Makita AN621 User manual

Other Makita Power Tools manuals

Makita

Makita XSH06 User manual

Makita

Makita 4324 User manual

Makita

Makita AT450H User manual

Makita

Makita WT02Z User manual

Makita

Makita JN3200 User manual

Makita

Makita DUP361 User manual

Makita

Makita DTW450ZJ User manual

Makita

Makita 4327 User manual

Makita

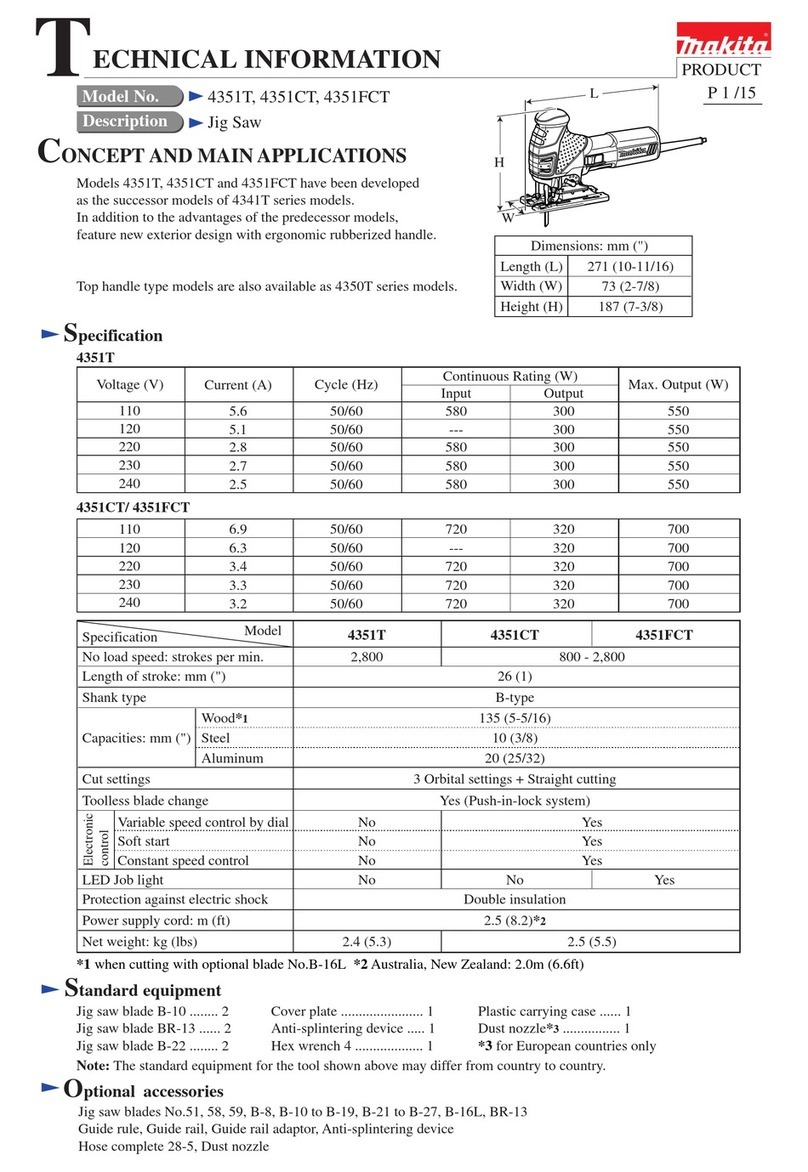

Makita 4351CT Manual

Makita

Makita 1806B User manual

Makita

Makita DTW181 User manual

Makita

Makita JN1601 User manual

Makita

Makita DTW190 User manual

Makita

Makita HM1511 User manual

Makita

Makita BJN160 User manual

Makita

Makita 9218SB User manual

Makita

Makita AN634H User manual

Makita

Makita DHS680 User manual

Makita

Makita KP0810 User manual

Makita

Makita TB131 User manual