperatures the ODU will automatically back off the output power

to preserve operation and prevent damage to the unit.

5

Technical Specifications

Table 1 General Specifications

Indoor Unit (IDU) Outdoor Unit (ODU)

Size 17.5 x 14.9 x 3.5 in

(44.1 x 37.8 x 8.9 cm)

15.0 x 3.7 x 9.0 in

(38.1 x 22.9 x 9.2 cm)

Weight 11 lb (5 kg) 16.5 lb (7.5 kg)

Oper Altitude 15,000 ft 15,000 ft

Operating Temp -20 - +55º C -20 - +55º C

Stor. Temp -30 - +70º C -40 - +80º C

Relative Humidity 98% NC 100%

Power Req 105-260 VAC 50/60 Hz 48 VDC (supplied by IDU)

Ventilation Requirements Fan inlet and outlets must have no

obstruction

Fins must be oriented vertically on

antenna mast

Specification

Frequency 6.4 – 7.2 GHz

(Pre-programmed with US 12 MHz and 17MHz BAS channel plans

including offsets)

Tuning Step Size 250KHz

Frequency Stability +/- 5ppm max

Power Consumption 200W max

Recommended IDU-ODU Cable 100ft max

50 or 75 Ωcable (selectable)

Average Output Power

(6.4 – 7.2 GHz) FM COFDM

4 W (typical) 4 W (typical)

6

Table 2 Analog (FM)

Feature Spec

Video

Video Deviation (MHz) 4.0MHz pk /17 MHz Ch

3.5MHz pk /12 MHz Ch

Video Pre-Emphasis 405

(Per CCIR Recommendation)

VSNR (@12 MHz) 2 GHz 63 dB Typical (60 dB min.)

7 GHz 63 dB Typical (61 dB min)

Audio

Audio Sub-Carriers (2) Frequency (Programmable)

#1 4.83, 5.5, 5.8, 6.2, 6.8 MHz

#2 5.5, 5.8, 6.2, 6.8, 7.5 MHz

Audio Deviation ± 75kHz pk

Audio Pre-Emphasis 75 µS

Audio Distortion 1% max

Table 3 Digital (COFDM)

Feature Spec

Bandwidth 6, 7, 8 MHz Selectable

Constellation QPSK, 16 QAM, 64 QAM, Selectable

Guard 1/4, 1/8, 1/16, 1/32 Selectable

Code Rate 1/2, 2/3, 3/4, 5/6, 7/8 Selectable

Scrambler Proprietary 6 digit PIN code

MPEG – 2 4:2:0 SP@ML 1.5 – 15 Mb/s, 0.1 Mb/s Resolution

MPEG – 2 4:2:2 SP@ML 1.5 – 32 Mb/s, 0.1 Mb/s Resolution

GOP Structure I/IP/IBBP/422IBBP Variable

GOP Length 6/12/18/24 Selectable

Audio Sampling Rates 32, 64, 128, or 192 kb/s per Channel

Audio, Video, PCR PID User programmable

7

Table 4 TCII Input/Output

I/O Format

IF OUT (to ODU) 70 MHz IF Output with Control & Power

(selectable 50 or 75 ohms)

IF IN 70 MHz (0dBm, 75 Ω)

Aux. IF OUT 70 MHz (0dBm, 75 Ω, BNC-f)

ASI IN 75 Ω(HD Capable)

ASI OUT Encoder Output 75 Ω(BNC-f)

Digital Video IN SDI w/Embedded Audio

(SMPTE 259C CCIR 601)

Aux Inputs (4) General purpose inputs that control respective Form

‘C’ contact closures available at the ODU.

Summary Alarm Form ‘C’ Contact Closure (Rated 1A Max )

External Control 1

(Remote Control Of TCII)

Ethernet 10/100 bT

Digital (COFDM) Analog (FM)

Audio Inputs (2)

Impedance 600 ohm Bal

Level +0 dB nom

menu adj atten +4 to -9dB,

in 1dB steps

+9dBm

(Factory Set)

Composite Video Input

Level 1V p-p

Return loss 26dB min

Impedance 75 ohms unbal

YUV Video Input (Optional) Optional Not Available

RS232 (general purpose data channel to CRS-

DCII)

User selectable

1200, 4800, 9600 baud

Not operational

1Consult Factory For Protocols

8

This Page Intentionally Left Blank

9

UNPACKING

No special instruction is required for removing the items from the packaging other than to open the box

with care as to not damage any of the contents.

Parts List

Manuals

Item Part Number Quantity

TRUCK-CODER II INSTALLATION AND

OPERATION MANUAL

6051419100 1

Components

Item Part Number Quantity

Indoor Unit (IDU) 8014191000 1

Outdoor Unit (ODU) 8014192700 1

Installation Kit 7614191020 1

Cables

The versatile design of the TCII makes it suitable for many different applications. Depending on the needs

of the ENG, there is a great variety of cable configurations. The table below provides a list of all the cables

that the TCII can accommodate and along with the BMS part numbers. The specific cable set for any

application is defined when an order is placed. Please refer to the packing list and/or the original sale order

for the specific cables included with your TCII System.

Cable Recommended

Cable

P/N

Length End

Connector

P/N

70 MHz/ 48 VDC (to ODU) TIMES SF-214

(STANDARD)

100 ft ( 30.5 m) 210009800

70 MHz/ 48 VDC triax (to

ODU) Belden 8232 100 ft ( 30.5 m) 210071813

70 MHz IN 100 ft ( 30.5 m)

70 MHz OUT 100 ft ( 30.5 m)

SDI IN w/ AUDIO 100 ft ( 30.5 m)

ASI IN 100 ft ( 30.5 m)

ASI OUT 100 ft ( 30.5 m)

VIDEO IN 100 ft ( 30.5 m)

VIDEO OUT 100 ft ( 30.5 m)

Y,U, V input

600001300

100 ft ( 30.5 m)

210015200

AUDIO 1 IN 100 ft ( 30.5 m)

AUDIO 2 IN 600000100 100 ft ( 30.5 m) 210019300

RS-232 DCE 100 ft ( 30.5 m)

RS-232 CONTROL 100 ft ( 30.5 m)

RS-232 AUX DATA

Custom

100 ft ( 30.5 m)

210022000

10

This Page Intentionally Left Blank

11

INSTALLATION

NOTE:

The TCII equipment installation should only be performed by qualified technicians in compliance with

safety regulations and accepted industry practices.

Equipment Installation

The following equipment will need to be installed:

Indoor Unit (IDU)

Outdoor Unit (ODU)

Please refer to component footprint drawings listed in Table 5 to aid installation.

Table 5 Component Mounting Requirement Reference

Component Footprint

Indoor Unit (IDU) Figure 4

Outdoor Unit (ODU) Figure 5

12

This Page Intentionally Left Blank

Table of contents

Other BMS Transmitter manuals