BN BNT-40 User manual

Page | 1

Operating Instructions

BNT-40 Automatic Rebar Tying Machine

is Tool Has

Passed ISO9001 International

Quality System Certication

e charger has passed ETL Certication

Please read this manual carefully before using this machine to

make sure you are familiar with all safety and warning instructions.

Page | 2

e BN-40 is a hand-held battery operated tool. In this manual you will learn that this machine

consists of four parts: the machine body, special wire coil, battery box and a charger. e tool is

designed to be used for the fast tying of rebar or steel used in construction sites for the building

trades. Due to its speed, convenience and safety, this machine can save a great deal of valuable la-

bor and material resources. In addition, the parts and components as well as advanced production

technologies are made from well-known manufacturers both here and abroad. is machine was

developed as an economical and practical tying machine with many international patents.

--------------------------------------------------------------------------------

Table of Contents

3 | Machine Call-Outs

4 | Safety

5 | Safety Locks

5 | Product Specications and Technical Parameters

6 | Battery and Charger Usage

6 | Machine Operation and Methods

7 | Replacement of Gears

7 | Care and Maintenance

8 | Common Faults and Removal Methods

--------------------------------------------------------------------------------

Please read this manual carefully before using this machine to

make sure you are familiar with all safety and warning instructions.

Page | 3

OPERATION INSTRUCTION

Machine Call-Outs

Page | 4

Safety

is machine is a high-performance battery operated tool.

Failure to follow the warnings and instructions may result in

an electric shock, re or serious injuries.

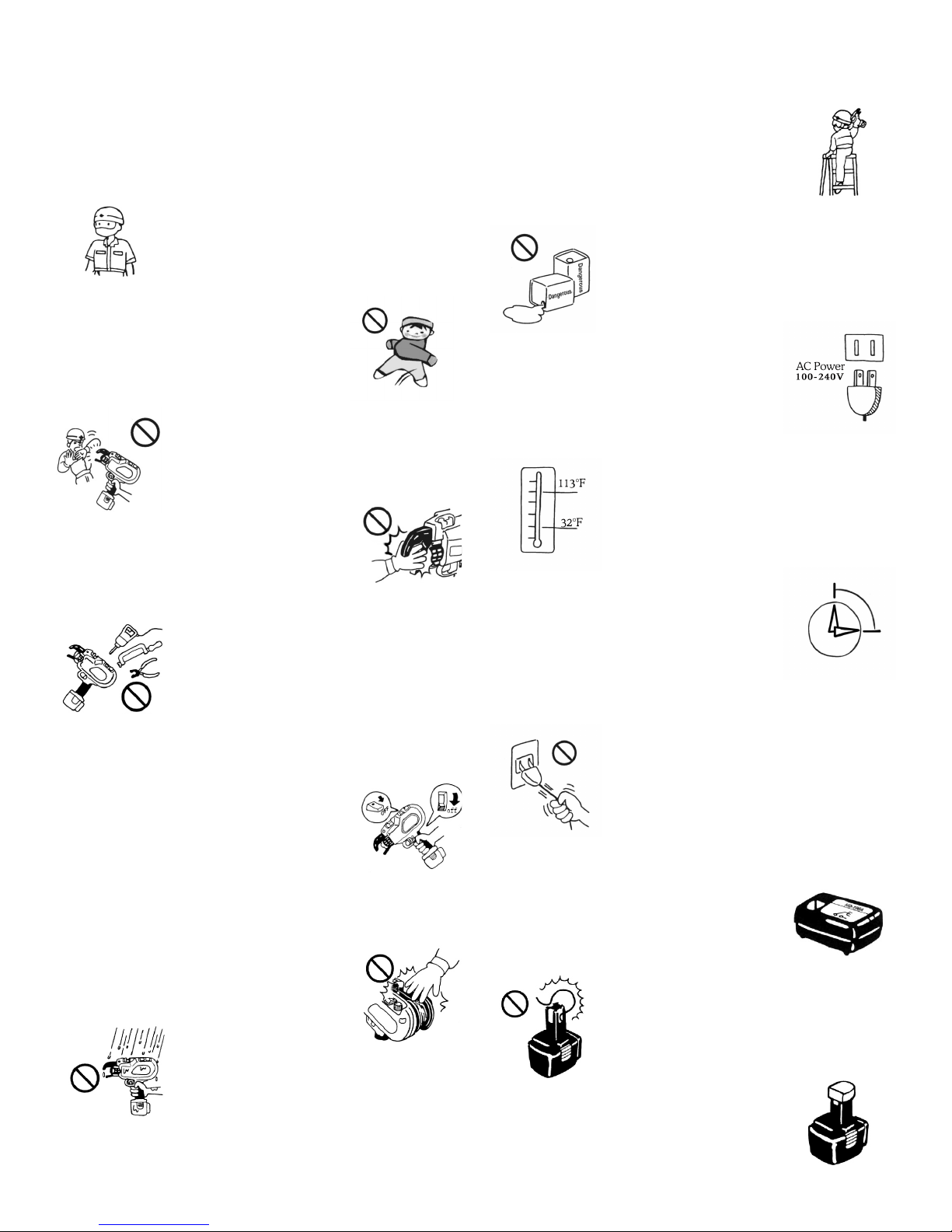

• Always operate the tool with personal

protection equipment (safety helmet and

eye protection, etc...). Using the appropri-

ate safety equipment at all times will avoid

body injury.

• Keep children and bystandards away

while operating this tool. Distractions may

cause serious accidents.

• Do not aim the tool at

those standing around your work area. Se-

rious accidents can happen if you mishan-

dle this tool.

• Do not place your hand

or position the machine mouth (between

arm A and the curl guide) near the body.

is will cause serious injury.

• Do not attempt to dismantle, modify or

perform any major maintenance on this

tool. Any modication may result in a de-

teriorations of the tool’s performance and

may cause serious injury and void any war-

ranty.

• Make sure that the electric switch is in

the o position when the tool is not being

used or when abnormalities occur. When

changing or adjusting the wire coil, or

when changing the battery pack, make sure

to turn o the main power switch and lock

the trigger.

• Do not place ngers or hands in the wire

coil area. is may result in distortion of

the coil and may cause injury to you.

• Do not operate this tool

in the rain or areas where

moisture is present. is may result in

electrical shock or accident.

• Stay particularly alert while working in

a lo area. Do not operate any power tool

under the inuence of drugs, alcohol, or

medication. A moment of inattention may

result in serious injury to you or someone

near you.

• Do not operate this tool in a hazardous

area containing ammable liquid, gas or

powders which may ignite and cause a re.

• e charger has been de-

signed to use standard AC

power (100-240V ~ 50-60Hz). Do no re-

charge the battery using a generator power

supply as this will cause the charger to mal-

function.

• Our batteries charge best when the ambi-

ent temperature is between 32°F and 113°F.

Super-cooling or over-heating environ-

ments are not suitable for charging.

• Continuous use of the

charger is not advised as this will shorten

the life span of the battery and the perfor-

mance of the charger itself. When not in the

charging mode the power supply must be

turned o.

• Please do not carry the charger by the

cord. Do not pull out the power cord from

the wall socket with a strong force, this will

damage the cord and break the wires or

cause a short circuit. A damaged cord must

be repaired or replaced immediately.

• Use only the specied charger that came

with your machine. Using a unauthorized

charger may result in damage to the battery

components and possible explosion.

• Avoid battery terminal

contact with other metal objects. Trying to

recharge the battery with an external wire

could result in a short circuit of the battery.

• Do not throw away the

protective battery cap. Use it to cover the

terminal when not in use.

Page | 5

Safety Locks

Make sure that all safety features are operational before us-

ing any power tool.

DO NOT OPERATE THE TOOL IF THE SAFETY LOCKS

ARE NOT FUNCTIONAL.

is tool is equipped with the following safety devices:

• e Main Switch: Please turn the main

switch on the power supply o when not in

operation.

• e Trigger Lock: Always

turn the trigger lock to

the o position when not in use or when

changing the wire coil.

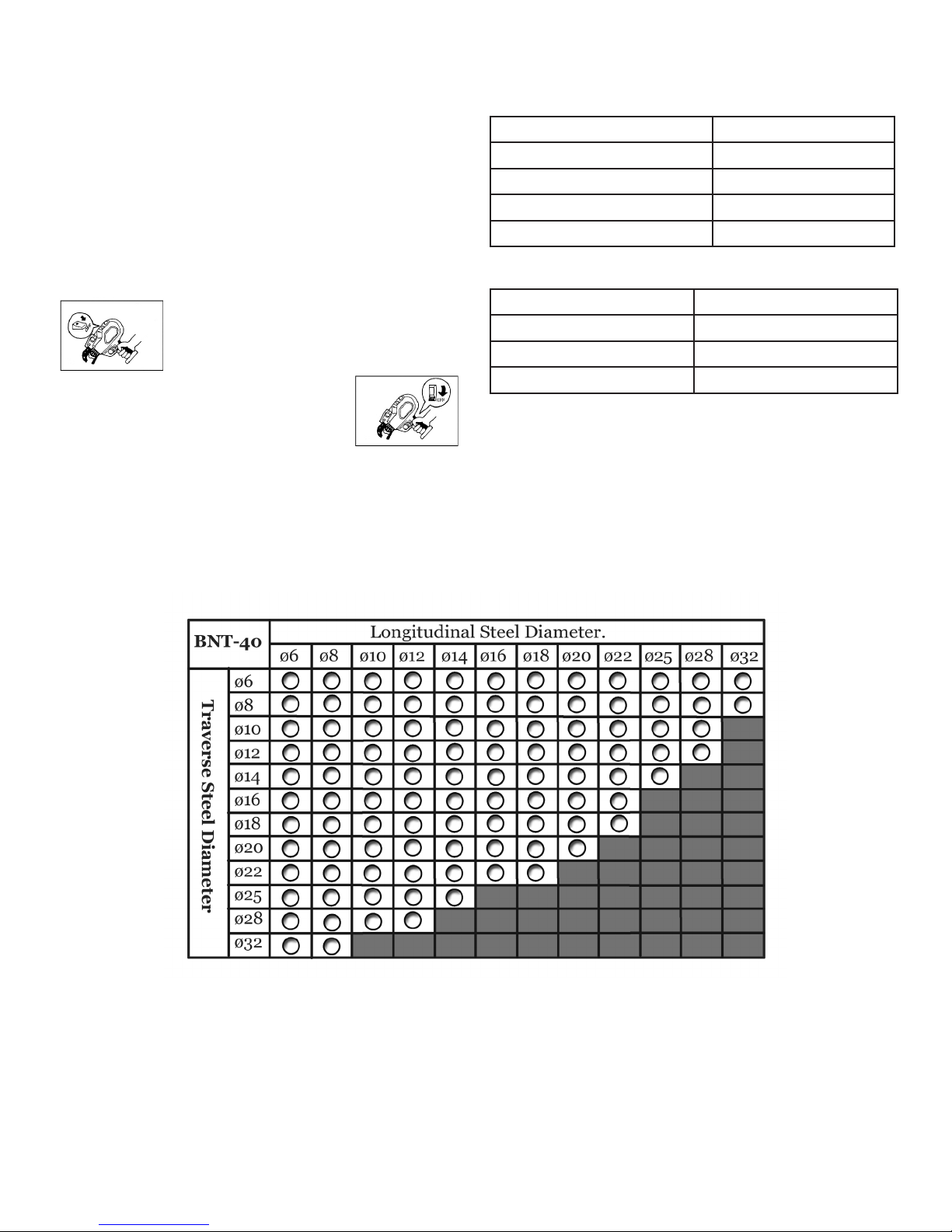

Tool Technical Parameters

Model BNT-40

Dimensions (in.) 11.22 x 3.93 x11.65

Weight (lbs) 4.85 Incl Battery

Voltage (V) 14.4

Max Tying Diameter (in.) 1.57

Wire Technical Parameters

Type NY80

Dimeter (in.) ø0.03

Material Q195

Length (in.) 3937(approx)

Product Specications and Technical Parameters

(mm)

Page | 6

Battery and Charger Usage

• Before inserting or removing the battery from this tool,

please set the main switch to the o position.

• To avoid a short circuit to the battery, always use the bat-

tery terminal cover when it is not in use with the tool.

• When placing the battery into the tool, press the battery

lock before placing it into the battery holder. When remov-

ing the battery, press the battery lock button before pulling

it out of the battery holder.

• Use 100-240V ~ 50-69Hz AC power supply for the charger.

Fully insert the battery into the charger slot and it will begin

to charge automatically as indicated by the charging light.

It will take approximately 74 minutes to fully complete the

battery charge.

• It is recommended to charge the battery between 32°F and

113°F. Do not charge in extreme cold or hot environments.

Machine Operation and Methods

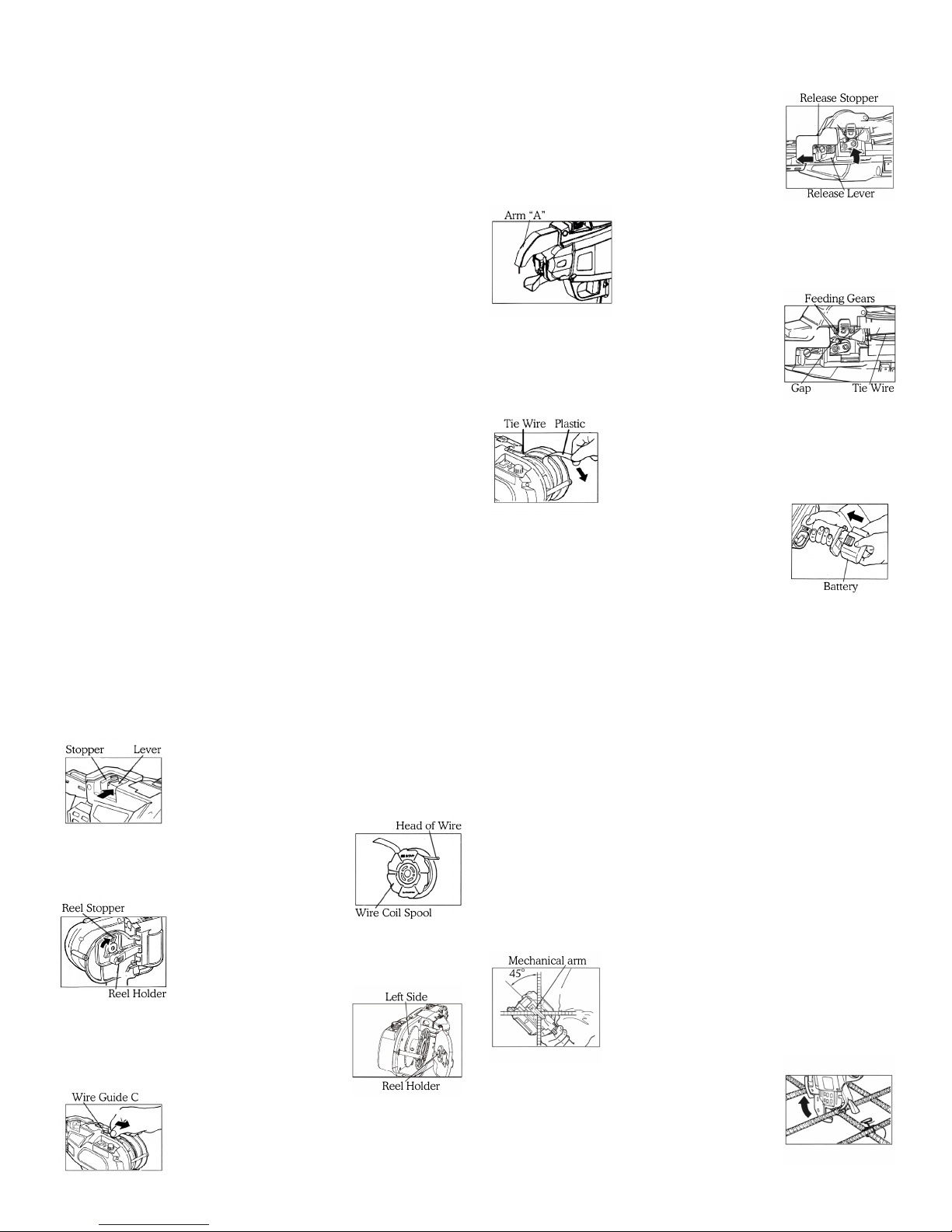

Before inserting and removing the wire coil spool turn the

main power switch to the o position, lock the trigger switch

and remove the battery.

Installing the wire coil spool. Please only use matching

wire without rust in this tool.

Only use original wire coil. Using non-

standard wire or spool could cause the tool

to malfunction.

Remove part of the ad-

hesive tape and cut about 2 inches of wire

from the coil.

Push the reel stopper to

release the reel stay and open the gate at

the same time.

Install the wire coil with the le side fac-

ing the tool. Lock the opening by closing

the reel holder.

Insert the wire into the

wire guide “C” (Note: the wire must not

be bent or curved).

e wire must pass through the wire

guide “C” in between the two feeding

gears until it reaches the end gap. en

push the wire until it reaches the machine

arm.

Keep pushing the wire until it reaches

the arm “A” unit.

Release the release

stopper and conrm

the release lever has

returned to its original position. (Note:

the wire coil must be clamped the gap of

the feeding gears).

Remove the rest of the remaining adhe-

sive tape from the wire spool.

Install the battery into

the machine, when

you hear a locking

sound the battery has been installed cor-

rectly. (Note: make sure that the main

power switch is in the o position and

that the trigger is locked before installing the battery).

Turn on the main power switch. e machine is now ready

for use.

How to remove the wire coil spool

Turn o the main power switch, lock the trigger and remove

the battery.

Press the release lever and conrm that it is caught in the

open position.

Remove the plastic wire coil spool.

e Tying Procedure

Unlock the trigger lock. Keep the me-

chanical arm on the rebars to be tied with

a 45° angle at a vertical position to the

rebars.

Press the trigger and the

tool will tie automatically.

Remove the tool when the tying is com-

Page | 7

plete.

Do not press the trigger when the me-

chanical arm is not on the rebar surface.

(Note: if this should happen turn o the

maching, position the trigger lock to the

“o” position and remove the trapped

wire with a pair of pliers inside the me-

chanical mouth).

Adjust the tie tightness. ere are 5 tightness levels that can

be adjusted with the “adjusting dial”.

Replacement of Gears

• Remove the screws that fasten the plastic housing over the

motor as show above.

• Remove the wire guide “C” which is fastened on the plate

as shown above.

• Use a pair of pliers to remove the E-ring and washer xed

on the feed gear as shown above.

• With a pair of pliers remove Spring “A” at the end of the

release lever as shown above.

• Be careful not the drop the smaller Spring “B” at the oth-

er end of the release lever when you take out Spring “A” as

shown above.

• Remove the hex screws of the release lever from the plate

and take out the release lever in the direction of the arrow

as shown above.

• Aer you remove the release lever you can remove the E-

rings with pliers and the feeding gears “B” and then replace

them as shown above.

NOTE:

Aer you nish replacing the gears all of the tool parts must

be reassembled in order.

• First install the release lever and fasten it.

• Fit Spring “A” at the end of the release lever

• Install the feeding gears, washer and E-ring in sequence

• Fix wire guide “C” on to the plate

• Finally attach the plastic cover with screws.

Care and Maintenance

• Please do a daily inspection prior to using this tool

• Please maintain this electric tool carefully, making sure

that the adjustments are correct and that it has been stored

properly.

• Inspect the tool for damage and cracks in the housing and

that the power supply is in good working order.

• Make sure theat the battery charger is the one that came

with your machine. Using another charger could cause

damage to the battery and/or charger and could even cause

a re.

Page | 8

• Improper use of the battery could cause it to leak. If this

happens it will need to be replaced and properly recycled.

Please do not touch any leaking material from this battery.

If you come in contact with the battery liquid ush with

clean water and seek medical attention immediately.

• When not in use, store this tool carefully in the supplied

case. It can be washed with a so cloth and soapsuds aer

you nish work. Do not use petrol chemicals or alcohol to

clean this tool.

• In the event that this tool malfunctions or drops in per-

formance you can call our Customer Service Repair Center

(800) 992-3833 or send us a note to mail@bnproducts.com

BN Products-USA

3450 Sabin Brown Road

Wickenburg, AZ 85390

(800) 992-3833 • mail@bnproducts.com

Common Faults Warning

Sound

Indicator

Light Items To Inspect Possible Cause Actions

e machine does not

work aer

putting in a new wire

spool.

None O Inspect the battery

terminal

Oxidation or there

is dirt on the elec-

trodes

Use a dry cloth to

wipe the surfaces

Beep---- On- Conrm that the battery

is charged

Low power in the

battery

Recharge the battery

Beep,

Beep,Beep

On O On O

On o...

Check wire guide “A” to

see if there is stray wire in

the guide

e head of the wire

was caught in the

guide

Using a pair of pliers

remove the wire

Beep, Beep,

Beep, Beep...

On O On O

On o...

Check the curl guide to

see if there is a stray wire

caught in the tool

Tying strength may

be to strong

Adjust the tying

force and remove the

caught wire

e wire does not feed

correctly

Beep, Beep On O On O

On o...

Check the curl guide e curl guide is

open

Close the curl guide

Beep, Beep,

Beep

On O On O

On o...

Check the diameter of the

rebars

e diameter of the

rebar exceeds chart

Use the proper diam-

eter rebars

Beep, Beep,

Beep, Beep...

On O On O

On o...

Check the tightness of the

wire coil

e wire is too tight

on the coil

Clear the winded wire

Irregular binding and

wire stepping out of

the curl guide

None On- Alarm when pressing the

trigger- No alarm when

released

Overheated motor

from constant use

Let the motor cool

down

Failure to cut the wire

aer binding

None On- Check if the wire hits the

rebar when tying

e wire hitting the

rebar will stop the

action

Pay attention so that

the wire does not hit

the rebar

Tying knot is loose

None On- Check to see if the cutting

mechanism is working

correctly

ere may be a stray

piece of wire in the

cutting mechanism

Clean the cutting

mechanism

None On- Check the operation

instruction

Wrong operation Please read the

operation manual

Tying knot is not cor-

rect

None On- Check the tying strength e tying force is

too great

Adjust to the proper

tying force

Common Faults

is tool alerts you to the following fault conditions by means of a warning sound and warning light. If the problem is not

solved please contact our maintenance support department: (800) 992-3833.

Table of contents