BMS HELI-CODER 4 User manual

HELI-CODER™ 4 TRANSMITTER

Operation Manual

Doc. No. 6051452100 Rev.C1

Broadcast Microwave Services, Inc. | www.bms-inc.com

Corporate Headquarters

12367 Crosthwaite Circle | Poway, CA 92064 US

Phone: +1 800-669-9667 (US) | +1 (858) 391-3050 | Fax: +1 (858) 391-3049

BMS European Office

Schwalbacherstr. 12 | 65321 Heidenrod-Kemel GERMANY

Phone: +49-6124-7239-00 | Fax: +49-6124-7239-29

2012 Broadcast Microwave Services. All rights reserved.

This document and the information contained in it is the property of Broadcast Microwaves Services, Inc. and may be the subject

of patents pending and granted. It must not be used for commercial purposes nor copied, disclosed, reproduced, stored in a

retrieval system or transmitted in any form or by any means (electronic, mechanical, photocopying, recording or otherwise),

whether in whole or in part, without BMS prior written agreement.

This printed document is uncontrolled and is for reference only. Users are to verify that this is the latest approved version.

Heli-Coder 4 Transmitter Operation Manual | Doc. No. 6051452100 Rev. C

Broadcast Microwave Services, Inc. i

Document Revision History

DRAFT

November 2011

Preliminary Release

April 2012

Preliminary Update

May 2012

Initial Release

June 2012

Rev -

Add Additional Figures and Software Installation Section.

December 2012

Rev A

Amend DO-160 compliance table

July 2013

Rev B

Amend for references to encryption options

December 2013

Rev C

Amend FCC & Channel Bandwidth

June 2014

Rev C1

Conventions Used in This Manual

1.

NOTE: Notes provide supplementary information. They are highlighted for emphasis, as in this example, and

are placed immediately after the relevant text.

CAUTION: Cautions give information which, if strictly followed, will prevent damage to equipment or other

goods. They are boxed for emphasis, as in this example, and are placed immediately preceding the point at

which the reader requires them.

WARNING: Warnings give information which, if strictly observed, will prevent personal injury or death, or

damage to personal property or the environment. They are boxed and shaded for emphasis, as in this example,

and are placed immediately preceding the point at which the reader requires them.

2. ATTENTION!

DO NOT use right-angle connectors or adapters on the RF Power Out cable assemblies. Right-angle

connectors may have significant RF power loss at the operating frequencies of this system.

3.

FOR ALL BMS TRANSMITTERS –Operation of a BMS transmitter product generally requires a license. It is the

responsibility of the user to obtain all required operating licenses.

4.

ONLY FOR PRODUCTS AWAITING FCC CERTIFICATION –This device has not been authorized as required

by the rules of the US Federal Communications Commission. This device is not, and may not be, offered for

sale or lease, or sold or leased, in the US until authorization is obtained.

Acceptance Test Procedure (ATP) test data results by product serial number are typically shipped with all units

and indicate the equipment to be operating within advertised specifications. Contact BMS to request this data.

Read and Follow Instructions! All safety and operating instructions should be read before this product is

operated. All operating and use instructions should be followed. This manual should be retained for future

reference.

EMC Compliance –This equipment is certified to the EMC requirements detailed in the technical specifications.

To maintain this certification, only use the cables supplied or if in doubt contact BMS Customer Service.

Broadcast Microwave Services, Inc. ii

PAGE INTENTIONALLY LEFT BLANK

Broadcast Microwave Services, Inc. iii

Contents

1INTRODUCTION ..............................................................................................................................................1

2SAFETY............................................................................................................................................................2

3PRODUCT DEFINITION ...................................................................................................................................4

3.1 Product Specifications..............................................................................................................................2

3.2 Model Information.....................................................................................................................................2

4CONNECTORS AND PINOUTS.......................................................................................................................3

5INSTALLATION................................................................................................................................................7

5.1 Locating the Components.........................................................................................................................7

5.2Fasteners .................................................................................................................................................8

5.3 Mounting the Transmitter..........................................................................................................................8

5.4 Wiring Connections and Signal Interfaces..............................................................................................11

5.4.1 Power Input (J2) ................................................................................................................................................. 11

5.4.2 Radio Frequency Output (RF Out) (J5) .............................................................................................................. 11

5.4.3 Serial Digital Video Input (J12)............................................................................................................................ 11

5.4.4 Composite Video (CVBS) Input (J9).................................................................................................................... 11

5.4.5 ASI Input............................................................................................................................................................. 11

5.4.6 ASI Output.......................................................................................................................................................... 11

5.4.7 Audio Input ......................................................................................................................................................... 11

5.4.8 GPS.................................................................................................................................................................... 11

5.4.9 Data Wayside Input ............................................................................................................................................ 12

5.4.10 KLV Data ....................................................................................................................................................... 12

5.4.11 Auxiliary Data................................................................................................................................................. 12

5.4.12 Ethernet ......................................................................................................................................................... 12

5.4.13 USB ............................................................................................................................................................... 12

5.4.14 ARINC ........................................................................................................................................................... 12

5.4.15 Control ........................................................................................................................................................... 12

6TRANSMITTER OPERATION ........................................................................................................................13

6.1 Operating the Transmitter with the DLC50 Control Panel ......................................................................13

6.2 DLC50 Menu Structure...........................................................................................................................14

7BMS Geo-Point™ System.............................................................................................................................16

7.1 Geo-Point System Description ...............................................................................................................16

7.2 Enabling Geo-Point™.............................................................................................................................16

8SOFTWARE INSTALLATION ........................................................................................................................17

9ACCESSORIES..............................................................................................................................................18

10 ADDITIONAL REFERENCES ........................................................................................................................18

11 REGULATORY...............................................................................................................................................19

11.1 Electromagnetic Compliance..................................................................................................................19

11.2 FCC........................................................................................................................................................19

11.3 Environmental Qualifications ..................................................................................................................19

12 PREVENTIVE MAINTENANCE......................................................................................................................20

12.1 Maintenance Schedule...........................................................................................................................20

12.2 Maintenance Procedures........................................................................................................................20

12.3 Spare Parts ............................................................................................................................................20

13 REPAIR SERVICE AND WARRANTY ...........................................................................................................20

13.1 Customer Service...................................................................................................................................21

14 GLOSSARY....................................................................................................................................................22

15 CONNECTION AND WIRING DIAGRAMS ....................................................................................................24

Broadcast Microwave Services, Inc. iv

List of Figures

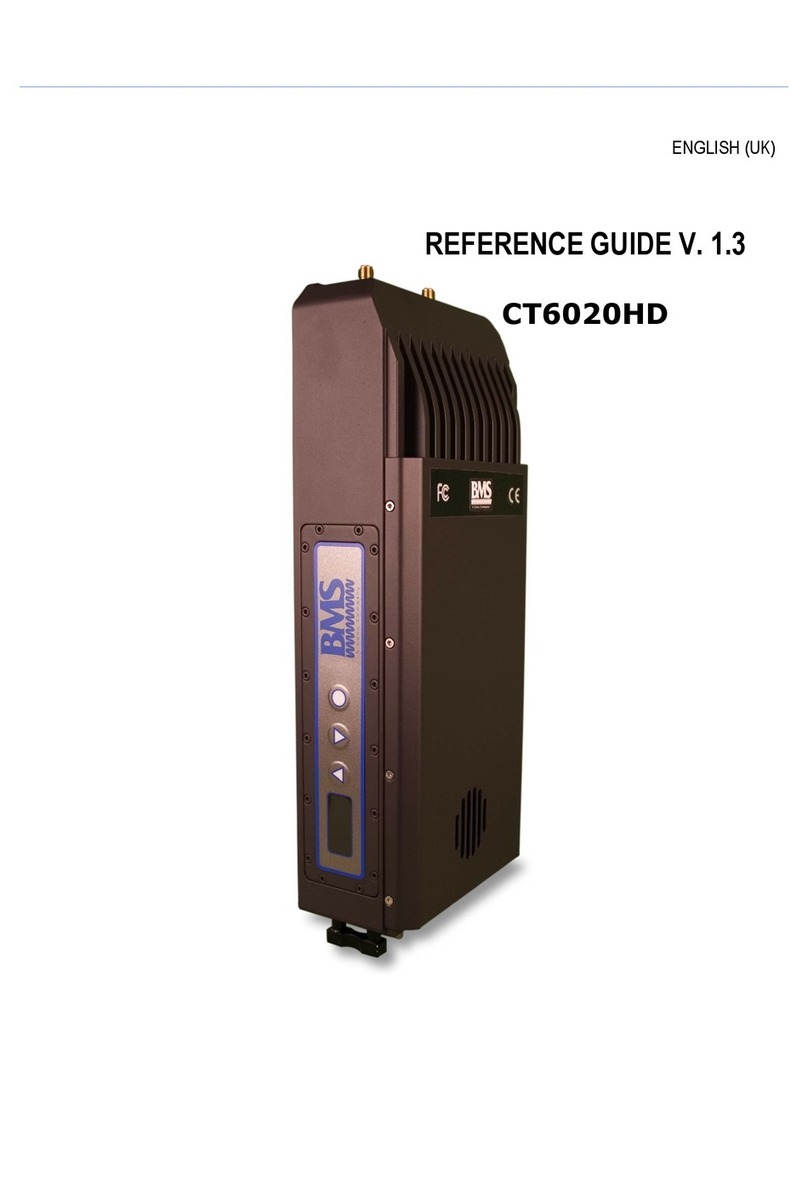

Figure 1. Heli-Coder 4 Transmitter ............................................................................................................................4

Figure 2 HC4 Front Panel Labels ..............................................................................................................................3

Figure 3 Transmitter mounting bracket .....................................................................................................................8

Figure 4 HC4 positioned in aircraft mounting bracket ................................................................................................8

Figure 5 HC4 Outline Drawing ...................................................................................................................................9

Figure 6 CT-A-MP HC4 Mounting Plate - Dimensioned Drawing............................................................................10

Figure 7 DLC50-A AVIONICS CONTROL PANEL (FRONT) ...................................................................................13

Figure 8 DLC50-A AVIONICS CONTROL PANEL (BACK)......................................................................................13

Figure 9 DLC50 Commands ....................................................................................................................................14

Figure 10 DLC50 Outline .........................................................................................................................................15

Figure 11 Product Label...........................................................................................................................................21

Figure 12 Typical airborne installation diagram (without TAA-101 Antenna Actuator) .............................................25

Figure 13 Wire Hook-Up Diagram for HC4 System (without TAA-101 Antenna Actuator) .......................................26

Figure 14 Typical airborne installation diagram (including TAA-101 Antenna Actuator) ..........................................27

Figure 15 Wire Hook-Up Diagram for HC4 System (including TAA-101 Antenna Actuator) ....................................28

List of Tables

Table 1 MPE per FCC OET65 (1.5 GHz to 100 GHz)................................................................................................3

Table 2. Product connector descriptions in Figure 1..................................................................................................4

Table 3. HC4 connectors ...........................................................................................................................................3

Table 4. Connector pin outs.......................................................................................................................................4

Table 5. HC4 Component Placement Planning .........................................................................................................7

Heli-Coder 4 Transmitter Operation Manual | Doc. No. 6051452100 Rev. C

Broadcast Microwave Services, Inc. 1

1 INTRODUCTION

This document provides instructions for installation, operation and maintenance of the Heli-Coder 4 (HC4) COFDM

Transmitter controlled by a DLC50 Downlink Control Panel.

BMS offers a wide selection of airborne products to meet the video and data requirements of today’s real world

applications. The Heli-Coder™ 4 (HC4) together with the DLC50 controller provides a simple, powerful solution

containing everything needed for high-quality, reliable transmission. This includes the video encoder, modulator,

up-converter and high-power amplifier and an intuitive powerful control interface (see Figure 1.).

Standard COFDM modulation offers excellent performance in urban and non-line of sight environments with

significant multipath. The HC4 also provides an integrated GPS data interface that reduces the components

needed to integrate location data into tracking systems. The HC4 provides everything required to achieve 10 W

output power in an ultra-compact case. The DLC50 control panel allows the HC4 unit to be mounted remotely

within the avionics bay while providing full control from the flight deck.

With the flexibility of MPEG-2 and H.264 compression, the HC4 efficiently handles SD or HD video and can be

configured to deliver high speed data as an ethernet radio. The HC4 is also Geo-Point™ capable. Geo-Point™

uses metadata supplied by the equipment serving as the video source and allows the display of bearing and

distance to the location shown on the screen in real time. (Geo-Point™ requires a compatible receiver.)

NOTE: The standard version of the HC 4 is configured to be controlled by a DLC50 Control Panel. Custom

configurations and control schemes may be supported. Contact BMS regarding your operational requirements and

the range of solutions BMS offers.

Broadcast Microwave Services (BMS) is a leader in wireless digital microwave technology providing innovative

products for the television broadcast, video, telemetry and surveillance industries. A wholly owned subsidiary of

Cohu, Inc., BMS designs and manufactures a comprehensive line of microwave communications equipment for

broadcasting sports venues, law enforcement and military applications. BMS also builds and integrates the

command and control centers to provide fully functioning, complex, end to end digital systems.

For the latest product and system information please visit www.bms-inc.com.

Broadcast Microwave Services, Inc.

12367 Crosthwaite Circle

Poway, CA 92064

Tel: +1 (858) 391-3050

Toll free (US): 800-669-9667

Fax: +1 (858) 391-3049

Email:[email protected]

www.bms-inc.com

Heli-Coder 4 Transmitter Operation Manual | Doc. No. 6051452100 Rev. C

Broadcast Microwave Services, Inc. 2

2 SAFETY

WARNING- RF Hazard: Non-Ionizing RF Emission

Operators of this equipment should be familiar with basic RF equipment operation and safety concepts. Users

must consider many unique factors to maintain RF safety. We offer the following guidelines with the

recommendation that each individual and organization establish an RF Safety and Awareness program based on

their combination of hardware and usage environment.

Radiation Exposure

The frequencies present in BMS equipment produce non-Ionizing radiation. The FCC reference document

regarding RF exposure limits is OET Bulletin 65 and can be viewed by visiting the FCC web site (www.fcc.gov ) or

by clicking here;

http://www.fcc.gov/Bureaus/Engineering_Technology/Documents/bulletins/oet65/oet65.pdf

(Link valid as of 6/25/2012)

We also reference EU Standard EN 50392 (02-2004). BMS references these standards as reasonable guidelines.

The OET 65 document sets maximum permitted exposure (MPE) and is widely cited within the U. S. and Canada.

Exposure is divided into two categories, “controlled” and “uncontrolled” environment. The uncontrolled

environment is the harshest criteria and applies to exposure where you may not be aware and/or cannot control

the exposure. Examples are where a residence is located near a cell site or other radio tower. You live there,

cannot remove yourself from the field and cannot control the RF. Exposure is long term and not in your control.

The “controlled environment” applies to most professional radio users. It is assumed they are trained in RF Safety,

they are aware there is an RF field, exposure is limited by transmission duty cycles, the flight or testing ends, hang

up the cell phone, put up the walkie-talkie, etc.

BMS recommends that operators use the uncontrolled exposure category from OET 65 as it applies to an

uncontrolled environment; a maximum power density limit of 1mW/cm².

The limit table from Bulletin 65 is reproduced below. X axis is frequency and y axis is mW/cm².

Heli-Coder 4 Transmitter Operation Manual | Doc. No. 6051452100 Rev. C

Broadcast Microwave Services, Inc. 3

Use the formula from OET65 to determine the minimum recommended distance according to your individual usage

circumstances.

Your organization should develop an understanding of its unique RF usage and create a plan to train personnel

regarding recommended exposure limits according to the FCC and EU recommendations.

General Safety Rules;

a) Do not operate the transmitter or power amplifier with covers removed.

b) Never walk in front of directional antennas when radiating.

c) Switch off supplies before removing covers or disconnecting any RF cables, and before inspecting damaged

cables or antennas.

d) BMS recommends returning the HC4 to the factory for service or repair.

In addition you can limit your exposure by raising awareness and using some common sense rules.

Default to low power if available using hi-power only as required.

Never stand in front of a transmitting directional antenna.

Limit transmission duty cycles (turn on/off as needed).

Table 1 MPE per FCC OET65 (1.5 GHz to 100 GHz)

TRANSMITTER OUTPUT (w)

10

ANTENNA GAIN dBi

0

2

4

6

9

11

14

22

UNCONTROLLED ENVIRONMENT:

MINIMUM PERMISSABLE

DISTANCE INCHES

1.005 mW/cm2

11.08

13.95

17.56

22.10

31.22

39.31

55.52

139.47

CONTROLLED ENVIRONMENT:

MINIMUM PERMISSABLE

DISTANCE INCHES

(5.005 mW/cm2)

4.96

6.25

7.87

9.91

13.99

17.61

24.88

62.50

NOTE: Calculations do not factor reflections

Heli-Coder 4 Transmitter Operation Manual | Doc. No. 6051452100 Rev. C

Broadcast Microwave Services, Inc. 4

3 PRODUCT DEFINITION

Figure 1. Heli-Coder 4 Transmitter

Table 2. Product connector descriptions in Figure 1

1

GPS Antenna Input

2

28VDC Power

3

Ethernet port

4

Communications Port Connector –RS-232

5

RF Output (N-type)

6

Audio Input

7

Control cable Input (from DLC50 Control Panel)

8

ARINC Connector (Reserved for future use)

9

Analog Video Input (CVBS composite video)

10

ASI (Asynchronous Serial Interface) video out

11

ASI (Asynchronous Serial Interface) video in

12

HD/SDI (Digital –uncompressed) video in

13

USB 2.0 port

14

Mounting bracket (x2)

15

Ethernet Status Indicators: Yellow SPEED LED:

ON=100BaseT, OFF=10BaseT Green LINK LED:

Flashing=Valid Ethernet Link, Off=NO Valid

Ethernet Link

16

Power LED: YELLOW when power cable

plugged in; GREEN when unit turned on via

DLC50 Control Panel

Alarm LED: YELLOW indicates a transmit

problem

TxEn LED (Transmit Enabled): YELLOW means

Standby mode; GREEN means transmitter active

9

10

11

12

5

2

3

1

4

6

7

8

13

14

16

15

14

Heli-Coder 4 Transmitter Operation Manual | Doc. No. 6051452100 Rev. C

Broadcast Microwave Services, Inc. 2

3.1 Product Specifications

Frequency

6425-6525 MHz

Channel Bandwidth

6/7/8 MHz

RF Output Power

5W/10 W switchable

Modulation

COFDM 2k

QPSK, 16/64 QAM

FEC 1/2, 2/3, 3/4, 5/6, 7/8

Guard 1/4, 1/8, 1/16, 1/32

Other modulation available; consult factory

Video Encoding

H.264 (MPEG2 option)

Audio Encoding

MPEG 1, Layer II

Channels

Two audios, multiple wayside data channels up to 115kbit/s

Internal Test Generator

Video/Audio Test pattern

Local Control

External Control Panel*

Power Input

24 to 32 VDC (3 A @ 28 VDC)

Consumption

85 W @ RF-Output 10 W

Compliance

CE marked in accordance with EU Low Voltage and EMC Directives

EMC Compliance: EN55022, EN55024

Operating Temp.

-15 to +55° C (5 to +131° F)

Storage Temp.

-55 to +85° C (-67 to +185° F)

Dimensions

5“ W x 9“ D x 6“ H; 270 in.2(127 x 229 x 153) mm

Weight

6 lbs. (2.73 kg)

FCC

This device has not been authorized as required by the rules of the Federal

Communications Commission. This device is not, and may not be, offered for

sale or lease, or sold or leased, until authorization is obtained.

FCC (Part 74) product certification pending.

Regulatory

(See section 10)

FCC Parts 74, 90, 101

RTCA DO-160, designed to be compliant

CE Mark

3.2 Model Information

PART NO.

MODEL

PROFILE

HC4-(xx)-H

H.264, SD/HD

SD=MP@L4 | HD=MP@L4; HP@L4

HC4-(xx)-M

MPEG2, SD/HD

SD=SP@ML; 422@ML | HD=SP@HL

HC4-(xx)-MH

MPEG2/H.264, SD/HD

MPEG2: SD=SP@ML; 422@ML | HD=SP@HL

H.264: SD=SP@L4; HI422@L4 | HD=SP@L4

* where (xx) is center frequency in MHz

Heli-Coder 4 Transmitter Operation Manual | Doc. No. 6051452100 Rev. C

Broadcast Microwave Services, Inc. 3

4 CONNECTORS AND PINOUTS

Figure 2 HC4 Front Panel Labels

Table 3. HC4 connectors

J1

GPS In (with optional DC Bias Out)

TNC(f), 50 ohm

J2

Power In

Souriau 3-pin male 851-02R12-3P50

J3

Ethernet

M12-4 Socket (early model used RJ45)

J4

COMM

RS232 External GPS

RS232 External AAAP

RS232 KLV or Camera Metadata

Tri-Start, Size 11, 13 Socket

J5

RF Out

N(f), 50 ohm

J6

Analog Audio In (2 channels)

D38999-26WC, 35 pin

J7

Control Panel

Souriau (male) 10-pin

J8

ARINC 429 (reserved for future use)

D38999-26 WA355N socket

J9

CVBS In (NTSC, PAL)

BNC(f), 75 ohm

J10

ASI Out

BNC(f), 75 ohm

J11

ASI In

BNC(f), 75 ohm

J12

SDI, HD-SDI In

BNC(f), 75 ohm

J13

USB 2.0

Type A (Host)

Heli-Coder 4 Transmitter Operation Manual | Doc. No. 6051452100 Rev. C

Broadcast Microwave Services, Inc. 4

Table 4. Connector pin outs

GPS J1

610006040, TNC(f), 50 ohm

GPS ANTENNA INPUT

TNC CONN (FEMALE)

50 OHM

HC4

Provides variable DC

bias or none.

SIGNAL

SHIELDING GND

Power Input J2

3-pin SOURIAU (m)

HC 4

A

28VDC

B

GND

C

N/C

ETHERNET J3

M12-4, 4 pin socket

USB 2.0 SERIAL DATA

HC4

SOCKET 1

TD+

SOCKET 2

RD+

SOCKET 3

TD-

SOCKET 4

RD-

SHIELDING

GROUND

COM J4

210069751, Connector Tri-start, Size 11, 13 Socket,

PCB Tail

COM

HC4

1

GND

2

AERO RS232 TX

3

AERO RS232 RX

4

GND

5

TGT DATA RS232 TX, (KLV

Data Tx)

6

TGT DATA RS232 RX (KLV

Data Rx)

7-13

DO NOT USE

Heli-Coder 4 Transmitter Operation Manual | Doc. No. 6051452100 Rev. C

Broadcast Microwave Services, Inc. 5

RF OUTPUTJ5

RF OUTPUT N-

CONN(FEMALE)

50 OHM

HC4

UP TO 10W RF

OUT COFDM

SIGNAL

SHIELDING GND

Audio J6

210069752, Connector Tristart size 13, 22Pin PC-tails

AUDIO

HC4

1

AUDIO 1 L GND

2

AUDIO 1 L+

3

AUDIO 1 L-

4

AUDIO 1 R GND

5

AUDIO 1 R+

6

AUDIO 1 R-

7-12

N.C.

13-22

DO NOT USE

CONTROL J7

210004408, Connector Size 12, 10 Pins, PCB Tails

CONTROL

PANEL

HC4

A

LOOP_OUT (RAW 28V OUT)

B

LOOP_IN (28V FROM DLC50)

C

NC

D

Remote control Rx

E

GND

F

Remote control TX

G

GND

H

NC

J

NC

K

NC

ARINC J8

210069750,Connector, Tri_Start, Size 9, 6 Socket,

PCB tail

ARINC

HC4

1

AOUT (ARINC 429 bus Tx)

2

BOUT (ARINC 429 bus Tx)

3

RIN A (ARINC 429 bus Rx)

4

RIN B (ARINC 429 bus Rx)

5

GND

6

GPS DATA Rs232RX

Heli-Coder 4 Transmitter Operation Manual | Doc. No. 6051452100 Rev. C

Broadcast Microwave Services, Inc. 6

CVBS INPUT J9

BNC(f), 75 ohm

COMPOSITE VIDEO INPUT

BNC CONN(FEMALE) 75 OHM

HC4

May be NTSC or PAL

SIGNAL

SHIELDING

GROUND

ASI OUTPUT J10

BNC(f), 75 ohm

ASI SERIAL DATA OUTPUT

BNC CONN(FEMALE) 75 OHM

HC4

DVB-ASI SIGNAL

SIGNAL

SHIELDING

GROUND

ASI INPUT J11

BNC(f), 75 ohm

ASI SERIAL DATA INPUT BNC

CONN(FEMALE) 75 OHM

HC4

DVB-ASI SIGNAL

SIGNAL

SHIELDING

GROUND

SDI INPUT J12

BNC(f), 75 ohm

HD OR SD SDI INPUT BNC

CONN(FEMALE) 75 OHM

HC4

SERIAL DIGITAL VIDEO

SIGNAL

SIGNAL

SHIELDING

GROUND

USB 2.0 J13

USB Type A socket

USB 2.0 SERIAL DATA

HC4

SOCKET 1

+5 VDC

SOCKET 2

Data -

SOCKET 3

Data +

SOCKET 4

Ground

SHIELDING

GROUND

Heli-Coder 4 Transmitter Operation Manual | Doc. No. 6051452100 Rev. C

Broadcast Microwave Services, Inc. 7

5 INSTALLATION

Installation should only be performed by an FAA Certified A/P or Avionics Technician.

The HC4 and associated equipment should be installed in compliance with FAA regulations and accepted industry

practices.

Other than allowing adequate air circulation above and below the transmitter, there are no set standards for

placement of the HC4 equipment. The information in Table 5 is a guide for choosing the best placement for each

component. Every aircraft installation is different, with unique interior space requirements to meet the needs of the

pilot, operator and passengers. It is left to the customer to review the size, space, cable and ergonomic needs to

best determine where the components should be installed.

The HC4 may be ordered with the HC4-CONN-KIT which contains all mating connectors except those

locally available (BNC, N, and USB). Alternatively BMS will supply a partially assembled wiring harness upon

order request.

Consult BMS regarding custom cable requirements

5.1 Locating the Components

Table 5. HC4 Component Placement Planning

Component

Space Requirement

Wt

Suggested

Location

Connecting

Component

DLC50 Primary

Airborne Control

Panel

4.9 in. x 5.75 in. x 1.5 in.

12.4 cm x 14.6 cm x 3.8 cm

<1 lb

<.45 kg

Cabin, near

operator

HC4

2 AMP BREAKER

(IF SUPPLIED) TAA-

101

HC4 TRANSMITTER

(with CT-A-MP

mounting tray)

5“ W x 9“ D x 6“ H

(127 x 229 x 153 mm)

6 lb

2.72 kg

Usually baggage

compartment but

varies. Allow

ventilation space

above and below

transmitter

DLC50

Video-in

Audio-in

10 AMP BREAKER

GA-35

MAIN ANTENNA

RS-232 DATA IN

KLV DATA IN

GA-35 GPS Antenna

Unobstructed View

5 in. x 3 in. footprint

12.7 cm x 7. 6cm

.25 lb

0.11 kg

Top Exterior

Tail (Varies)

HC4

Bulkhead Feed-Thru

Customer Furnished

Varies

Exterior Location

(Varies)

RF Antenna

Heli-Coder 4 Transmitter Operation Manual | Doc. No. 6051452100 Rev. C

Broadcast Microwave Services, Inc. 8

5.2 Fasteners

Installation of the HC4 is unique to every aircraft. It is left to the installer to provide the properly certified fasteners

for the application.

5.3 Mounting the Transmitter

The HC4 transmitter should be mounted in aircraft or other craft using the BMS-supplied mounting bracket (BMS

P/N 4414414000). The transmitter/bracket assembly must have adequate space above and below the unit to

allow free air flow. Three thermostatically controlled fans contained within the HC4 chassis keep the unit at

operating temperature.

1. Place the transmitter so that the two holes on its rear side fit the pins on the mounting bracket.

2. Tighten the mounting screw fasteners. Ensure the round nut captures the mounting bracket on the transmitter.

Figure 3 Transmitter mounting bracket

Figure 4 HC4 positioned in aircraft mounting bracket

Heli-Coder 4 Transmitter Operation Manual | Doc. No. 6051452100 Rev. C

Broadcast Microwave Services, Inc. 9

Figure 5 HC4 Outline Drawing

Heli-Coder 4 Transmitter Operation Manual | Doc. No. 6051452100 Rev. C

Broadcast Microwave Services, Inc. 10

Figure 6 CT-A-MP HC4 Mounting Plate - Dimensioned Drawing

9.09"

(23.1 cm)

3.94"

(10.0 cm)

M6 Threaded

Hole (4 plcs)

1.85"

(4.71 cm)

1.79"

(4.55 cm)

11.18"

(28.4 cm)

5.12"

(13 cm)

0.98" (2.5 cm)

Heli-Coder 4 Transmitter Operation Manual | Doc. No. 6051452100 Rev. C

Broadcast Microwave Services, Inc. 11

5.4 Wiring Connections and Signal Interfaces

Reference Figure 12 Typical airborne installation diagram (without TAA-101 Antenna Actuator)”and Figure 13 Wire

Hook-Up Diagram for HC4 System”shown later in this document. Also reference section 16 of this manual titled

“CONNECTION AND WIRING DIAGRAMS”during installation for detail related to a typical installation.

Contact BMS regarding issues related to custom or modified installations if applicable. Additional service or fees may

apply.

5.4.1 Power Input (J2)

J2 connects aircraft 28VDC from an available 5 AMP breaker. Use AWG 20 gauge wire or larger.

5.4.2 Radio Frequency Output (RF Out) (J5)

J5 conducts the radio frequency energy out to a transmit antenna. Achieving optimum link performance

includes assuring a maximum RF energy is delivered to the antenna assembly via properly mated connector

assemblies and well installed cables. RF cable should be 50Ωfoam dielectric coaxial cable. Belden type FSJ-50A or

equal is recommended. Cable lengths should be as short as practical in the installation to reduce RF loss. Observe

the cable manufacturer’s minimum “bend radius” recommendation during installation. Kinks, pinches, or sharp bends

in high frequency cable will cause significant power losses. Check all connections for proper termination and use

high-quality type N connectors. Hand-tighten connectors; do not use a wrench or pliers as over-tightening will damage

a connector and reduce the system performance by introducing RF loss in the transmission line. Seal mated exterior

connections with self-vulcanizing rubber tape in order to avoid moisture in the connection joint which may also

introduce RF loss or physically damage the connector over time.

It is good practice to avoid the use of 90° elbow adaptors within the RF coax cable run.

5.4.3 Serial Digital Video Input (J12)

J12 is a standard 75ΩBNC jack that is for a Serial Digital Interface. This is the digital video signal that comes out of

most modern video cameras. The signal may be standard definition SDI (SMPTE-270) or high definition HD-SDI

(SMPTE-292). A high quality, double shielded coaxial video cable should be used such as Belden 8281 or equal.

Take care to terminate the cable with a 75ΩBNC plug.

5.4.4 Composite Video (CVBS) Input (J9)

J9 accepts a standard definition composite video signal (PAL or NTSC). Follow the same cabling instructions as in

5.4.3.

5.4.5 ASI Input

J11 accepts an asynchronous serial input (ASI) also known as DVB-ASI (digital video broadcasting). The signal

consists of a compressed MPEG transport stream. The input by-passes the internal encoder built into the HC4 and

goes right into the modulator. This allows use of external video or data encoders whose outputs are an ASI transport

stream. The input must conform to the ISO/IEC 13818-1 standard.Follow the same cabling instructions described

in section 5.4.3.

5.4.6 ASI Output

J10 ports out an ASI transport stream consisting of the encoded video currently being transmitted by the HC4. This

output allows external monitoring of the compressed signal and the use of a backup transmitter or other configurations.

Follow the same cabling instructions described in section 5.4.3.

5.4.7 Audio Input

J6 is a multi-pin connector where pins 1-6 are dedicated to two balanced audio channels, each 600Ωimpedance. Use

a high quality shielded twisted pair audio cable.

5.4.8 GPS

J1 is an input connector for an external GPS antenna. The recommended antenna is a Garmin GA 35 but other

antennas will work. The output connector is a TNC(f) and should be cabled with a good quality 50Ωcoax. Follow the

antenna manufacturer’s instructions for cable/ connector type and cable length.

Table of contents

Other BMS Transmitter manuals