BMT 932 User manual

BMT MESSTECHNIK GMBH

BMT MESSTECHNIK GMBH, Berlin, Germany. Tel. +49 - 3329 - 696 77 - 0, fax +49 - 3329 - 696 77 - 29

OSTI Inc., Monterey, California, USA Tel. +1 - 831 - 649 11 41, fax +1 - 831 - 649 11 51

OZONE MONITOR BMT 932

Manual

Rev. 02/21

OZON E MON I TOR BMT 932

BMT ME

S

S

TEC

HNIK, BE

R

LIN

OSTI , MONTE

RE

Y

Auto Channel 3:

0.123 ppm

BMT ME

SS

TEC

HNIK, BERLIN

O S

TI, MON TER

EY

OZONE MONITOR BMT 932 Manual, Rev. 02/2021

2

OZONE ANALYZER BMT 932

Contents

1 General Description 4

2 Features, Options 5

3 Accessories, Spare Parts 6

4 Cautions and Warnings 6

5 Ozone Photometry 7

6 Units of Measure: ppmv, µg/m3 (1 atm/different temperatures) 8

7 The OZONE MONITOR BMT 932 8

8 Scrubber 10

9 Mechanical Installation 10

10 Pneumatic Installation 13

10.1 Sample Gas Filters 13

10.2 Tubing 14

10.3 Moist Sample Gas 14

11 Electrical Installation 15

11.1 Power Connections 15

11.2 Output and Control Terminals 15

11.3 Channel Identification 16

11.4 Emergency-Off Relays 17

11.5 Serial Interface 18

12 Switching On the Instrument 18

13 Front Panel Operation 19

Changing Parameters 21

The Menu View Parameters 21

The Menu Set Parameters 23

Unit Ozone 25

Alarms 25

High-Alarms 25

Low-Alarms 26

Set EMOs 27

Input/Output 27

Simulate Analog Out 27

RS-232 27

Test Scrubber 27

Time/Date 28

Time 28

Date Format 28

Date 28

Other Parameters 28

Set Active Channels 28

Set Sniffer On / Off 28

OZONE MONITOR BMT 932 Manual, Rev. 02/2021

3

Alarm Beep 29

Reset Parameters 29

14 The Serial Interface 29

User-Mode 30

Link-Mode 31

15 Use of the Limit-Alarms 31

16 Error Handling 32

Lamp Low Warning 32

Lamp Low Error 33

Lamp Off Error 33

Lamp High Error 33

Lamp High Warning 33

Scrubber Error 34

Overpressure 34

Overrange 35

EEPROMError 35

Low Flow Error 35

17 Event- and Error-Log 35

18 The Software BMT 932 Link 36

19 Accessories and Spare Parts 38

20 Trouble Shooting 39

19.1 Negative Ozone Concentration Values 39

21 Maintenance 40

20.1 Replacement of UV Lamp and Scrubber 40

20.2 Optical System: Disassembling, Cleaning 41

22 Specifications 42

Appendix A: Link-Mode Commands 43

Appendix C: Cabinet Version BMT 932 C 48

C1 General Description 48

C2 Pneumatic Installation 49

C3 Electric Connections 49

C4 Operation 50

Appendix R: Relay Box (Option) 51

Appendix U: UBA Certificate 52

This manual describes the standard version of the analyzer.

For the Cabinet version BMT 932 C, please refer to the appendix at the end of this manual. It

describes the associated differences.

OZONE MONITOR BMT 932 Manual, Rev. 02/2021

4

1 General Description

The OZONE MONITOR BMT 932 is a state-of-the-art UV photometer for measuring and

monitoring ozone content of the ambient air. The ozone content is displayed in ppmv or µg/m³

(at 1 atm and 20°C), a dimension requiring temperature and pressure compensation. This is the

reason why the OZONE MONITOR BMT 932 is temperature and pressure compensated, of

course.

The instrument may be ordered with 1, 3, or 6 sample channels. Switching from channel to

channel is automatic, or manual via a push button.

The BMT 932 is designed to allow direct handling of three independent EMO circuits (Emergen-

cy Machine Off) with multi-channel monitors to facilitate the direct control of ozone generators

in workplace safety applications.

Since the application of the BMT 932 mainly is TLV (Threshold Limit Value) monitoring, con-

tinuous and safe operation of the instrument is the predominant requirement. This is the reason

why the BMT 932 has two scrubbers (the scrubber is one of the most important elements of an

ambient ozone monitor). And it has a built-in ozone generator for intermittent automatic testing

the function of the utility scrubber. When this scrubber fails in completely removing the ozone

from the sample ozonated by the ozone generator, the instrument automatically switches from

the utility scrubber to the reserve scrubber, and at the same time activates the Scrubber Alarm

indicating a scrubber failure.

The ozone concentration is displayed on a two-line 40-character alphanumeric display. The con-

centration unit can be changed during operation. Additional modifiable parameters are among

others :

Alarm parameters (two alarm thresholds for each channel, alarm latching, audible, opening

or closing relays, EMO circuit to alarm assigment)

Date and time

RS-232 interface parameters

These parameters can be set with the three pushbuttons on the front panel as well as by connect-

ing the serial interface to a Windows-PC running the software BMT 932 Link, which is supplied

with each instrument. Another way of configuring the instrument is to use the so-called Link

Mode via the serial interface.

Active sample channels for automatic sampling can be chosen as desired. It is also possible to

choose only one channel for measurement. Switching from automatic to single channel sampling

is easily done by just pressing the ENTER key.

The sample gas flow rate is maintained constant by a pump which is automatically controlled by a

built-in electronic flow meter. In case the pump fails and the flow rate drops, the warning signal

LOW FLOW is activated indicating a pump failure.

The highly stable UV radiation source has a life expectancy of well over 5 years. Via an automatic

control loop the radiation output of the UV lamp is precisely maintained constant during its ser-

vice life. When the lamp's performance drops significantly, the early warning signal LAMP LOW

is activated indicating that the lamp should be replaced by a new one during the next few weeks.

OZONE MONITOR BMT 932 Manual, Rev. 02/2021

5

Any failure including the warning states mentioned above, and any electric failure will activate the

ERROR/WARMUP warning signal; even power down is signalled by the error relay coupled

with the failure warning.

The OZONE MONITOR BMT 932 features a "Sniffer Mode" which suppresses the zero cycle.

This mode which can be used for easy ozone leak detection.

The instrument has a built-in clock with calendar, which is used to provide time stamps for an

Event-Log (103 entries, e.g. power on/off, alarms) and an Error-Log (16 entries, e.g. Overrange,

Low Flow). These logs can be read out and printed via the serial interface with the mentioned

software BMT 932 Link. A "Relay Box" built into the OZONE MONITOR BMT 932 is availa-

ble to offer electric contacts for each threshold, low and high, of each sample channel, see Ap-

pendix R.

2 Features, Options

UV photometer with temperature and pressure compensation

ranges available: 1.0, 2.0, 5.0, 10.0, 20.0, 50.0, 100.0, 250.0 ppmv

unit µg/m³ selectable

resolution: 0.001 ppmv (2 line x 20 character display)

19'' rack mount, 132 x 300 mm (H x D), 9 kg

or wall mount cabinet NEMA 4X, 357 x 440 x 133 mm (W x H x D), 7 kg

traceable to international standard (NIST)

CE mark, cTUVus NRTL-listed

1, 3, or 6 sample channels

two threshold alarm levels (relay contacts)

three EMO circuits with 6 relays

cycle time 20 s per channel

sniffer mode

two scrubbers (utility + reserve)

ozone generator for automatically testing the utility scrubber every 24 hours

reserve scrubber: automatically replaces the utility scrubber when it is faulty

safety catalyst for the off gas

sample gas flow 1 l/min, auto controlled via an electric flow meter

full internal diagnostics with event and error log

pre-filters + fittings included (one filter holders per channel + 200 inserts)

analog outputs, isolated: 4-20 mA, 0-1 V, 0-10 V

isolated RS 232 serial interface, Windows software included

firmware update by user with PC and serial cable

ambient temperature 0 – 45°C (non-condensing)

universal line voltage (100 - 240 VAC, 60/50 Hz/35 VA)

optional: 18-36 VDC, 25 W

"Relay Box" (optional)

also available as wall-mount cabinet

OZONE MONITOR BMT 932 Manual, Rev. 02/2021

6

3 Accessories, Spare Parts

The OZONE MONITOR BMT 932 comes with all the accessories needed for its operation.

A Spare Parts Kit "932-SPARE" is available as an option, see page 38.

4 Cautions and Warnings

The exclamation point within an equilateral triangle is intended to alert the

user to the presence of important operating and maintenance (servicing) in-

structions in the literature accompanying the instrument.

The lightning flash with arrowhead symbol, within an equilateral triangle is

intended to alert the user to the presence of uninsulated “dangerous voltage”

within the product’s enclosure that may be of sufficient magnitude to consti-

tute a risk of electric shock to persons.

Ozone may be dangerous and harmful, even at a low concentration. The 8-hour exposure to

ozone should not be to a higher ozone content than in the order of 0.1 ppmv.

Ozone in the sample gas is automatically destroyed after passage through the OZONE

MONITOR BMT 932. Caution: Since the sampling tube could contain ozone in a dangerous

concentration, be careful to not open the sample gas lines leading to the instrument whilst the

ozone producing system is on.

When the instrument is opened without disconnecting it from line power, two dangers are pre-

sent: UV radiation from the UV lamp, and high voltage from the power line and from the inter-

nal high voltage power supply of the UV lamp.

Warning: Always disconnect the instrument from line power before opening it!

Warning: UV radiation can cause eye damage. Do not look into the UV lamp without proper eye

protection.

Warning: This product relies on the building's installation for short-circuit (overcurrent) protec-

tion. Ensure that a fuse or circuit breaker no larger than 15 A at 120 VAC (10 A at 240 VAC) is

used on the phase conductor.

Warning: If the mains cable is replaced, the new cable shall have a current rating of at least 10 A.

This product has been tested to the requirements of CAN/CSA-C22.2 No. 61010-1,

second edition, including Amendment 1, or a later version of the same standard incor-

porating the same level of testing requirements

Précaution:

L'ozone peut être dangereux pour la santé, même à faible concentration. La concentration sur votre

lieu de travail ne devrait pas dépasser 0,1 ppmv pendant 8 heures. L'ozone est intégralement détruit après avoir

passé le BMT 932. Mais comme les conduites de gaz à mesurer peuvent le contenir à forte concentration, il faut

veiller à ne pas ouvrir les conduites de gaz à mesurer qui mènent à l'appareil pendant que le générateur d'ozone est

en fonction dans le système.

Si l'appareil est ouvert pendant qu'il est en marche, deux dangers doivent être pris en compte: le rayonnement ultra-

violet de la lampe à ultra-violet, la tension du secteur et la haute tension sur le module à haute tension de la lampe.

Attention: Avant d'ouvrir l'appareil débrancher le secteur.

OZONE MONITOR BMT 932 Manual, Rev. 02/2021

7

Les rayons ultra-violets peuvent endommger la vue. ne jamais regarder la lampe sans protection adéquate.

Attention

: Ce produit se sert de l’équipement de protection de votre installation électrique concernant les sur-

charges et les courts-circuits. Vous devez vous assurer que l'intensité de la fusible ou du disjoncteur protégeant le

conducteur de phase ne dépasse pas 15 A à 120 VAC (10 A à 240 VAC).

Att.:

Si le câble d'alimentation est remplacé, le nouveau câble doit avoir un courant nominal de 10A ou plus.

5 Ozone Photometry

UV radiation with wavelengths below 300 nm is dramatically decreased by the passage through

ozone gas. This is one reason for the existence of life on earth. UV radiation coming from the

sun converts oxygen into ozone in the higher regions of our atmosphere, and hence provides

protection of our planet from exactly this UV radiation.

Between 200 and 300 nm wavelength (Hartley band) ozone has one of its strongest absorption

bands. The maximum absorption in this band occurs at about 254 nm. It happens that the

strongest mercury line (the wavelength of the highest radiation intensity produced by mercury

plasma) is at 253.7 nm. This is the reason why the radiation of a mercury lamp is exceptionally

well suited for photometric detection of ozone.

In the year 1729 Pierre BOUGUER, a professor of hydrography, published his "Essai d'Optique,

sur la Gradation de la Lumière". He already knew that light passing through a medium is de-

creased logarithmically. In the year 1760 Johann Heinrich LAMBERT published his "Photome-

tria sive de mensura et gradibus luminis, colorum et umbrae". Based on Bouguer's findings, he

described the passage of light through a medium more mathematically. BEER alleged in 1852

that, when the product of concentration and pass length is constant, extinction is also constant.

This is an important statement for general photometry, but is less important for ozone measure-

ment with UV radiation.

Figure 1

OZONE MONITOR BMT 932 Manual, Rev. 02/2021

8

The law of BOUGUER-LAMBERT says that the product of the concentration, e.g. of ozone in

air, and the cuvette length, is proportional to the logarithm of the quotient of both light intensi-

ties, at the input to the cuvette and the output. This logarithm is also referred to as the extinction.

The coefficient of proportionality for ozone at 254 nm wavelength has been investigated thor-

oughly by many scientists. The different results agree to about plus/minus one percent. The actu-

al number of the extinction coefficient depends upon the definition of "concentration", and upon

the dimensions chosen. The number recommended by the IOA (International Ozone Associa-

tion) is 3000 ltr/cm mol with the concentration in mol/ltr at 1 atm and 0°C.

To measure ozone content in a sample gas, an ozone monitor has to measure the extinction of

UV radiation of high spectral purity at 254 nm wavelength during its passage through the cuvette

of well known length. At the same time the monitor has to measure temperature and pressure of

the sample gas in the cuvette, because the ozone "concentration" to be evaluated would be mean-

ingless without the knowledge of the thermodynamic condition of the sample. Actually the tem-

perature during measurement usually is around 293 K (20°C), but the pressure may vary dramati-

cally with the altitude and with the inevitable pressure drop in the sampling tube.

6 Units of Measure: ppmv, µg/m3 (1 atm/different temperatures)

The internationally agreed upon definition of ozone content in the ambient air is ppmv (parts per

million, volume of ozone per volume of sample gas). The International Standard

ISO/FDIS 13964 of 1998 defines ambient ozone content as µg/m3 at 1 atm/25°C, or at 20°C,

or at 0°C. Actually the definition of 1mg/m3 (1000 µg/m3) at 1 atm/20°C (usually used in the

European Community) is practically identical with 0.5 ppmv.

7 The OZONE MONITOR BMT 932

The OZONE MONITOR BMT 932 has a cuvette 285 mm in length. The cuvette is an

6.3 mm ID PTFE tube. The tube is mounted inside a thick-walled aluminium tube as the rigid

optical bench. Sample gas temperature is measured in the highly thermally conductive aluminum

tube. Sample gas pressure is measured directly inside the cuvette.

The low pressure mercury lamp is mounted directly to the aluminium optical bench. The

UV radiation passes a semi-reflective mirror, through which the radiation intensity is measured by

the reference detector just before entering the cuvette through a quartz window. At the other end

of the cuvette the measuring detector is mounted behind another quartz window. The reference

intensity signal is used to auto control the power to the lamp to precisely stabilize the

UV radiation. A LAMP LOW WARNING is activated when the UV lamp is near the end of its

service life.

Sample gas is sucked through the cuvette by a silent membrane pump. The flow rate is measured

by an electric flow meter. A control loop holds the mass flow rate constant at 1 l/min by control-

ling the power to the pump, automatically stabilizing the flow.

OZONE MONITOR BMT 932 Manual, Rev. 02/2021

9

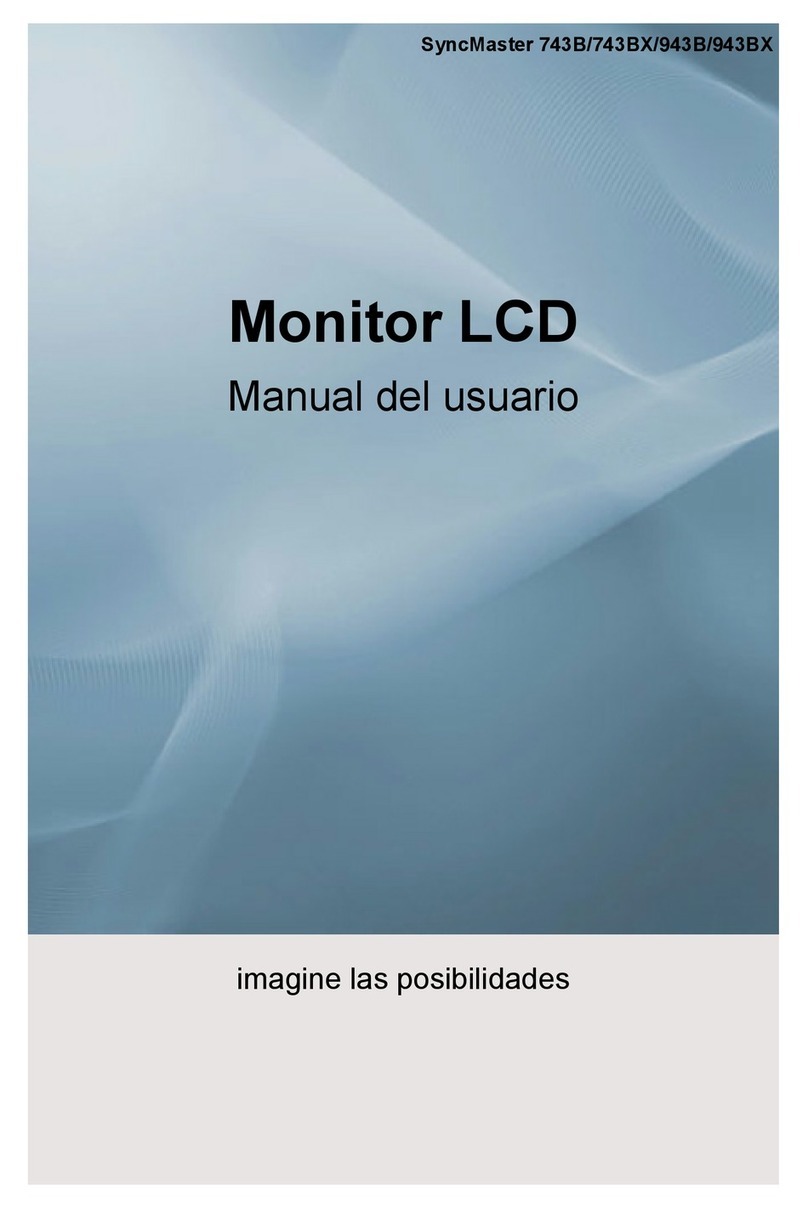

Figure 2

Ozone

Generator Utility

Scrubber

Reserve

Scrubber

UV Det.Temp.Press.

UV Det.

UV Lamp

Timing

Flow Control

Tests

&

Warnings

Photometric

Calculations Display

Limit

Alarms

Select

Select

Flow

Meter Catalyst Pump

Cuvette

Filter

Sample

Points

6

5

4

3

2

1

Sample

Select

ERROR/WARMUP

LAMP LOW

LOW FLOW

SCRUBBER

HIGH ALARM

LOW ALARM

Purge Block

OZONE MONITOR BMT 932 Manual, Rev. 02/2021

10

By means of a solenoid valve assembly, the sample gas is delivered directly to the cuvette, or via

an ozone scrubber with high selectivity to ozone alone. During this phase (with no ozone in the

cuvette) the photometric ozone signal is set to zero. The scrubber thus is the element which shall

give the zero ozone reference. From time to time, a solenoid valve switches an ozone generator

in front of the scrubber to check its ability to remove any ozone from the sample.

In case the utility scrubber fails to remove the ozone completely, another scrubber (the reserve

scrubber) is switched into the circuit, and SCRUBBER WARNING is activated to tell the user

that the utility scrubber has to be replaced soon. The OZONE MONITOR contains an ozone

destruct to remove any ozone from the sample leaving the instrument. But it does not contain a

sample gas filter. The reason is that any sample filtering should be performed at the inlet of the

sampling tube to protect the inner tube surfaces from becoming dirty. The sample gas filters

shipped with the instrument have to be provided at the inlets of the sample tubes, and have to be

replaced on a regular basis (see page 13).

8 Scrubber

The scrubber is one of the most important elements of an ambient ozone monitor. It shall re-

move any ozone in the sample gas whilst it shall not affect any other substances which could

produce an extinction of the UV radiation. Perhaps not any kind of scrubber really fulfills these

demands perfectly.

The non-ideal behaviour of a scrubber material of course depends upon the species and quanti-

ties of substances contained in the sample air which may be affected by the scrubber. In other

words: The optimal choice of a scrubber material always depends upon the situation in which the

ozone monitor is operated.

For ambient ozone monitoring (instruments with measurement range 1 ppmv) we are using the

scrubber material which seems to be the best choice today. But we are continuously looking for

the performance of our scrubber in order to eventually find even better solutions.

ATTENTION: The ambient scrubber material is a consumable. Excessive ozone concentra-

tions can dramatically shorten the scrubber life. Therefore, during startup, if there are gross

ozone leaks, it may be necessary to replace the ambient scrubber several times.

For all applications of the OZONE MONITOR BMT 932 which are not for ambient monitoring

(TLV monitoring), and for all ranges higher than 1 ppmv , we are using a catalytic scrubber mate-

rial which is not a consumable, but eventually can be destroyed or deteriorated, of course.

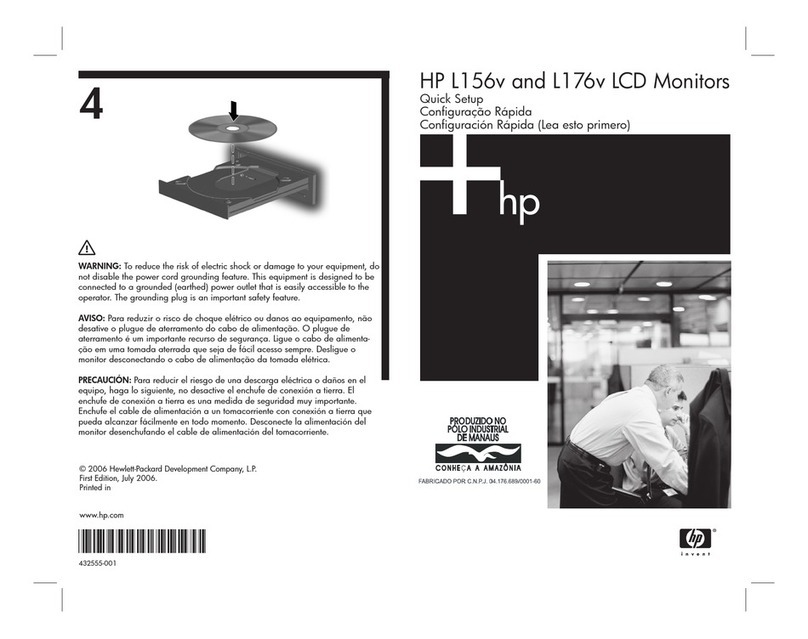

9 Mechanical Installation

The OZONE MONITOR BMT 932 is in a 19'' rack mount enclosure, 132.5 mm high, 300 mm

deep (see Figure 3), or in a splash-proof wall mounted aluminium cabinet 357 x 440 x 133 mm.

Additional room for cables and tubing should be provided about 120 mm behind the back panel

of the rack mount instrument. Free air circulation should be provided around this instrument for

convection cooling. Temperature of the ambient air should be in the range of 0 to 45°C (non-

condensing).

OZONE MONITOR BMT 932 Manual, Rev. 02/2021

11

446

3

0

0

44 120

483 (19")

132.5

Auto Channel 3:

0.123 ppm

room for cables & tubings

OZO N E M O NI TOR BMT 93 2

BMT M ESSTECHN I K, BERLIN

OS TI, MO NTEREY, CA.

Figure 3

OZONE MONITOR BMT 932 Manual, Rev. 02/2021

12

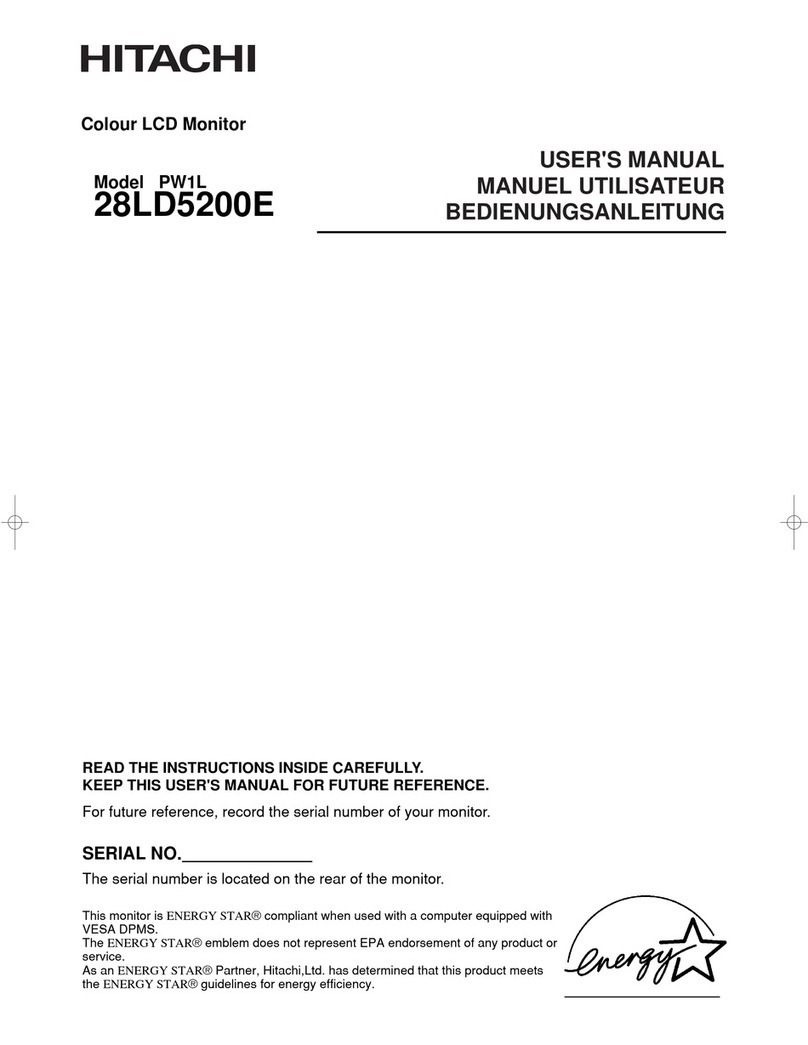

Figure 4

RS-232SIGNALS EMO CH.ID

OUT

S

A

MP

L

E

IN

100

-

2

4

0

V

A

C

3

5

V

A

DISCONNE

C

T

M

A

I

N

S

BEFORE O

P

E

N

I

N

G

OZONE MONITOR BMT 932 Manual, Rev. 02/2021

13

10 Pneumatic Installation

The OZONE MONITOR BMT 932 has either 1, or 3, or 6, sample gas inlet fittings (according

to the model ordered). The fittings are bulkhead compression fittings for ¼'' OD (.250" x .156"),

or 6 mm OD (6 x 4 mm) tubing. The cabinet version BMT 932C accepts only 1/4" tubing (refer

to Appendix C, page 48). Tubing material has to be fluorinated plastic, preferably transparent

FEP to make any internal droplets or coarse dirt visible. Sample tubing length should be as short

as possible. Maximum recommended length is 20 m.

The instrument intentionally has no internal dust filter. The

reason is that the dust filter has to protect not only the ozone

monitor, but also has to protect the inner surface of the

sample gas tubing leading to the monitor. Thus the filter has

to be mounted at the inlet of the sample tubing. The

OZONE MONITOR BMT 932 comes with one fitting

(932-MALEFIT) per channel. This fitting provides fast con-

nection between the sample tubing inlet and the filter holder

(932-HOLDER). This fast connection simplifies replacement of the filter inserts on a regular

basis.

Caution: We strongly recommend not to use SS tubing. Use of SS tubing will most likely lead to

measurement errors. Since in most installations of other ozone monitors there are no sample gas

filters provided at the sample tubing inlets, this older tubing probably is

more or less dirty inside resulting in more or less ozone destruction in the

sample gas. This is the reason why we strongly recommend that old tub-

ing be removed and replaced, preferably by transparent FEP tubing. We

strongly recommend to replace SS tubing by FEP tubing in older installa-

tions.

One outlet fitting is provided for the sample gas after being measured.

The outlet fitting is also for ¼'' or 6 mm tubing. Inside the OZONE

MONITOR BMT 932 an ozone catalyst is installed to remove ozone from the sample gas re-

leased from the outlet fitting. From this catalyst particles might come which then are contained in

the out gas. In very clean environments the sample gas outlet should be vented to an exhaust.

10.1 Sample Gas Filters

It is very important that the sample gas tubes and

the ozone monitor are kept clean inside. The

OZONE MONITOR BMT 932 must always be

operated with one clean sample gas filter

(932-HOLDER) at the inlet of each sample gas

line. One filter holder per channel, one fitting for

mounting the filter holder, and 200 filter inserts

are shipped with the instrument. The filter inserts are of fine pure glass fiber to remove nearly

special mounting of filter in the sample gas line near the

inlet of the tubing (order code: 932-ADAPT. Special

inline filter on request, not included.

Please note: do not use the 932-HOLDER, it is not de-

signed for inline configurations!)

932-HOLDER & 932-

MALEFIT:

standard

mounting of filter at the inlet of the

sample gas tubing (in

cluded with every

BMT 932)

1

3

2

932-HOLDER

OZONE MONITOR BMT 932 Manual, Rev. 02/2021

14

any aerosol particles from the sample without affecting the ozone. This latter property may de-

crease with increasing amount of dirt retained by the filter. This is the reason why the filter in-

serts should be replaced on a regular basis. The replacement interval strongly depends on the

quantity and the kind of the dirt to be retained by the filter. Each user has to find out the interval

optimally adapted to his specific situation.

Caution: The BMT 932 is designed to measure ozone in ambient air at the workplace. Placing an

ozone sample port in a corrosive and/or contaminated environment could cause damage to the

instrument and affect the accuracy of measurements.

10.2 Tubing

We strongly recommend not to use SS tubing. Use of SS tubing will most likely lead to measure-

ment errors. Sample tubing has to be 1/4'' (OD) or 6 mm, respectively (BMT 932C: 1/4" only).

We strongly recommend to use tubing material which is transparent like FEP. Transparency is

important in case some dirt - namely droplets of condensated water - would travel along the tub-

ing. With an intransparent tubing (e.g. PTFE) droplets are invisible.

10.3 Moist Sample Gas

When the sample gas contains water vapour at a dew point temperature higher than the ambient

temperature around the sample tubing, condensation will occur inside the tubing. This has to be

avoided strictly!

Concerning Moist Sample Gas please refer to our TechNotes TN-1 page 6 and TN-3, to be

found on our website www.bmt-berlin.de

If it is not clear whether or not condensation might occur we recommend to include a WATER

TRAP (part no. 932-WATER TRAP) into the sample tubing line. When no condensate will form

over an extended period of time (one year, or more) the WATER TRAP will remain empty, and

OZONE MONITOR BMT 932 Manual, Rev. 02/2021

15

thus demonstrate that the sample gas is dry enough. The WATER TRAP then should be re-

moved. If condensate will be observed in the WATER TRAP the value of the TRAP now was

twofold: it has shown the neccessity of drying the sample gas, and it has held back the condensate

and thus has protected the OZONE MONITOR BMT 932. If the sample gas would need drying

please refer to our Peltier-electric Sample Gas Dryers DH3b-LC and DH5-LC.

11 Electrical Installation

11.1 Power Connections

The rear panel of the 19" rack mount version of the OZONE MONITOR BMT 932 includes a

3-wire power receptacle. The instrument will work from any mains voltage in the range of

100 to 240 VAC. Power consumption is less than 35 VA. The instrument contains Universal

Modular Fuses, which allow global operation without having to make a decision between IEC

and UL type fuses. Fuses cannot be replaced by the user. The wall mount cabinet version

BMT 932C has a special water-proof mains receptacle on the right side. The according special

water-proof connector comes with the instrument.

Warning: This product relies on the building's installation for short-circuit (overcurrent) protec-

tion. Ensure that a fuse or circuit breaker no larger than 15 A at 120 VAC (10 A at 240 VAC) is

used on the phase conductor.

The power receptacle or the mains socket-outlet the instrument is connected to should be easily

accessible for fast interruption of power, or other means for switching off power should be pro-

vided.

Warning: If the mains cable is replaced, the new cable shall have a current rating of at least 10 A.

The BMT OZONE MONITOR 932 with (optional) power 24 VDC (18-36 VDC) has a three

pole terminal block for connection of the power supply:

1 Protective Ground

DC power connector: 2 Positive } (18-36 VDC, 25 W SELV-supply)

3 Negative

11.2 Output and Control Terminals

The following signals are available at the green terminal block named "SIGNALS” on the rear

panel of the OZONE MONITOR BMT 932:

Signal Name Pin No. Description

Alarm Low Common 1 Relay contact

Alarm Low Closed 2 Pins 1-2 closed when LOW alarm

Alarm Low Open 3 Pins 1-3 opened when LOW alarm

Alarm High Common 4 Relay contact

Alarm High Closed 5 Pins 4-5 closed when HIGH alarm

OZONE MONITOR BMT 932 Manual, Rev. 02/2021

16

Signal Name Pin No. Description

Alarm High Open 6 Pins 4-6 opened when HIGH alarm

4-20 mA (GND) 7 Current loop output return

4-20 mA 8 Current loop output

Voltage Outputs (GND) 9 Voltage outputs return

Voltage Output 1 V 10 Max. concentration Range = 1 V

Voltage Output 10 V 11 Max. concentration Range = 10 V

Lamp Low 12 Relay contact

Lamp Low 13 Pins 12-13 open when LAMP LOW

Error Common 14 Relay contact

Error Closed 15 Pins 14-15 closed when error

Error Open 16 Pins 14-16 opened when error

Relay Outputs: the Alarm Relay contacts will operate at a max. voltage of 28 V (DC or AC) and a

max. current of 1 A. Further details of the Alarm Relays operation are described in section 15 on

page 31. The Error Relay and Lamp Low Relay will switch 28 V (AC or DC) at a max. current of

1 A. All relays are in the alarm/error position if no power is applied to the instrument.

Analog Outputs: The analog outputs are updated with every new measurement (about every 20

seconds).

The voltage outputs are isolated voltage signals 0 to 10 V and 0 to 1 V, proportional to the con-

centration (actually the 0 - 10V signal swings down to about -0.25 V below zero). Input resistance

of the load should be higher than 1 k.

The current output is an isolated current signal 4 to 20 mA, proportional to concentration (with

an offset of 4 mA). Input resistance of the load should be less than 600 (optional 1350 ).

The current output provides the energy for the curent loop. Attention:

The current output must not be connected to an external power supply !

11.3 Channel Identification

The green terminal block named "CHANNEL ID” provides six semiconductor relay contacts

with information on which sample channel the analog output concentration signal corresponds

to. A closing relay identitfies a channel.

Signal Name Pin No. Description

Channel 1 1 Output from sample on Channel 1

Channel 2 2 Output from sample on Channel 2

Channel 3 3 Output from sample on Channel 3

Channel 4 4 Output from sample on Channel 4

Channel 5 5 Output from sample on Channel 5

Channel 6 6 Output from sample on Channel 6

Common 7 Common contact for all relays

OZONE MONITOR BMT 932 Manual, Rev. 02/2021

17

CHANNEL ID relays may carry a max. current of 0.5 A at a voltage of 28 V (AC or DC). Cau-

tion: CHANNEL ID relays are protected by a 1 A fast-blow fuse at the Common contact, so

care should be taken not to overload these outputs. For the physical connection of the wires to

the spring cage contacts a screw driver 0.4 x 2.0mm is provided in the accessories.

11.4 Emergency-Off Relays

The OZONE MONITOR BMT 932 provides three logical EMO functions (Emergency Ma-

chine Off) for multi-channel operation. Hardware for each of these three EMO functions con-

sists of 2 independent relays. All 12 relay contacts (six relays with two contacts each) are available

at the terminal block named "EMO”. Two relays of each logical EMO function, which are driven

by separate software functions, can be connected in series in order to provide enhanced safety

against "hanging” relays.

Note: For single-channel operation use terminals 1 to 6 instead (connector "SIGNALS": High &

Low Alarm).

All concentration alarms (max.12) can be assigned to each of the three logical EMO functions. If

an alarm assigned to an EMO function becomes active (concentration is above threshold), the

corresponding two relays will open. Assignment of alarms to logical EMO functions can be done

on the front panel and with the software BMT 932 Link provided with the instrument. Max. cur-

rent is 1 A (AC or DC) at a voltage of 28 V.

Example: three generators with two sample points each have to be monitored by one OZONE

MONITOR BMT 932. In the event of an ozone leak in one generator only this generator shall be

switched off by the instrument. One logical EMO function is available for each generator, so the

four high and low alarms responsible for the two sample ports from each generator can be as-

signed to one logical EMO function individually, which means that an alarm on one generator

will not stop operation of the other two generators.

Signal Name Pin No. Description

G1R1a 1 EMO Group 1 Relay 1 Contact a

G1R1b 2 EMO Group 1 Relay 1 Contact b

G1R2a 3 EMO Group 1 Relay 2 Contact a

G1R2b 4 EMO Group 1 Relay 2 Contact b

G2R1a 5 EMO Group 2 Relay 1 Contact a

G2R1b 6 EMO Group 2 Relay 1 Contact b

G2R2a 7 EMO Group 2 Relay 2 Contact a

G2R2b 8 EMO Group 2 Relay 2 Contact b

G3R1a 9 EMO Group 3 Relay 1 Contact a

G3R1b 10 EMO Group 3 Relay 1 Contact b

G3R2a 11 EMO Group 3 Relay 2 Contact a

G3R2b 12 EMO Group 3 Relay 2 Contact b

OZONE MONITOR BMT 932 Manual, Rev. 02/2021

18

All EMO-Relays are in the open position if no power is applied to the instrument. A relay con-

tact will only close if all channels with assigned alarms were sampled and concentrations were

found below thresholds.

Shielded cables should be used on all connectors. The shields should be connected to the ground

connector ( ) at the rear panel. For the physical connection of the wires to the spring cage

contacts a screw driver 0.4 x 2.0mm is provided in the accessories.

11.5 Serial Interface

The bidirectional isolated serial interface is used for communication with a PC or other automa-

tion components in an industrial environment. Software updates can also be performed over this

interface. A serial cable for connection to a PC is a standard accessory.

Connection:

Pin Function Description

2 TxD Data sent

3 RxD Data received

5 GND RS-232 ground

The data format used is eight bits, one stopbit, no parity (8N1). See page 27 for configuration of

the interface, page 29 for its usage.

12 Switching On the Instrument

After application of power the instrument will display the following:

Bootloader VX.XX

Checking Flash:

VX.XX denotes the software version of the Bootloader. The Bootloader is a small application

which is run first. It checks the contents of the main flash memory for integrity, which takes a

few seconds. The Bootloader is also responsible for updating the firmware via the serial interface

(see p. 18). In case no problems are found it releases control to the main application. The follow-

ing is displayed:

BMT 932 VX.XX

VX.XX denotes the software version of the main application. After this the concentration range

is displayed. If the instrument is cold or has not been used in a while,

Waiting for Lamp

could be displayed, which will be followed by an indication of the measurement range.

This display is followed by a warmup period, the duration of which is being determined by the

state of the lamp. During warmup the Error Relay is switched to error. All other relay contacts

are open. The analog outputs put out 1 V, 10 V and 20 mA respectively. The serial interface (see

page 29) puts out max. concentration and the code for the warmup-state. The time left for

OZONE MONITOR BMT 932 Manual, Rev. 02/2021

19

change into normal operating mode is displayed and counted down, giving an indication on when

warmup will end. The time period between switching on and normal operating mode can last

between 40 s and 420 s. During this time the front panel keys are deactivated. Serial communica-

tion is possible. Warmup will end with the display:

Waiting for

first result

At the end of the warmup period, the Error Relay, the Lamp Low Relay, and the Low and High

concentration alarm relays will switch to their normal position (non-error).

The EMO-Relays will only close if the corresponding sample concentrations were found to be

below the assigned alarm thresholds (see pages 31 and 25). This means, that it can take an addi-

tional two minutes when using a six channel instrument before equipment (ozone generators)

connected to the EMO-outputs are allowed to start operation.

13 Front Panel Operation

The front panel consists of a two line x 20-character alphanumeric display (LCD with white

backlight illumination) and three pushbuttons. The concentration display will be updated when-

ever a new concentration measurement result is available, i.e. every 20 s. All other messages (er-

rors, warnings, concentration alarms) will be displayed immediately.

BMT MESSTECHNIK, BERLIN

OSTI, MONTEREY

BACK SCROLL/SET ENTER

In normal operation the display shows the mode of operation and channel information in the

first line, while ozone concentration is displayed in the second line.

The pushbuttons can be used to perform the following operations:

Switch between automatic sampling mode and manual sampling of a single channel

View parameters

Change the parameters

The following diagram shows the functions of the main menu:

OZONE MONITOR BMT 932 Manual, Rev. 02/2021

20

Auto Concen-

tration

View

Parameters

Set

Parameters

Main Menu

ENTER

SCROLL

BACK

Press Scroll for

at least 2 s

PIN-Protection

Ch1 Concen-

tration

Ch2 Concen-

tration

Ch3 Concen-

tration

Ch4 Concen-

tration

Ch5 Concen-

tration

Ch6 Concen-

tration

Deactivated channels are skipped

Expressions printed bold in the following sections of text always relate to the contents of the

instrument menus.

The button SCROLL / SET moves to the right within the menu, the key ENTER downwards

and the button BACK moves upwards. The SCROLL action will continue on the left side, once

it has reached the right side of the diagram. This is also valid for the later explained menus View

Parameters and Set Parameters.

From now on, when relating to the multi-functional key SCROLL / SET only the function

meant in the context will be mentioned.

In multi-channel instruments, the two measurement modes available are Auto and Manual. In

Auto mode the monitor will sequently measure concentrations on all active channels (see p. 28)

in 20 s intervals. If in Auto mode the ENTER button is pressed the instrument will change to

Manual mode, meaning that only one channel will be sampled continuously. Each time ENTER

is pressed in Manual mode, the monitor will select the next active channel. If ENTER is pressed

while the highest active channel is selected, the instrument will return to Auto mode.

Coming from Auto mode, the display will show concentrations on the different channels, when

pressing the ENTER key. This is a convenient way to do a fast check on concentrations on sam-

ple channels, without having to wait for measurement cycles to complete.

In single-channel instruments, the ENTER key does not provide the functions described above.

Starting with Concentration pressing the button SCROLL will lead to View Parameters. After

pressing ENTER the parameters can be viewed, but they cannot be changed. The BMT 932 will

go on measuring concentrations in all position of the menu system.

Table of contents

Other BMT Monitor manuals