F12�Chassis�Dynamics

Contents

1. Introduction.............................................................................................................................................................................................................................................1

1.1. Driving�dynamics�and�comfort..........................................................................................................................................................1

1.2. Bus�system�overview....................................................................................................................................................................................... 2

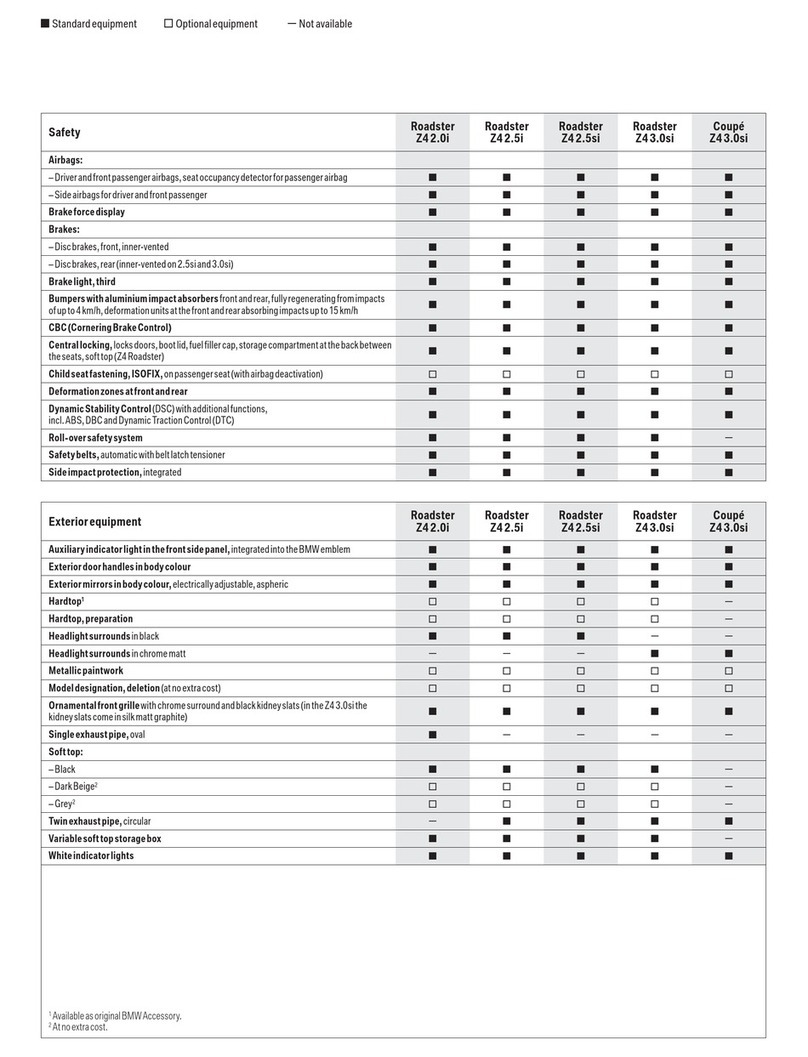

2. Models...............................................................................................................................................................................................................................................................5

2.1. Comparison..................................................................................................................................................................................................................... 5

3. Chassis�and�suspension................................................................................................................................................................................................. 6

3.1. Front�axle............................................................................................................................................................................................................................ 6

3.1.1. Technical�data............................................................................................................................................................................7

3.1.2. Service�Information........................................................................................................................................................... 7

3.2. Rear�axle...............................................................................................................................................................................................................................8

3.2.1. Technical�data........................................................................................................................................................................10

3.2.2. Service�Information.......................................................................................................................................................10

3.3. Suspension/dampers................................................................................................................................................................................... 11

3.3.1. Electronic�Damper�Control�(EDC)..........................................................................................................11

3.4. Wheels�&�Tires......................................................................................................................................................................................................12

3.5. Tire�Pressure�Monitor�System..................................................................................................................................................... 13

3.5.1. System�function................................................................................................................................................................. 13

3.5.2. System�overview............................................................................................................................................................... 15

3.5.3. System�wiring�diagram............................................................................................................................................16

3.5.4. Notes�for�Service............................................................................................................................................................. 17

4. Brakes............................................................................................................................................................................................................................................................19

4.1. Service�brakes........................................................................................................................................................................................................ 19

4.2. Electromechanical�Parking�Brake�(EMF)...................................................................................................................... 20

4.2.1. System�overview............................................................................................................................................................... 21

4.2.2. System�wiring�diagram............................................................................................................................................23

4.2.3. System�structure.............................................................................................................................................................. 24

4.2.4. System�function................................................................................................................................................................. 24

5. Steering......................................................................................................................................................................................................................................................33

5.1. Basic�steering..........................................................................................................................................................................................................34

5.1.1. System�overview............................................................................................................................................................... 34

5.1.2. System�wiring�diagram............................................................................................................................................36

5.2. Integral�Active�Steering........................................................................................................................................................................... 37

5.2.1. Functional�ranges............................................................................................................................................................ 38

5.2.2. System�wiring�diagram............................................................................................................................................41

5.2.3. EPS�with�24�V.......................................................................................................................................................................43

5.2.4. Rear�axle�slip�angle�control�HSR............................................................................................................. 50