BNT PRO-100Q User manual

7.1 Alignment by view finder & shading plate

7.2 Alignment using LEVEL LED

7.3 Alignment by audio tone indicator

7.4 Alarm memory function

7.5 Environment function

8.1 Four channel frequency selection

8.2 Beam power selection

8.3 Response time changeover function

The PRO-100Q/200Q are quad photoelectric detectors designed to activate an alarm relay upon the detection of

Intruder through 4 pulsed infrared beams.

For stable operation, the PRO-100Q/200Q are equipped with the following features.

■ High power infrared

The active infrared transmission is exceptionally strong with a maximum arrival distance ten times greater than

the specified protection distance.

■ Four frequency selections

4 separate choices of frequency avoids cross-talk in stacked or long linear installations.

■ Beam transmission strength selection

2 levels of beam transmission strength which can be set to suit the protection distance.

■ Auto-gain lock

Optimal sensitivity gain is automatically set at any coverage distance up to the maximum protection distance.

(Audible tone indicates setting is completed)

■ Environmental module

Environmental trouble signal is sent when beam reception level is reduced below an acceptable level.

■ Programmed AGC function

Sensitivity is automatically increased in bad weather to contend with fog, rain, of frost.

■ Alarm memory indicator

Alarm memory LED located on Receiver can be manually reset (at sensor) or remotely controlled via panel.

■ Audible signal for alignment

An alignment tone aids in quick set-up of beams for electrical measurement of alignment

■ Retransmitting function

The advantage is elimination of wiring from a detector or switch, back to the control panel.

■ Other features

Monitor output, Level LED , Response time changeover, Tamper output.

WARNING ! Indicate that incorrect operation causes significant danger of accident resulting in death or serious

Injury to the user.

CAUTION ! Indicate that incorrect operation causes possibility of injury to the user of damage to the unit.

Read the following prior to installing, wiring and regular maintenance.

CAUTION ! DO NOT INSTALL THE UNIT

① where trees, plants, of falling leaves will block the beams.

② where intense source of light, sunlight will be reflected directly into the receiver optics.

A foreign light incoming within ±3° angle of each receiver axis may cause false alarms.

③ on movable surfaces.

④ where subject to foul water or sea spray.

⑤ where over the max range on each model.

⑥ where subject to strong electrical noise or RFI

⑦ where subject to strong vibration.

⑧ where subject to corrosive or explosive gas.

AVOID

① external temperature and humidity.

② magnets or any magnetized material.

③ running power and output wires near voltage power sources.

IMPORTANT

① Face upper/lower optical modules on the transmitter and receiver towards each other.

② Be sure of the beam in alignment optical modules can be adjusted within ±90° horizontally and ±3° vertically.

WARNING !

① Do not perform installation and wiring when it thunders.

② Do not supply power until all wiring is completed.

③ Keep power between 10 V ~ 28 VDC anytime.

④ Do not disassemble or modify the unit.

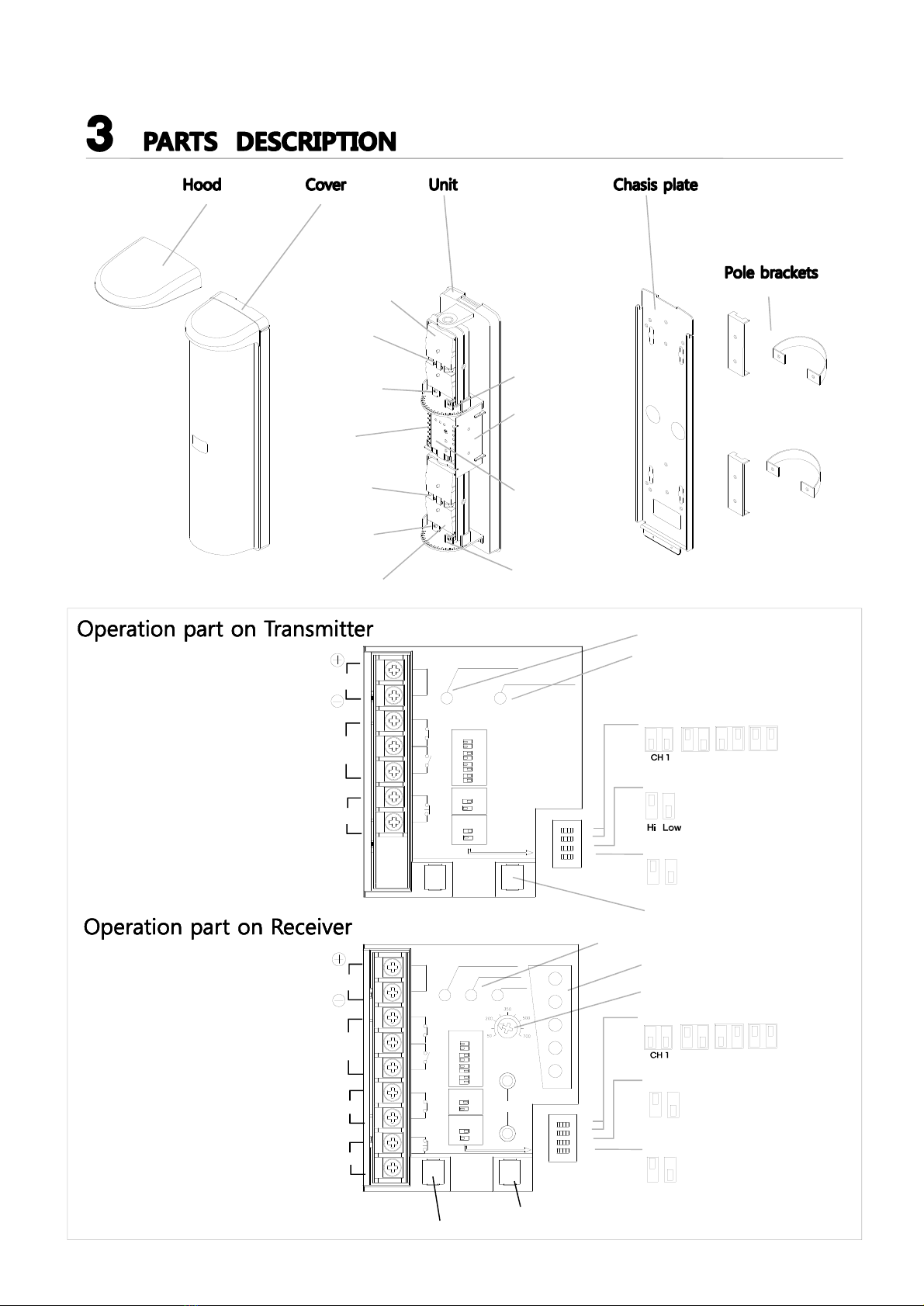

Mirror (upper)

Vertical

adjustment

screw (upper)

Terminal

Vertical

adjustment

screw (lower)

Operation part

(see below)

Horizontal

adjustment

screw (upper)

Horizontal

adjustment

screw (lower)

Mirror(lower)

View finder

View finder

Shading plate

Operation LED

Re-transmit LED

CH 2 CH 3 CH 4

Beam channel (1,2)

Beam power (3)

O

n

O

f

f

Retransmitting (4)

Tamper switch

CH 2 CH 3 CH 4

Beam channel (1,2)

Sound tone (3)

O

n

O

f

f

Alarm memory (4)

Level LED on/off

Tamper switch

Level meter

Status LED (Memory /Alarm / ENV)

Response time adjustment

Power 10V ~ 30V DC

(non-polarity)

Re-transmitting (input)

Tamper

Power 10V ~ 30V DC

(non-polarity)

Alarm output

Environment output

Tamper

O

n

O

f

f

POWER

TAMPER

RETRANS

OPERATION

Re-TRANSMIT

N.C

N.O

Channel

1 2

CH1

CH2

CH3

CH4

1 2 1 2 1 2

Beam power

Low

High

3

Off

On

44

Re-transmit

ON

1 2 3 4

ENV

TAMPER

POWER

ALARM

ENV

ON

1 2 3 4

ALARM

MEMORY

+

_

N.C

N.O

N.C Monitor

Excellent

Good

Fair

Realign

Poor

+

_

Channel

1 2

CH1

CH2

CH3

CH4

1 2 1 2 1 2

Sound

Off

Memory

On

33

Off

On

44

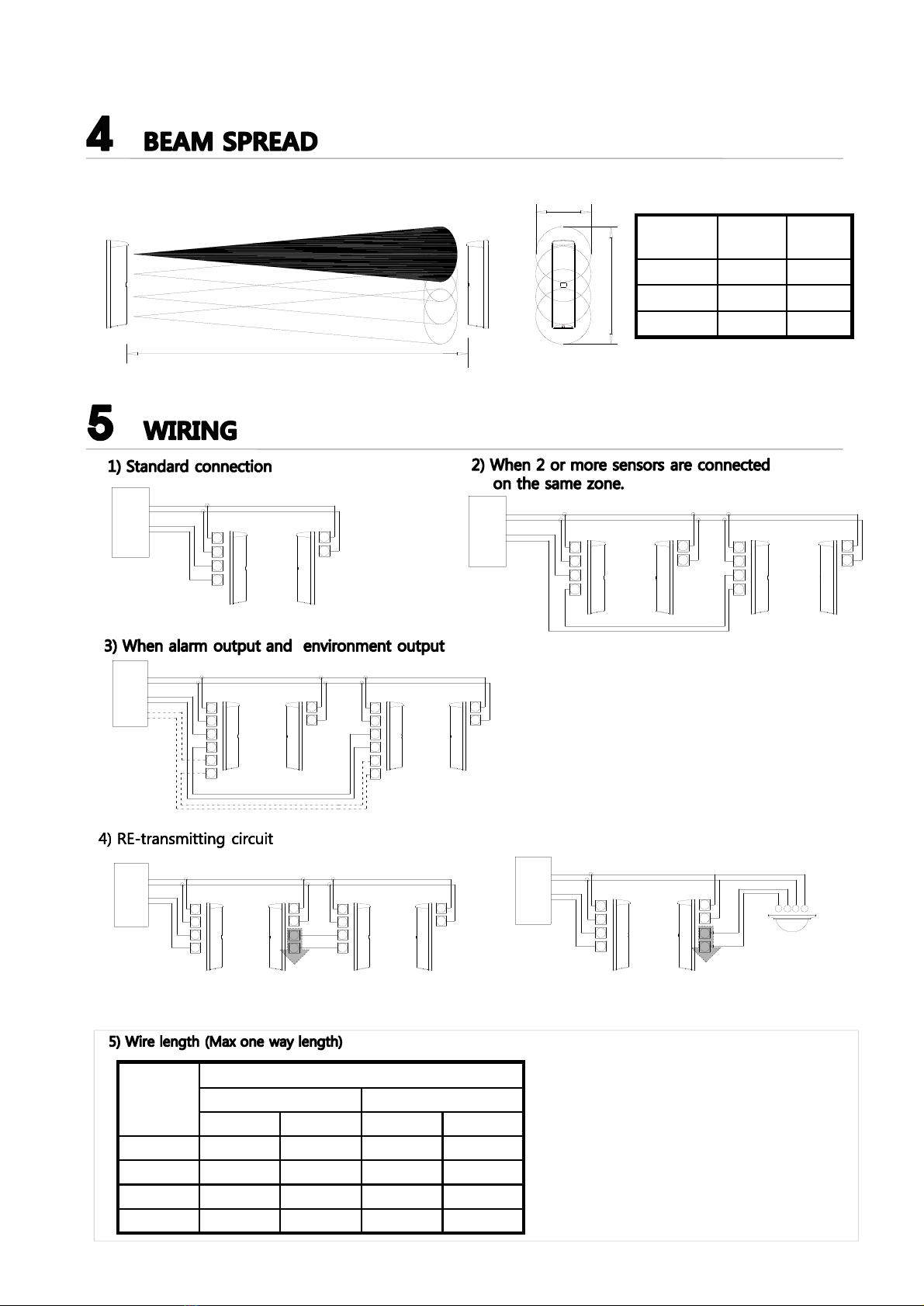

A

B

C

The beam spread sngle is 1.4°. Refer to the right table and the diagrams below

to determine the installation conditions.

Distance

(A)

Spread

(B)

Spread

(C)

100m 2.5m 2.7m

150m 3.7m 4.0m

200m 5.0m 5.2m

RX TX

+

-

COM

N.C

+

-

POWER

DC 12V

Alarm

input

Control Panel

RX RX

TX TX

+

-

COM

N.C

+

-

+

-

COM

N.C

+

-

POWER

DC 12V

Alarm

input

Control Panel

RX RX

TX TX

+

-

COM

N.C

+

-

POWER

DC 12V

Alarm

input 1

Alarm

input 2

Control Panel

+

-

COM

N.C

+

-

COM

N.C

COM

N.C

RX RX

TX TX

COM

N.C

+

-

COM

N.C

+

-

POWER

DC 12V

Alarm

input 1

Control Panel

+

-

COM

N.C

+

-

Wire

Gauge

Maximum distance (meter)

PRO-100Q PRO-200Q

12V DC 24V DC 12V DC 24V DC

AWG 22 100 900 90 800

AWG 20 190 1,700 160 1,500

AWG 18 280 2,600 250 2,200

AWG 14 600 5,370 500 4,570

Note1) Max. wiring distance when two or more sets

are connected is the above value divided

by the number of sets.

Note2) Be sure the control panel is equipped with

adequate standby battery and charging circuit.

Use 12v (at least) Ni-cd or lead acid battery

with minimum capacity of 0.5 AH.

RE-TRANSMITTING

(INPUT)

+

-

POWER

DC 12V

Alarm

input 1

Control Panel

RX TX

COM

N.C

+

-

NC COM

+

-

COM

N.C

RE-TRANSMITTING

(INPUT)

* The advantage of this method is elimination of wiring from a detector or switch, back to the control panel.

Detector or switch

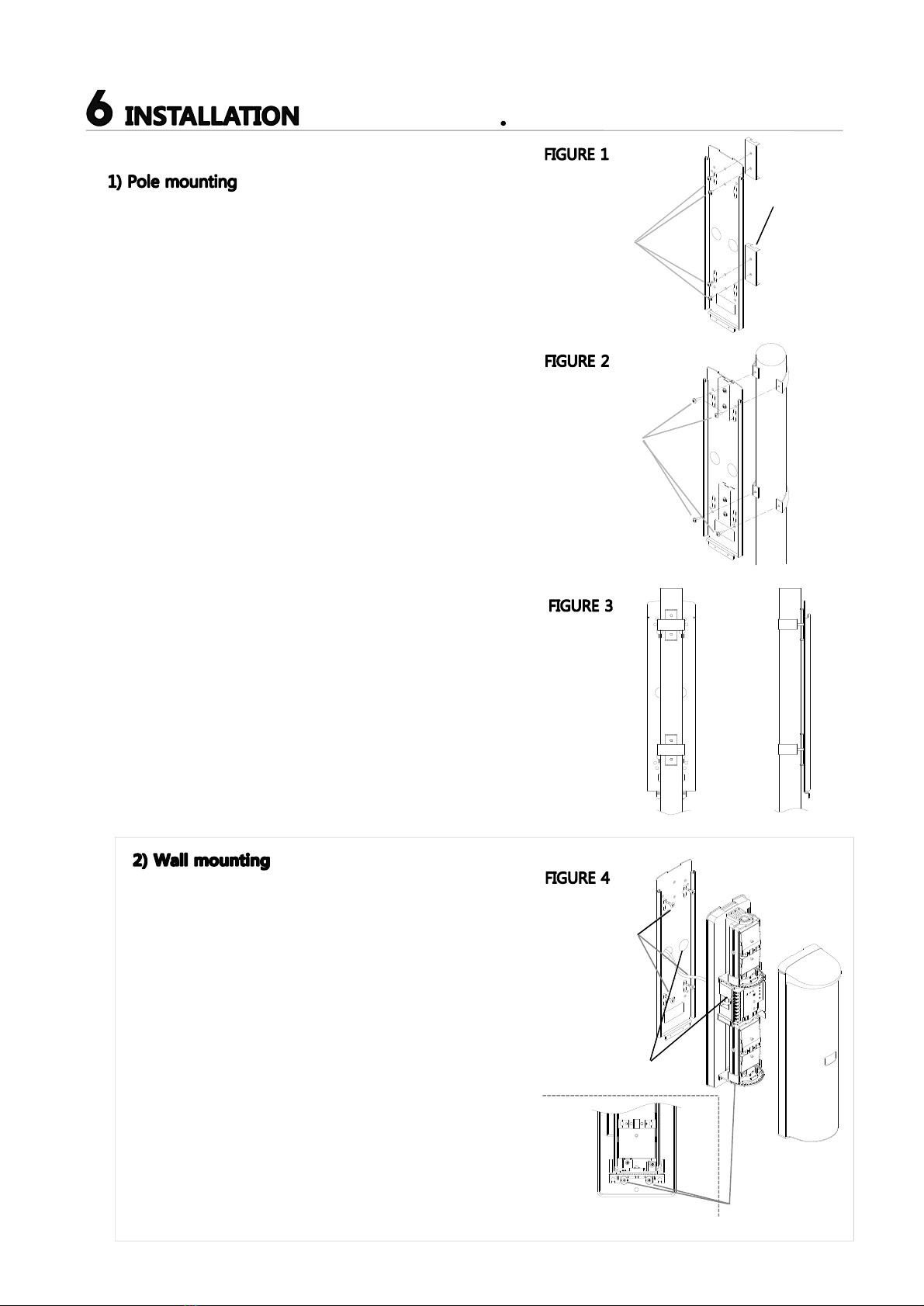

- Chose an appropriate mounting location for the system.

Install the poles with a clear linesight between the transmitter

and the receiver

- Loosen the transmitter’s cover mounting screw and remove

the cover.

- Loosen the 2 unit mounting screws and remove the chassis

by sliding it down againse the unit.

- Attach the mounting plates to the chasis with the clamping

screws (short) (see FIGURE 1)

- Firmly attach the chassis to the poles with the U-clamps and

the screws (long) (see FIGURE 2). Make sure the transmitter

is mounted in direct line-of- sight with the receiver.

- Route wiring through the chassis wire entrance, leaving

enough wire to access the transmitter’s terminal strip.

-Route wiring through the transmitter’s wire entrance.

- Slide the transmitter onto the chassis. Tighten with the unit

mounting screws.

- Repeat this mounting process for the receiver. Make sure it is

mounted in direct line-of-sight with the transmitter.

- Loosen the transmitter’s cover mounting screw and remove

the cover.

- Loosen the 2 unit mounting screws and remove the chassis

by sliding it down against the unit.

- Route wiring through the wire entrance of the chassis.

Leave enough wire to access the transmitter’s terminal strip.

- Mount the chassis to the mounting surface with the chassis

mounting screws.

- Route wiring through the wire entrance of the transmitter.

If surface mounting is used, knock-out the thin-wall wire

entrance at the bottom of the transmitter.

- Reattach the transmitter to the chassis.

- Repeat this mounting procedure for the receiver.

Make sure it is mounted in direct line-of-sight with the

transmitter.

Clamping

Screw

(short)

Clamping

Screw (long)

Pole

Diameter

38~43 mm

Chasis mounting

Screws (included)

Wire entrance

Unit mounting

screws

Completed

of chassis plate

This manual suits for next models

1

Table of contents