Initial Print Date: 02/2000 Revision Date: 03/21/00

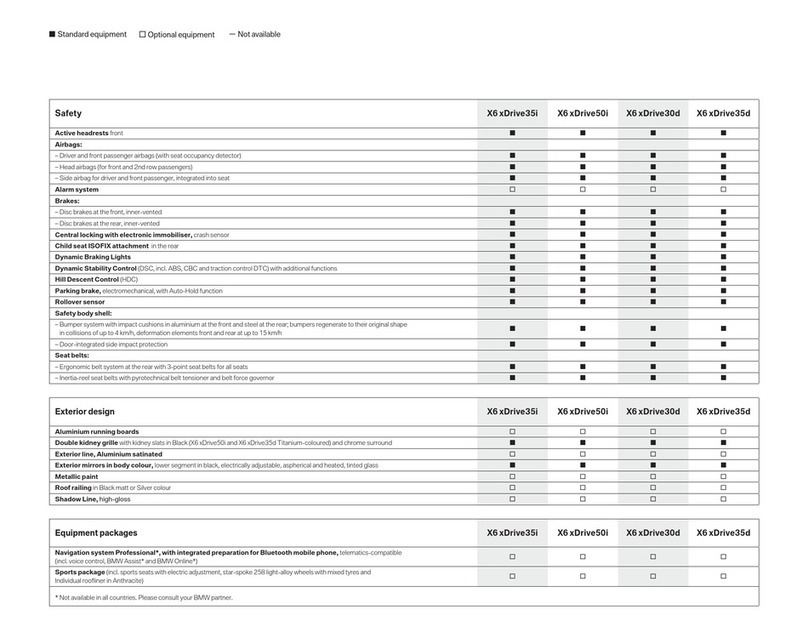

Subject Page

Introduction ......................................................................................... 3

System Components

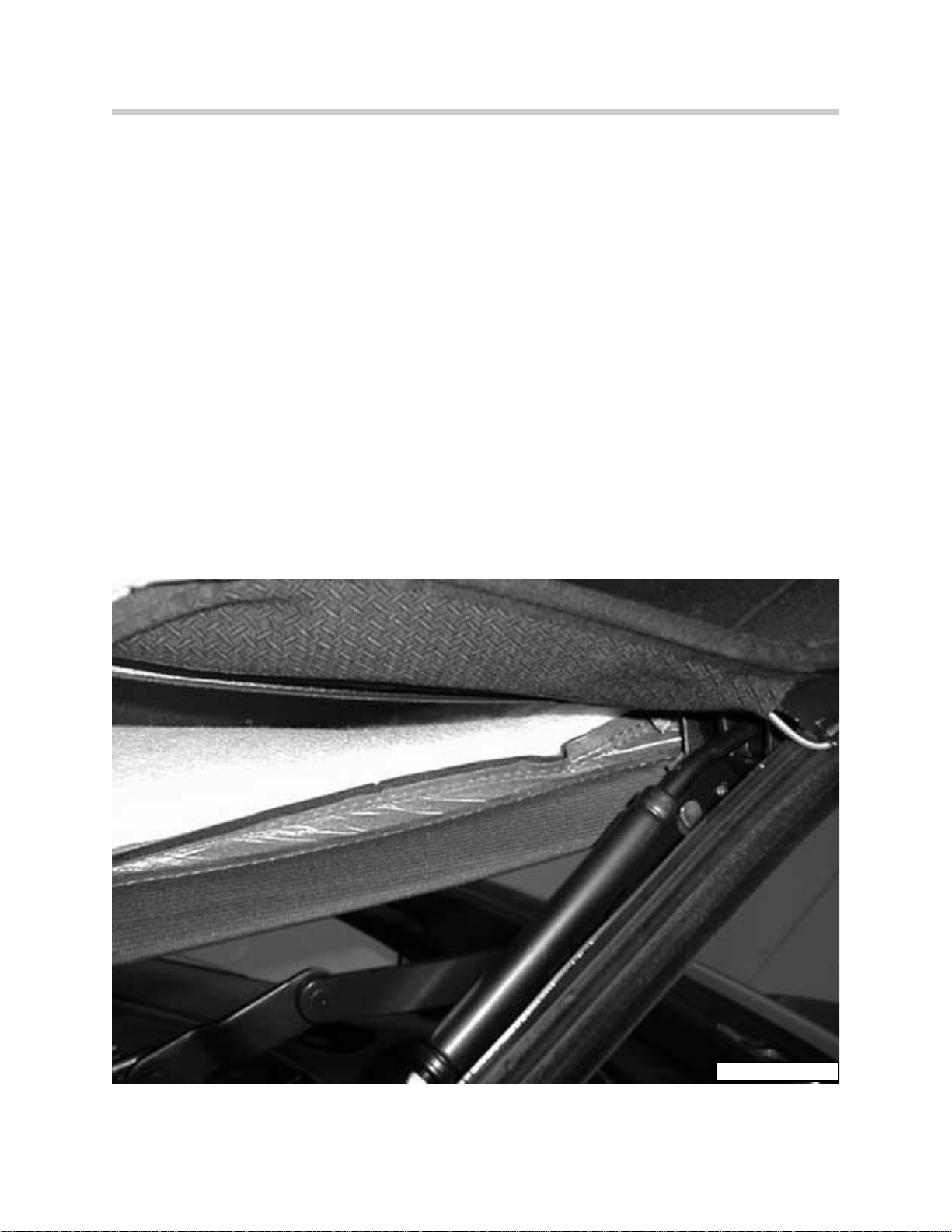

Top and Frame.................................................................................. 4

CVM ......................................................................................... 5

Hydraulic Unit.................................................................................... 6

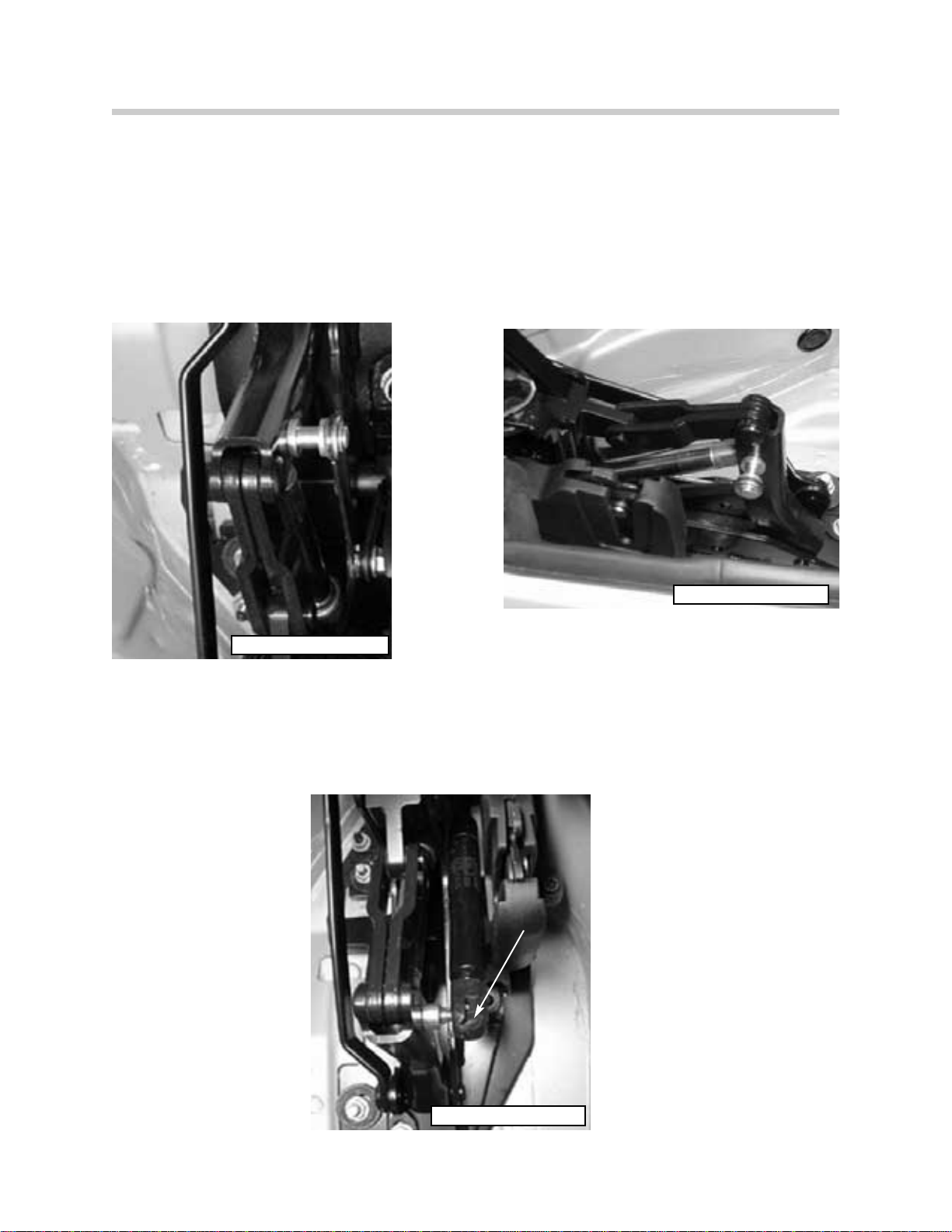

Hydraulic Cylinders............................................................................ 7

Hydraulic Solenoids........................................................................... 9

Storage Cover Motor......................................................................... 10

Windshield Frame Lock Assembly..................................................... 11

Top Switch ........................................................................................ 12

Hall Sensors...................................................................................... 13

Angle Hall Sensors ............................................................................ 19

Compartment Floor Micro Switch...................................................... 20

I P O ......................................................................................... 22

System Operation................................................................................... 23

Emergency Operation............................................................................. 28

Comfort Operation.................................................................................. 29

Diagnosis ......................................................................................... 30

Hard Top ......................................................................................... 33

Workshop Hints...................................................................................... 35

Roll Over Protection System................................................................... 40

Components...................................................................................... 42

Roll Over Sensor ............................................................................... 44

I P O ......................................................................................... 47

Table of Contents